Patents

Literature

30results about How to "Convenient and reasonable control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

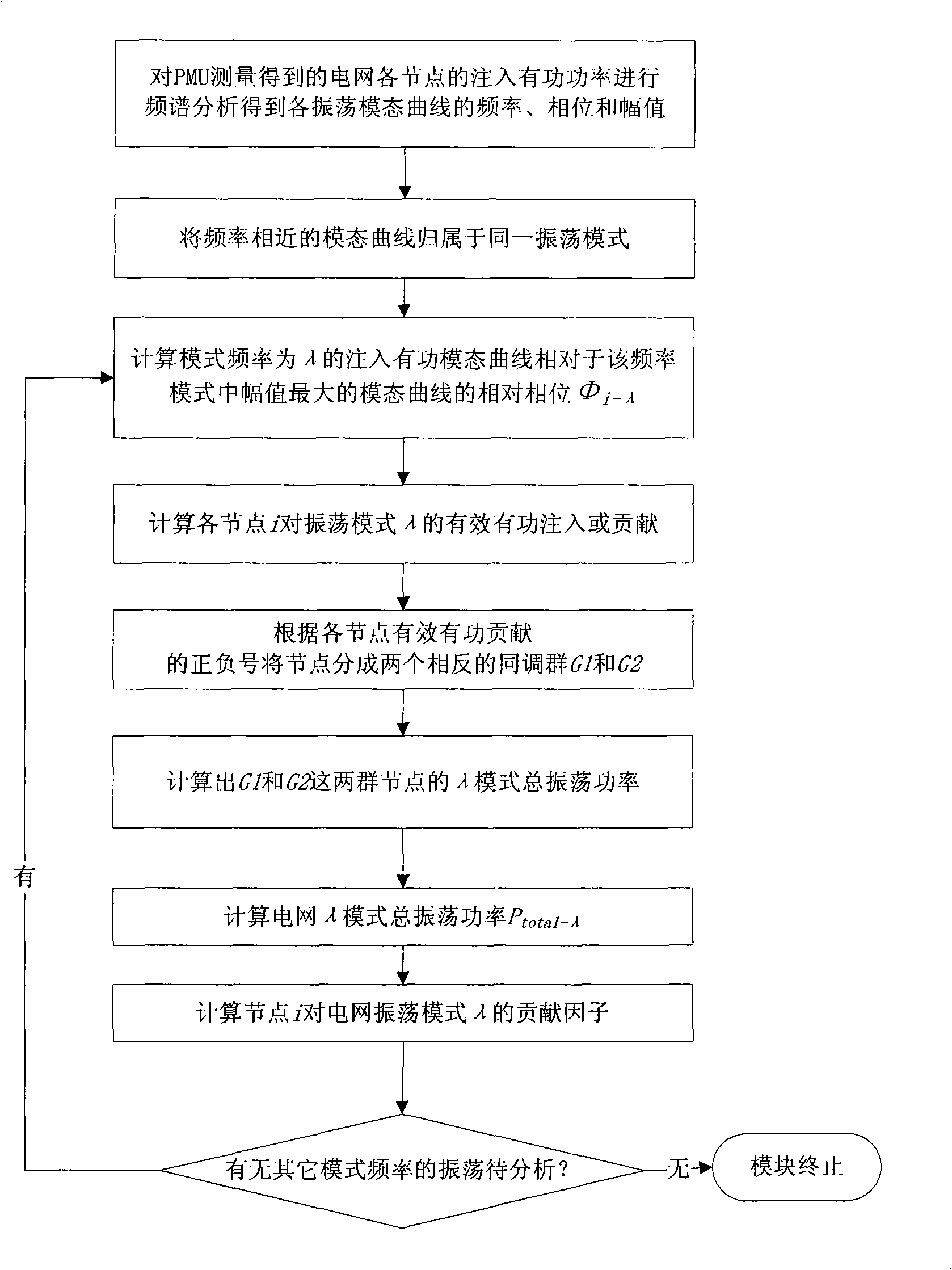

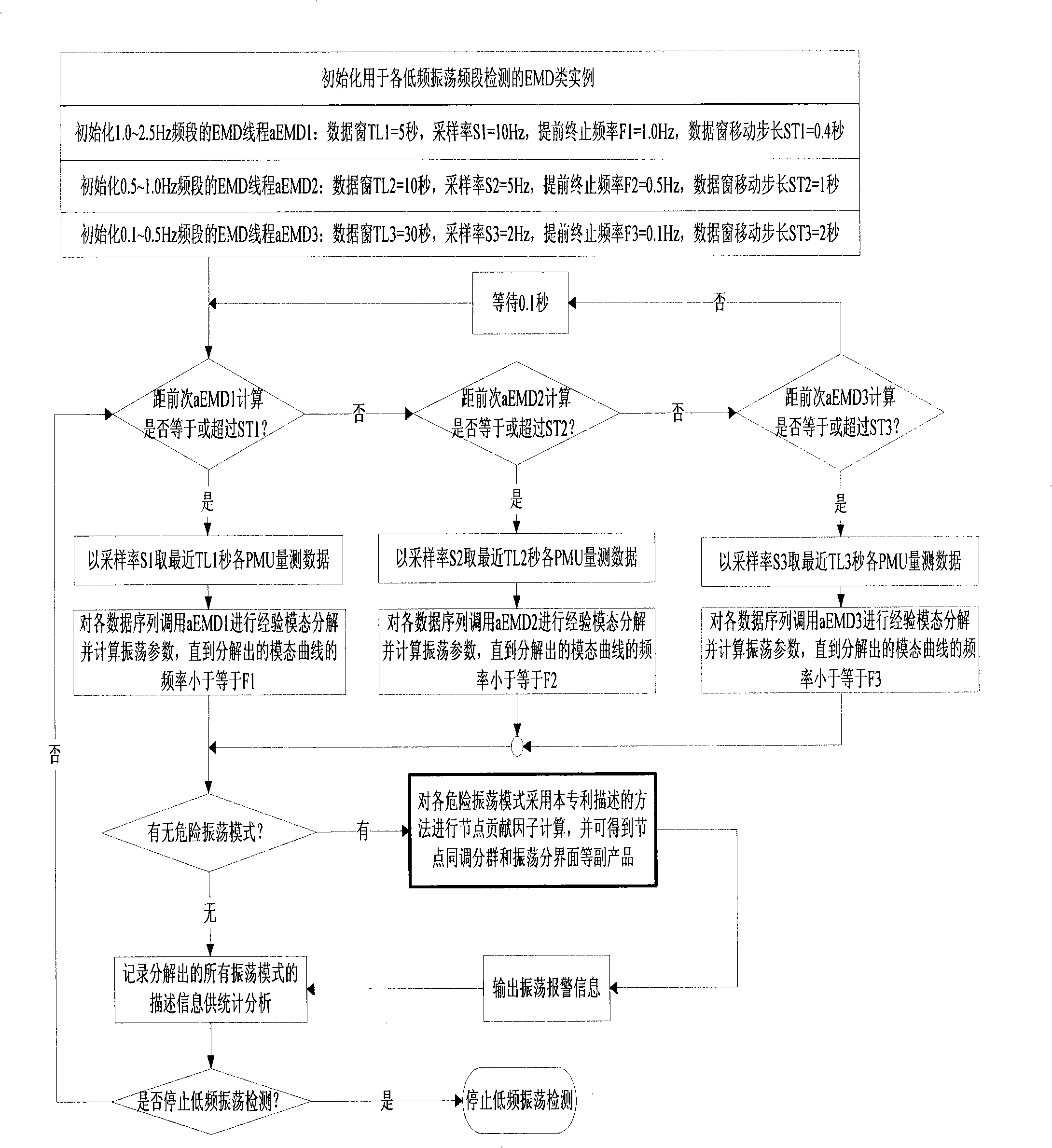

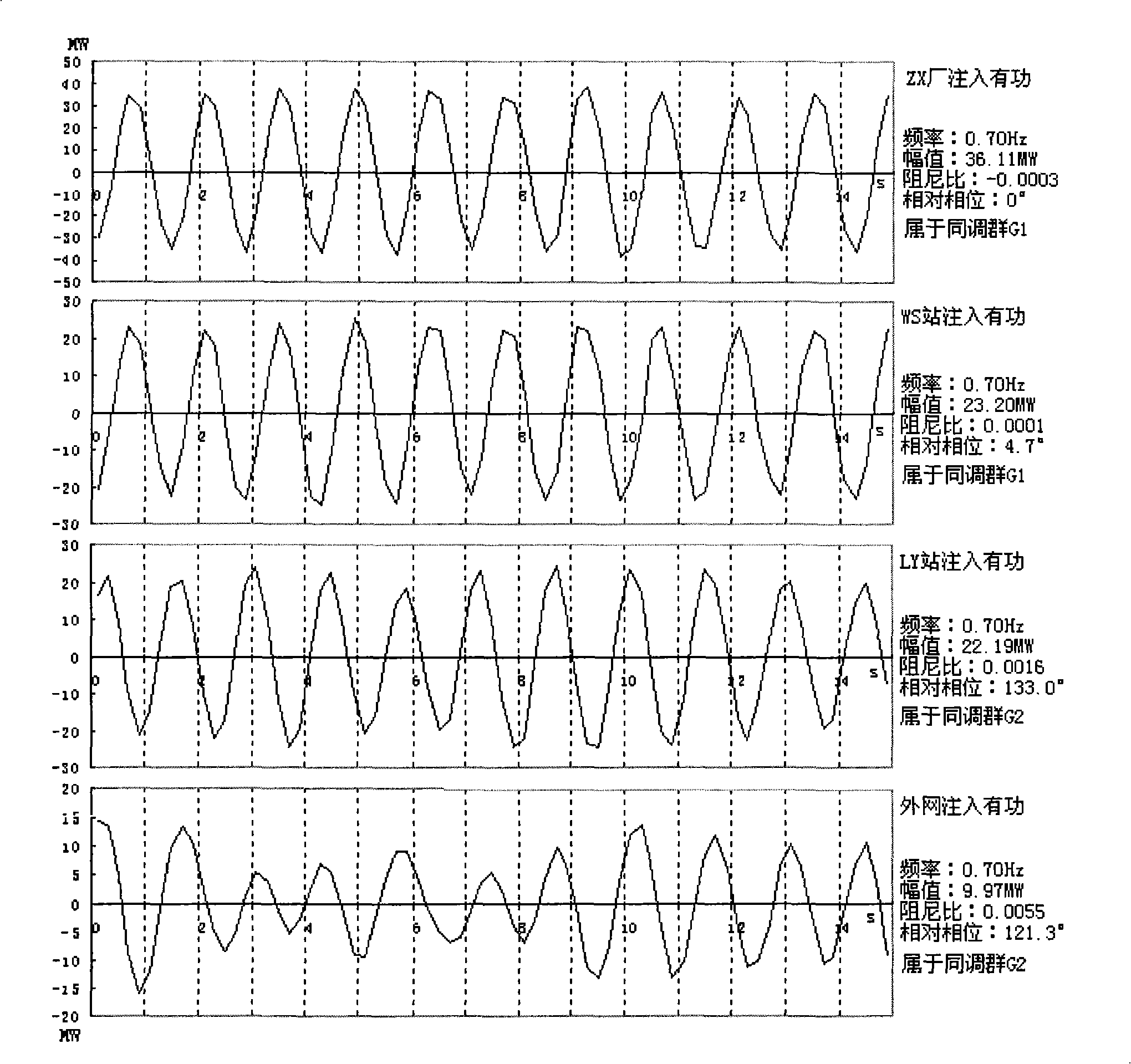

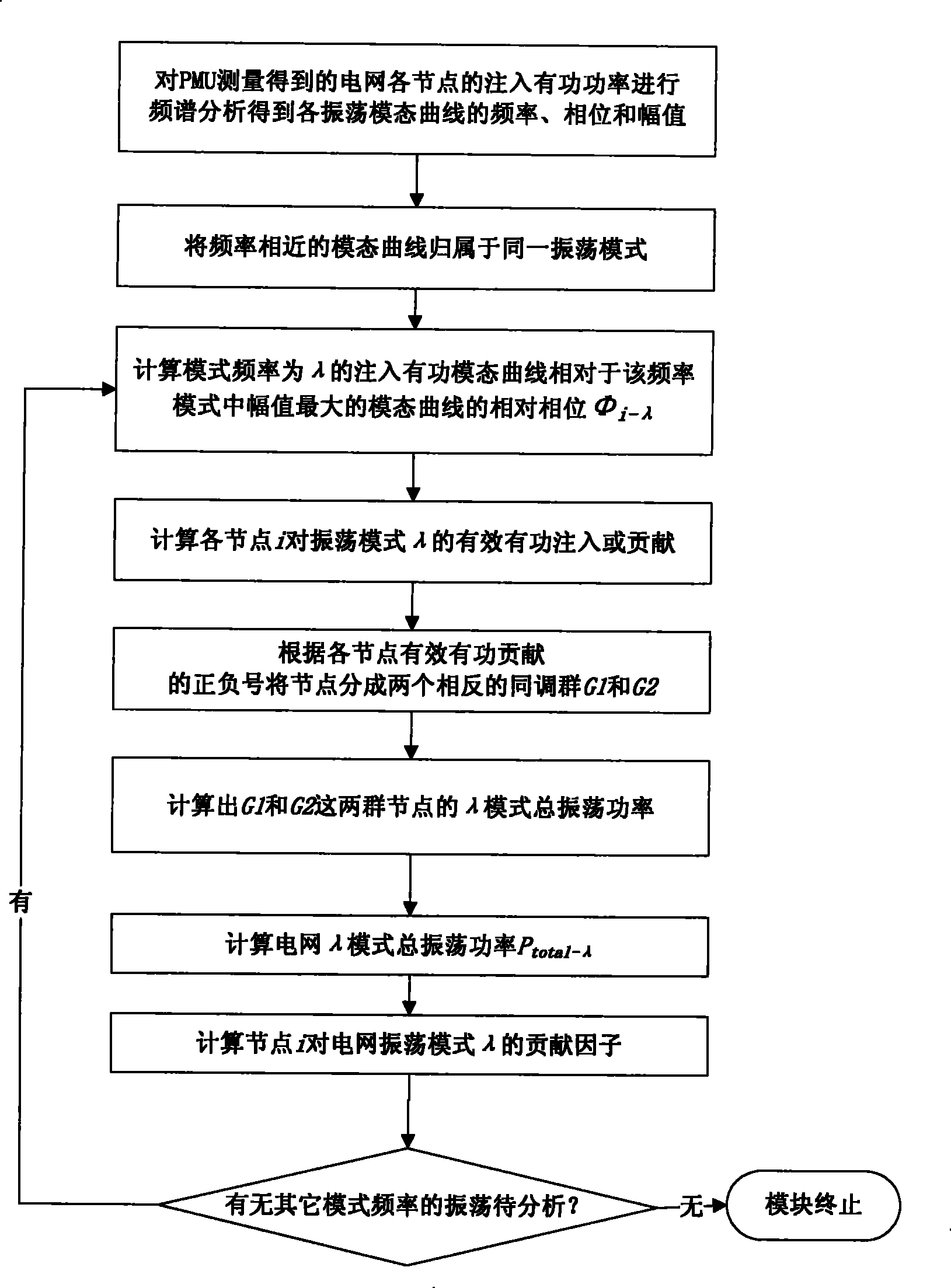

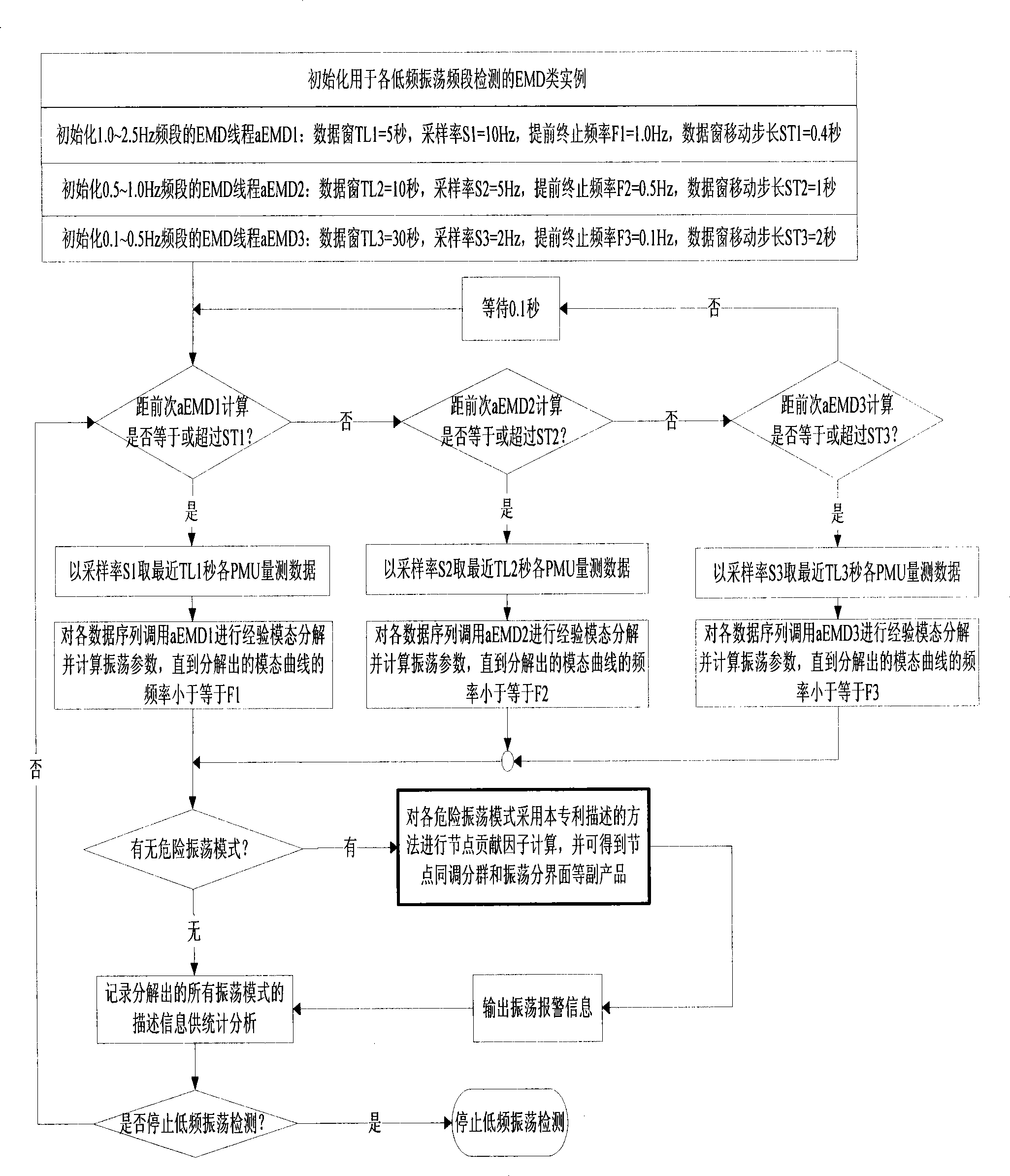

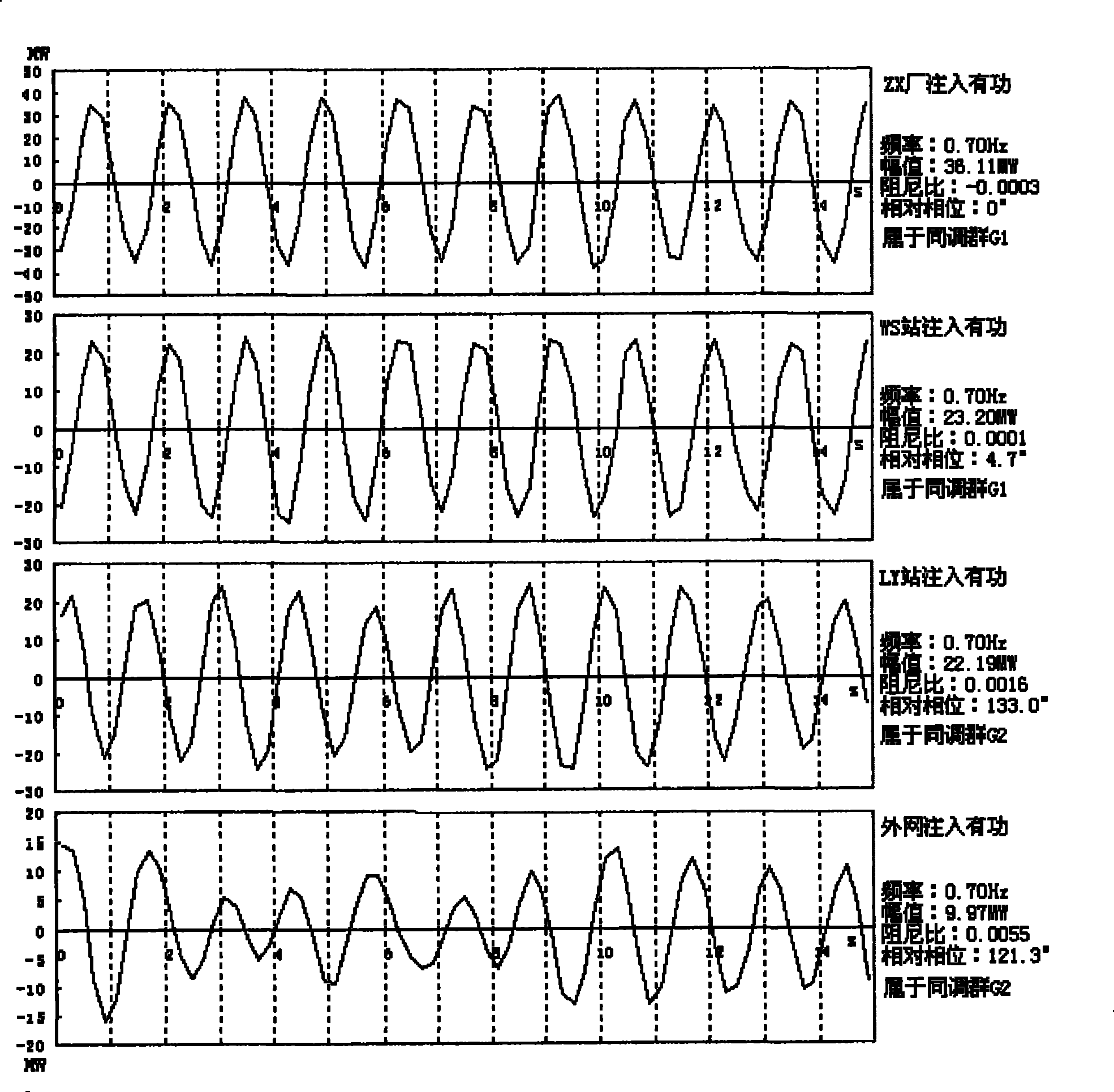

Analysis method of low-frequency oscillation node contribution factor based on wide field measuring information

ActiveCN101408577AConvenient and reasonable controlRealize online quantitative measurementSpectral/fourier analysisElectrical testingWide fieldRelative phase

The invention belongs to the technical field of the on-line detection and analysis of electric power system low-frequency oscillation. The invention provides a method for quantitatively evaluating the contribution degree of an electric generating set associated with a node participating in the oscillation of certain mode to the oscillation power of the mode in a power system, only based on the information of Wide Area Measurement System. In the method, a concept of node contribution factor is first proposed based on injection active oscillatory power, and then according to the amplitude of injection active oscillatory power and the relative phase position among active oscillatory power curves under certain frequency mode, an analysis and calculation method is provided corresponding to the node contribution factor of the frequency mode, and the homology and grouping of the node are realized at the same time. The method is applicable to a system without an electromagnetic ring net and consideration for losses and can also be used for an actual electric power system which has the above characteristics through simplification.

