A preparation method of microencapsulated zirconium phosphate and a halogen-free flame-retardant PC composed of it

A technology of microencapsulation and zirconium phosphate, applied in the field of halogen-free flame-retardant PC, to achieve the balance between mechanical and flame-retardant properties, better flame-retardant effect, and maintain the effect of essential color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

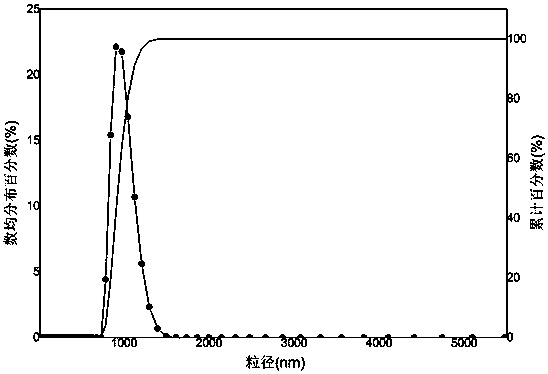

[0044] Uniformly disperse zirconium phosphate with a particle size of 1.0 μm and a mass of 15 g in tetrahydrofuran solvent to obtain a zirconium phosphate dispersion; at the same time, the reaction reagents (phosphazene, 4,4'-biphenylmethylene diisocyanate, ethyl The molar ratio of diamine is 1:2:4) added to the above zirconium phosphate dispersion, and the ratio of the added reaction reagent to the molar number of zirconium phosphate is controlled to be 0.2:1, and the reaction temperature is raised to 120°C, mechanically stirred and reflux, the stirring rate is controlled at 200 rpm, and the reaction time is controlled at 24 hours. After the reaction is completed, it is washed alternately with acetone and deionized water for 2 to 3 times, and then freeze-dried at -40°C for 24 hours to obtain microcapsules. zirconium phosphate.

[0045] A halogen-free flame-retardant PC containing microencapsulated zirconium phosphate prepared by the above method for preparing microencapsulate...

Embodiment 2

[0048] Uniformly disperse zirconium phosphate with a particle size of 1.0 μm and a mass of 15 g in tetrahydrofuran solvent to obtain a zirconium phosphate dispersion; at the same time, the reaction reagents (phosphazene, 4,4'-biphenylmethylene diisocyanate, ethyl The molar ratio of diamine is 1:2:4) added to the above zirconium phosphate dispersion, and the ratio of the added reaction reagent to the molar number of zirconium phosphate is controlled to be 0.7:1, and the reaction temperature is raised to 120°C, mechanically stirred and reflux, the stirring rate is controlled at 200 rpm, and the reaction time is controlled at 24 hours. After the reaction is completed, it is washed alternately with acetone and deionized water for 2 to 3 times, and then freeze-dried at -40°C for 24 hours to obtain microcapsules. zirconium phosphate.

[0049] A halogen-free flame-retardant PC containing microencapsulated zirconium phosphate prepared by the above method for preparing microencapsulate...

Embodiment 3

[0052] Uniformly disperse zirconium phosphate with a particle size of 1.0 μm and a mass of 15 g in tetrahydrofuran solvent to obtain a zirconium phosphate dispersion; at the same time, the reaction reagents (phosphazene, 4,4'-biphenylmethylene diisocyanate, ethyl The molar ratio of diamine is 1:2:4) into the above zirconium phosphate dispersion, and control the ratio of the added reaction reagent to the molar number of zirconium phosphate to be 1:1, raise the reaction temperature to 120°C, and mechanically stir and reflux, the stirring rate is controlled at 200 rpm, and the reaction time is controlled at 24 hours. After the reaction is completed, it is washed alternately with acetone and deionized water for 2 to 3 times, and then freeze-dried at -40°C for 24 hours to obtain microcapsules. zirconium phosphate.

[0053] A halogen-free flame-retardant PC containing microencapsulated zirconium phosphate prepared by the above method for preparing microencapsulated zirconium phospha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com