Improved tabletting equipment

A kind of equipment and tableting technology, which is applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of insufficient pressure applied by the punch, reduce the quality of tableting, prolong working hours, etc., and achieve better tableting effect , Improving the efficiency of tablet pressing, and the effect of precise lifting and matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

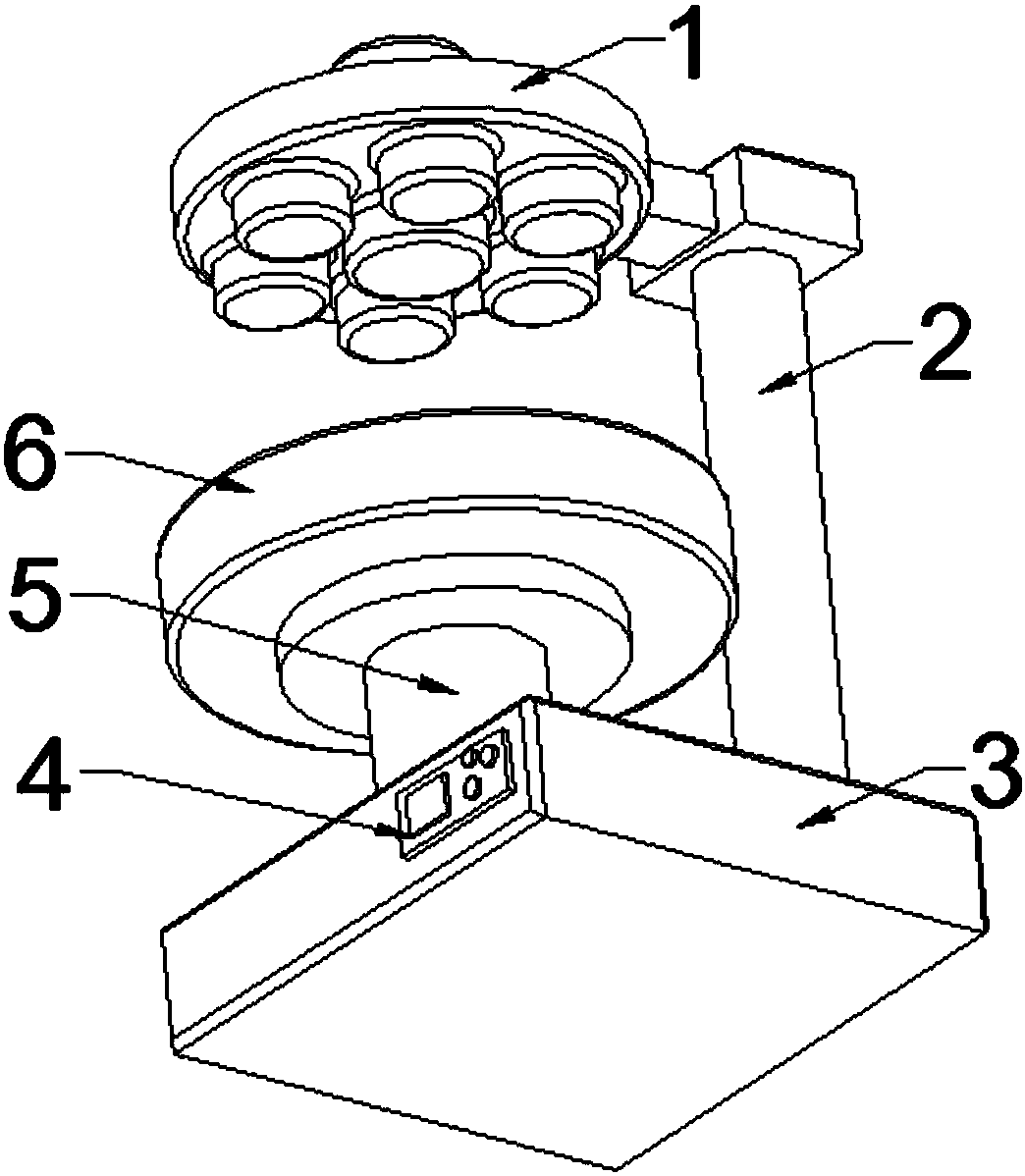

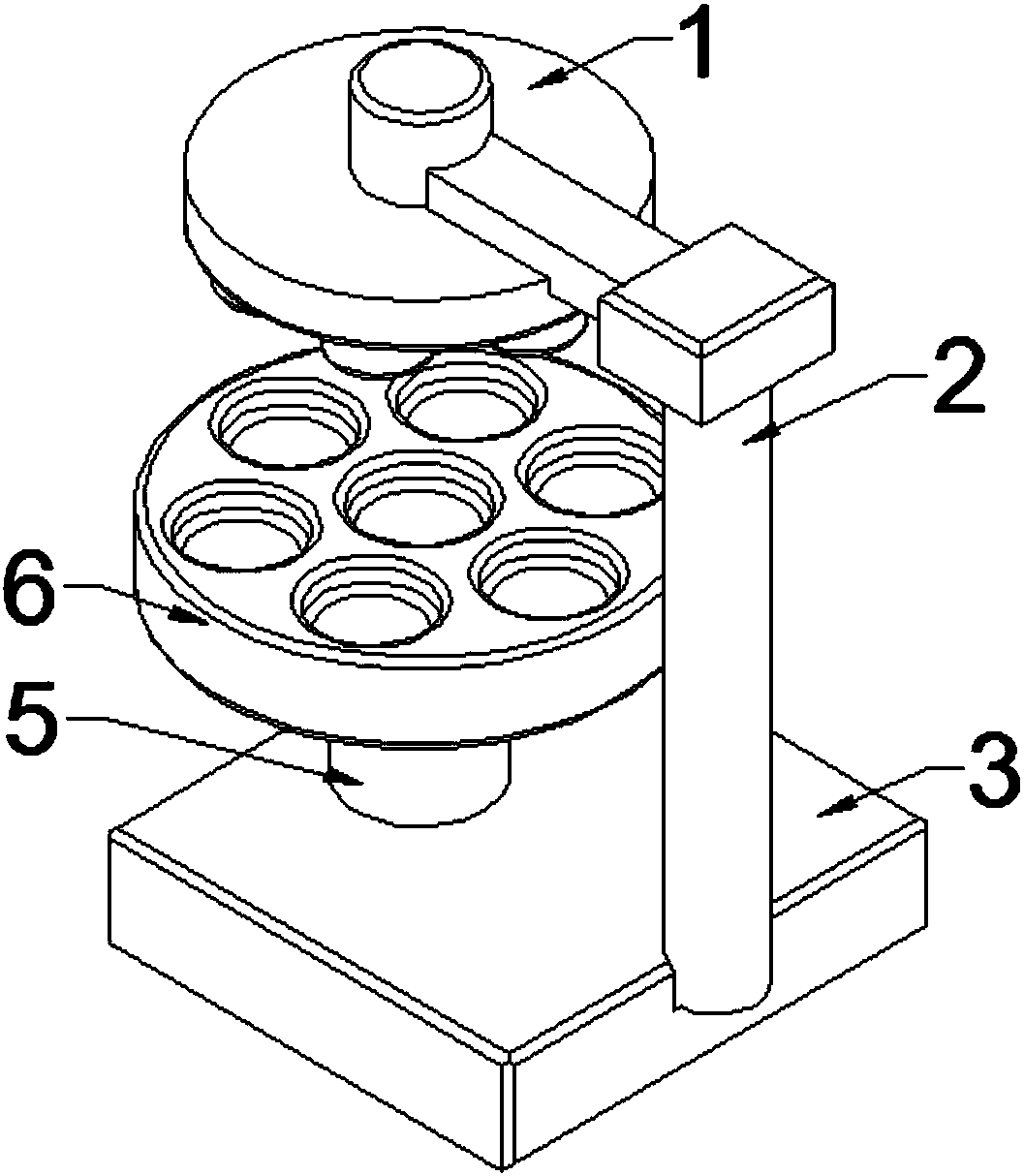

[0020] Such as Figure 1-2 As shown, an improved tablet pressing equipment includes a pressing plate 1 , a top plate 6 is provided directly below the pressing plate 1 , and a base 3 is provided below the pressing plate 1 and the top plate 6 . A power device is provided inside the base 3, a first lifting rod 2 is provided between the pressure plate 1 and the power device, and a second lifting rod 5 is provided between the top plate 6 and the power device. The lower end surface of the press plate 1 is provided with a plurality of punches, and the upper end surface of the top plate 6 is provided with a plurality of dies, and the punches in the descending press plate 1 just fall into the upper end of the ascending top plate 6. In the die.

[0021] In this embodiment, the lifting of the pressing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com