Owner:BEIJING SIFANG JIBAO AUTOMATION +1

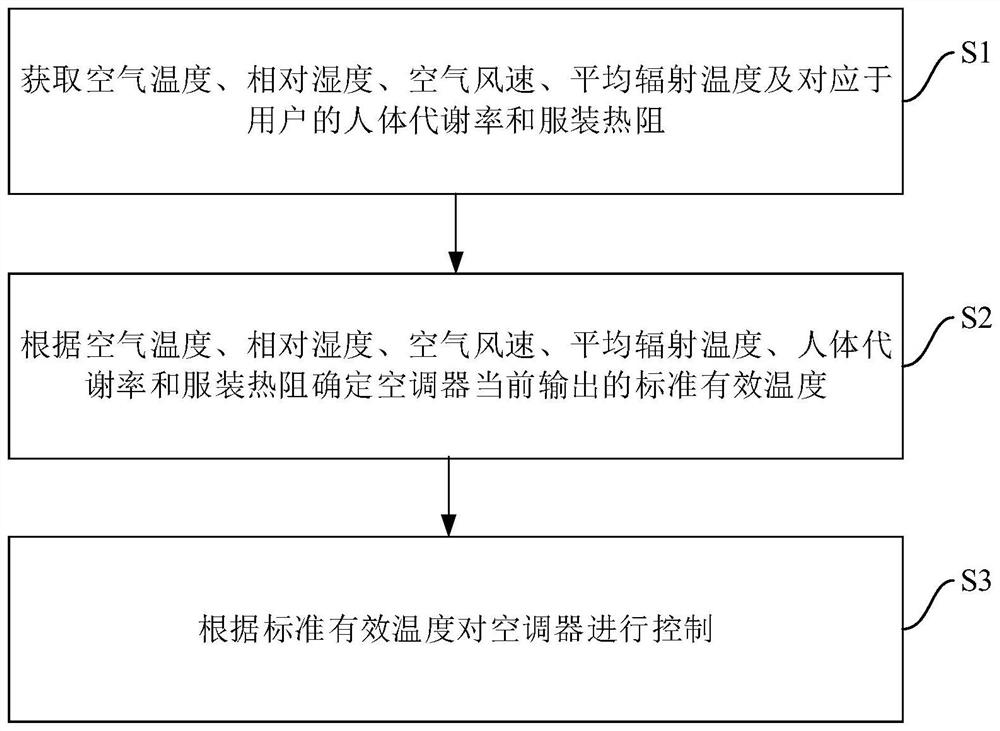

Air conditioner control method and device and air conditioner

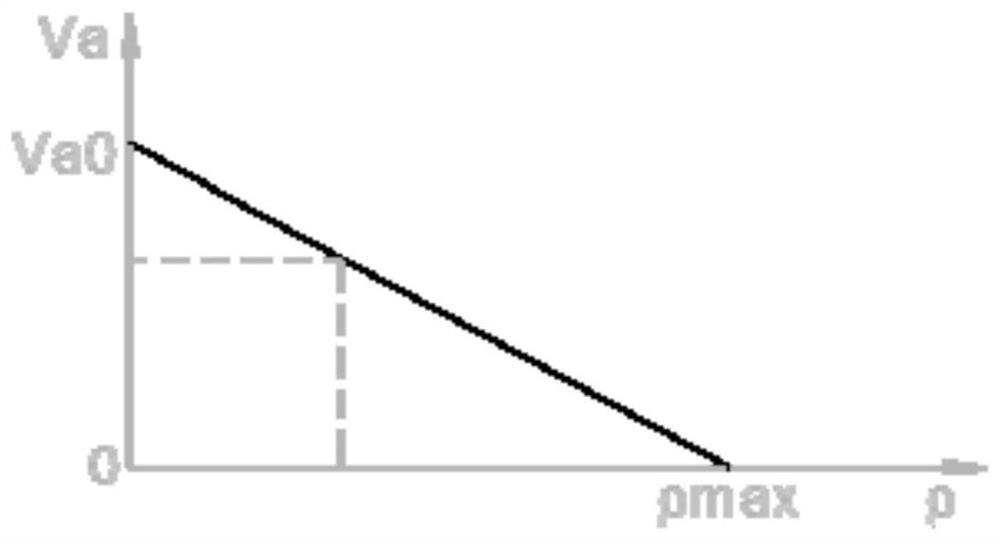

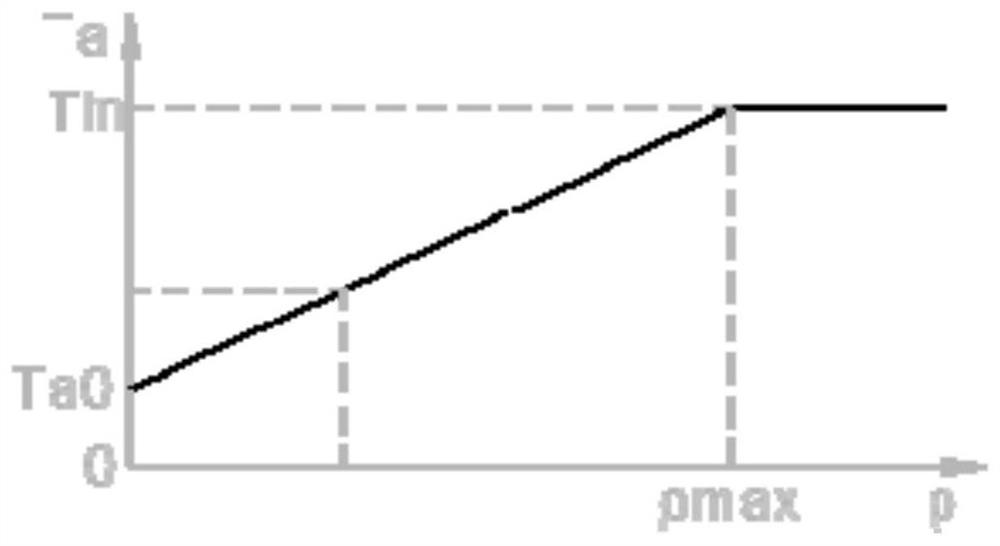

PendingCN114251793AImprove humanityImprove intelligent controlMechanical apparatusSpace heating and ventilation safety systemsMetabolic rateAir velocity

The invention discloses a control method and device of an air conditioner and the air conditioner. The method comprises the steps that the air temperature, the relative humidity, the air speed, the average radiation temperature, the human body metabolic rate corresponding to a user and the clothes thermal resistance corresponding to the user are obtained; the standard effective temperature currently output by the air conditioner is determined according to the air temperature, the relative humidity, the air speed, the average radiation temperature, the human body metabolic rate and the clothes thermal resistance; and the air conditioner is controlled according to the standard effective temperature. The current standard effective temperature of the air conditioner can be accurately determined, the air conditioner can be reasonably controlled according to the standard effective temperature, the indoor comfort degree is optimal, the comfort experience of a user can be improved, and humanized and intelligent control over the air conditioner is improved.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

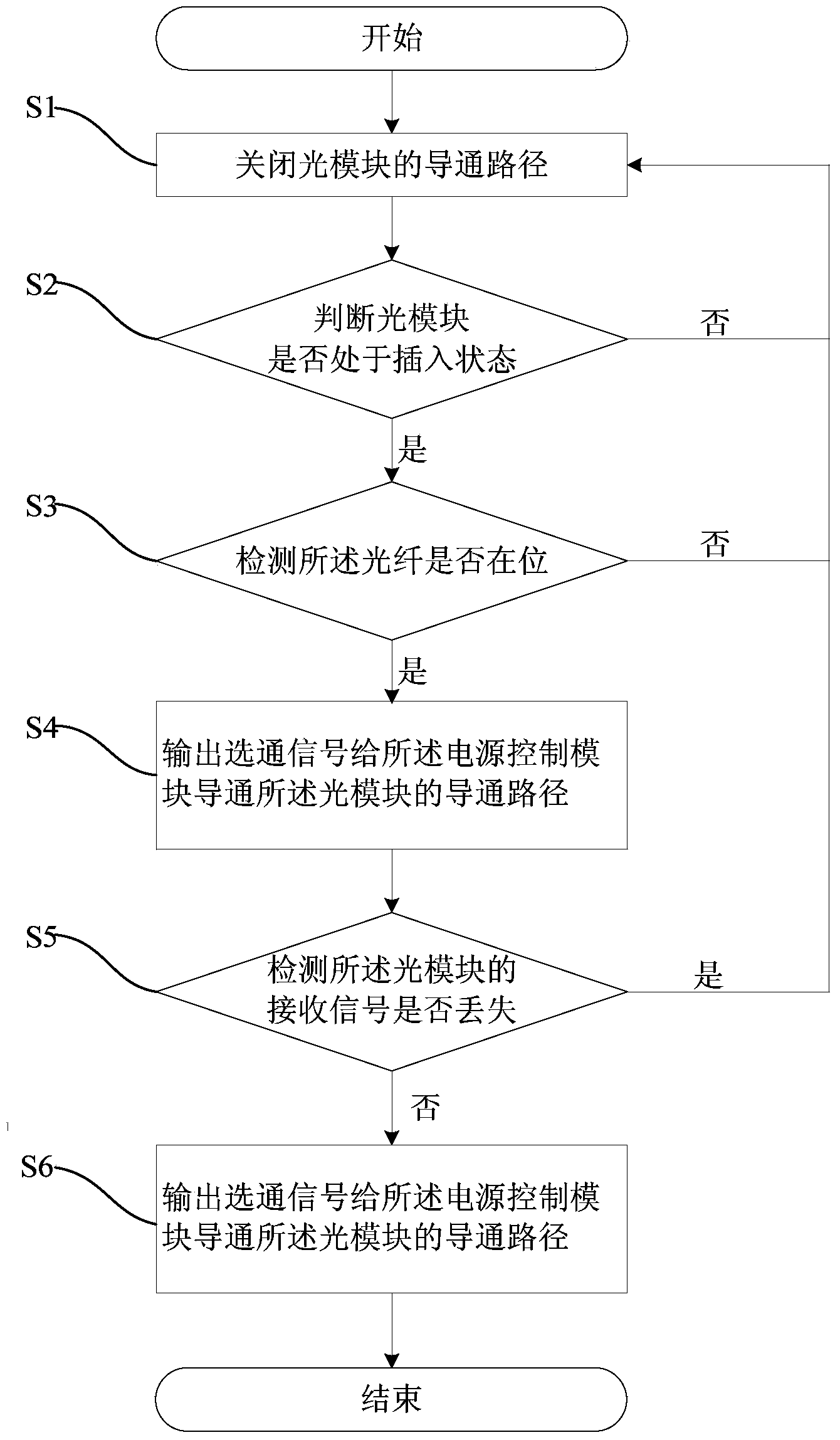

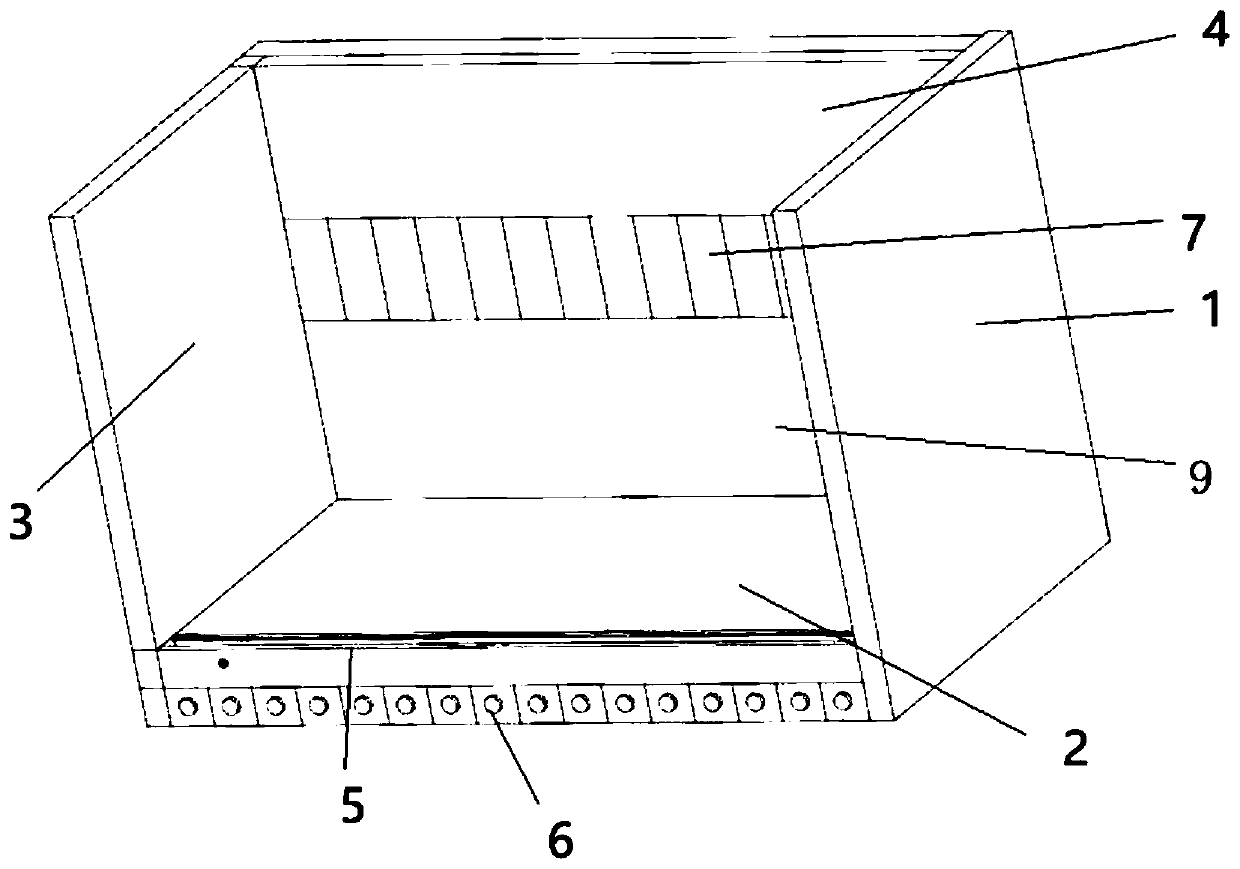

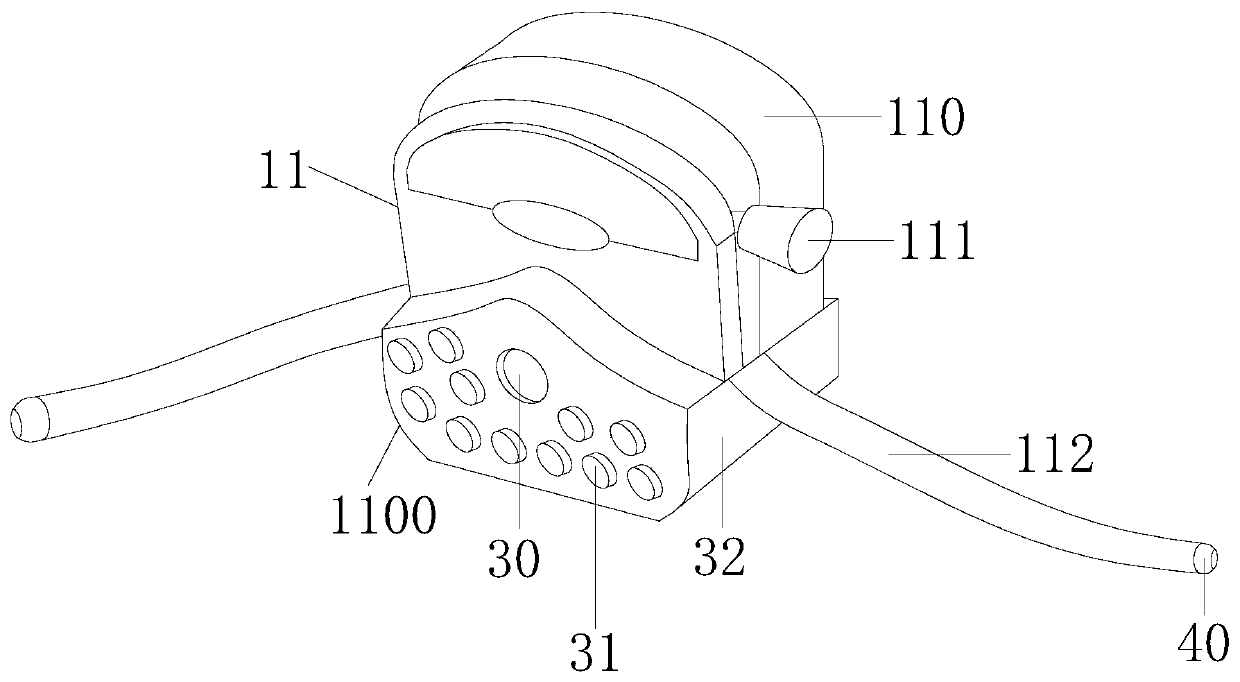

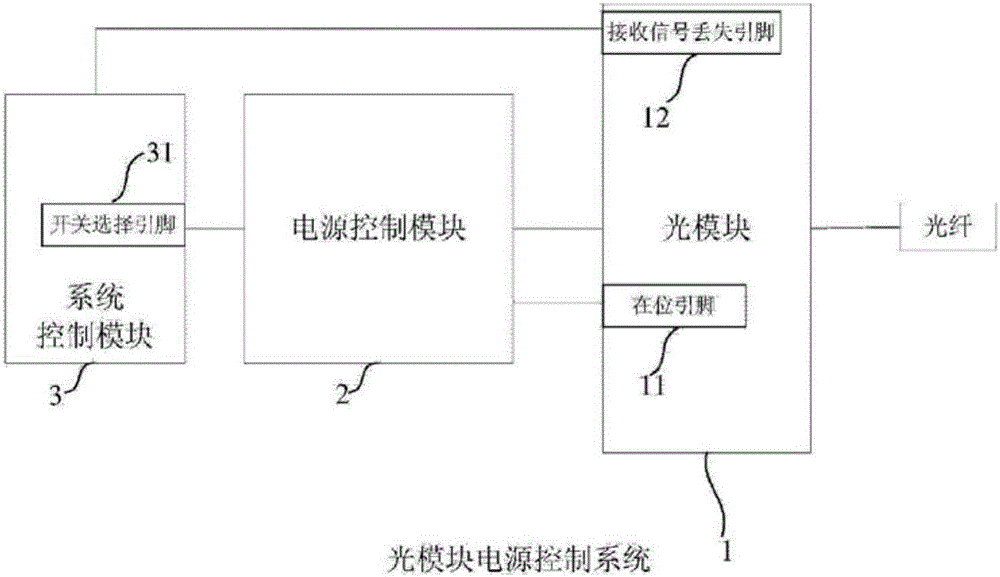

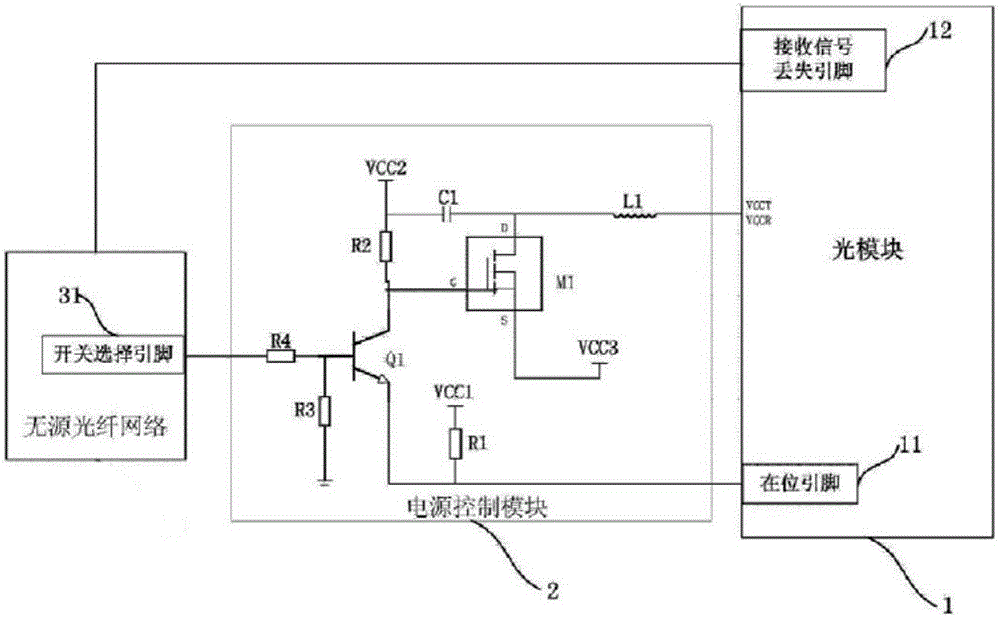

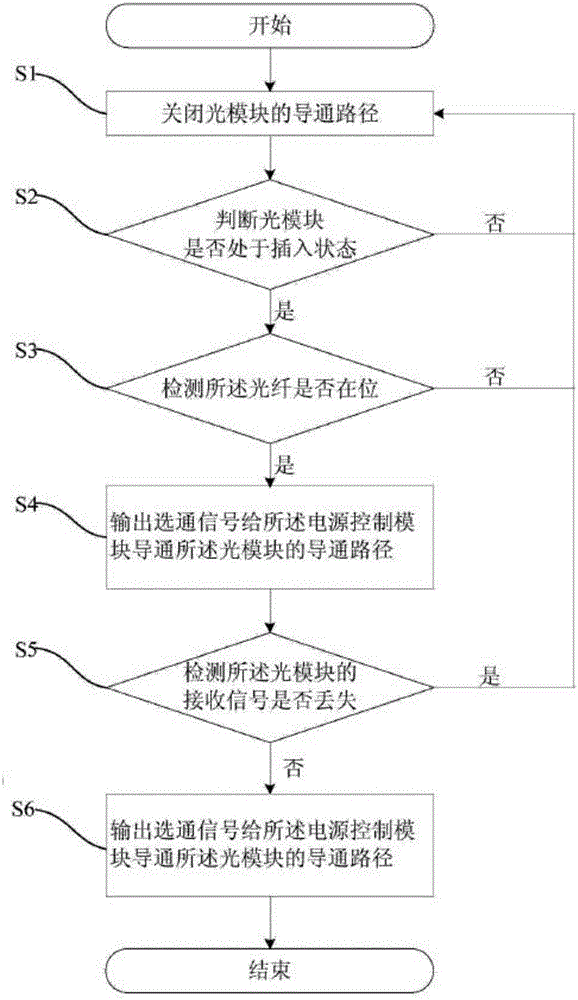

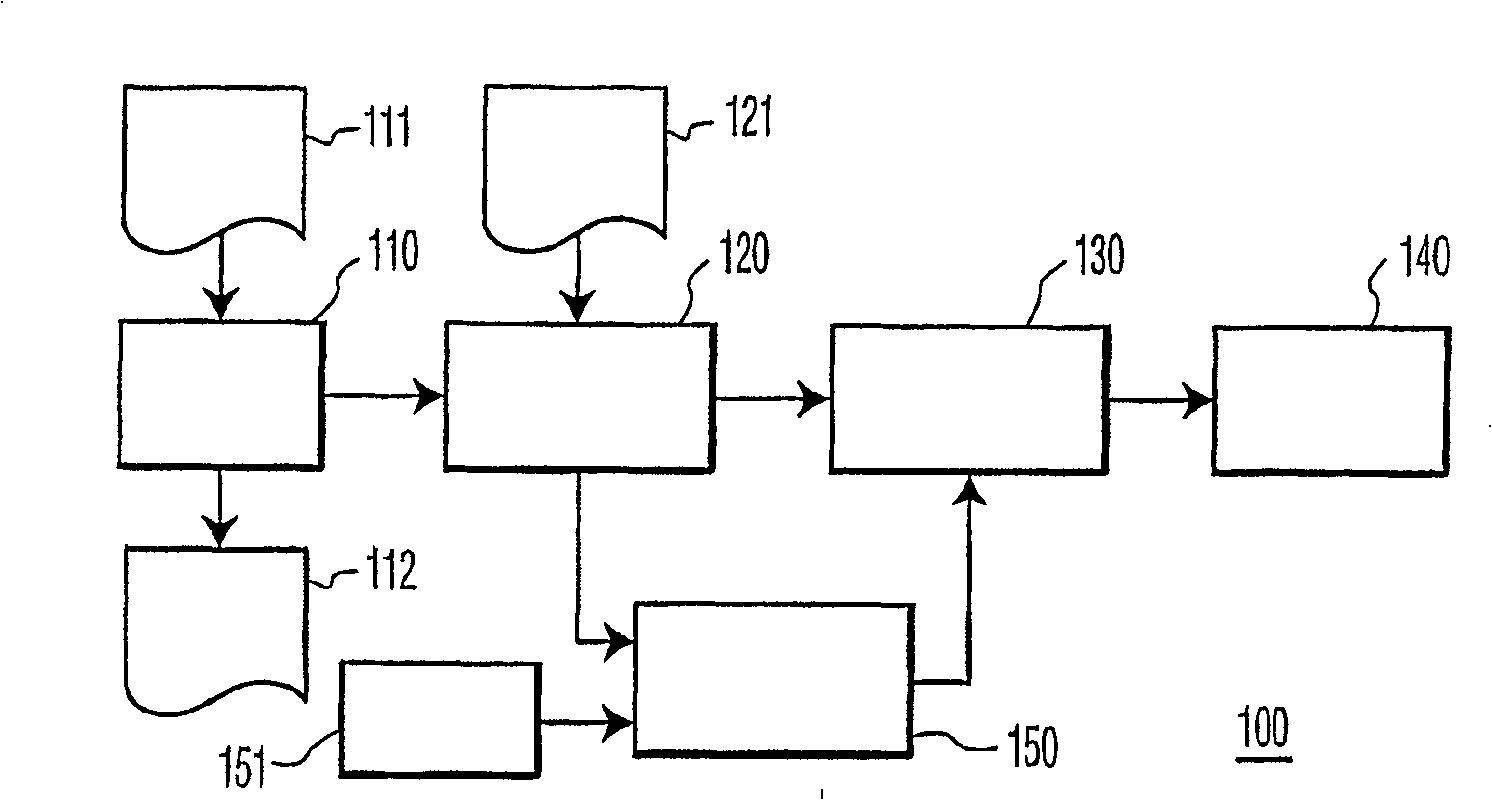

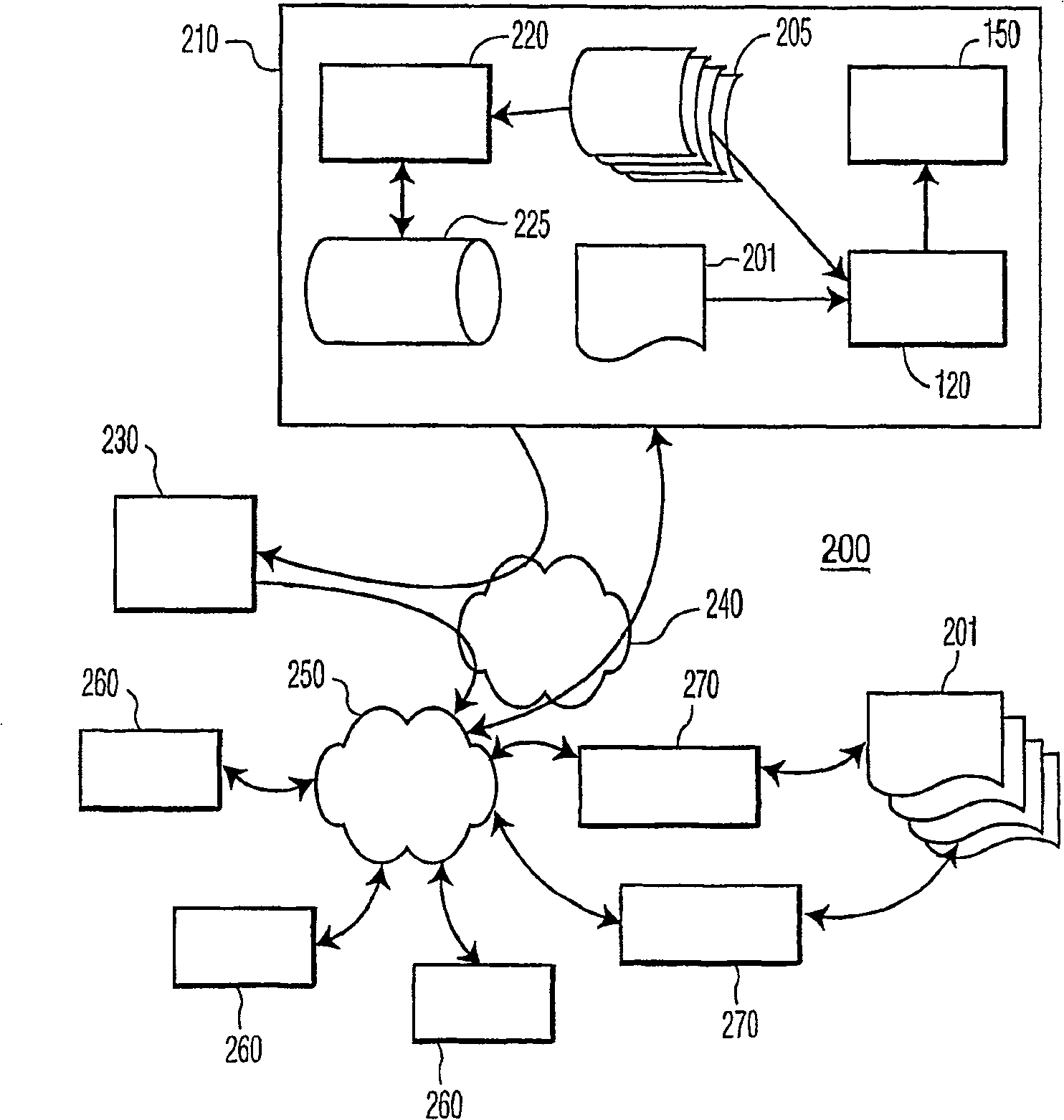

Light module power supply control method and system

ActiveCN103532541AAvoid damageConvenient and reasonable controlNon-electrical signal transmission systemsLogic circuitsOptical ModuleControl system

The invention provides a light module power supply control method, which is applied to a light module power supply control system consisting of a light module, a power supply control module and a system control module for controlling optical fibers. The method comprises the steps that the plugging state of the light module is detected, and if the light module is not plugged, forbidden signals are output for closing a conducting path of the light module; if the light module is plugged, whether the optical fibers are in position or not is detected, if the optical fibers are in position, gating signals are output to the power supply control module for conducting the conducting path of the light module; if the optical fibers are not in position, the forbidden signals are output for closing the conducting path of the light module; whether receiving signals of the light module are lost or not is detected, if the receiving signals of the light module are lost, the forbidden signals are output for closing the conducting path of the light module; if the receiving signals of the light module are not lost, the gating signals are output to the power supply control module for conducting the conducting path of the light source module. The light module power supply control method has the advantages that safety and reliability are realized during the plugging and the unplugging of the light module, the control is more convenient and reasonable, the damage to the light module is avoided, the existence of risk during the hot plugging and unplugging is reduced, and the energy consumption of the light module in the non-working state is reduced.

