Automation device for testing wind sensor

A technology of automation device and wind sensor, which is applied in the testing/calibration of measuring devices, instruments, speed/acceleration/impact measurement equipment, etc. The effect of precision, small size and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

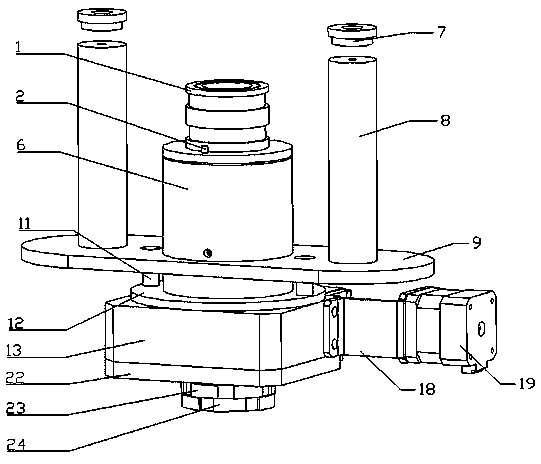

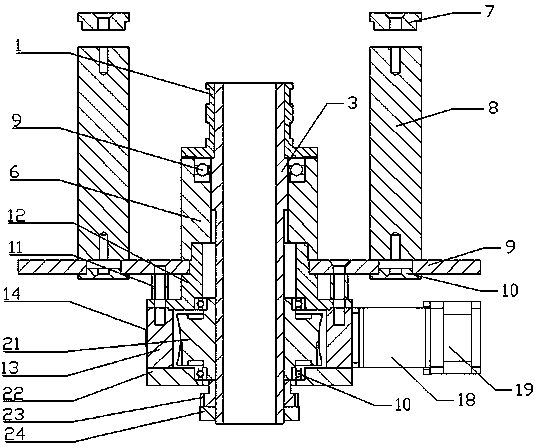

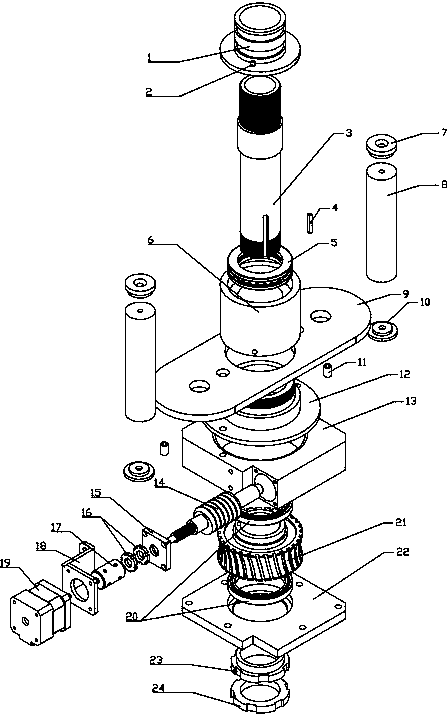

[0026] Such as figure 1 , figure 2 and image 3 As shown, the device is composed of two parts, the main part and the control part. The main part includes the wind sensor fixing part, the wind tunnel fixing part, the main part and the transmission deceleration part, and the wind sensor fixing part includes the wind sensor mounting seat 1 and the positioning pin 2. Wind tunnel fixed components include wind tunnel positioning block 7, support arm 8, horizontal plate 9, main body fastening block 10 and horizontal plate fixing sleeve 11; main body components include rotating shaft 3, flat key 4, plane thrust bearing 5, rotating Shaft casing 6, reduction box connection sleeve 12, bearing pre-tightening main ring 23 and bearing pre-tightening secondary ring 24; transmission reduction components include reduction box 13, deep groove bearing 20, worm wheel 21, reduction box b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com