Light module power supply control method and system

A technology for power control and optical modules, which is applied to non-electrical signal transmission systems, signal transmission systems, electrical components, etc. It can solve the problem that the power supply of optical modules is not isolated, it is difficult to control the power supply of optical modules, and it is easily affected by voltage fluctuations, etc. To achieve the effect of saving energy consumption, convenient and reasonable control, and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

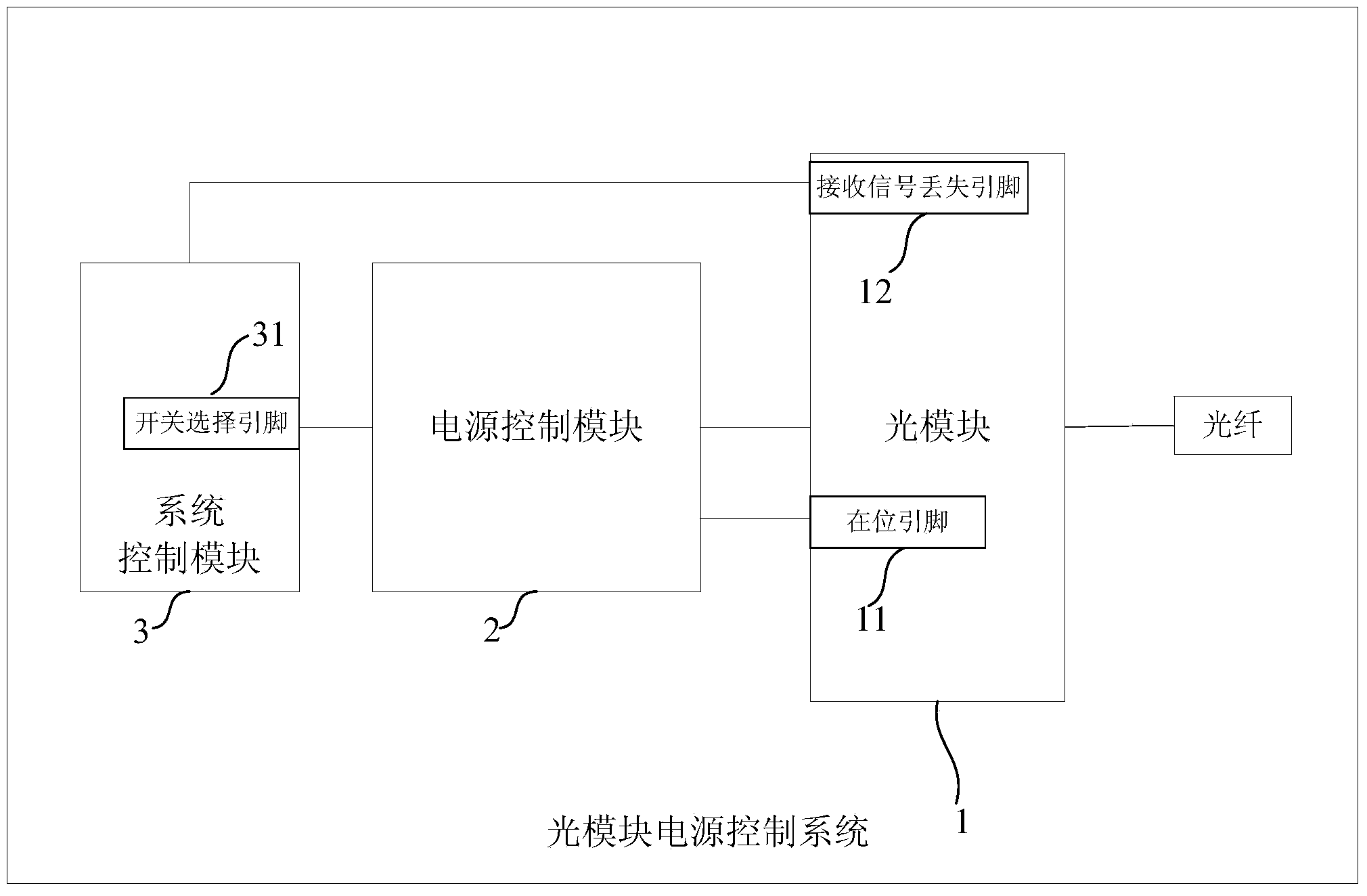

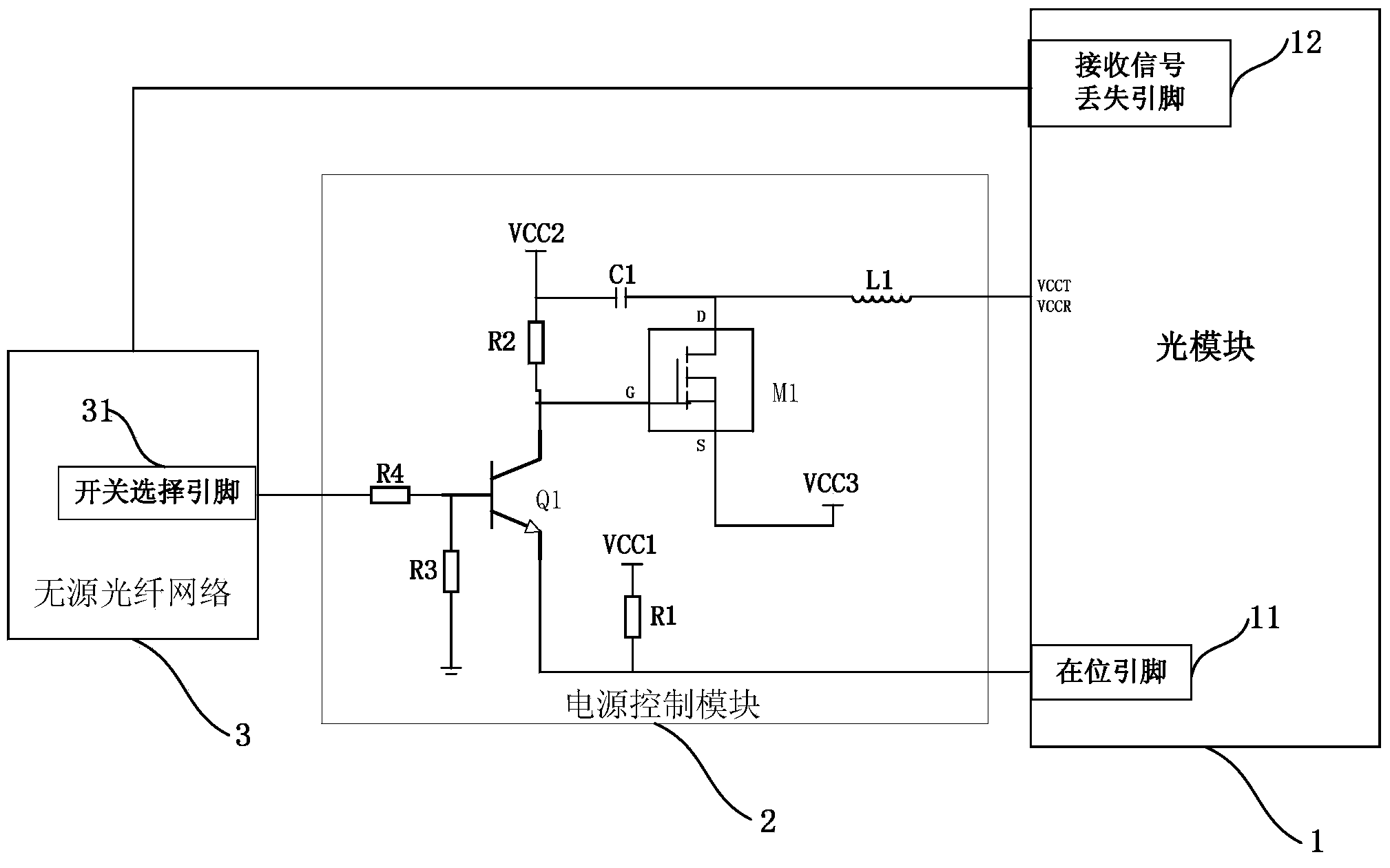

[0051] This embodiment provides an optical module power control system, which is used to control the signal transmission of the optical fiber. Please refer to figure 1 , which is a schematic structural diagram of the optical module power control system of the present invention. As shown in the figure, the optical module power control system controls the opening and closing of the optical module by adding a power switch control module to the power supply part of the optical module. The optical module power control system includes: an optical module 1 , a power control module 2 , and a system control module 3 .

[0052] Each component of the optical module power control system will be described separately below.