Owner:PHICOMM (SHANGHAI) CO LTD

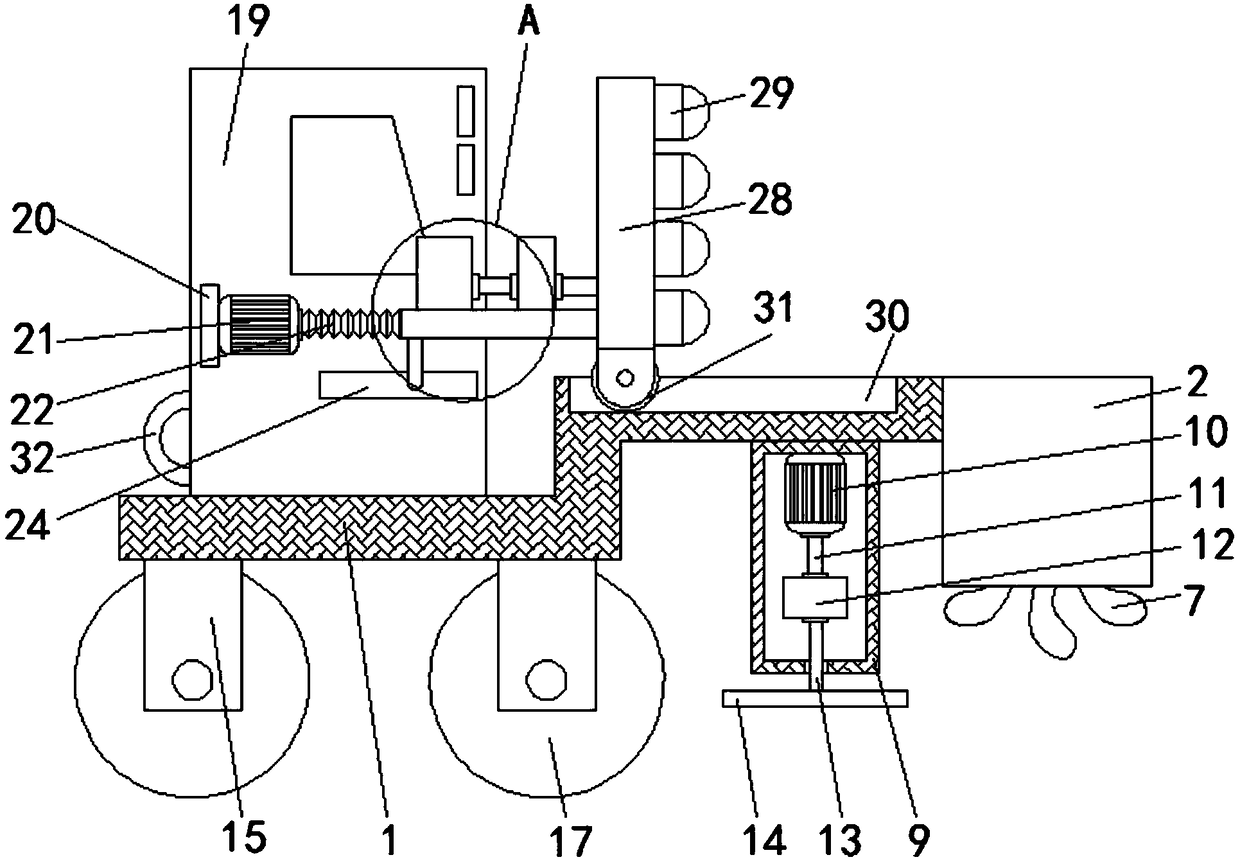

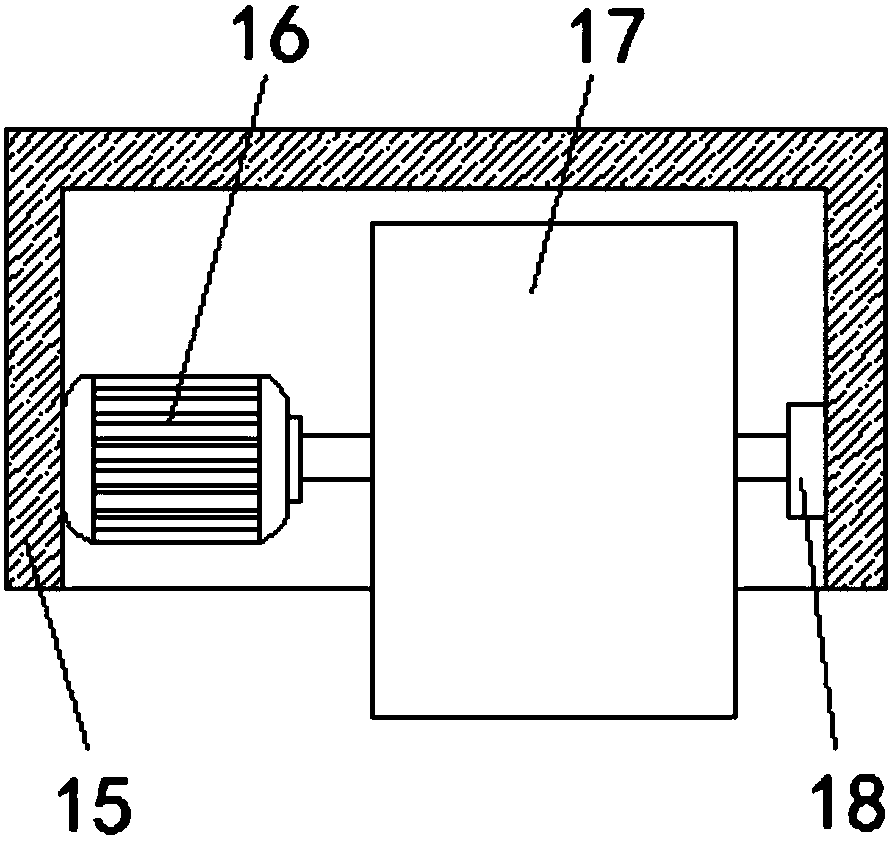

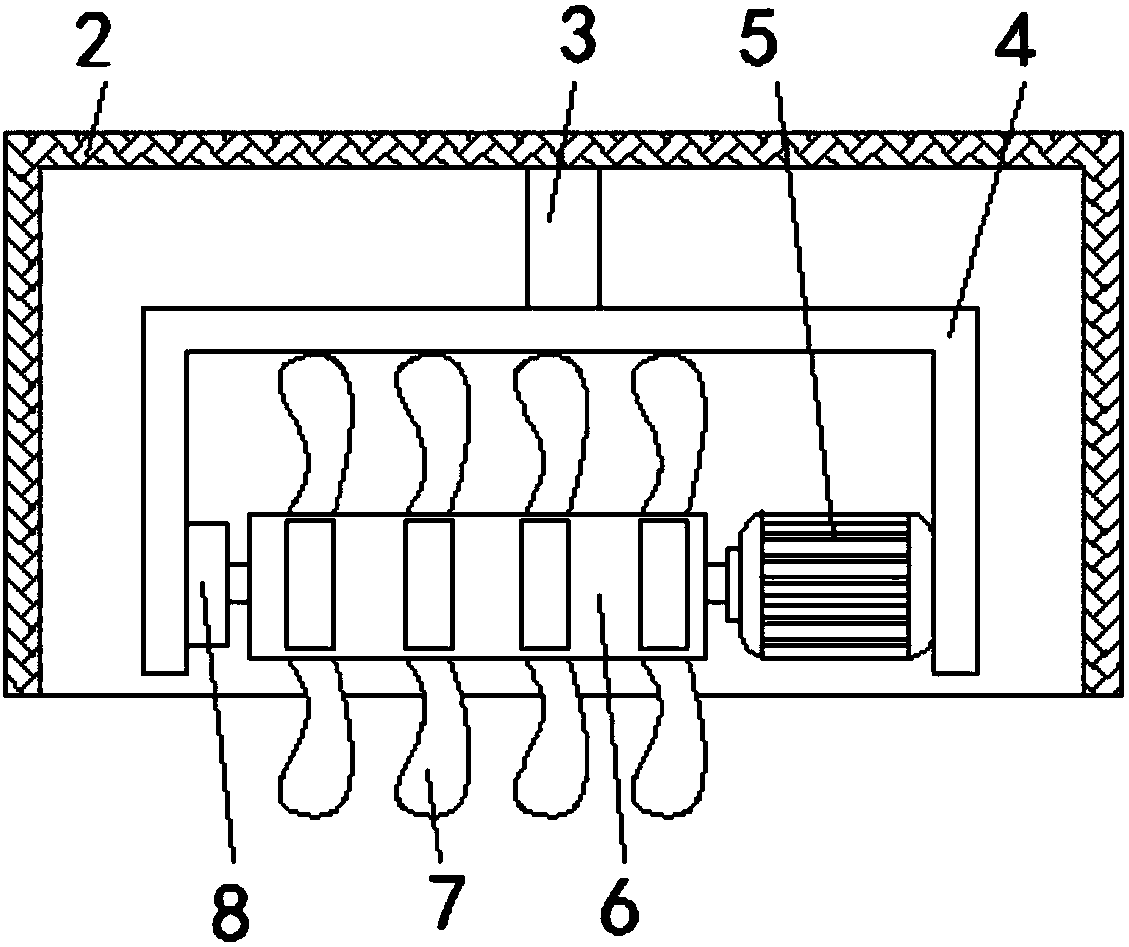

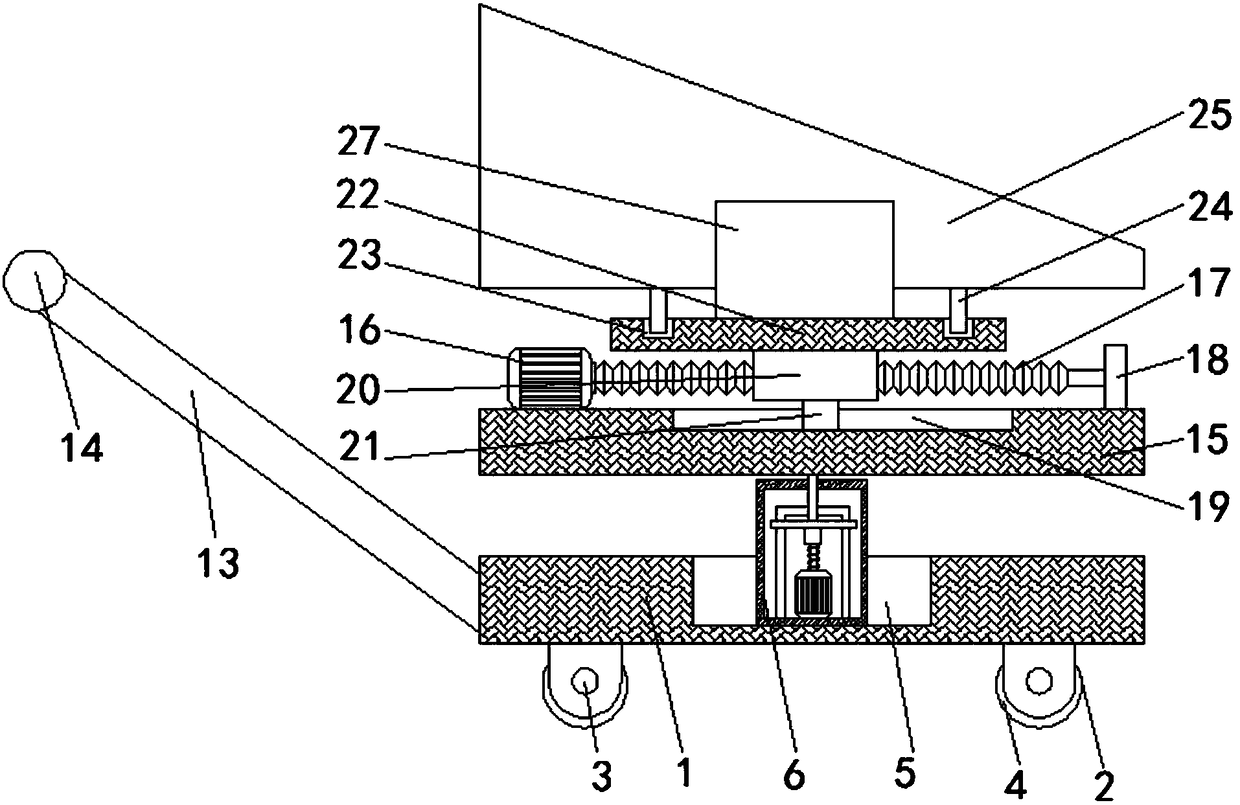

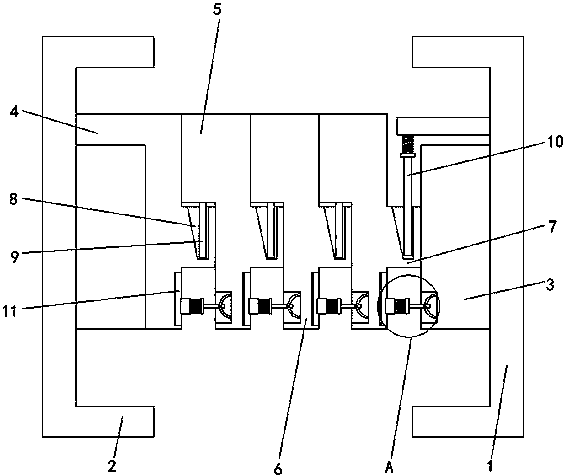

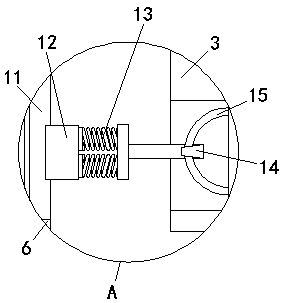

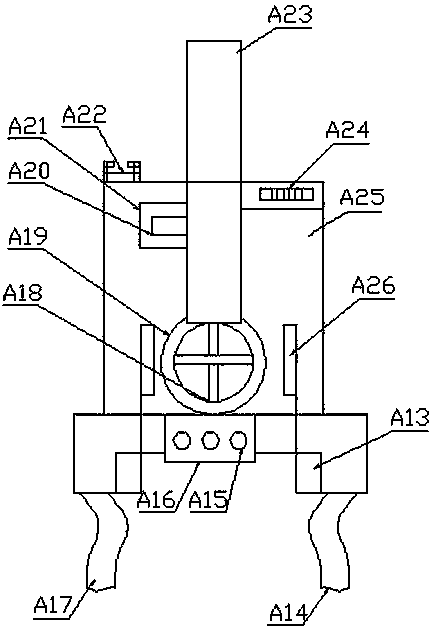

Roller for road laying

InactiveCN108589476AGuaranteed work efficiencyConvenient and reasonable controlRoads maintainenceSpiral bladeEngineering

The invention relates to the technical field of road laying and discloses a roller for road laying. The roller for the road laying comprises a bottom plate; a mounting box is fixedly connected to theright side of the bottom plate; the bottom of the mounting box is open; an electric push rod is fixedly connected to the internal wall of the top of the mounting box; and a first U-shaped plate is fixedly connected to the bottom end of the electric push rod. According to the roller for the road laying, by arranging a driving motor, a rotating column and a spiral blade, an effect of crushing biggersoil blocks and stone blocks is achieved; by arranging an asynchronous motor, a hydraulic machine and a pressing plate, an effect of pressing the crushed soil blocks and stone blocks is achieved; andfinally, by using a rolling shaft, an effect of rolling the soil blocks and the stone blocks is achieved; and therefore, situations that the soil blocks and the stone blocks cannot be rolled and therolling efficiency is low are avoided, and the working efficiency of the roller is greatly guaranteed to achieve an effect of being convenient for working personnel to reasonably control the working time.

Owner:齐全

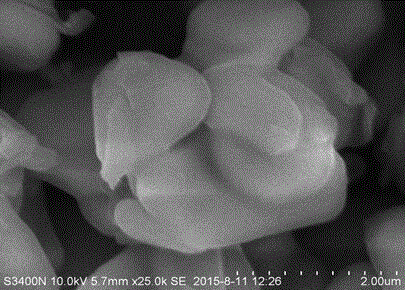

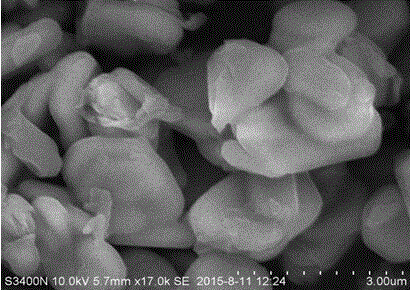

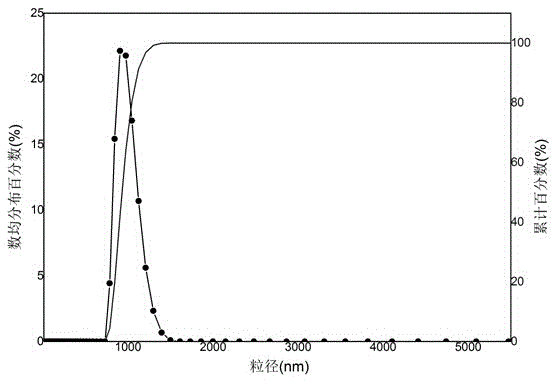

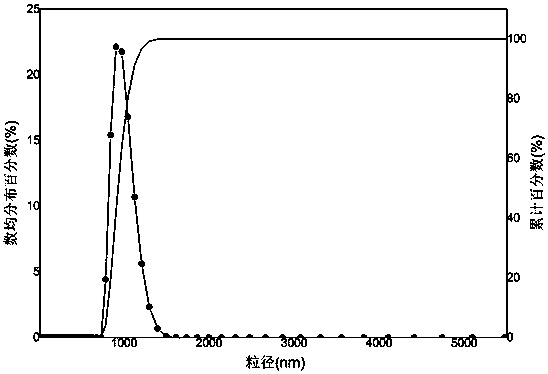

Preparation method of microencapsulated zirconium phosphate and halogen-free flame-retardant PC (polycarbonate) comprising microencapsulated zirconium phosphate

The invention discloses a preparation method of microencapsulated zirconium phosphate. The method comprises steps as follows: zirconium phosphate with the particle size being 0.8-1.2 mu m is evenly dispersed in a solvent, and a zirconium phosphate dispersion liquid is obtained; meanwhile, a reaction reagent is added to the zirconium phosphate dispersion liquid, the mixture is mechanically stirred and subjected to reflux at the temperature of 50-180 DEG C, a hybrid crosslinking reaction occurs, the reaction time is controlled within 1-36 h, and after the reaction ends, microencapsulated zirconium phosphate is obtained through washing and freeze-drying. The microencapsulated zirconium phosphate is prepared from zirconium phosphate with a microencapsulation technology, and the preparation technology is simple, easy to operate and suitable for industrial production; a prepared microencapsulated zirconium phosphate flame retardant has the more optimized and reasonable flame-retardant progress control and the more effective and lasting flame-retardant effect; prepared microencapsulated zirconium phosphate is added to a PC matrix, and the prepared halogen-free flame-retardant PC is easy to process and mold, halogen-free, environment-friendly and better balanced in mechanical performance and flame-retardant performance.

Owner:GUANGDONG UNIV OF TECH

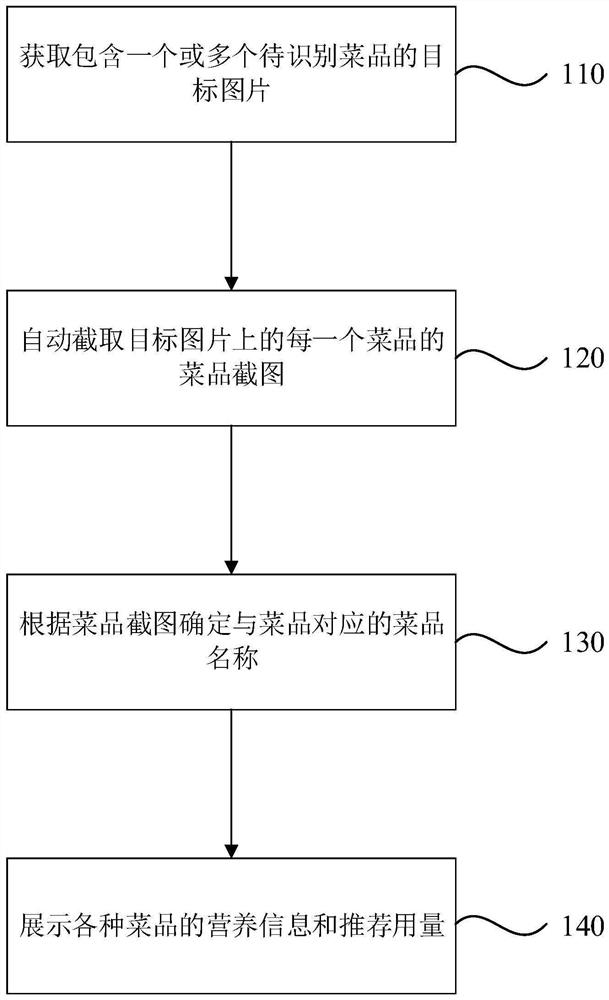

Diet information display method and device, equipment and a storage medium

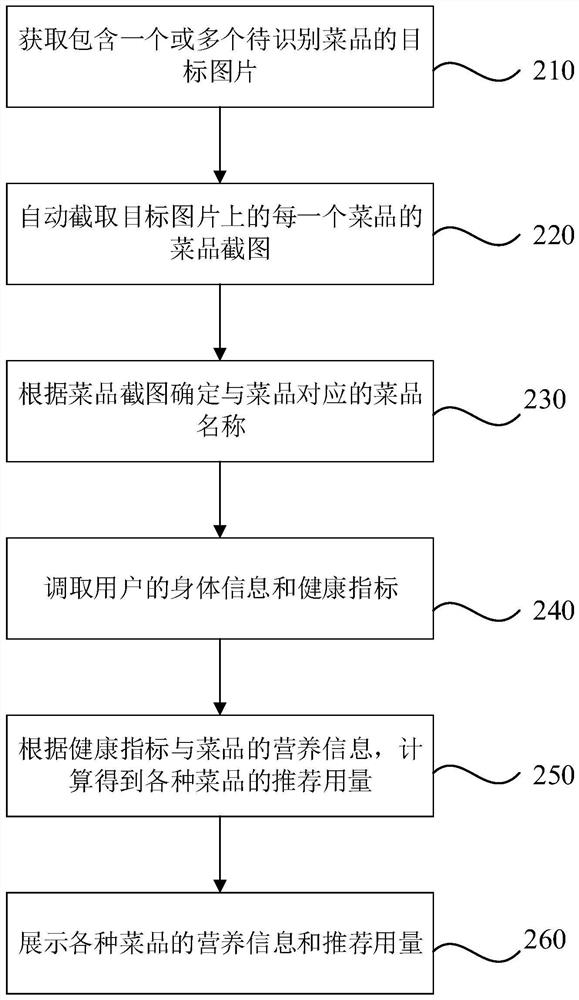

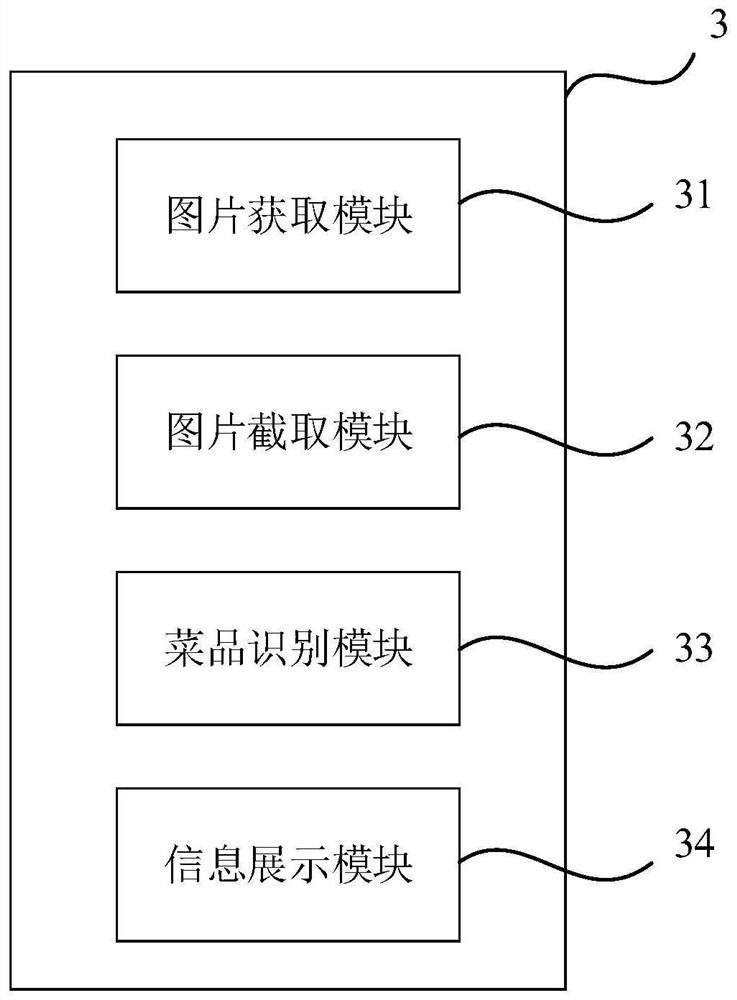

PendingCN111863194AConvenient and quick record of dietFacilitate reasonable diet controlNutrition controlNutritionNutrition information

The embodiment of the invention discloses a diet information display method and device, equipment and a storage medium. The method comprises the following steps: acquiring a target picture containingone or more dishes to be identified; automatically intercepting a dish screenshot of each dish on the target picture; determining dish names corresponding to the dishes according to the dish screenshots; and displaying the nutrition information and recommended dosage of various dishes. According to the embodiment of the invention, a screenshot of each dish is intercepted from a picture containinga plurality of dishes; the name and nutrition information of each dish are determined; the recommended consumption of each dish is calculated in combination with the user body information and the health indexes, so that the problems that a diet recording mode is inconvenient and consumption recommendation cannot be performed according to the health requirements of the user are solved, and the effects of conveniently recording a diet, recommending dish consumption according to the health requirements of a user and conveniently and reasonably controlling the diet by a user are achieved.

