Pipeline powdered coal particle size measuring device and measuring method

A technology for particle size and measuring device of pulverized coal, applied in the field of digital holography, can solve the problems of inability to meet the real-time adjustment of coal mills, low real-time performance, complicated operation steps, etc., so as to facilitate daily operation monitoring and maintenance work, and save manpower The effect of material resources and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

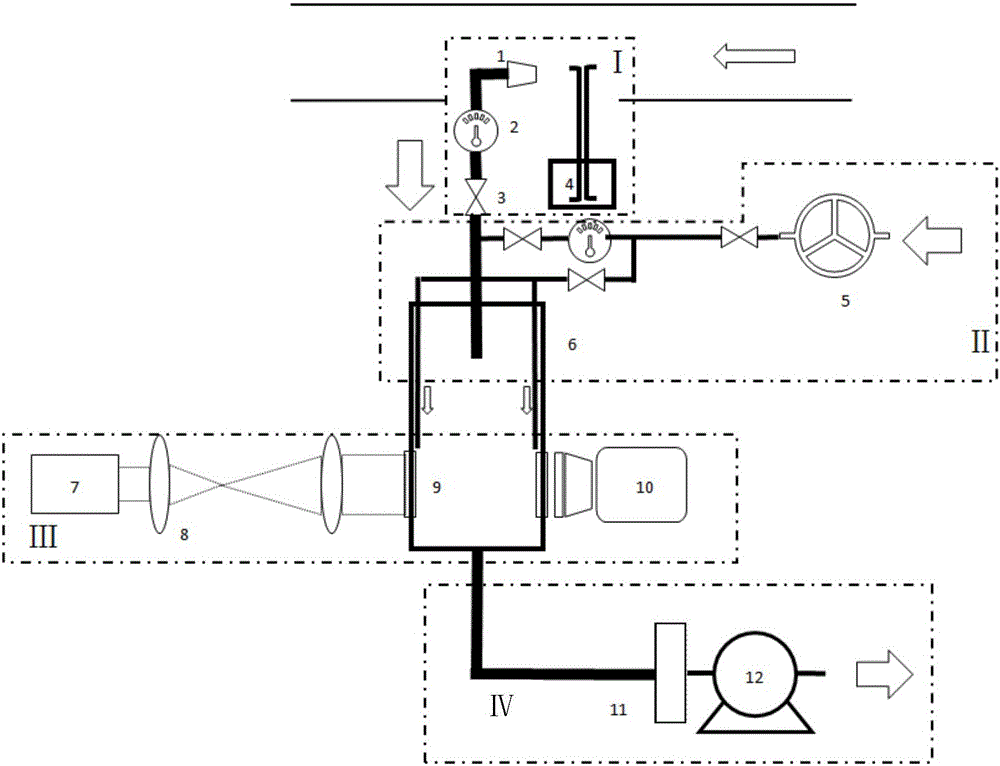

[0027] Carry out further detailed description below in conjunction with accompanying drawing:

[0028] The pipeline coal powder particle size measuring device in the present invention includes a sampling module I, an air delivery module II, a laser measurement module III and a negative pressure module IV.

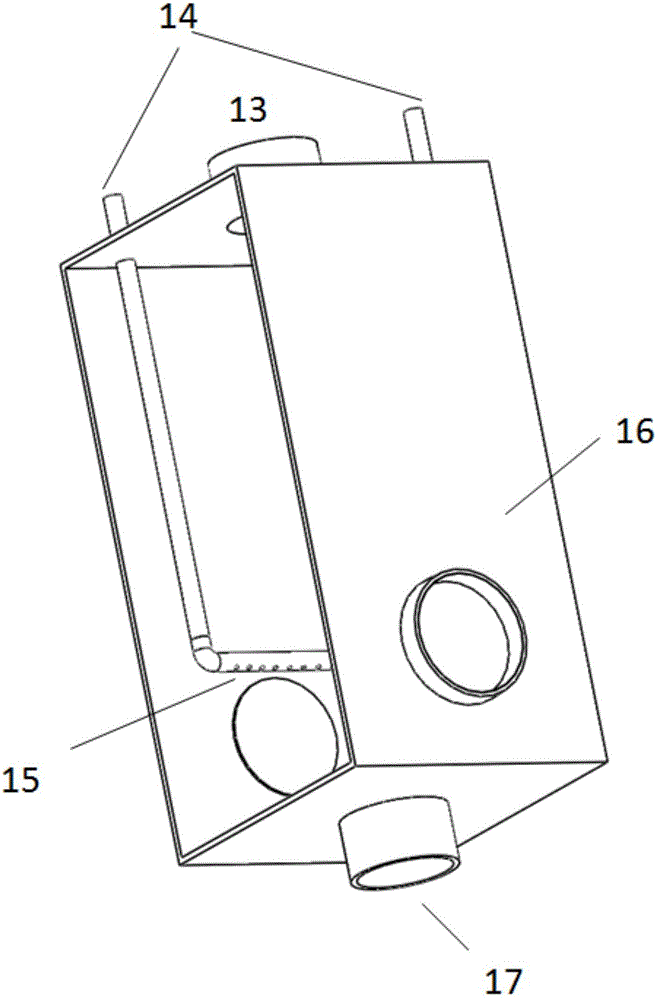

[0029] The sampling module I includes a sampling nozzle 1, a flow meter 2 and a valve 3 sequentially connected by pipelines; the sampling nozzle 1 can continuously and stably perform constant-speed sampling. The said isokinetic sampling means that the sampling nozzle 1 can work according to the predicted flow rate method, pitot tube parallel sampling method or instantaneous pressure zero point balance method. figure 1 The sampling nozzle 1 in the sample works according to the Pitot tube parallel sampling method, so the flowmeter 2 is a Pitot tube flowmeter, and the Pitot tube 4 is additionally configured. Valve 3 can be a manual valve or an electric valve to control the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com