[0053] Optical module 1 is connected with optical fiber, is used for converting electric signal into optical signal, and judges the insertion state of described optical module 1 according to the level input to the position pin on optical module 1; Described optical mo...

Embodiment 2

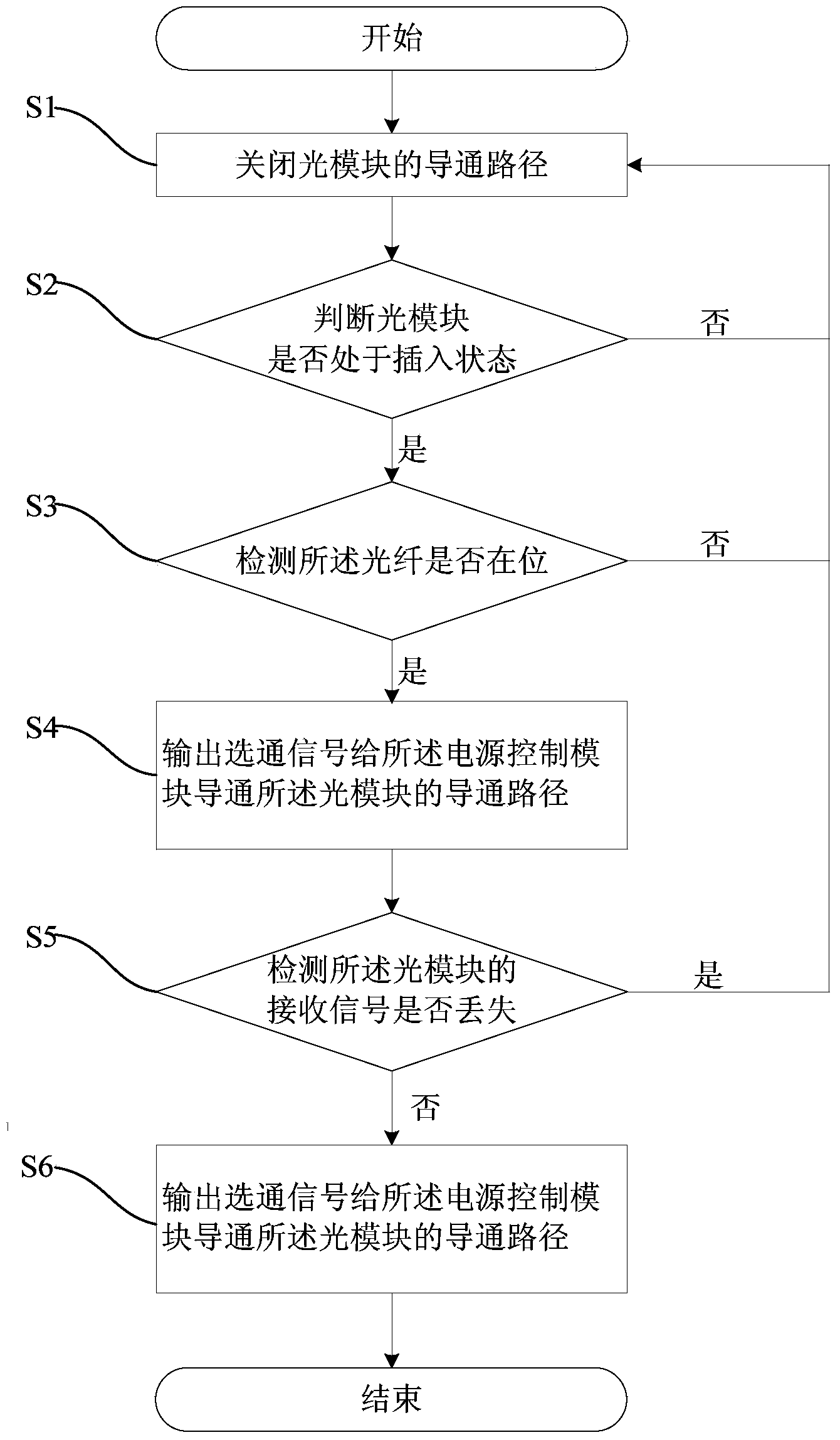

[0065] This embodiment provides an optical module power control method, which is applied to an optical module power control system including an optical module, a power control module, and a system control module to control signal transmission of optical fibers. The optical module power control method includes:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com