A preparation method of self-healing microcapsules and its application in superhydrophobic coatings

A self-healing microcapsule and superhydrophobic coating technology, which is applied in the direction of microcapsule preparation, microsphere preparation, coating, etc., can solve the problem of limiting the application of superhydrophobic materials, loss of superhydrophobic performance, and poor durability of artificial superhydrophobic surfaces etc. to achieve the effects of increased specific surface area, increased surface energy, and strong surface adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

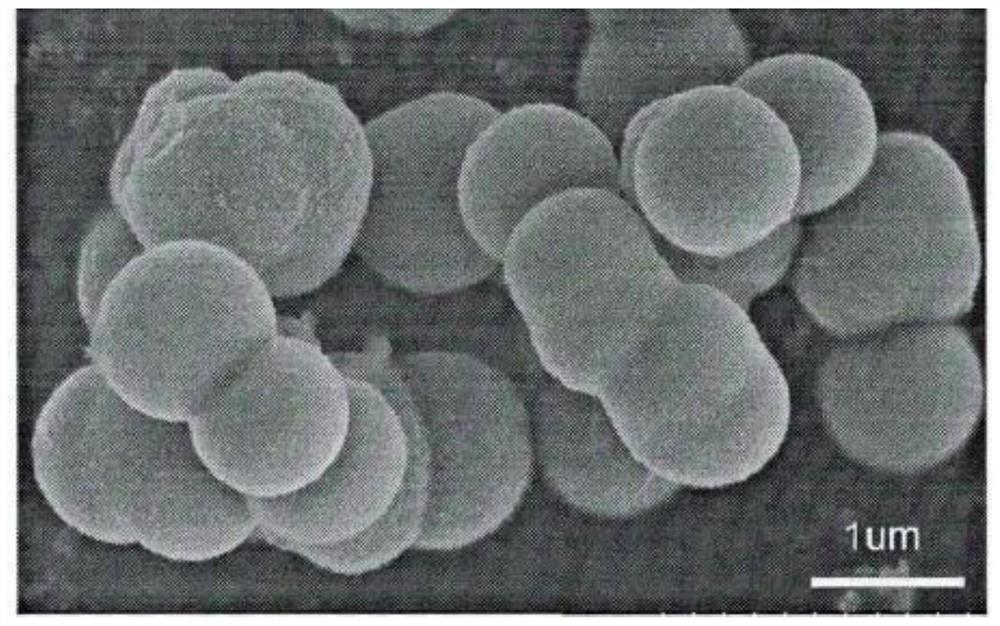

Image

Examples

Embodiment 1

[0036] A kind of preparation method of self-healing microcapsule of the present embodiment, comprises the following steps:

[0037] (1) First prepare porous titanium dioxide nanoparticles: porous titanium dioxide nanoparticles are prepared as follows: add ethanol, tetrabutyl orthotitanate, diethanolamine, and glacial acetic acid to the beaker in sequence according to the volume ratio of 1:0.5:0.05:0.8 Stir for 2 hours to form a milky white suspension and age for 12 hours. Pour off the supernatant and wash with acetone centrifuge for 3 times to remove impurity ions. Dry at 60°C for 12 hours and grind to obtain powdered titanium dioxide. Calcinate the powdered titanium dioxide at 300°C for 3 hours , to obtain porous titanium dioxide nanoparticles;

[0038] (2) Add the prepared porous titanium dioxide nanoparticles into a mixed solution of deionized water and ethanol with a volume ratio of 2:1, stir and dissolve, add the low surface energy substance into it and stir for 2.5h to f...

Embodiment 2

[0043] A kind of preparation method of self-healing microcapsule of the present embodiment, comprises the following steps:

[0044] (1) First prepare porous zinc oxide nanoparticles: porous zinc oxide nanoparticles are prepared as follows: 2.2g of zinc acetate is dissolved in 20ml of ethanolamine, and a mixture of deionized water and ethanol with a volume ratio of 1:2 is added 10ml of the solution was stirred for 30min, then reacted at a constant temperature at 175°C for 6h, centrifuged and washed until neutral, dried at 60°C for 12h, ground and calcined at 350°C for 3.5h to obtain porous zinc oxide nanoparticles;

[0045] (2) adding the prepared porous zinc oxide nanoparticles to a mixed solution of deionized water and ethanol with a volume ratio of 2:1, stirring and dissolving, adding a low surface energy substance to it and stirring for 2 hours to form a mixed solution A to obtain a capsule core, Wherein, 22g of porous zinc oxide nanoparticles, 25g of a mixed solution of de...

Embodiment 3

[0048] A kind of preparation method of self-healing microcapsule of the present embodiment, comprises the following steps:

[0049] (1) First prepare porous silica nanoparticles: porous silica nanoparticles are prepared as follows: 0.5g polyvinylpyrrolidone is dissolved in a mixed solution of 40ml ethanol and 60ml deionized water, 1g dodecylamine Dissolve it in 5ml of absolute ethanol and add it, stir for 60min, add 5ml of tetraethyl orthosilicate, and stir at 40°C for 6h to form a white colloid, after centrifugal cleaning, dry at 100°C for 12h, after grinding, at Calcined for 4h to obtain porous silica nanoparticles;

[0050] (2) Add the prepared porous silica nanoparticles into a mixed solution of deionized water and ethanol with a volume ratio of 2:1, stir and dissolve, add low surface energy substances into it and stir for 2 hours to form a mixed solution A, and obtain a capsule core , wherein, 30g of porous silica nanoparticles, 30g of a mixed solution of deionized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com