Owner:SHENZHEN YOLANDA SCI & TECH

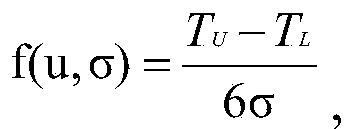

Method for comprehensively evaluating pipe manufacturing capacity of oil and gas conveying pipe factory

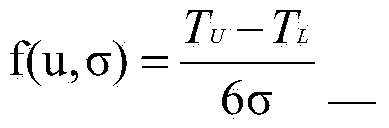

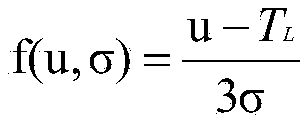

InactiveCN103995971AConvenient and reasonable controlConducive to reasonable control of control costsSpecial data processing applicationsOriginal dataUltimate tensile strength

A method for comprehensively evaluating the pipe manufacturing capacity of an oil and gas conveying pipe factory comprises the following steps that first, the fact whether the standards of all kinds of performance of an oil and gas conveying welding pipe has upper limit demands or not is used for determining corresponding computational formulas; second, test data are obtained according to the demands for group test frequency of the strength and the toughness of parent metal and welding joints, and through statistic analysis of original data, the average value and the standard deviation of the yield strength of the parent metal, the average value and the standard deviation of the tensile strength of the parent metal, the average value and the standard deviation of the impact power value of the parent metal, the average value and the standard deviation of the tensile strength of the welding joints, the average value and the standard deviation of the impact power value of the welding joints, and the average value and the standard deviation of the impact power value of the influencing area of the welding joints are obtained respectively and are substituted into the formulas. According to the method, process capability indexes are introduced to the pipe manufacturing industry to evaluate the pipe manufacturing level in a quantifying mode for the first time, the current product manufacturing condition of an enterprise can be judged, and the mutual balance of quality of economy is achieved.

Owner:BEIJING LONGSHINE OIL TUBULAR TECH

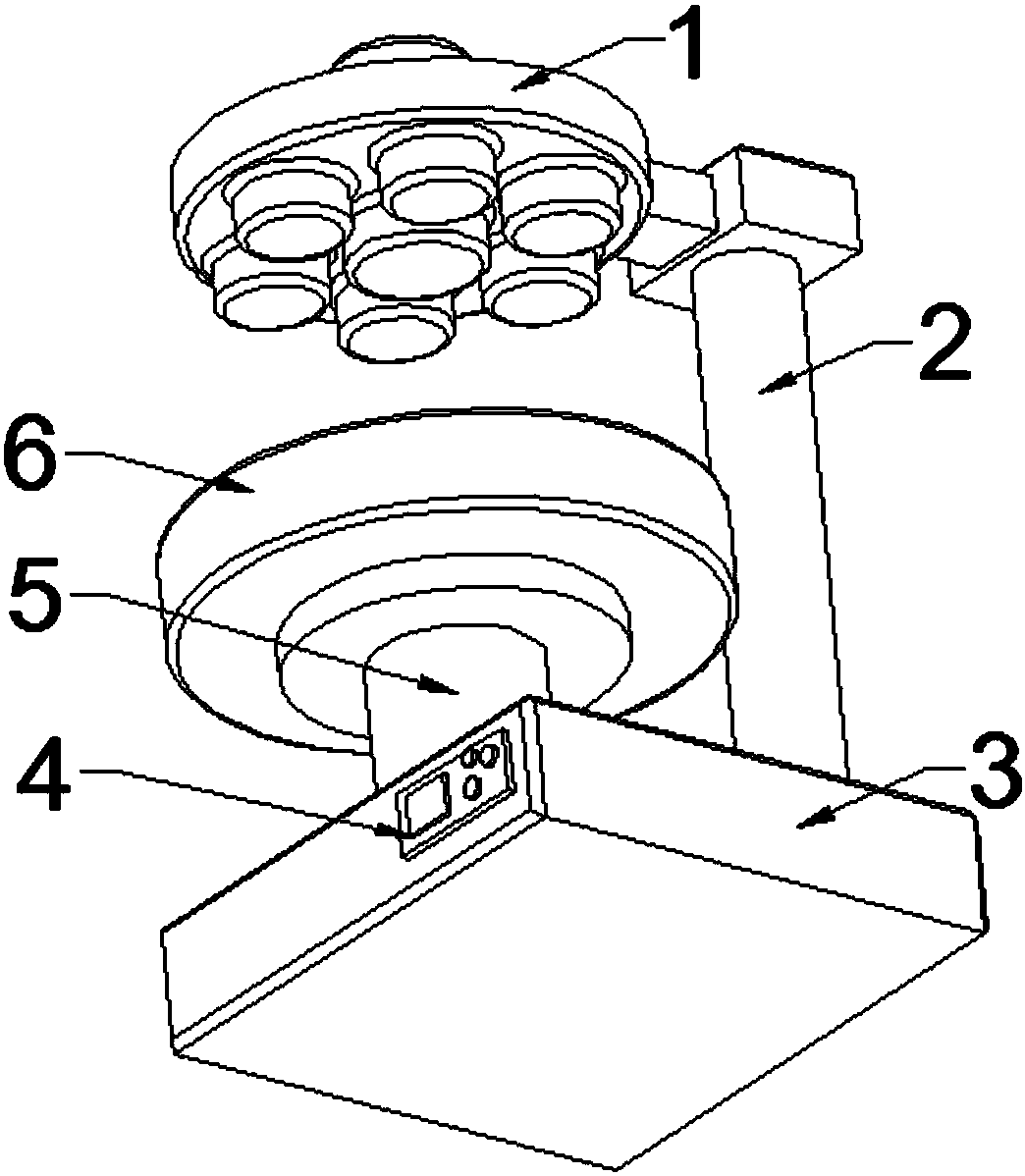

Improved tabletting equipment

InactiveCN108263015AReduce processing timeImprove processing efficiencyShaping pressEngineeringHigh pressure

Owner:天津椿盟科技有限公司

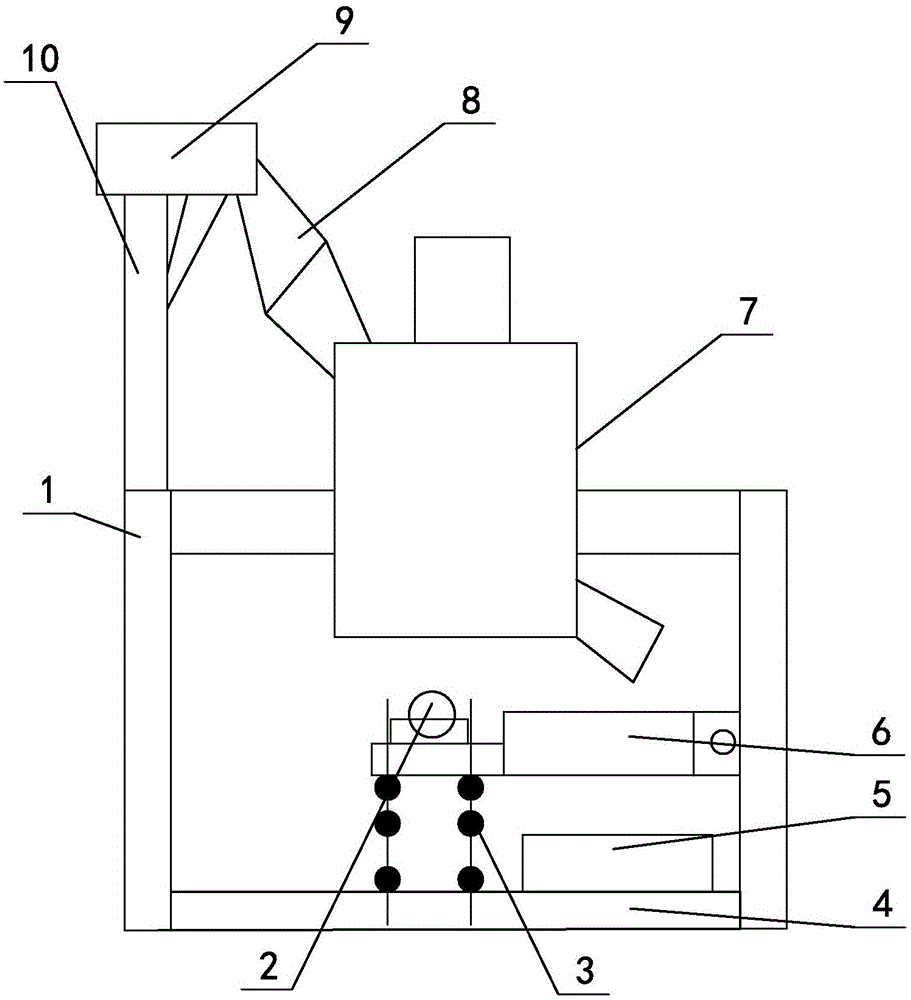

Flavoring crushing device with weighing function

InactiveCN106563538ASimple structureReduce manufacturing costSievingScreeningMechanical engineeringRaw material

The invention relates to a flavoring crushing device with a weighing function and belongs to the technical field of flavoring crushing. The flavoring crushing device comprises a work platform. A cutting type pulverizer is vertically installed on the work platform, and a storing plate is installed at the bottom of the work platform. A filter sieve is arranged on a discharge port corresponding to the cutting type pulverizer, a collecting tank is arrange below the filter sieve, and the collecting tank is stored on the storing plate. A connecting passageway is connected to a feeding port of the cutting type pulverizer, a weighing instrument is connected to the feeding end of the connecting passageway, and the weighing instrument is installed to the work platform through a support. The flavoring crushing device with the weighing function is simple in structure, low in manufacturing cost and very applicable to crushing flavorings, and the crushing effect is better than an existing pulverizer; and the flavoring crushing device with the weighing function is also very convenient to operate by workers, and raw materials are saved.

Owner:CHONGQING HONGQIAN AGRI DEV CO LTD

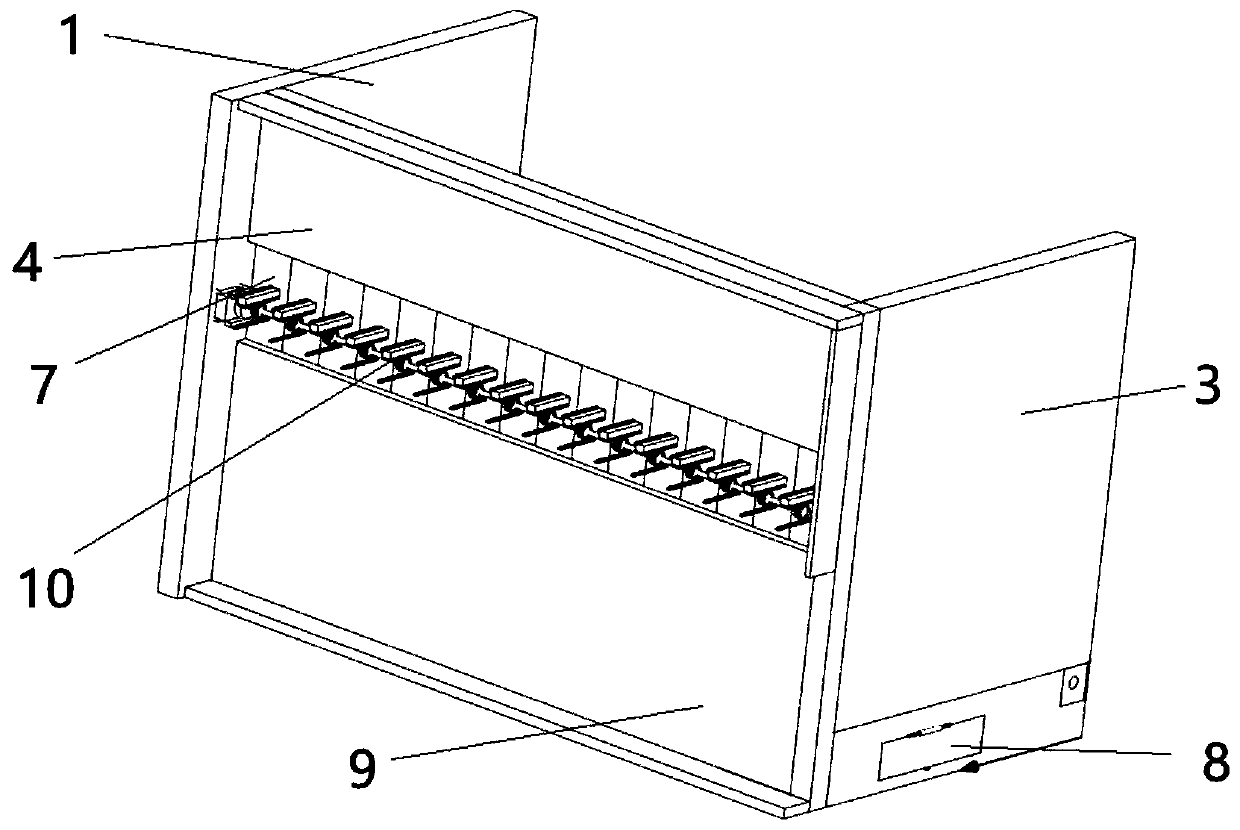

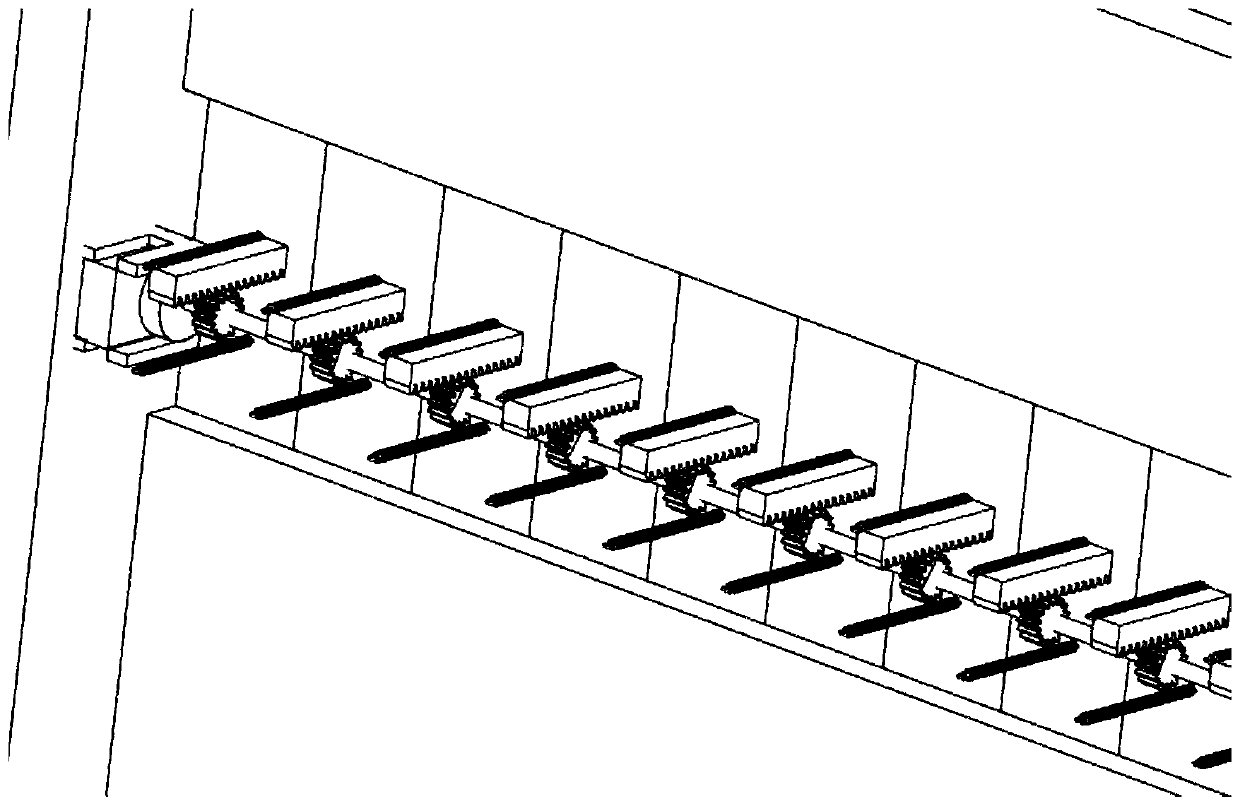

Telescopic bookend convenient to take book

The invention discloses a telescopic bookend convenient to take a book. The telescopic bookend comprises a right frame, a base, a left frame, an upper backing plate, a lower backing plate, a rear backing plate and a book popping assembly; the book popping assembly comprises N popping buttons, N popping plates, a motor, a rotating long shaft, N clutches, N gears, N racks, a first shrinking spring;the N popping buttons are sequentially arranged on the front end face of the base; the N popping plates are arranged between the upper backing plate and the lower backing plate; the motor is fixedly arranged on the right frame; the rotating long shaft is fixedly connected with an output shaft of the motor; N gears are respectively arranged at positions on the rotating long shaft, which correspondto N popping plates; each gear can implement connection with the rotating long shaft and disconnection from the rotating long shaft by the corresponding clutch; each gear is meshed with the corresponding rack; one end of each rack is fixedly connected with the corresponding popping plate; and N is greater than or equal to 2. The bookend disclosed by the invention is telescopic; and when a user wants to take the book, the book which the user wants to take can be conveniently popped up by the popping button.

Owner:NANJING UNIV OF SCI & TECH

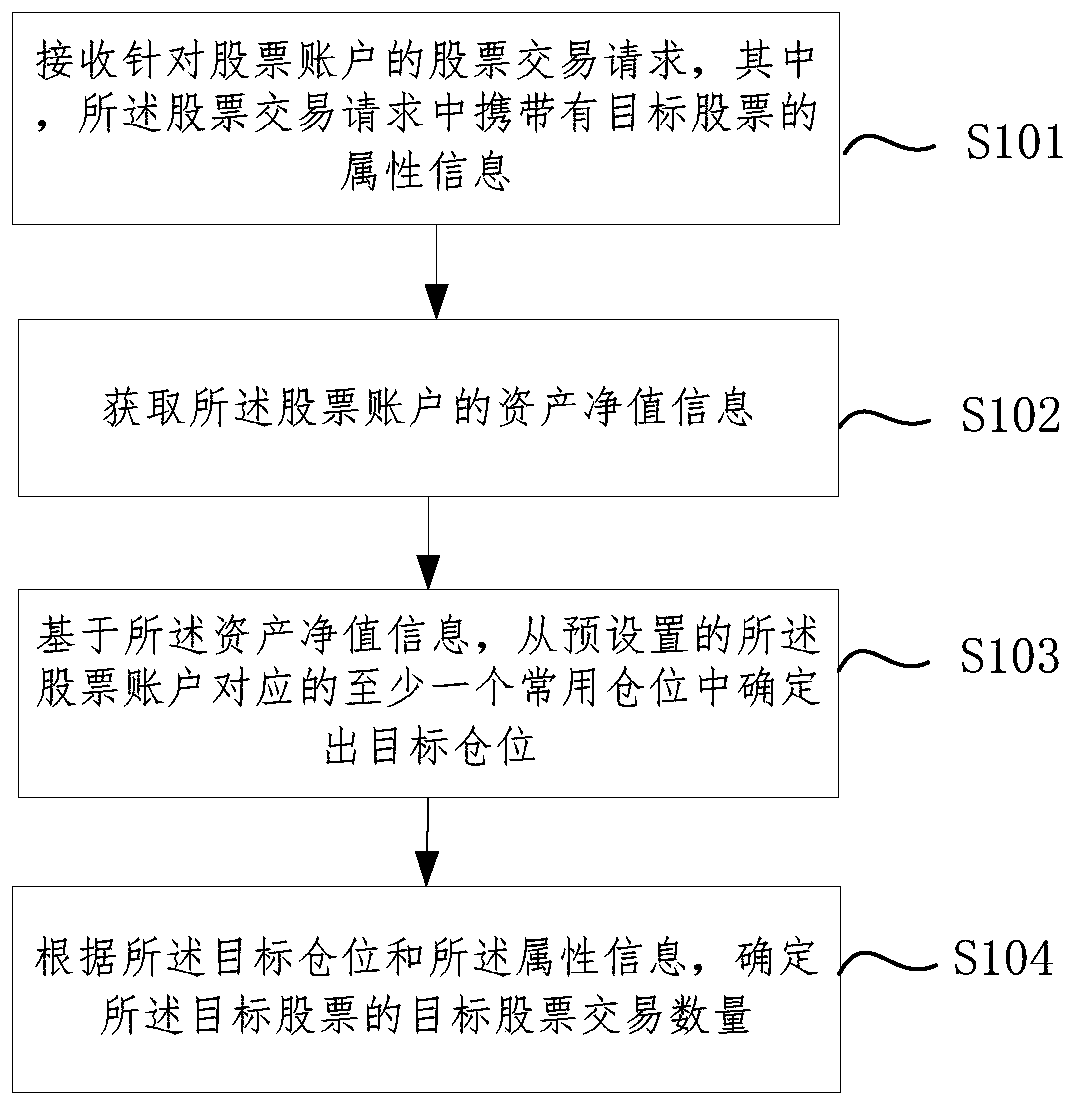

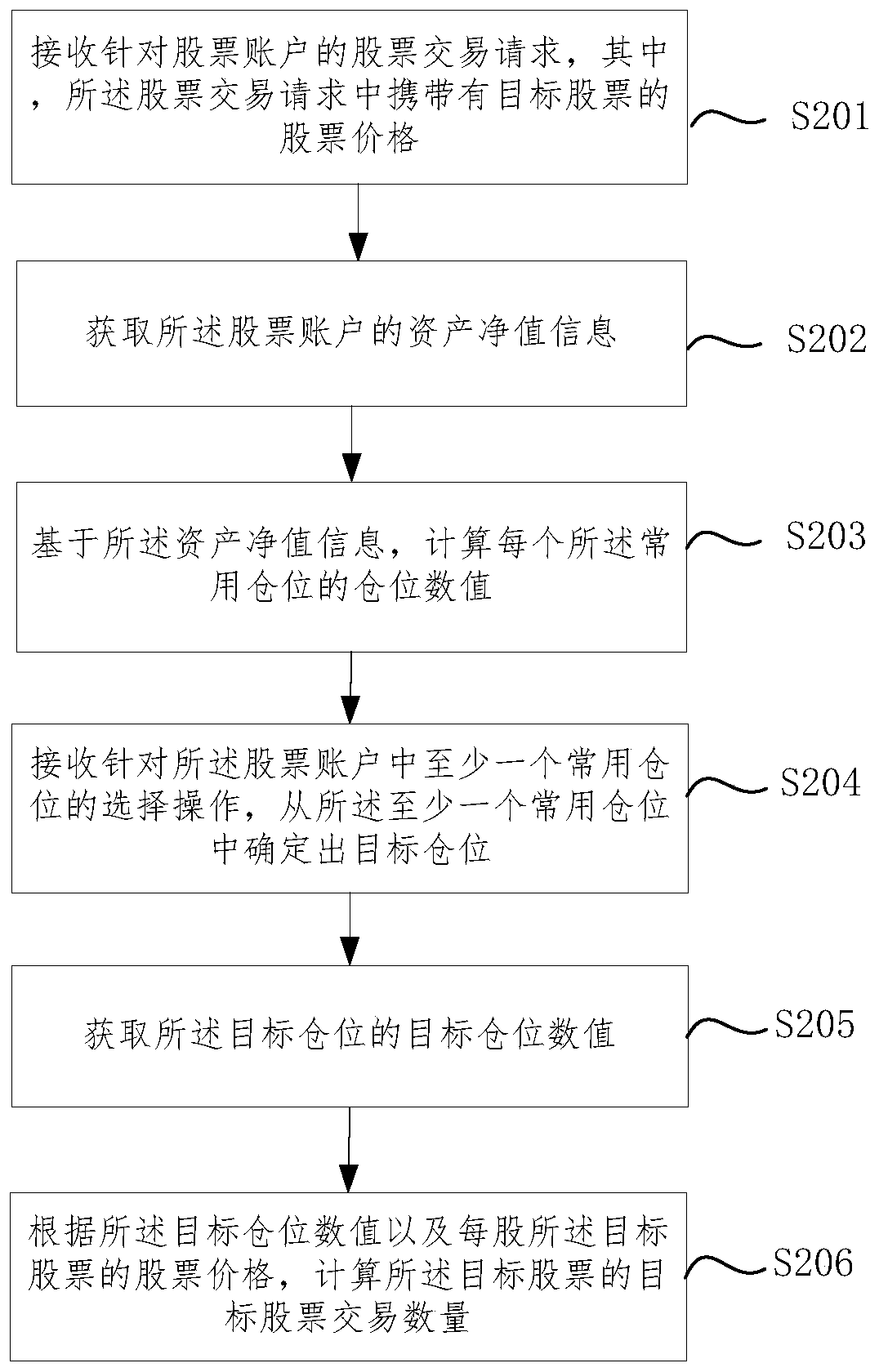

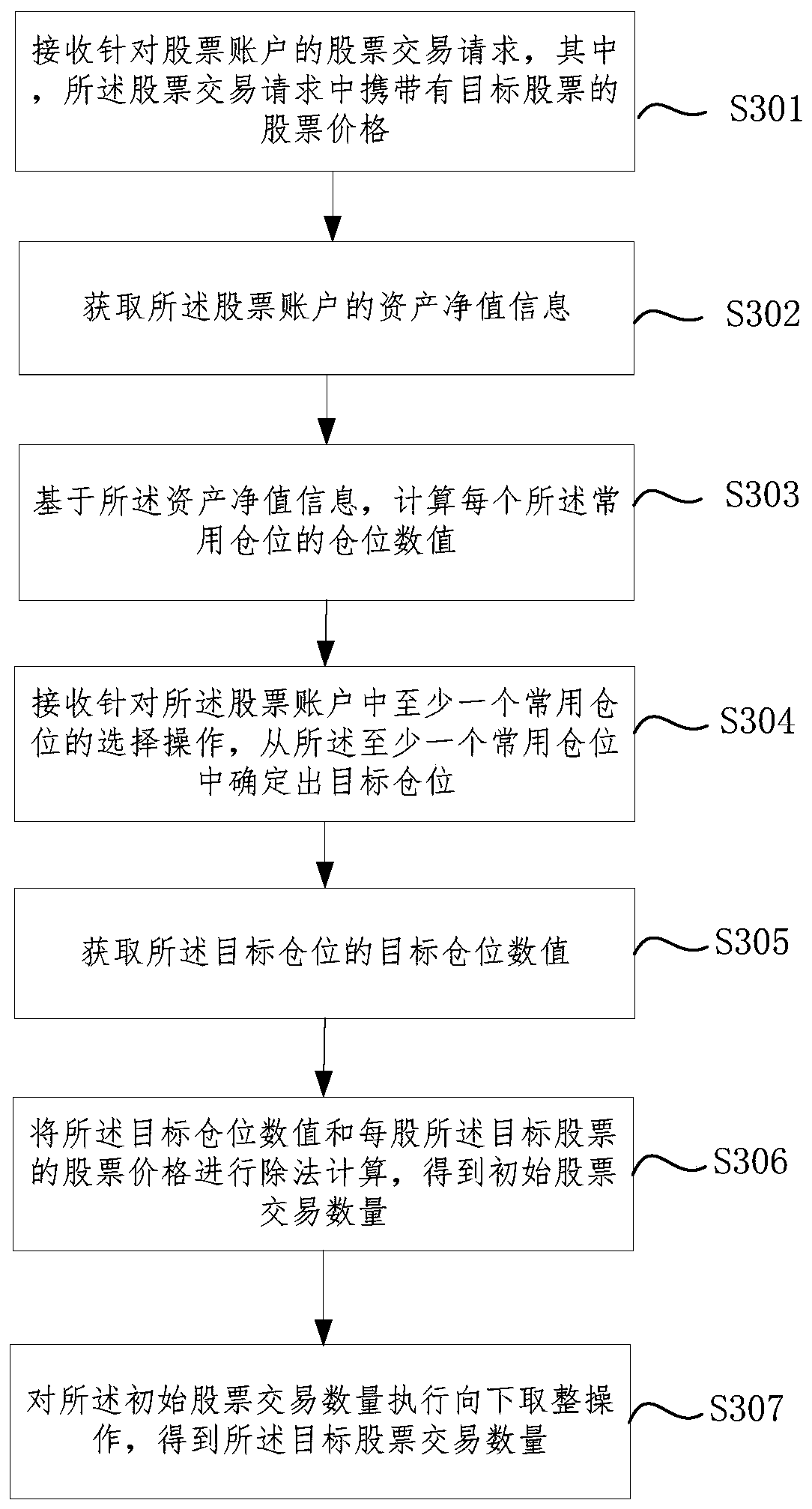

Stock transaction method, system, device and computer readable storage medium

PendingCN110992176AImprove transaction efficiencyConvenient and reasonable controlFinanceFinancial transactionData mining

The embodiment of the invention discloses a stock transaction method, a system, a device and a computer readable storage medium, and the method comprises the steps: receiving a stock transaction request for a stock account, and enabling the stock transaction request to carry the attribute information of a target stock; obtaining asset net value information of the stock account; based on the assetnet value information, determining a target warehouse position from at least one preset common warehouse position corresponding to the stock account; and determining a target stock transaction quantity of the target stock according to the target bin position and the attribute information. In stock transaction of a user, the target stock transaction quantity of the target stock to be transacted bythe user can be obtained according to the asset net value information of the current stock account of the user, and the transaction shipping space can be flexibly selected based on the asset net valueinformation, so that the user can conveniently and reasonably control the stock transaction scale, the transaction time is reduced, and the stock transaction efficiency of the user is improved.

