Self-repairing geopolymer-based permeable crystallization waterproof material and preparation method thereof

A technology of osmotic crystalline waterproofing and geopolymers, applied in cement production, etc., can solve problems such as poor durability, poor toughness, and bulging, and achieve good self-healing performance, good toughness and durability, and high compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a method for preparing the above-mentioned self-repairing geopolymer-based permeable crystalline waterproof material, comprising the following steps:

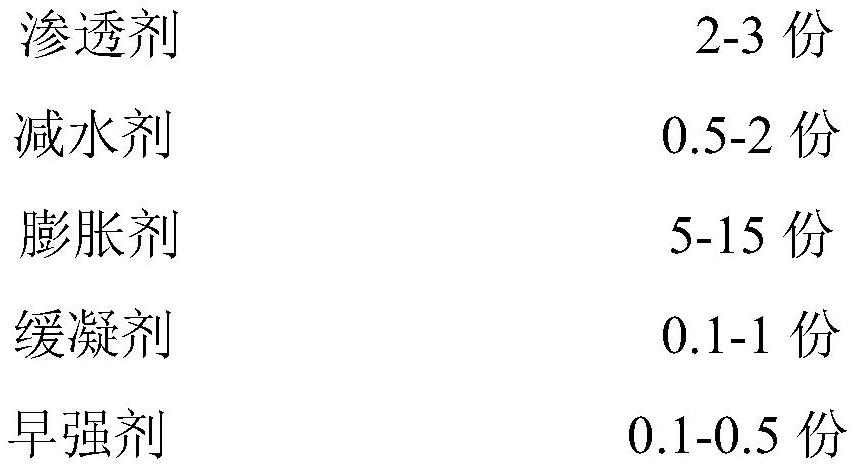

[0039] (1) Determine the ratio of water to material to be 0.35-0.55, first prepare the mixed solution A, accurately weigh 20-30 parts of alkaline activator, 2-5 parts of surface modifier, 2-10 parts of silane impregnating agent, and 2 parts of penetrant -3 parts, 0.1-0.5 parts of early strength agent and 1 / 3 of the total water consumption, put it into a planetary mixer, stir until the solute is completely dissolved and the mixture is uniform, after the stirring is completed, put it in a beaker to cool for later use, and mix for later use The temperature of liquid A is equivalent to room temperature.

[0040] (2) Then prepare mixed solution B, accurately weigh 20-50 parts of metakaolin, 10-30 parts of finely ground slag powder, 5-8 parts of fly ash, 3-5 parts of fused silica powder, and 0.5-2 parts ...

Embodiment 1

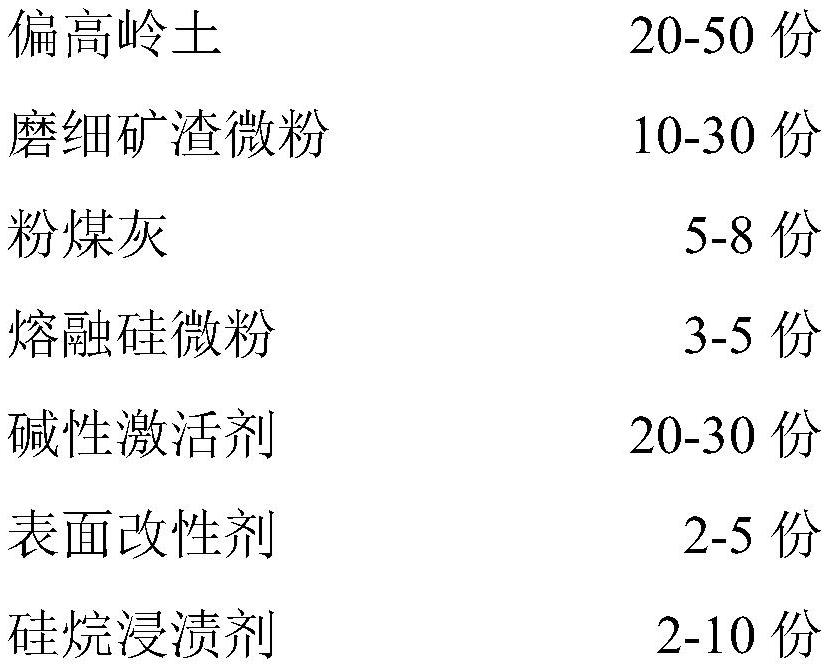

[0045] A self-healing geopolymer-based permeable crystalline waterproof material provided in this embodiment includes the following parts by weight:

