Method for comprehensively evaluating pipe manufacturing capacity of oil and gas conveying pipe factory

A comprehensive evaluation and conveying pipe technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems that it is difficult to judge the manufacturer's pipe production level, and achieve reasonable control of pipe production cost, quality and economic interaction balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0055] A method for comprehensively evaluating the pipe production capacity of an oil and gas transmission pipe factory, comprising the following steps:

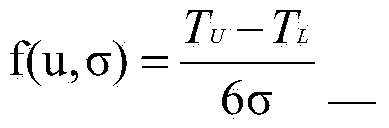

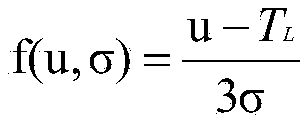

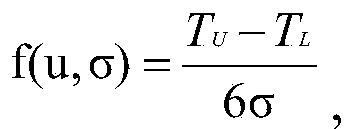

[0056] The first step is to determine the corresponding calculation formula according to whether there is an upper limit requirement for each performance standard of the welded pipe for oil and gas transportation. Through the optimized combination of weighting coefficients, the comprehensive evaluation formula for the strength and toughness index of the welded pipe for oil and gas transportation is determined as follows:

[0057] F(u,σ)=a 1 [f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com