Owner:SHENZHEN FUTU NETWORK TECH CO LTD

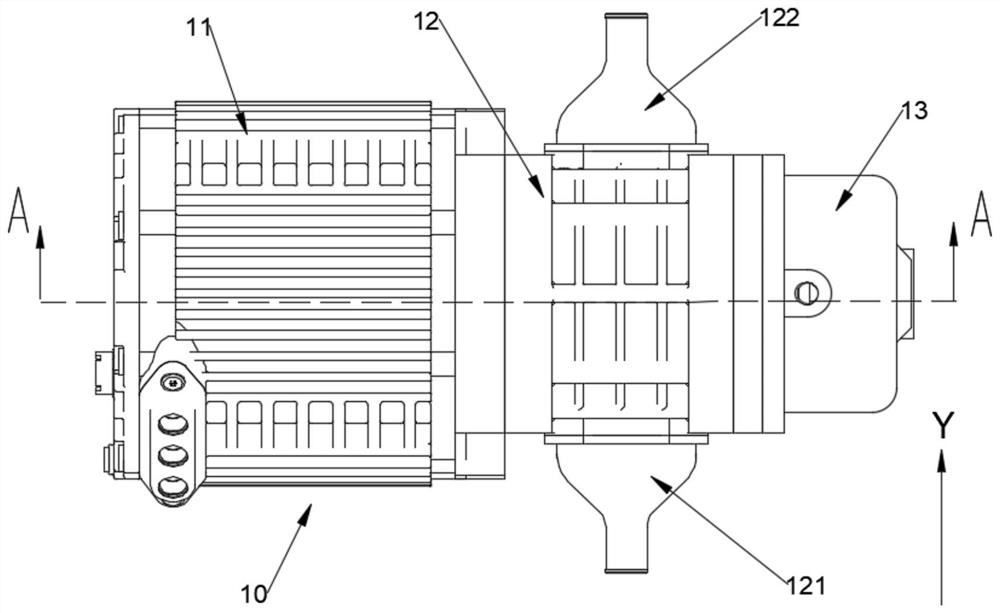

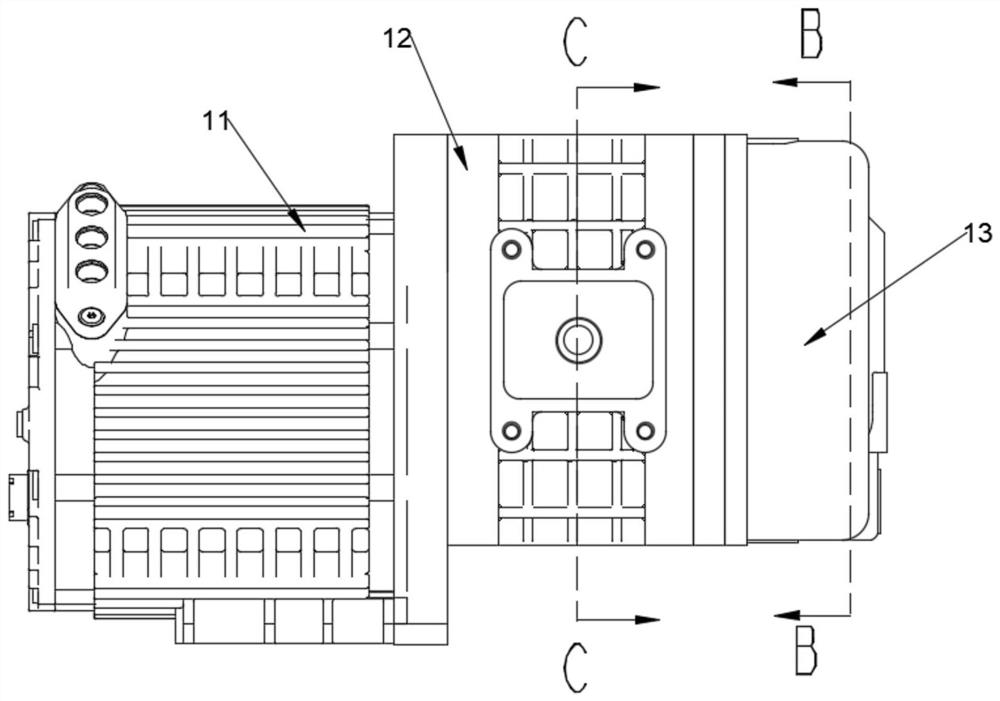

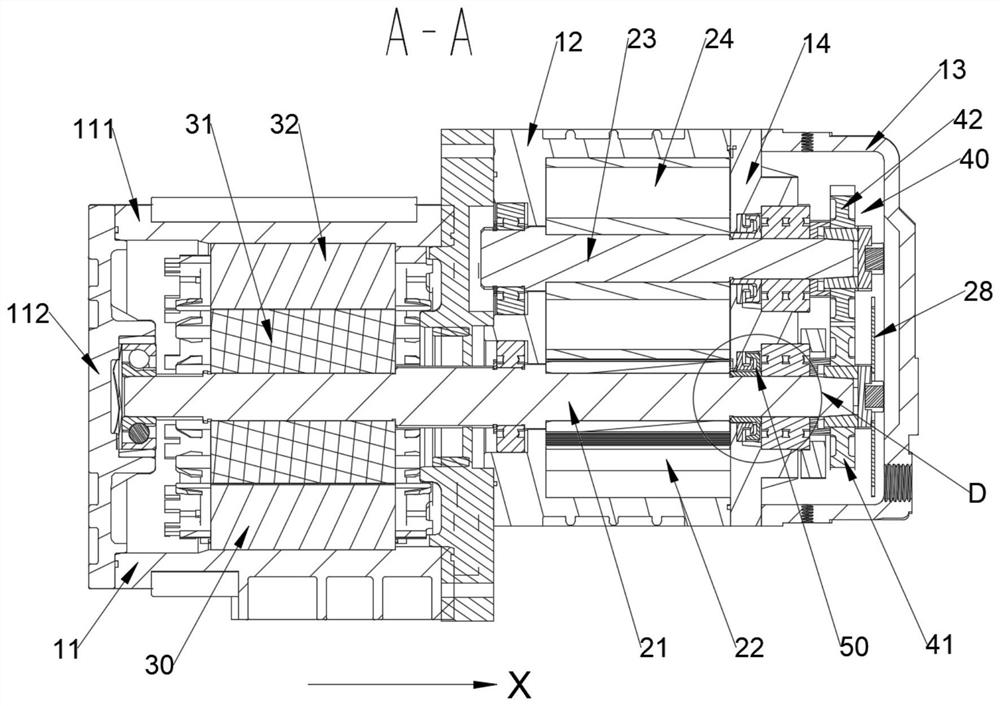

Hydrogen circulating pump for fuel cell

PendingCN112983815AImprove efficiencyAvoid pump jammingRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsPhysicsEngineering

The invention discloses a hydrogen circulating pump for a fuel cell, and belongs to the technical field of fuel cells. The hydrogen circulating pump comprises a machine shell, a motor, a male rotor and a female rotor, wherein the motor, the male rotor and the female rotor are arranged in the machine shell; the male rotor is connected to the output end of the motor; a gear transmission structure is arranged between the male rotor and the female rotor; the female rotor and the male rotor each comprise a rotor base body, an anti-expansion coating and a hydrophobic coating; each anti-expansion coating is arranged on the outer surface of the corresponding rotor base body, and the expansion coefficients of the anti-expansion coatings are smaller than those of the rotor base bodies; and each hydrophobic coating is arranged outside the corresponding anti-expansion coating. The anti-expansion coating and the hydrophobic coating are sequentially arranged on each of the surface of the female rotor and the surface of the male rotor from inside to outside, so that the pump is effectively prevented from being stuck.

Owner:FAW JIEFANG AUTOMOTIVE CO

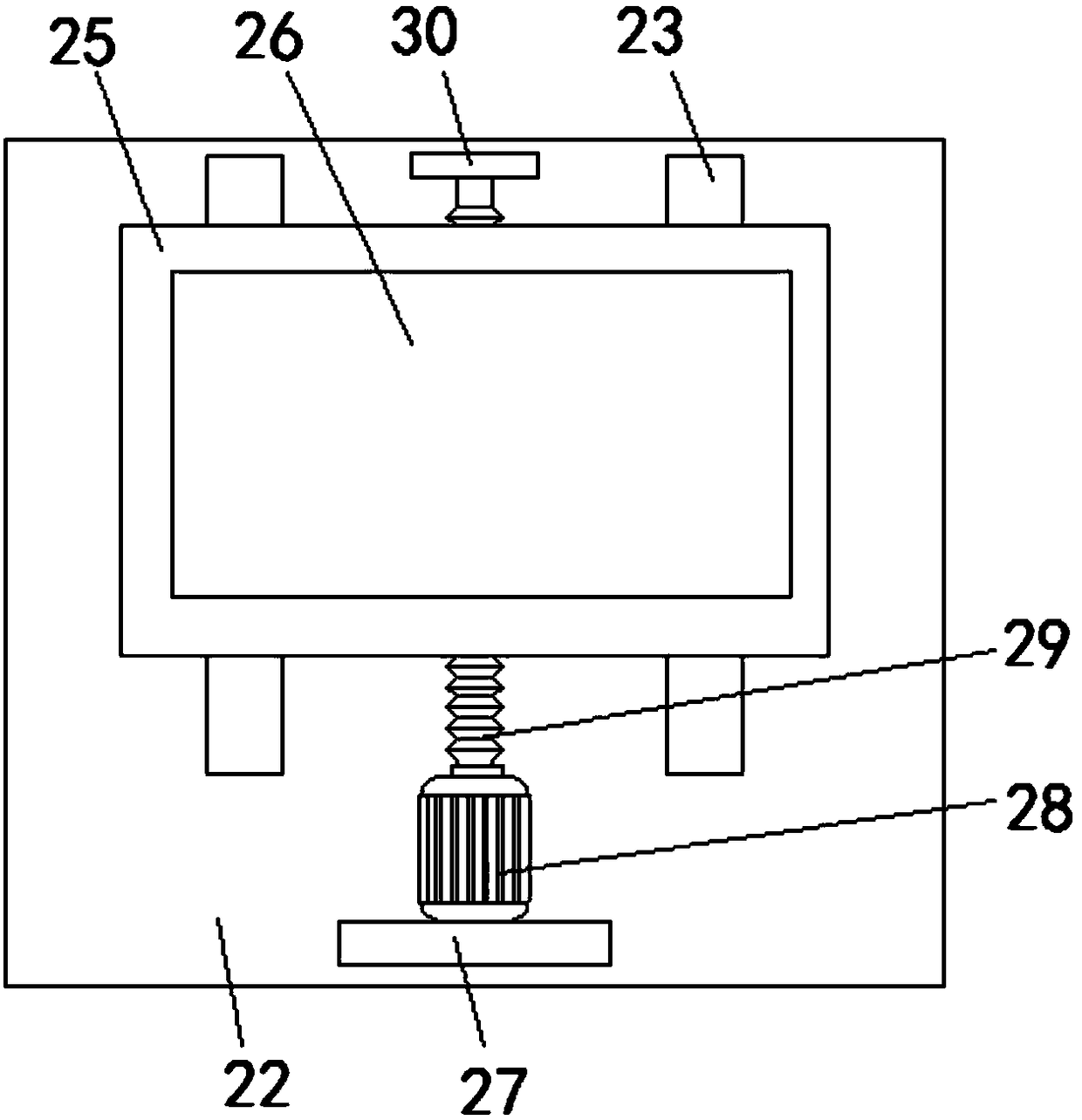

Architectural engineering cart capable of conveniently adjusting unloading positions according to construction situations

InactiveCN108454675AEasy to adjustConvenient and reasonable controlHand carts with multiple axesDrive motorEngineering management

The invention relates to the technical field of architectural engineering facilities, in particular to an architectural engineering cart capable of conveniently adjusting unloading positions accordingto construction situations. The architectural engineering cart comprises a base, two symmetrical U-shaped plates are fixedly connected at the bottom of the base, rollers are movably connected on theinner surfaces of the bottoms of the U-shaped plates through pins, a mounting groove is formed in the top of the base, and a power box is fixedly connected on the inner surface of the bottom of the mounting groove. According to the architectural engineering cart capable of conveniently adjusting the unloading positions according to the construction situations, the architectural engineering cart isprovided with a driving motor, a first threaded rod, a limit groove, a limit block, an asynchronous motor and a second threaded rod, so that forward and backward movement and bilateral movement of acart body are conveniently controlled and adjusted, the cart body can be omnidirectionally moved, so that a worker can conveniently pour materials, the material pouring efficiency of the worker in narrow space is greatly improved, and the worker conveniently and reasonably controls working time.

Owner:张灿

Analysis method of low-frequency oscillation node contribution factor based on wide field measuring information

ActiveCN101408577BConvenient and reasonable controlRealize online quantitative measurementElectrical testingPower oscillations reduction/preventionFactor baseWide field

The invention belongs to the technical field of the on-line detection and analysis of electric power system low-frequency oscillation. The invention provides a method for quantitatively evaluating the contribution degree of an electric generating set associated with a node participating in the oscillation of certain mode to the oscillation power of the mode in a power system, only based on the information of Wide Area Measurement System. In the method, a concept of node contribution factor is first proposed based on injection active oscillatory power, and then according to the amplitude of injection active oscillatory power and the relative phase position among active oscillatory power curves under certain frequency mode, an analysis and calculation method is provided corresponding to thenode contribution factor of the frequency mode, and the homology and grouping of the node are realized at the same time. The method is applicable to a system without an electromagnetic ring net and consideration for losses and can also be used for an actual electric power system which has the above characteristics through simplification.

Owner:BEIJING SIFANG JIBAO AUTOMATION +1

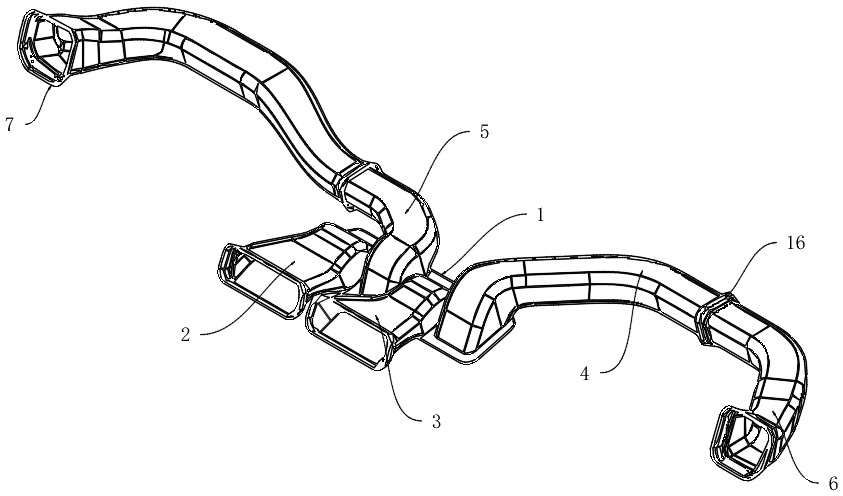

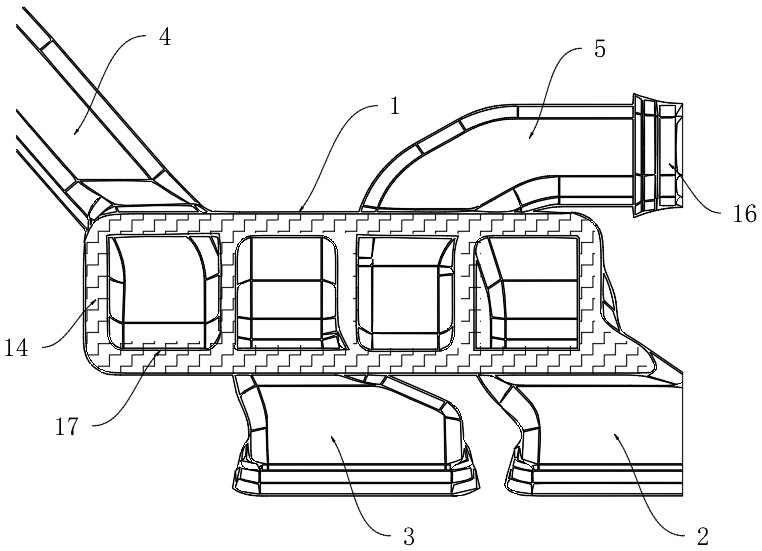

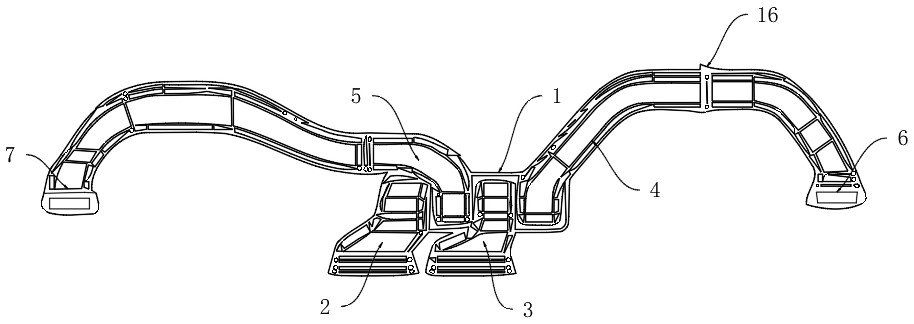

Air conditioner face blowing air pipe for pickup truck

PendingCN113682111AReduce design difficultyImprove design efficiencyAir-treating devicesVehicle heating/cooling devicesAir volumeEngineering

The invention discloses an air conditioner face blowing air pipe for a pickup truck, relates to the technical field of automobile refrigeration, and aims to solve problems that in the actual use of an existing air conditioner face blowing air pipe, a mixed flow transition section is generally connected to an outlet of an air conditioner box, air blown by an air conditioner is sent to different air outlets in four positions through different branches. Therefore, in the design process, in order to balance air volume distribution, a large amount of design optimization work needs to be conducted on different branch results and pipe type thicknesses, and large design errors always exist when the design target of air volume distribution is achieved. A first face blowing air pipe and a second face blowing air pipe are arranged at the upper end of an air pipe connecting piece, a first side face blowing air pipe is arranged on one side of the second face blowing air pipe, and a second side face blowing air pipe is arranged between the first face blowing air pipe and the second face blowing air pipe. A first side face blowing air pipe opening is formed in one end of the first side face blowing air pipe.

Owner:JIANGLING MOTORS

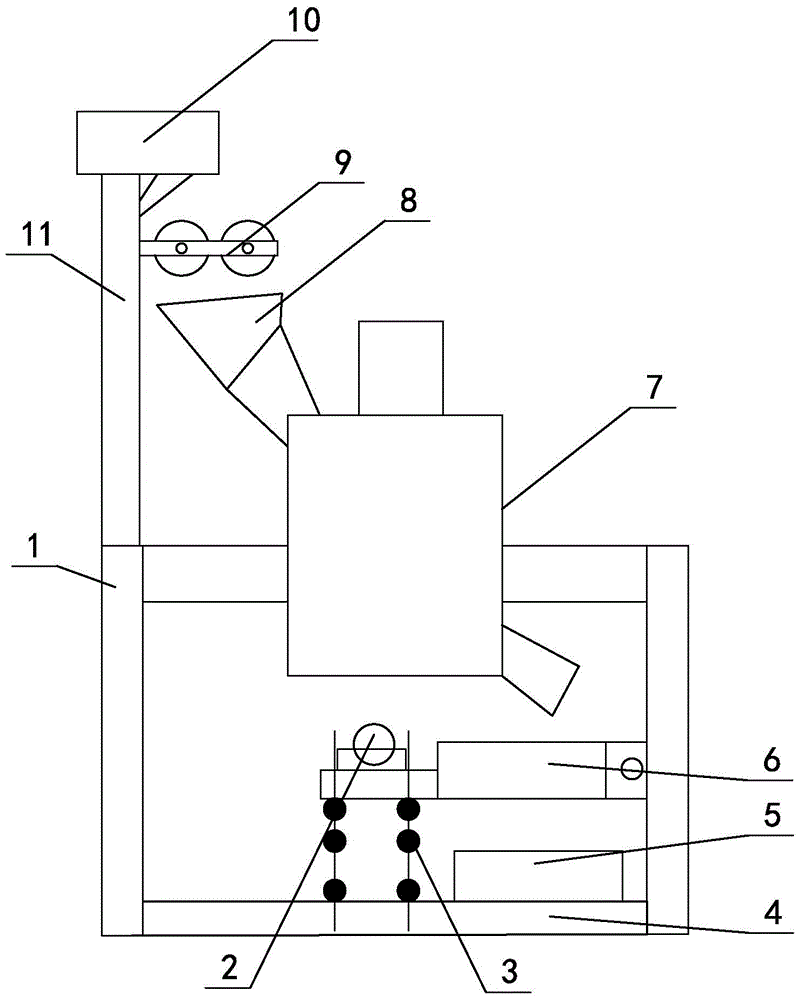

Seasoning milling all-in-one machine

InactiveCN106391226ASimple structureReduce manufacturing costSievingScreeningEngineeringMechanical engineering

The invention relates to a seasoning milling all-in-one machine and belongs to the technical field of seasoning milling. The seasoning milling all-in-one machine comprises a working table, wherein a cutting type mill is vertically mounted on the working table, a placing plate is mounted at the bottom of the working table, a filter sieve is arranged corresponding to a discharging opening of the cutting type mill, a collecting tank is arranged below the filter sieve, the collecting tank is placed on the placing plate, a feeding opening of the cutting type mill is connected with a connecting channel, the feeding end of the connecting channel is a funnel structure, an extruding roller group is arranged above the funnel structure, a weighing instrument is arranged above the extruding roller group, and the weighing instrument is mounted on the working table through a bracket. The seasoning milling all-in-one machine provided by the invention is simple in structure, is low in manufacture cost, is very suitable for seasoning milling use, has a better milling effect than the existing mill, is convenient for workers to operate, and saves more raw materials.

Owner:CHONGQING HONGQIAN AGRI DEV CO LTD

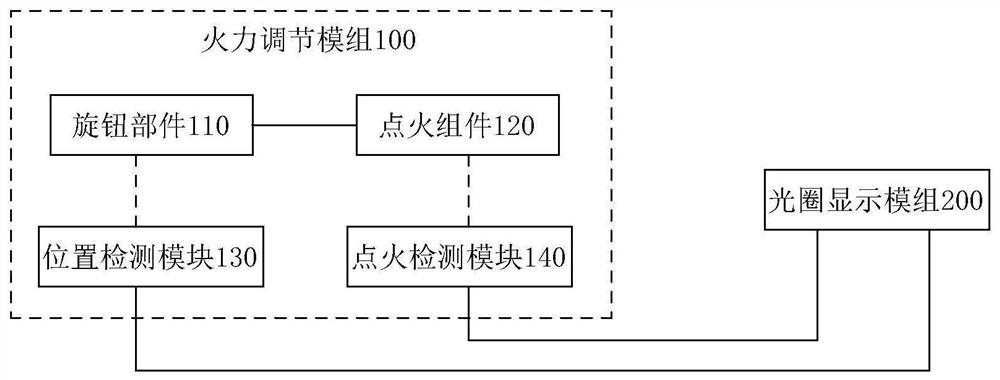

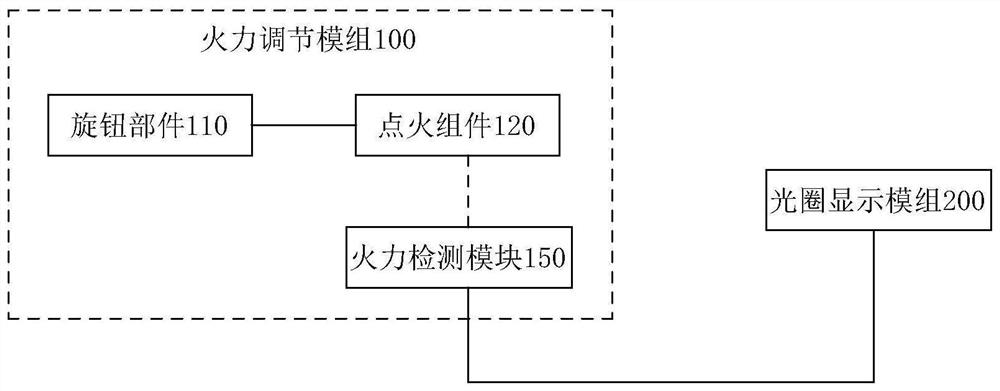

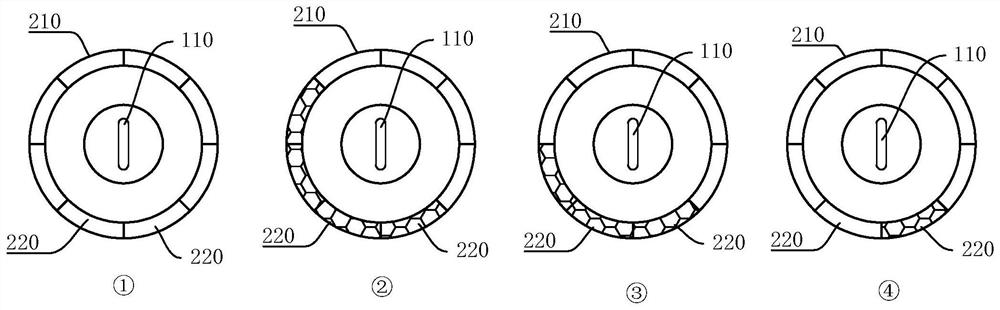

Firepower aperture display device and firepower aperture display method

PendingCN113432155AConvenient and reasonable controlAccurate firepowerDomestic stoves or rangesLighting and heating apparatusDisplay deviceEngineering

The invention discloses a firepower aperture display device and a firepower aperture display method. The firepower aperture display device comprises a firepower adjusting module and an aperture display module, wherein the firepower adjusting module can adjust the magnitude of firepower, the aperture display module comprises a plurality of indication light sources, the multiple indication light sources are annularly distributed to form firepower indication apertures, and the aperture display module is electrically connected with the firepower adjusting module to control the corresponding indication light sources to be lightened according to the magnitude of the firepower. According to the firepower aperture display device and the firepower aperture display method, the magnitude of the firepower is prompted to a user by utilizing the effect of light rays emitted by the indication light sources, meanwhile, the prompt of the magnitude of the firepower is more accurate, and the user can conveniently and reasonably control the magnitude of the firepower.