[0046]

[0047] A self-healing geopolymer-based permeable crystalline waterproof material provided in this embodiment, the preparation method thereof comprises the following steps:

[0048] (1) Determine that the water-material ratio is 0.50, first prepare mixed solution A, accurately weigh 20 parts of alkaline activator, 2 parts of surface modifier, 5 parts of silane impregnating agent, 2 parts of penetrating agent, 0.2 part of early strength agent and Put 1 / 3 of the total water consumption into a planetary mixer and stir until the solute is completely dissolved and the mixture is uniform. After the stirring is completed, place it in a beaker to cool it for later use. The temperature of the spare mixture A is equivalent to room temperature.

[0049] (2) Then prepare mixed solution B, accurately weigh 20 parts of metakaolin, ...

Embodiment 2

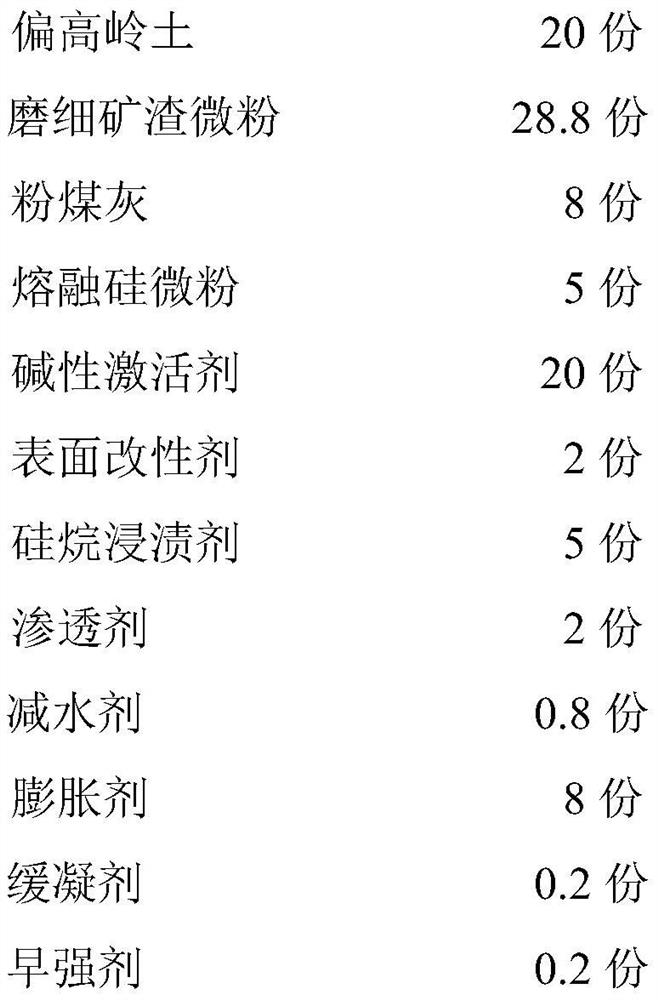

[0053] A self-healing geopolymer-based permeable crystalline waterproof material provided in this embodiment includes the following parts by weight:

[0054]

[0055] A self-healing geopolymer-based permeable crystalline waterproof material provided in this embodiment, the preparation method thereof comprises the following steps:

[0056] (1) Determine that the water-material ratio is 0.50, first prepare mixed solution A, accurately weigh 20 parts of alkaline activator, 2 parts of surface modifier, 5 parts of silane impregnating agent, 2 parts of penetrating agent, 0.2 part of early strength agent and Put 1 / 3 of the total water consumption into a planetary mixer and stir until the solute is completely dissolved and the mixture is uniform. After the stirring is completed, place it in a beaker to cool it for later use. The temperature of the spare mixture A is equivalent to room temperature.

[0057] (2) Then prepare mixed solution B, accurately weigh 30 parts of metakaolin, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com