Permeable concrete and preparation process thereof

A technology of permeable concrete and water reducing agent, which is applied in the field of concrete and can solve problems such as frost heaving and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

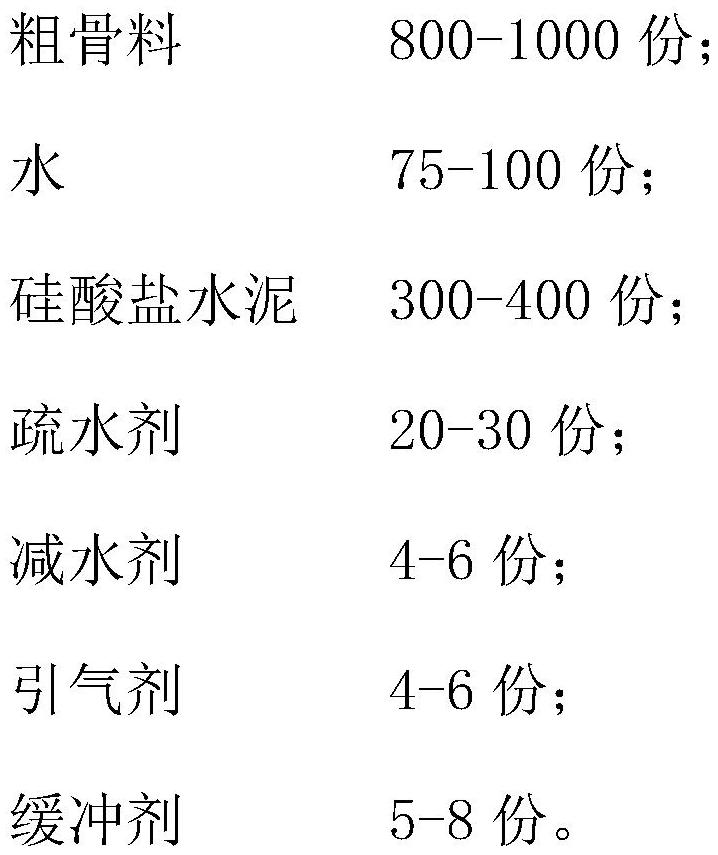

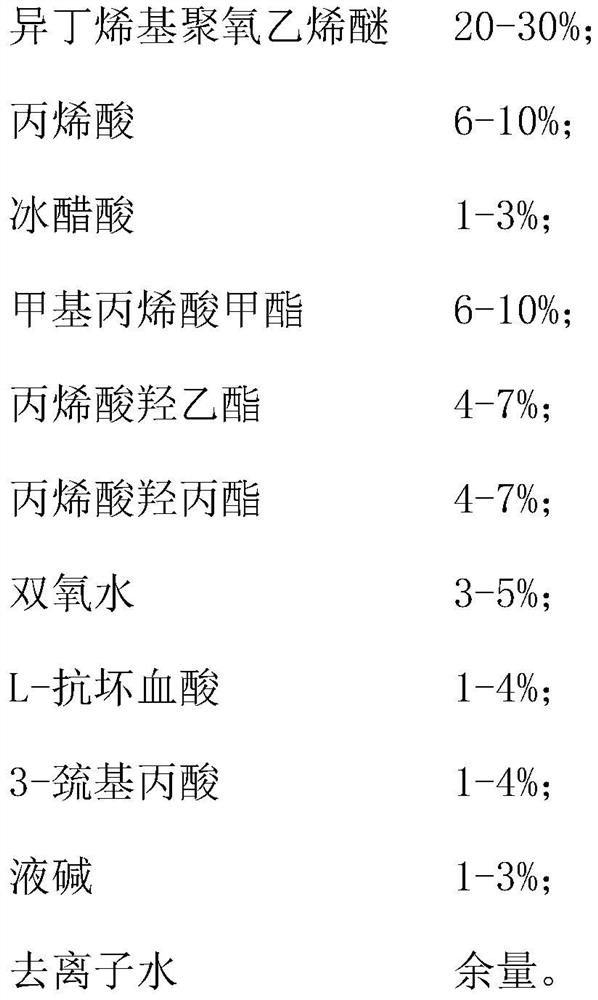

Method used

Image

Examples

Embodiment 1

[0089] The difference between Example 10 and Example 1 is that in step S2, isobutenyl polyoxyethylene ether and the remaining deionized water are mixed in proportion to prepare solution A, and glacial acetic acid is added in solution A in proportion to adjust the pH of solution A The value is 6.5.

Embodiment 11

[0090] The difference between Example 11 and Example 1 is that in step S2, isobutenyl polyoxyethylene ether and the remaining amount of deionized water are mixed in proportion to prepare solution A, and glacial acetic acid is added in solution A in proportion to adjust the pH of solution A The value is 7.

Embodiment 12

[0091] The difference between Example 12 and Example 1 is: in step S3, solution A is heated to 42.5°C, hydrogen peroxide is added dropwise to solution A in proportion and stirred, the stirring speed is controlled to be 100r / min, and the stirring time is controlled to be 2.5 minutes. Solution C and solution E were added dropwise to solution A, the dropping time was controlled to be 0.5h, the temperature was controlled to be 42.5°C, and the reaction time was controlled to be 1.25h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com