Owner:SUPERMAN ZHONGSHAN ELECTRIC APPLIANCES CO LTD

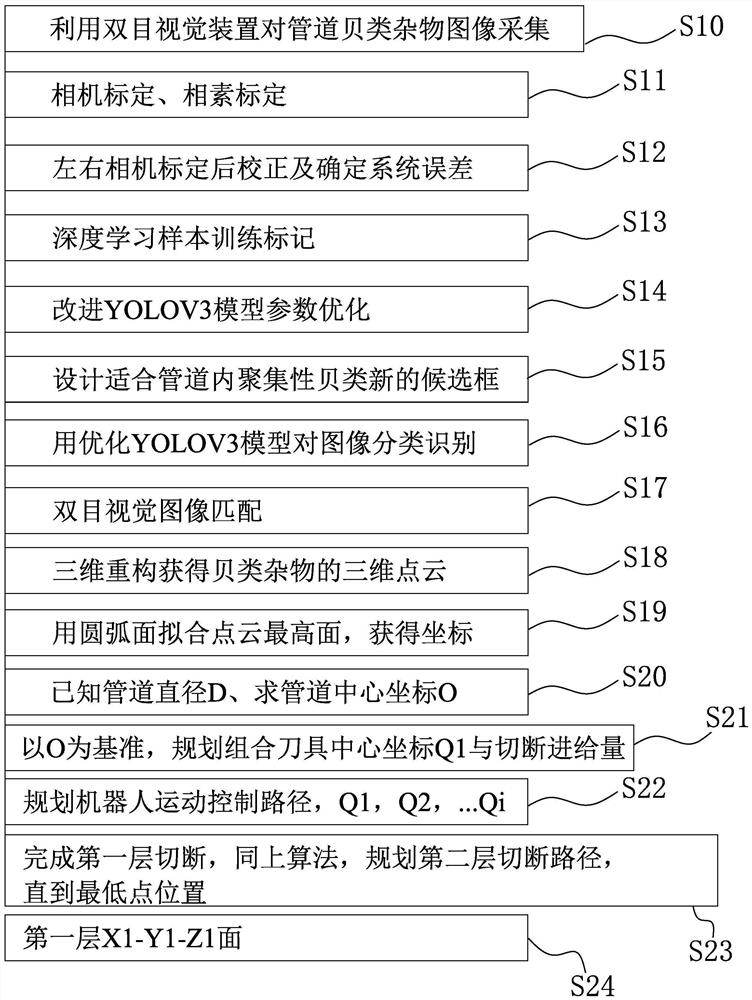

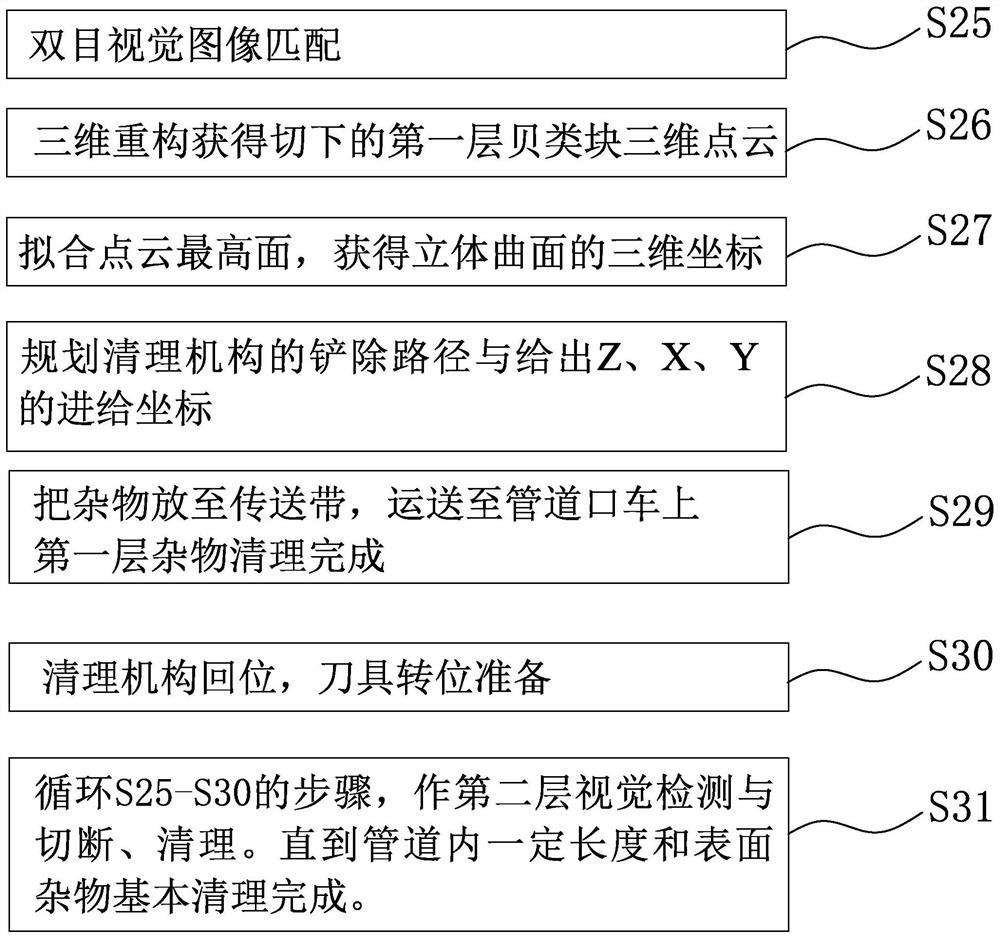

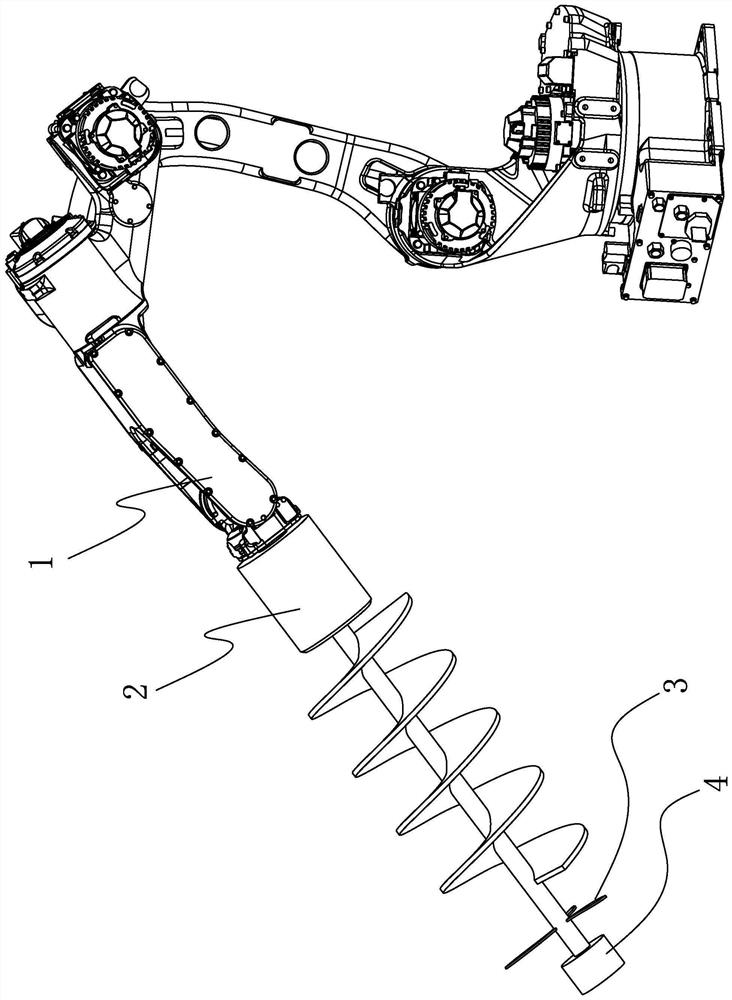

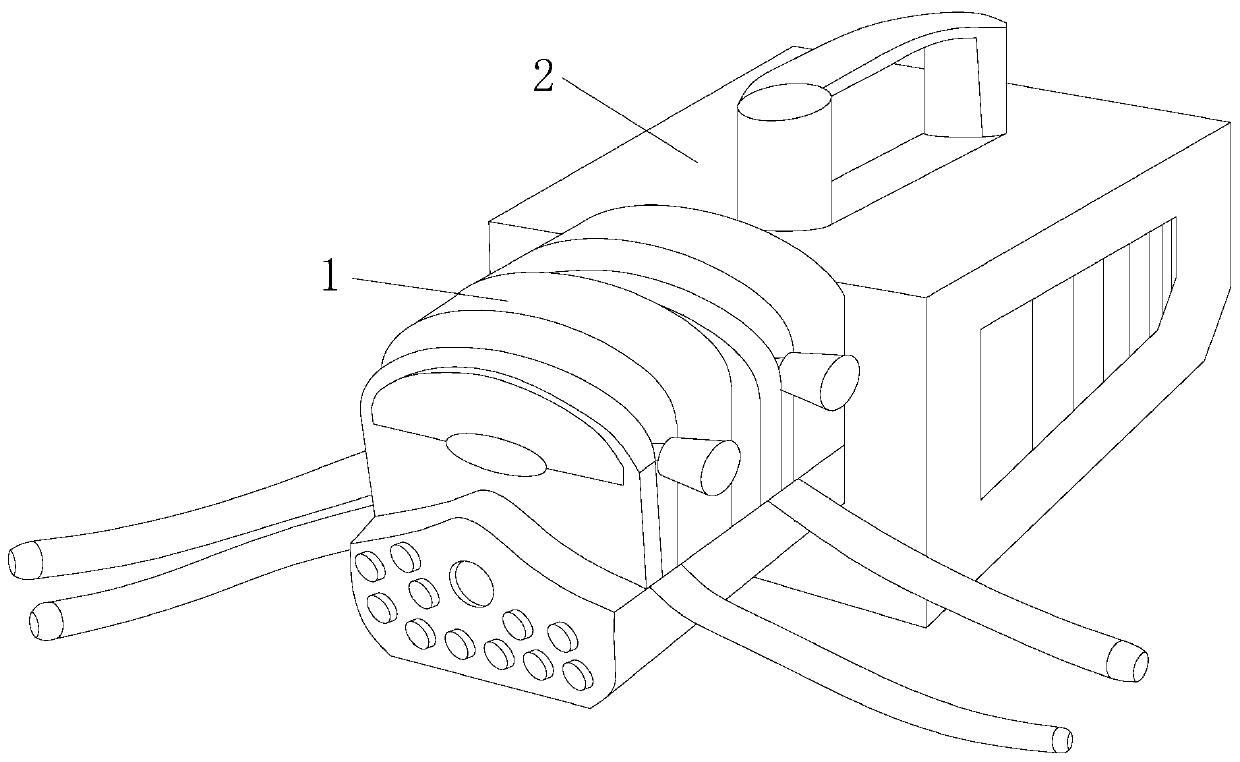

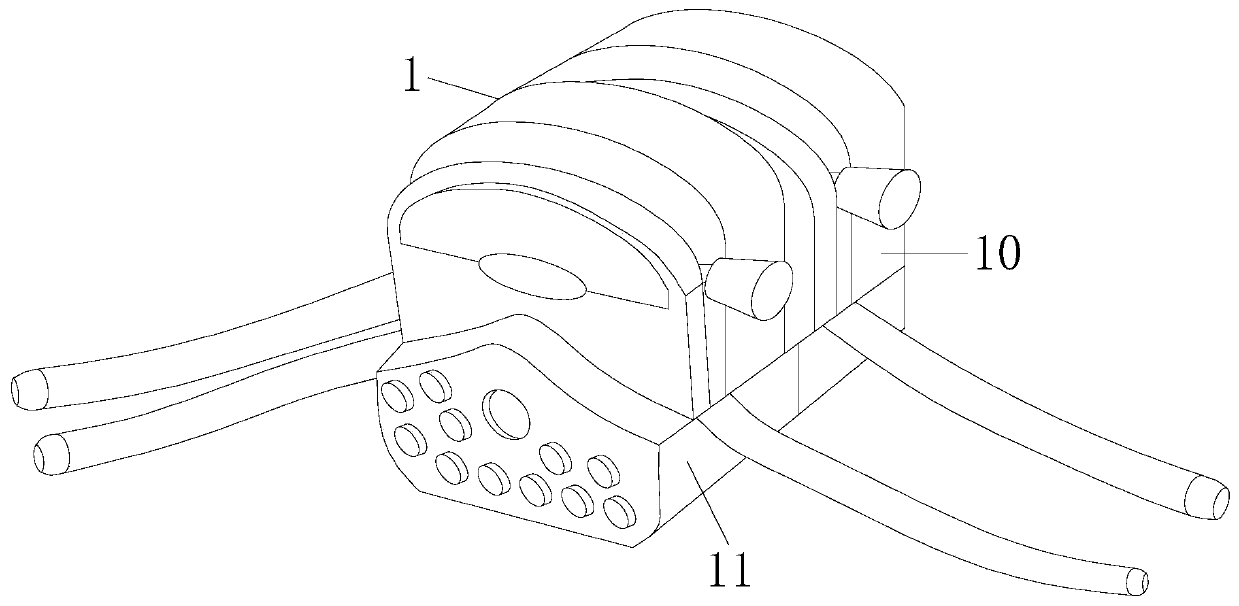

A visual robot method and device for removing shellfish in raw water pipelines

ActiveCN113305858BAuto clearConvenient and reasonable controlProgramme-controlled manipulatorControl engineeringProcess engineering

The invention discloses a visual robot method and device for removing shellfish in a raw water pipeline, comprising a robot, a cleaning device is provided on the driving arm of the robot, and a crushing device and a binocular device are respectively provided at the front end of the cleaning device. The vision device also includes a controller, the binocular vision device communicates with the controller, and the controller communicates with the robot, the cleaning device and the crushing device respectively. The present invention has the advantages of convenient and reasonable control, cleaning With the advantages of high efficiency and strong practicability, compared with the existing technology, it can automatically remove shellfish and their wreckage in the raw water pipe, realize automatic identification, crushing and cleaning, improve efficiency and reduce pollution.

Owner:ZHONGKAI UNIV OF AGRI & ENG

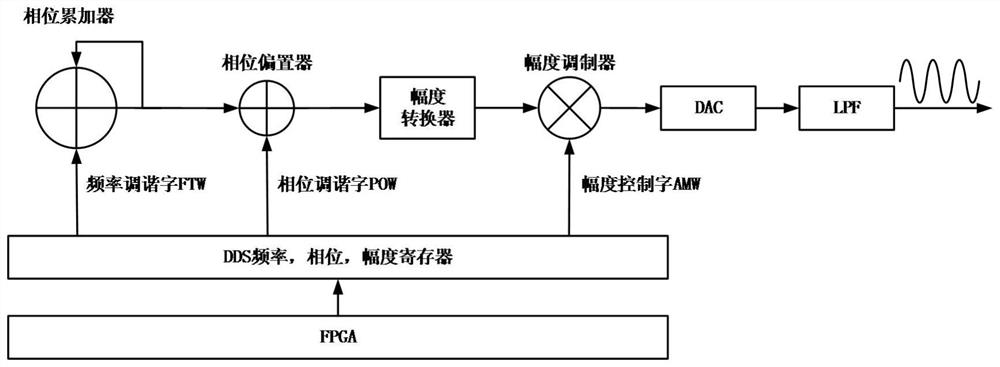

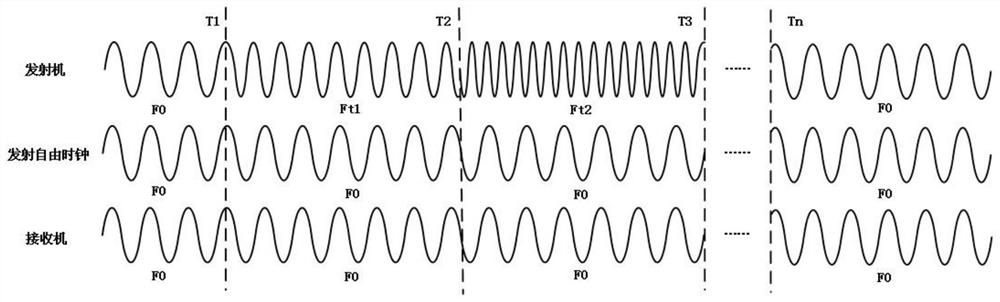

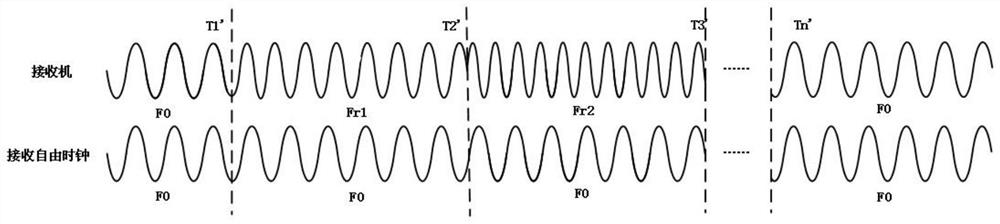

A device and method for maintaining phase coherence of transmit/receive channels

ActiveCN112083366BImprove performanceReduce designMeasurements using NMR imaging systemsProgrammable logic deviceElectrical and Electronics engineering

The present invention relates to a device and method for maintaining the phase coherence of transmitting / receiving channels, wherein the device includes a transmitting module and a receiving module, the transmitting module includes a first programmable logic device and a DDS; the receiving module includes a second programmable logic device and NCO, the transmitting module also includes a transmitting free clock generated internally by the first programmable logic device, and the receiving module further includes a receiving free clock generated internally by the second programmable logic device; The receiving free clock has the same frequency as the transmitting free clock. The invention can maintain the accuracy of phase coherence of the transmission / reception channel, shorten the time delay and improve the real-time performance.

Owner:EAST CHINA NORMAL UNIV

A preparation method of microencapsulated zirconium phosphate and a halogen-free flame-retardant PC composed of it

InactiveCN105524301BConvenient and reasonable controlSimple preparation processFreeze-dryingPhosphoric acid

The invention discloses a preparation method of microencapsulated zirconium phosphate. The method comprises steps as follows: zirconium phosphate with the particle size being 0.8-1.2 mu m is evenly dispersed in a solvent, and a zirconium phosphate dispersion liquid is obtained; meanwhile, a reaction reagent is added to the zirconium phosphate dispersion liquid, the mixture is mechanically stirred and subjected to reflux at the temperature of 50-180 DEG C, a hybrid crosslinking reaction occurs, the reaction time is controlled within 1-36 h, and after the reaction ends, microencapsulated zirconium phosphate is obtained through washing and freeze-drying. The microencapsulated zirconium phosphate is prepared from zirconium phosphate with a microencapsulation technology, and the preparation technology is simple, easy to operate and suitable for industrial production; a prepared microencapsulated zirconium phosphate flame retardant has the more optimized and reasonable flame-retardant progress control and the more effective and lasting flame-retardant effect; prepared microencapsulated zirconium phosphate is added to a PC matrix, and the prepared halogen-free flame-retardant PC is easy to process and mold, halogen-free, environment-friendly and better balanced in mechanical performance and flame-retardant performance.

Owner:GUANGDONG UNIV OF TECH

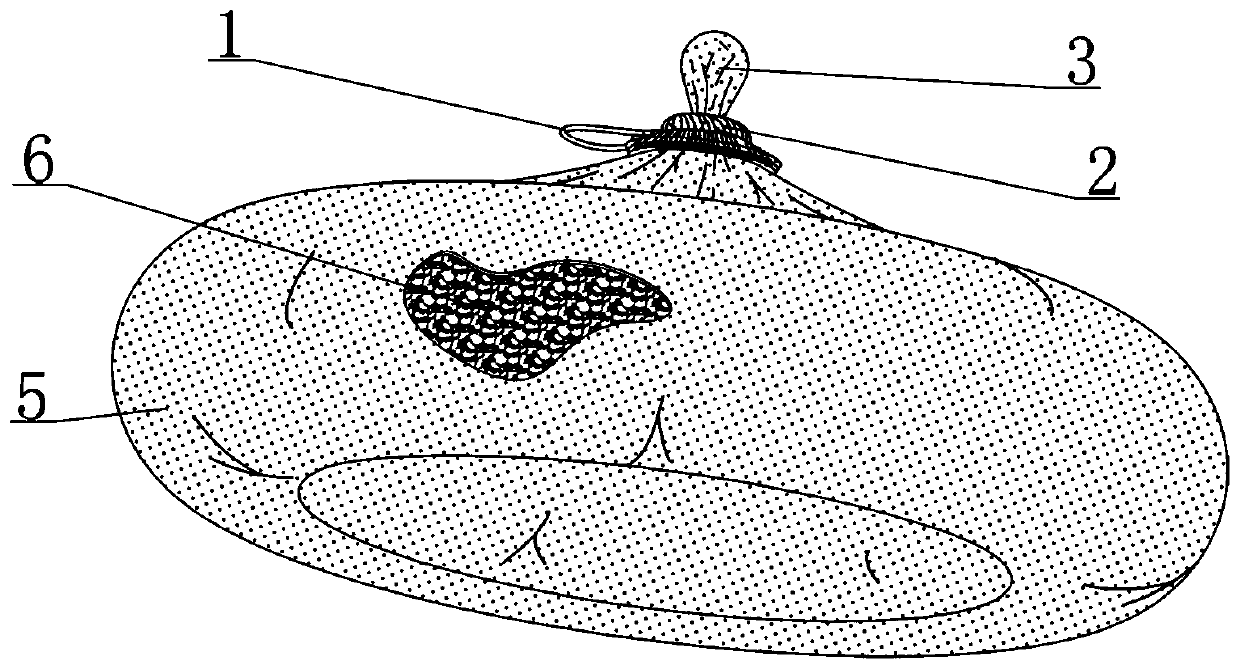

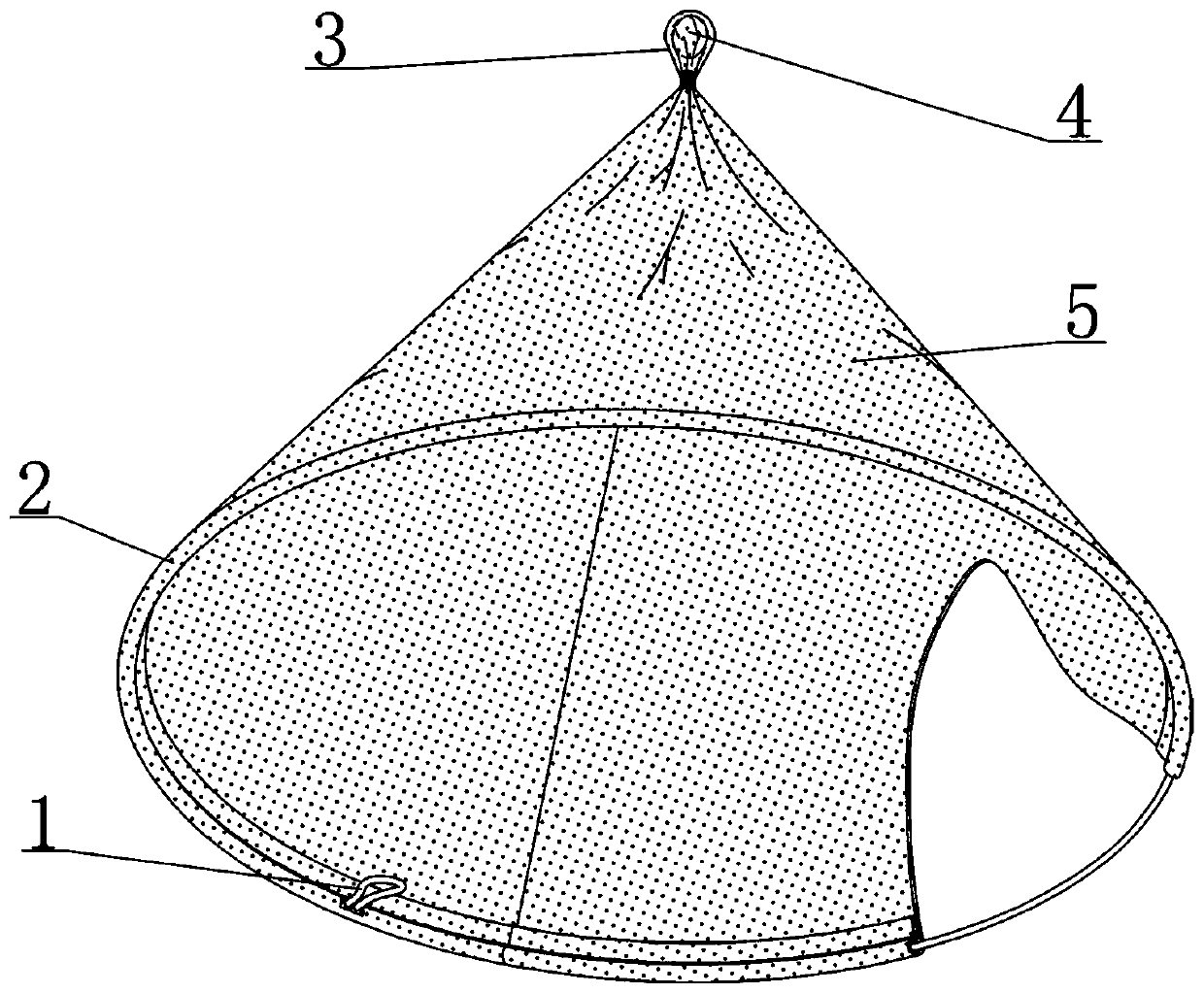

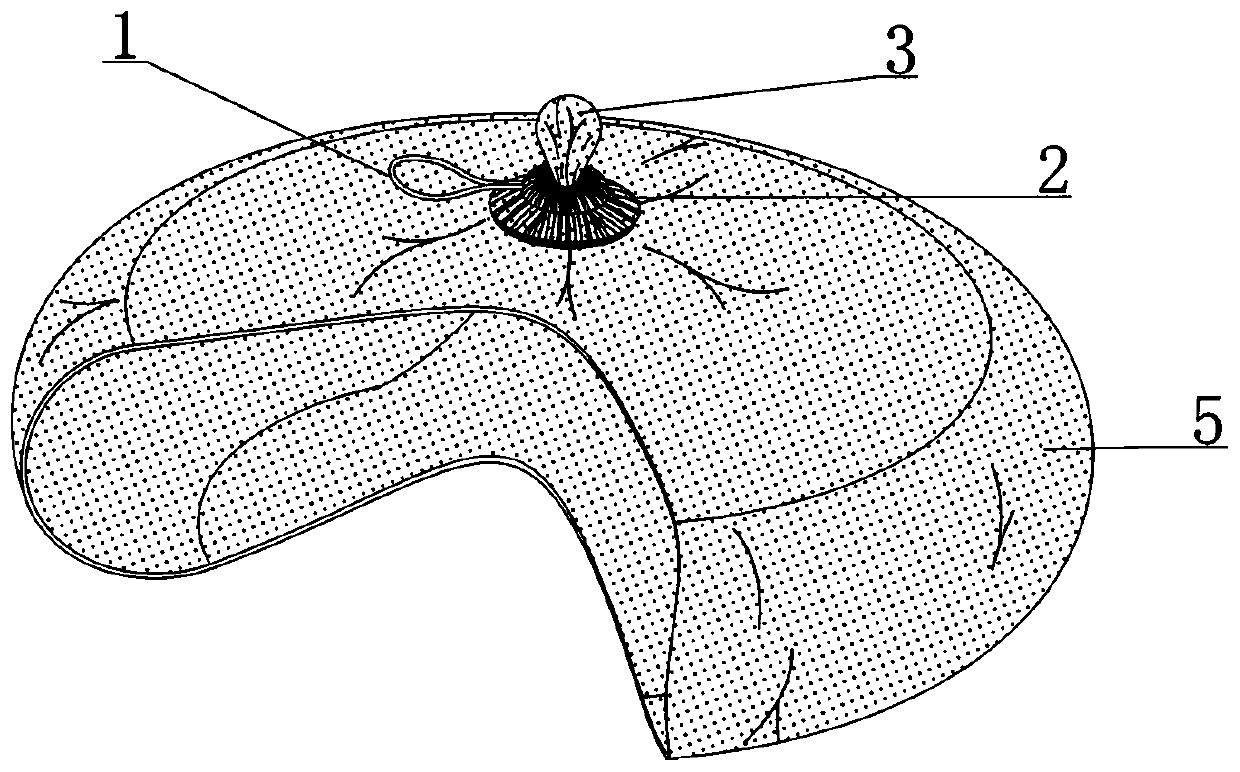

Traditional Chinese medicine decocting bag and preparation method thereof

InactiveCN110812233AInclusive effect is stableFlat shapeBag making operationsPaper-makingEngineeringString bag

The invention relates to a medical supply, in particular to a traditional Chinese medicine decocting bag. The decocting bag comprises a bag body which is in a conical shape in a stretched state, the tip end of the bag body is filled with a ball-shaped object, the bag body is located on the lower side of the ball-shaped object and bundled together, a ball head part is formed at the tip end of the bag body, a threading pipe is arranged at the opening end of the bag body, and a tying line is arranged in the threading pipe; the middle-lower part of the bag body is turned back to the outer side ofthe middle-upper part, and the opening end is tightened by the tying line and sleeves the lower side of the ball head part; and an annular cavity formed between the middle lower part and the middle upper part of the bag body is filled with traditional Chinese medicinal materials. The traditional Chinese medicine decocting bag is stable in structure, effective components in the traditional Chinesemedicinal materials at different positions can rapidly and efficiently seep out in the decocting process, and the decocting efficiency can be remarkably improved; the decocting bag is flat in shape, water amount control is facilitated, and excessive medicine soup can be avoided; when decoction is taken, the decoction adsorbed in decoction dregs can be conveniently and quickly extruded out; and thedecocting bag is low in cost and easy to implement, and can be widely applied to medicine decocting operation in occasions such as medicine decocting rooms, traditional Chinese medicine shops and families.

Owner:江冬生

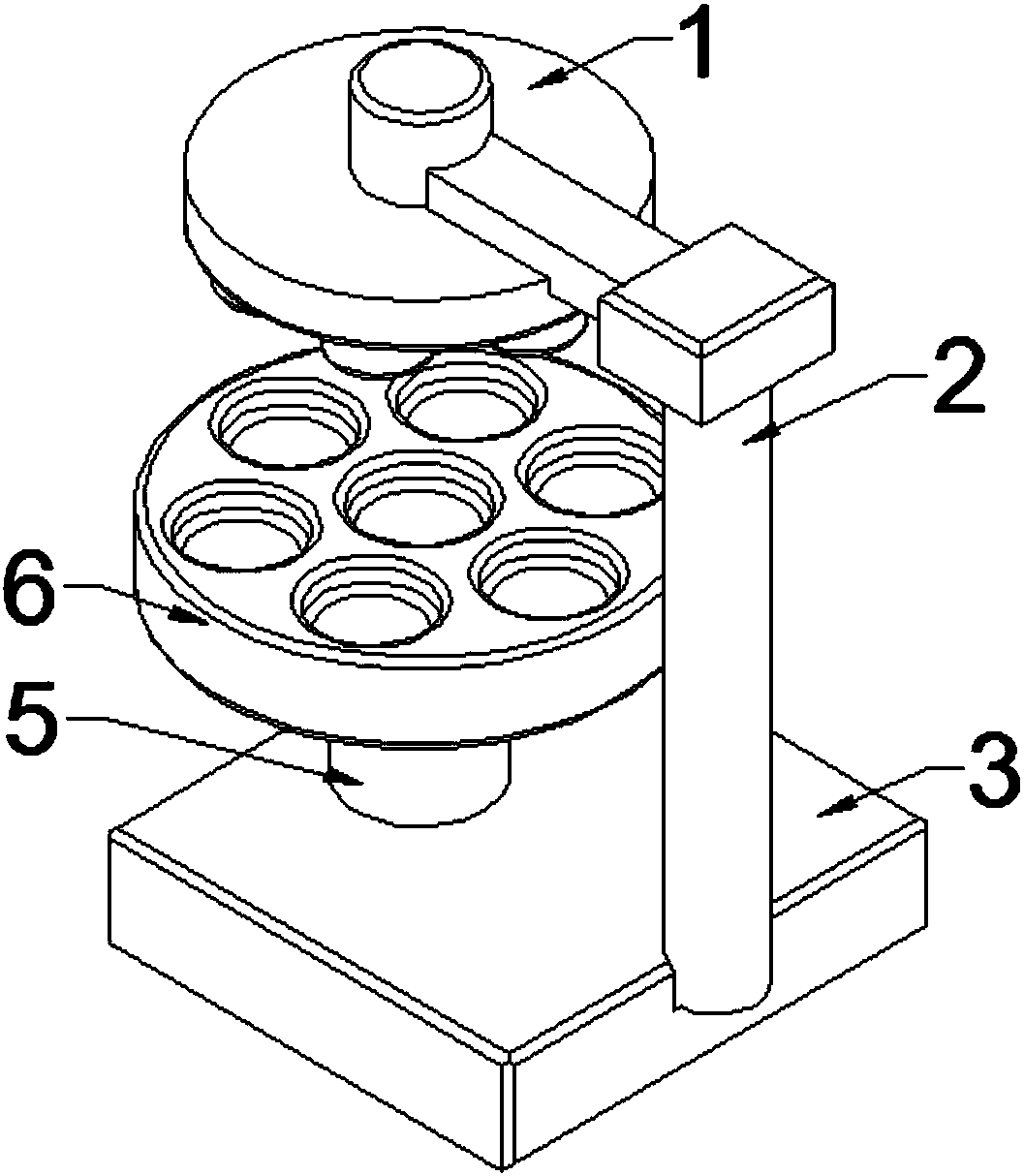

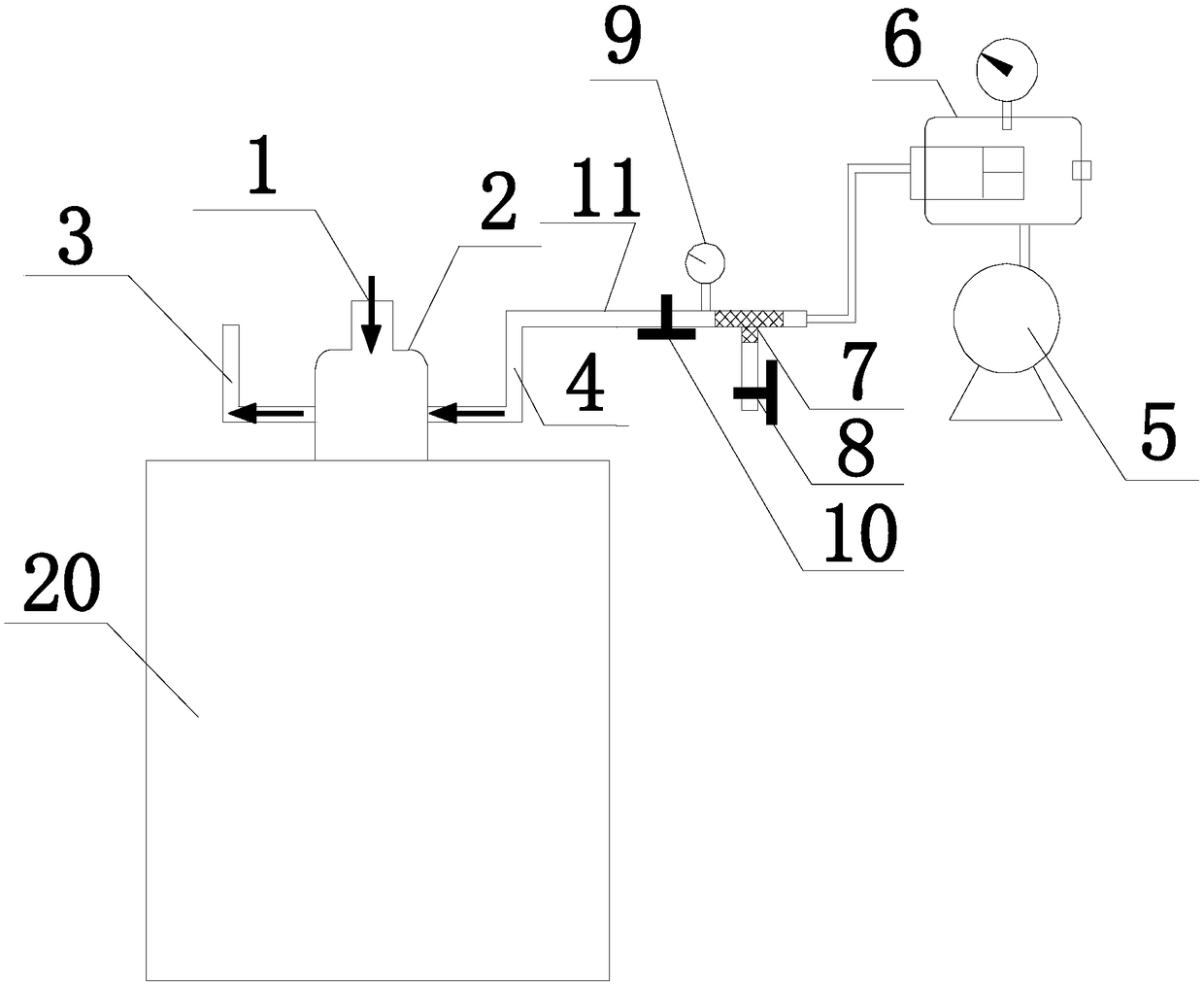

Combined toner filling device for multi-color carbon powder high-efficiency sealed filling based on color printing

InactiveCN110426930ASteady infusionConvenient and reasonable controlElectrographic process apparatusColor printingEngineering

The invention discloses a combined toner filling device for multi-color carbon powder high-efficiency sealed filling based on color printing. The structure of the combined toner filling device comprises a toner assembling device and a storage box, the toner assembling device is installed on the storage box, and the toner assembling device comprises a distributor and a two-position distributer which are spliced and connected and have the same structure. The combined toner filling device fully fills toners with different colors in an insertion port once and performs classification filling as required in the later stage, even though a box of toner with one color is exhausted, the other toners are added together when the toners are added with no need for dismounting and mounting of the toner boxes with different color numbers one by one which wastes time and labor and easily generates the condition of toner dispersion; and moreover, the toner inlet is regulated by a debugging rod, the toner inlet amount is regulated by a toner falling device, a toner adding head switches on-off of the toner box when an injection tube in pre-plugged out or plugged in to further ensure that the phenomenon that the toner is sprinkled at the bottle mouth when the toner is filled and avoid the device faults caused by bad factors due to toner sprinkling in the later stage.

Owner:南安易盾格商贸有限公司

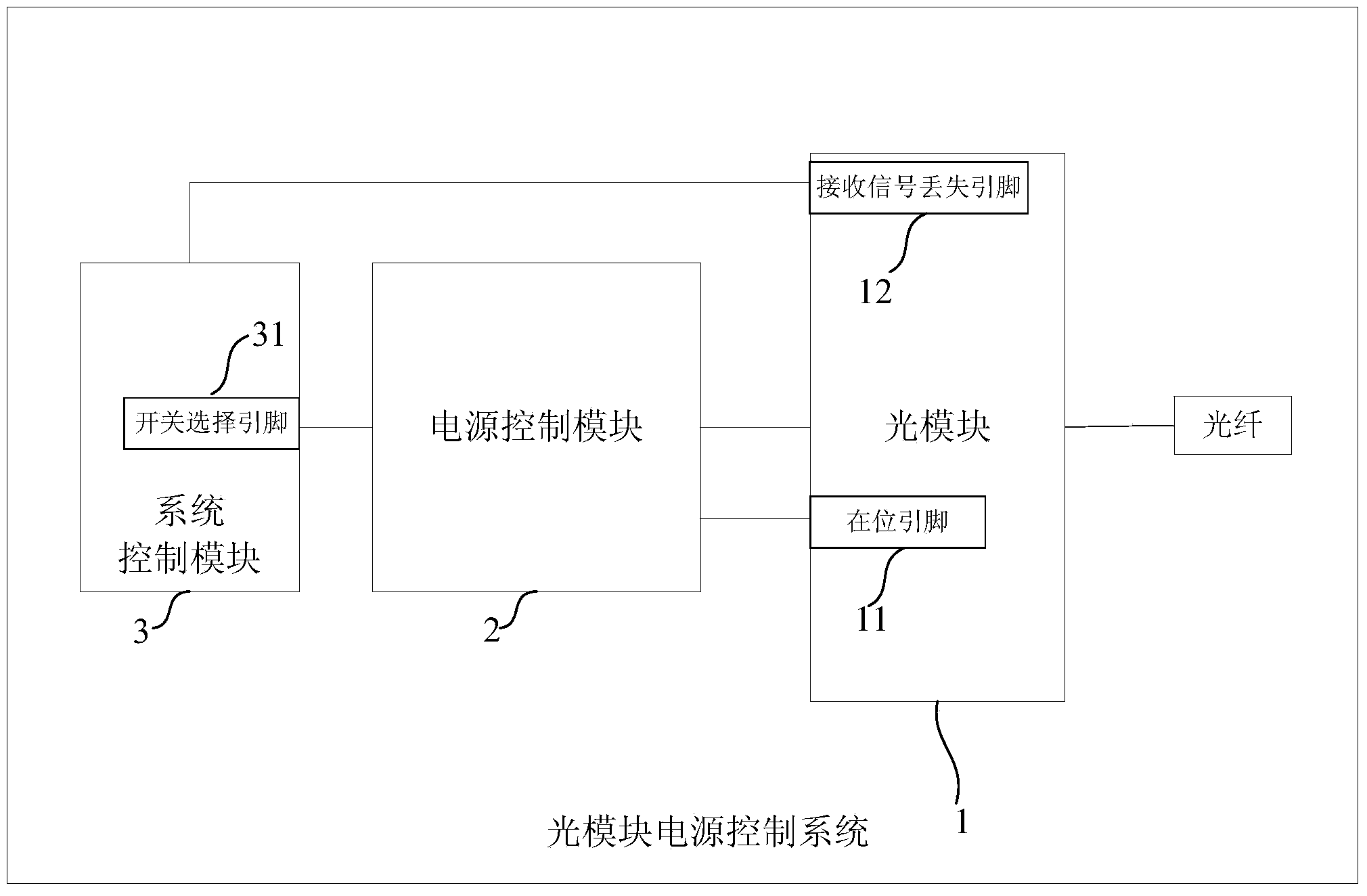

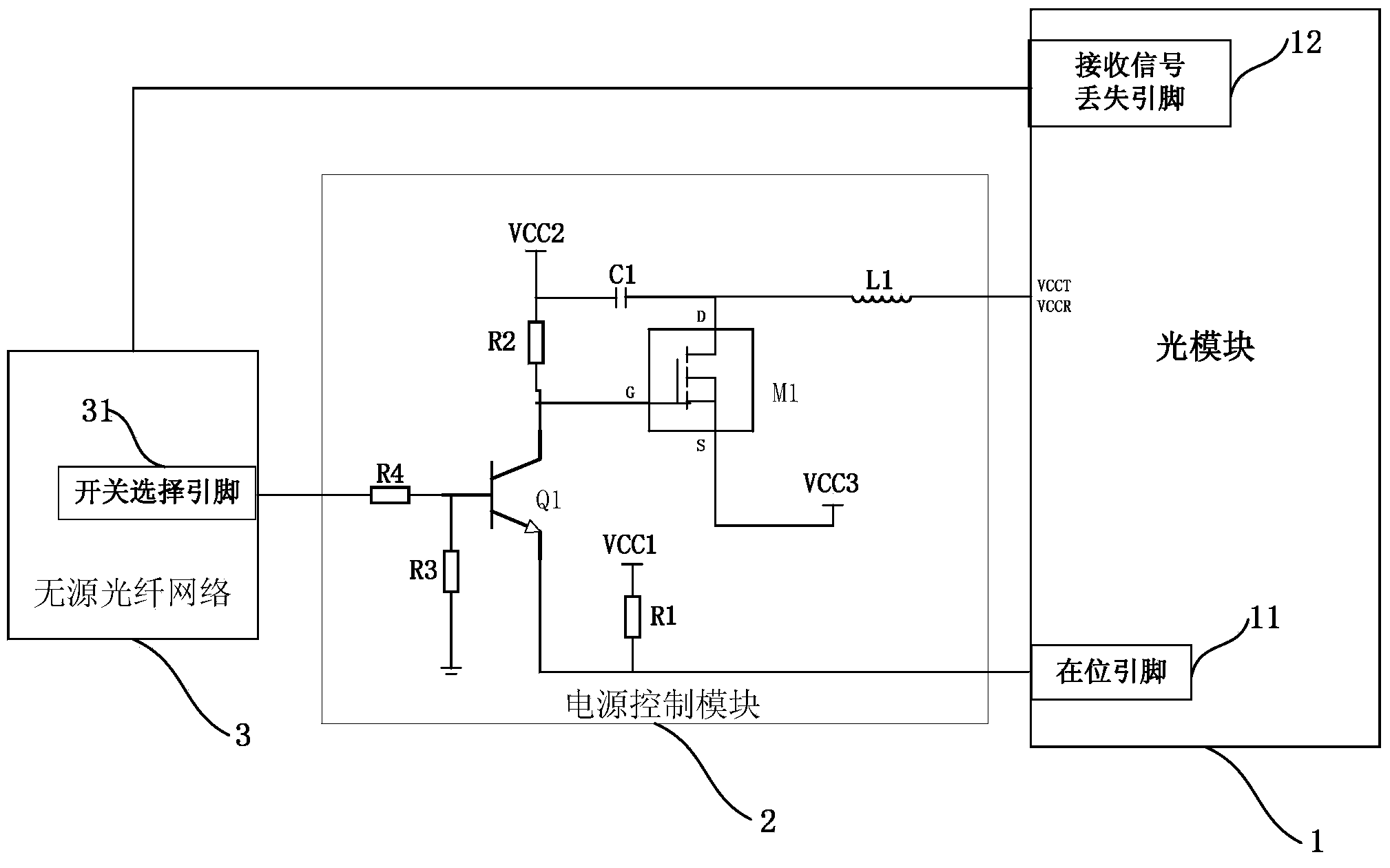

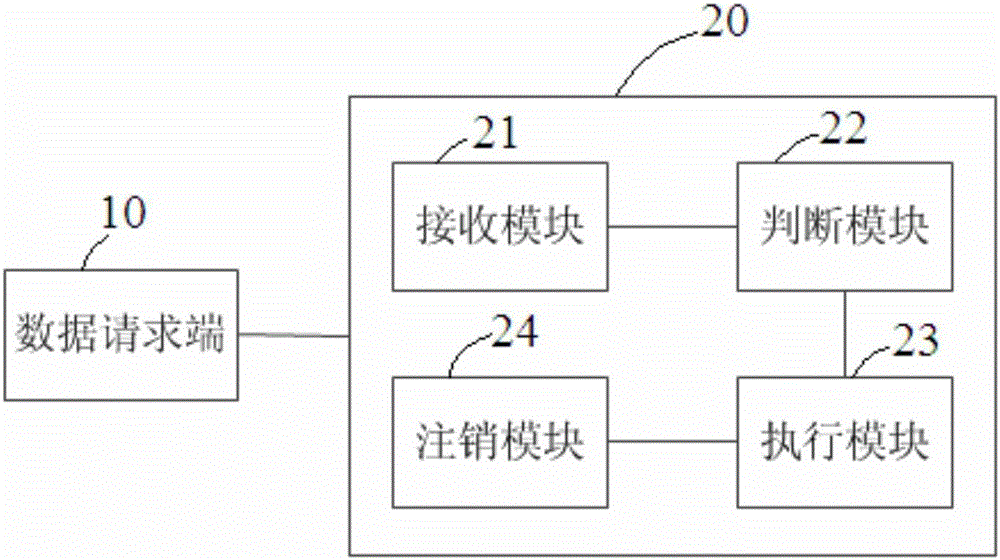

A method and system for controlling power supply of an optical module

ActiveCN103532541BAvoid damageConvenient and reasonable controlNon-electrical signal transmission systemsLogic circuitsOptical ModuleControl system

The invention provides a light module power supply control method, which is applied to a light module power supply control system consisting of a light module, a power supply control module and a system control module for controlling optical fibers. The method comprises the steps that the plugging state of the light module is detected, and if the light module is not plugged, forbidden signals are output for closing a conducting path of the light module; if the light module is plugged, whether the optical fibers are in position or not is detected, if the optical fibers are in position, gating signals are output to the power supply control module for conducting the conducting path of the light module; if the optical fibers are not in position, the forbidden signals are output for closing the conducting path of the light module; whether receiving signals of the light module are lost or not is detected, if the receiving signals of the light module are lost, the forbidden signals are output for closing the conducting path of the light module; if the receiving signals of the light module are not lost, the gating signals are output to the power supply control module for conducting the conducting path of the light source module. The light module power supply control method has the advantages that safety and reliability are realized during the plugging and the unplugging of the light module, the control is more convenient and reasonable, the damage to the light module is avoided, the existence of risk during the hot plugging and unplugging is reduced, and the energy consumption of the light module in the non-working state is reduced.

Owner:PHICOMM (SHANGHAI) CO LTD

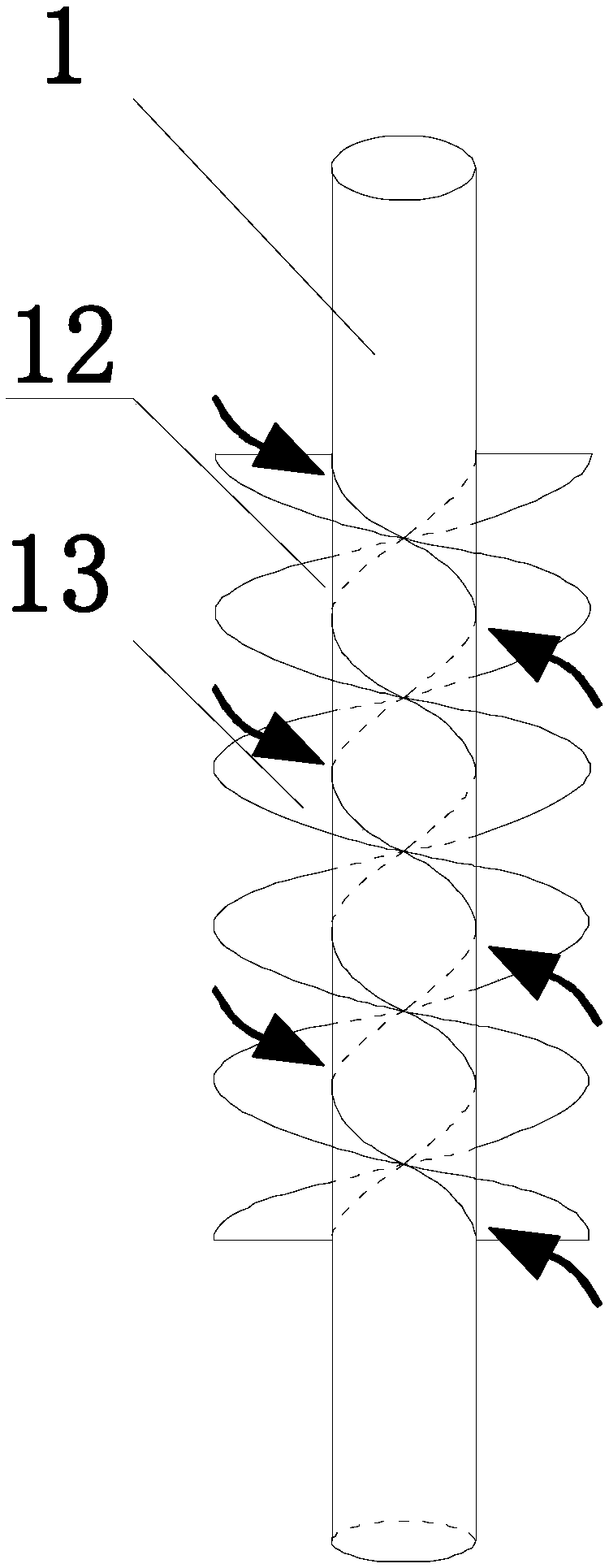

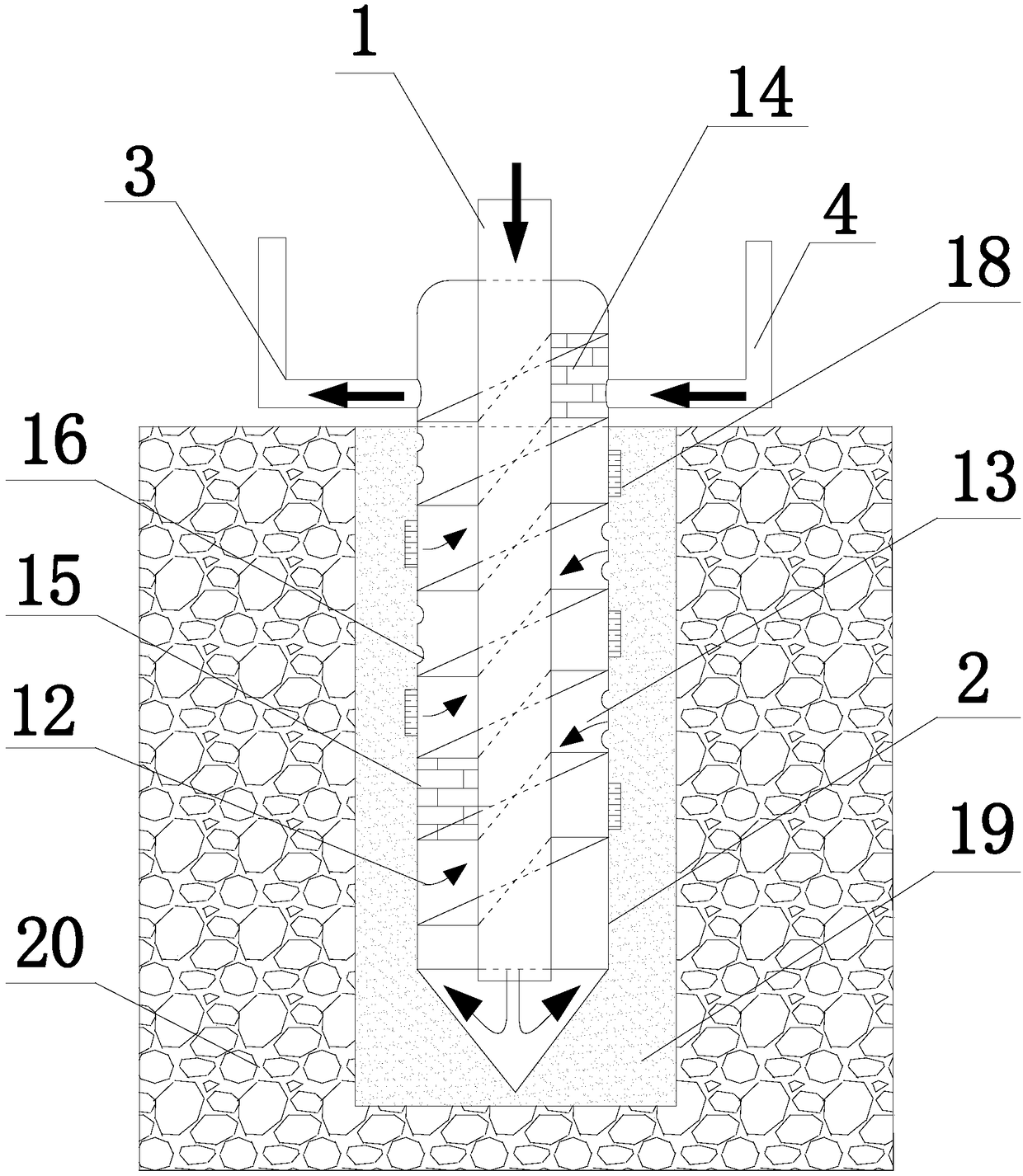

Double helix grouting type freezing device and construction method

ActiveCN107034874BLow costSimple construction methodSoil preservationSaline waterArchitectural engineering

The invention provides a double-helix grouting type freezing device and construction method. The double-helix grouting type freezing device comprises a double-helix grouting type freezing pipe, wherein the double-helix grouting type freezing pipe comprises a saline water supply pipe, and an outer pipe sleeving the saline water supply pipe outside; two helical channels are formed between the pipe wall of the saline water supply pipe and the pipe wall of the outer pipe, and separately share the pipe walls with the saline water supply pipe and the outer pipe; one of the helical channels is a saline water helical pipeline; and the other helical channel is a grout helical pipeline. Through the adoption of the double-helix grouting type freezing device and construction method provided by the invention, combination of a grouting and plugging water technology for ground consolidation, and a special artificial freezing construction technology is realized, and the underground pipelines for two construction technologies are arranged in one pipeline, so that the construction method is simplified, and drilling and pipeline cost is reduced.

Owner:ANHUI UNIV OF SCI & TECH

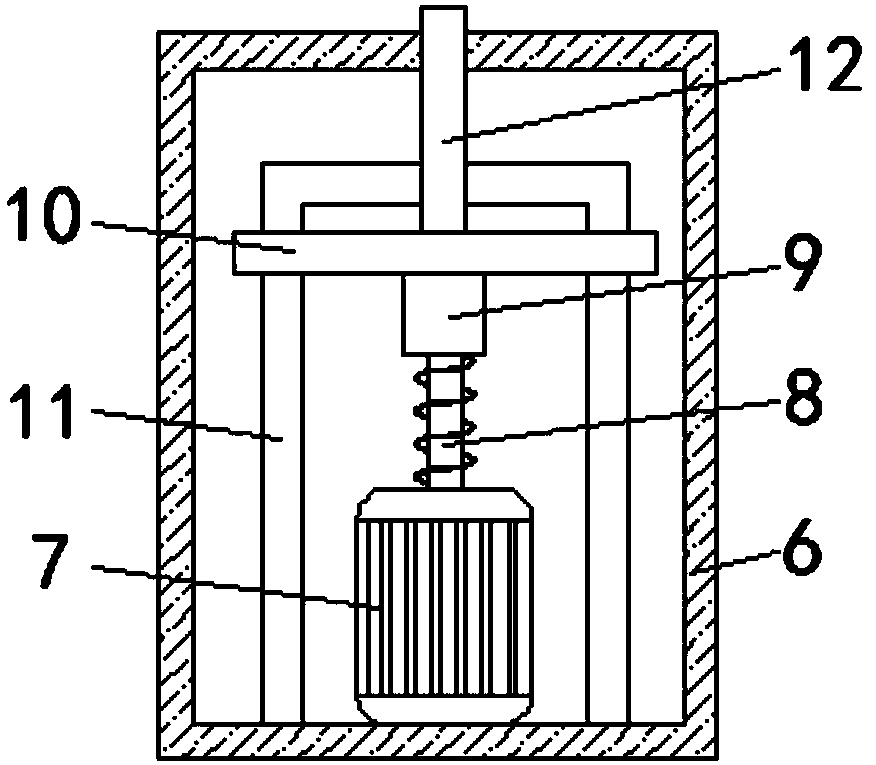

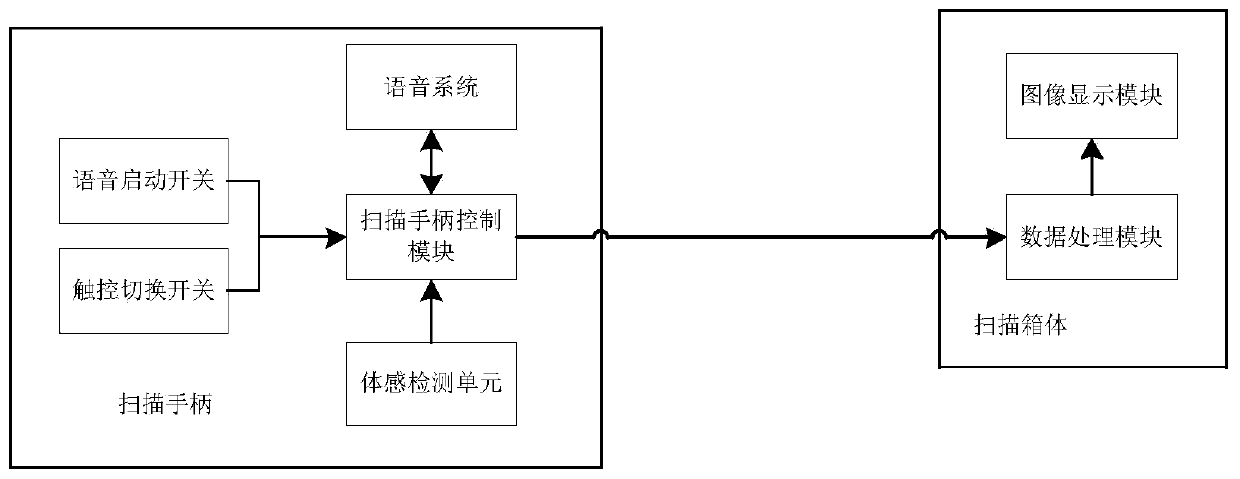

Control system and method of oral cavity scanner

InactiveCN110840399AEasy to viewAvoid infectionDiagnostic recording/measuringSensorsComputer hardwareMedicine

The invention discloses a control system and method of an oral cavity scanner. The oral cavity scanner comprises a scanning handle and a scanning box body, the scanning box body is provided with a data processing module and an image display module; the data output end of the scanning handle is connected with the data processing module; the scanning handle is internally provided with a somatosensory detection unit which is used for detecting the rotation state and the angle signal of the scanning handle; the output end of the scanning handle is connected with a scanning handle control module; the output end of the scanning handle control module is connected with the data processing module; and the data processing module adjusts the display angle of an oral cavity scanning image displayed bythe image display module according to the received rotation state and angle signals of the scanning handle. A switching mode switch and a gyroscope for somatosensory detection are added on the scanning handle to realize angle adjustment on the display of a modeled oral cavity image on a main machine box body.

Owner:延边修恩生物科技有限公司

Bridge-cutoff aluminum alloy section with adjustable thermal insulation thickness

InactiveCN108506718APlay a stabilizing roleEasy to adjustElongated constructional elementsThermal insulationThermal insulationAlloy

The invention discloses a bridge-cutoff aluminum alloy section with the adjustable thermal insulation thickness. The bridge-cutoff aluminum alloy section with the adjustable thermal insulation thickness comprises two edge strips. The top of each edge strip is fixedly connected with a flanging. The bottom of each edge strip is fixedly connected with a flanging. A thermal insulation chamber is fixedly connected with one side, close to the other edge strip, of each edge strip. The right side of the edge strip on the left side is fixedly connected with a connecting plate located on the right sideof the corresponding thermal insulation chamber. Standby thermal insulation block are arranged between the connecting plate and the thermal insulation chamber on the right side. A combination plate isfixedly connected with the bottom of each thermal insulation block. According to the bridge-cutoff aluminum alloy section with the adjustable thermal insulation thickness, installation blocks, installation grooves and limiting rods are arranged to play a role in that thermal insulation blocks and the combination plates are additionally arranged in or removed from the position between the two edgestrips, limiting springs, positioning hooks and positioning hanging rings are further arranged to play a role in steadying the thermal insulation blocks and the combination plates, the effect of conveniently adjusting the thermal insulation thickness by quickly and steadily adding or removing the thermal insulation structures is achieved, and then, it is convenient for workers to reasonably control the thermal insulation thickness to achieve the effect of guaranteeing the normal thermal insulation quality conveniently.

Owner:方亚琴

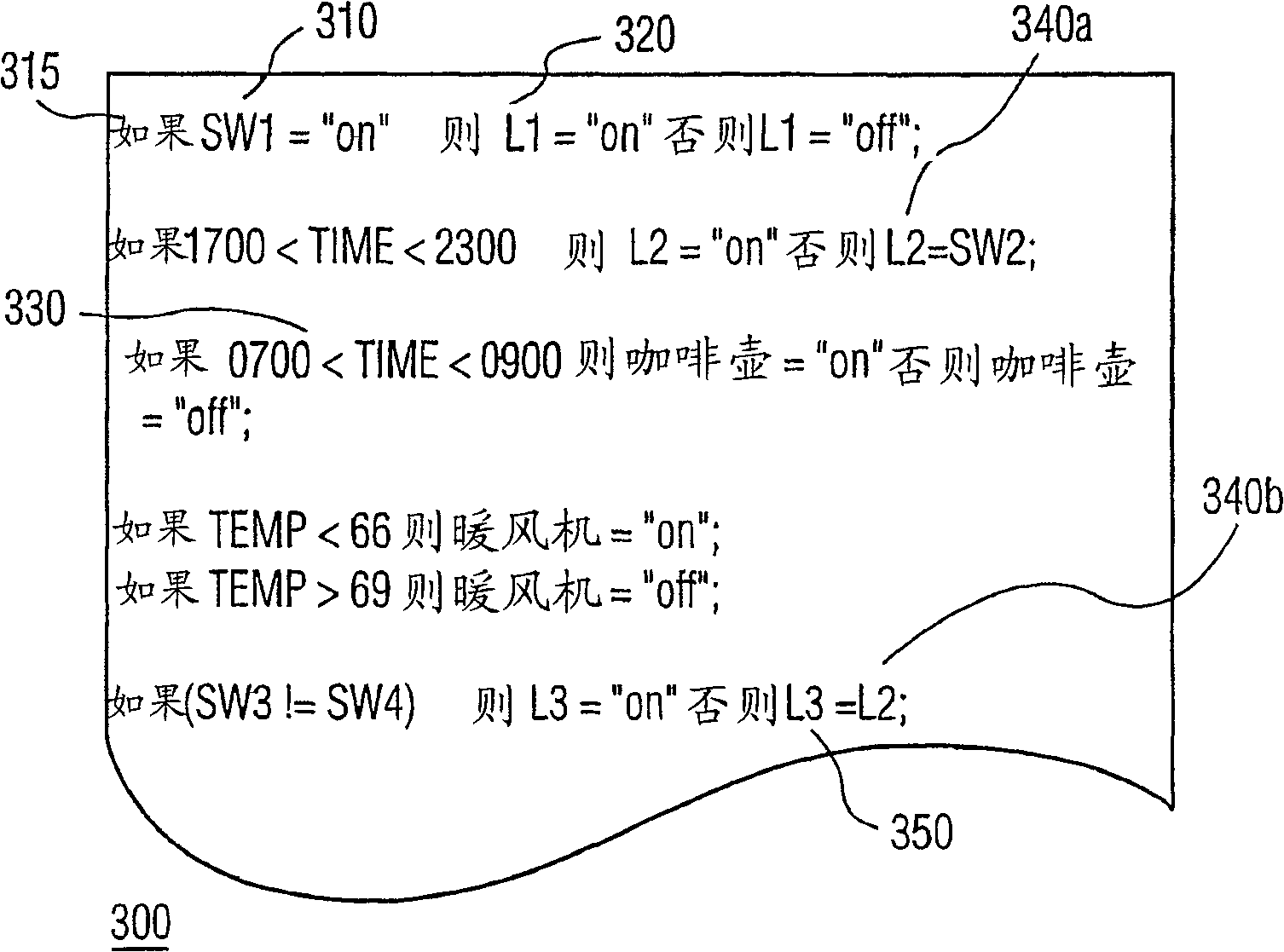

Visual anti-virus in a hetwork control environment

InactiveCN100423489CEasy to detectConvenient verificationPlatform integrity maintainanceSecuring communicationThird partyAnti virus

Detecting a potential virus-infected control script in a networking system, visual representations of control structures and operations effected by a suspect script are presented to a user. A visual representation of the control links that are contained within the suspect script is presented to the user, preferably in a manner such that inappropriate links and / or device states are easily recognized. To further assist in the identification of potential aberrant behavior, a manual or automated simulation process allows the user to visually observe the changes of state of appliances in response to control stimuli, based on the instructions contained in the suspect script. In addition to facilitating an identification of a virus-infected script, the visual representation of the control structure of the network described by the script, and the simulation or emulation of this control structure, also facilitates the development and de-bugging of well-mannered control scripts, particularly in a home or office networking system. A third-party provider may provide the visual representation and / or the simulation process, in return for information regarding the inventory of equipment at the user's site, to facilitate marketing opportunities.

Owner:META PLATFORMS INC

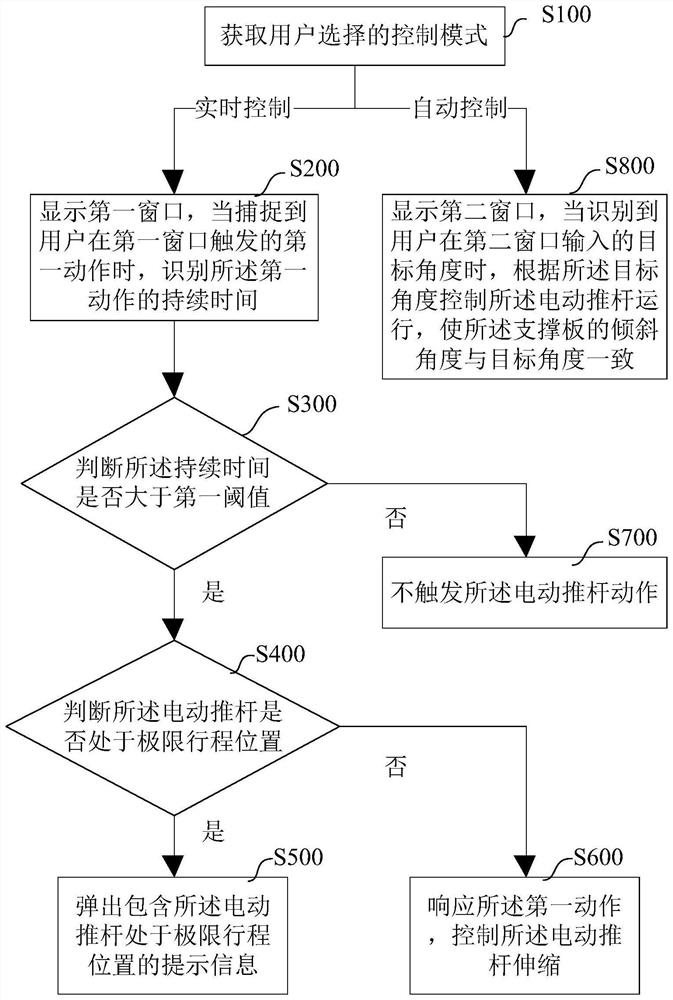

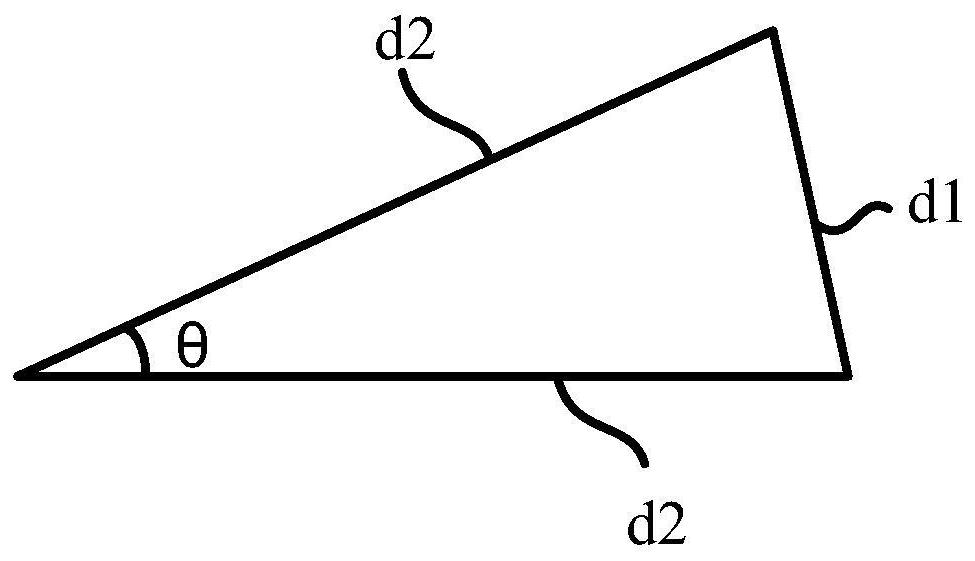

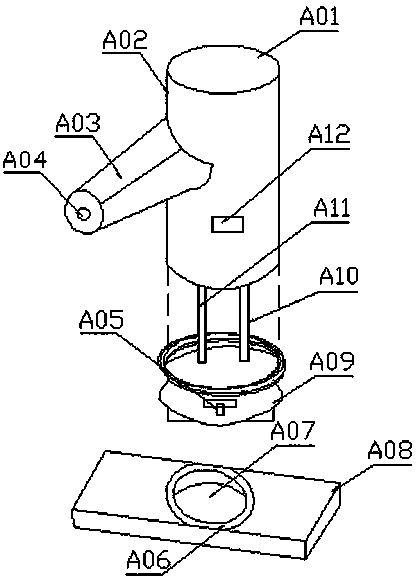

Notebook computer inclination control method and system

ActiveCN112987854ARealize autonomous and precise controlConvenient and reasonable controlDetails for portable computersEnergy efficient computingAutomatic controlSoftware engineering

The invention relates to the technical field of computer peripherals, in particular to a notebook computer inclination control method and system. The system comprises a supporting plate, an electric push rod and a notebook computer electrically connected with the electric push rod, and the method comprises the steps: obtaining a control mode selected by a user, and if the control mode is real-time control, displaying a first window, if the control is automatic control, displaying a second window; when a first action triggered by the user in the first window is captured and the duration time of the first action is greater than a first threshold value, judging whether the electric push rod is located at a limit stroke position, and if so, popping out prompt information including that the electric push rod is located at the limit stroke position; if not, responding to the first action, and controlling the electric push rod to stretch out and draw back; when the target angle input by the user in the second window is recognized, controlling the electric push rod to operate according to the target angle, so the inclination angle of the supporting plate is consistent with the target angle, and the inclination of the notebook computer can be autonomusly and accurately controlled.

Owner:GUANGDONG VOCATIONAL & TECHNICAL COLLEGE

Novel water-saving faucet used for hot water

InactiveCN108468829AWill not polluteSuitable for useOperating means/releasing devices for valvesDomestic plumbingWater savingWater discharge

The invention provides a novel water-saving faucet used for hot water, and relates to the technical field of faucets. The novel water-saving faucet comprises a faucet shell, a pressing handle is arranged at the upper end of the faucet shell, a water outlet spraying hole is formed inside a spraying nozzle, a valve element is arranged inside the faucet shell, a threaded connecting pipe is arranged at the lower end of a water discharging channel, a microswitch is arranged at the upper end of the controller, a transmission wheel is arranged at the lower end of a control box, a transmission shaft is arranged inside the transmission wheel, sterilization channels are arranged on the two sides of the transmission wheel, sterilization modules are arranged at the lower ends of the sterilization channels, hot water pipes are arranged at the lower ends of the sterilization modules, and circulation pipes are arranged on one sides of the hot water pipes. The novel water-saving faucet solves the problems that at present, a water-saving faucet on the market is single in design, the water quantity cannot be controlled, water resources are wasted due to the fact that some cold water needs to be discharged away before the hot water enters a hot water outlet, and great harms are caused on drinking by people due to internal dirt accumulation inside the faucet after long-time use.

Owner:CENXI DONGZHENG POWER TECH DEV

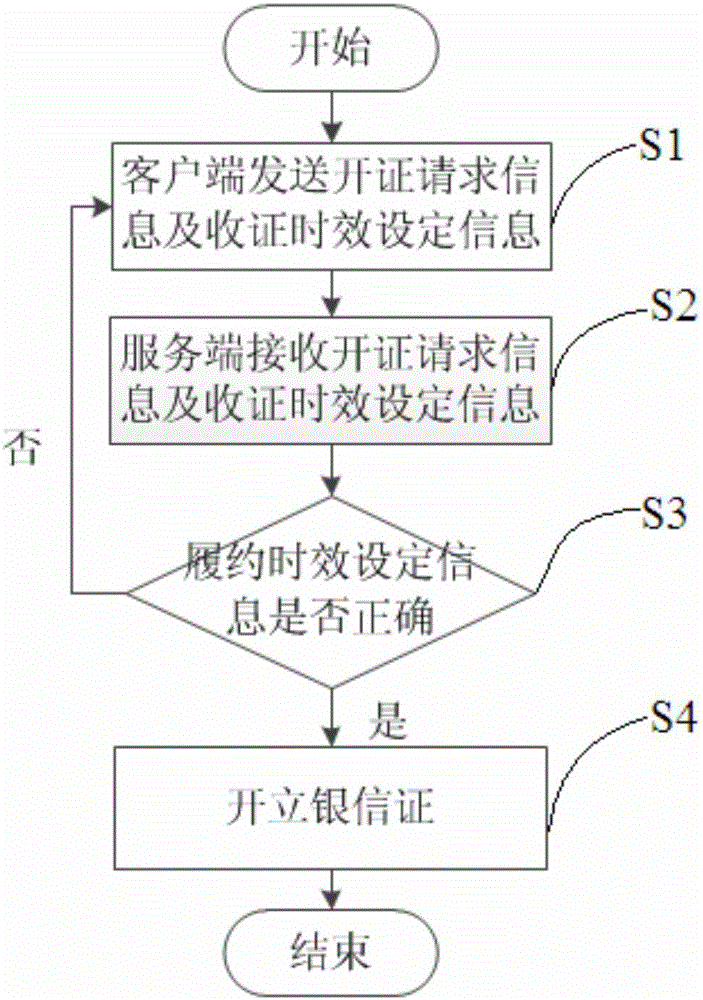

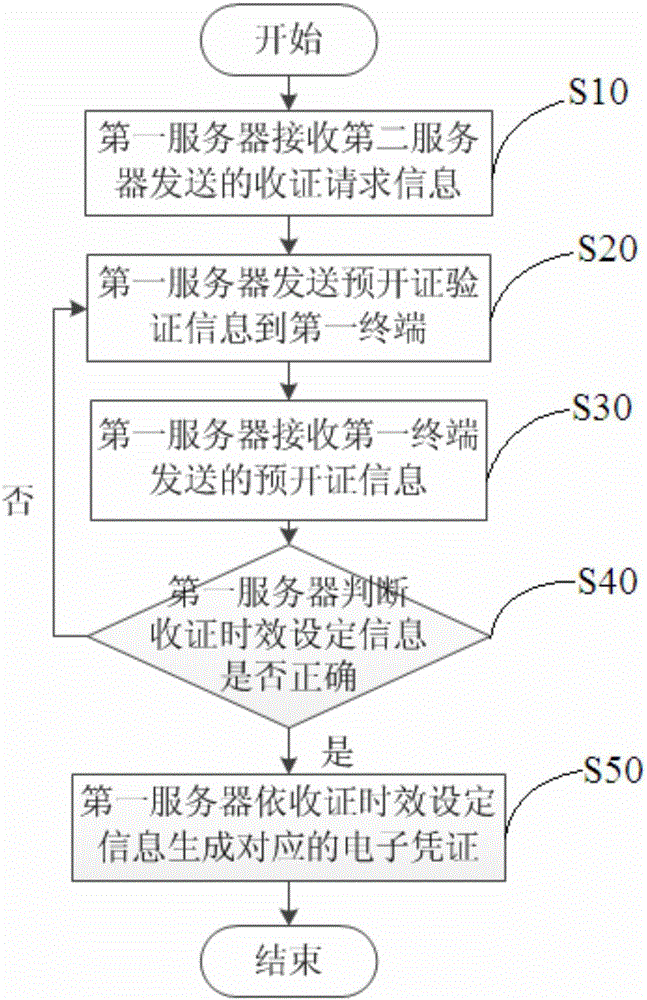

Method and system for setting valid period of electronic certificate receiving

InactiveCN106372915AFlexible useConvenient and reasonable controlElectronic credentialsPaymentClient-side

The application discloses a method and system for setting a valid period of electronic certificate receiving. The method comprises: a client sends electronic certificate issuing request information and valid certificate receiving period setting information; a server side receives the electronic certificate issuing request information and valid certificate receiving period setting information that are sent by the client; the server side determines whether the valid certificate receiving period is corrected; and if so, an electronic certificate is issued based on the valid certificate receiving period setting information. According to the invention, with setting of a valid certificate receiving period of an electronic certificate, a valid period regulation is provided for fund circulation, so that benefits of two sides can be safeguarded and correct allocation in terms of fund circulation of the two sides becomes convenient; and the electronic certificate receiving side can carry out performance timely, so that the electronic certificate can be used flexibly. Therefore, application of financial payment tools is diversified.

Owner:SHENZHEN CIFPAY NETWORK BANK TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com