Intelligent monitoring system for monitoring coal conveying belt for of coal conveying system

An intelligent monitoring system and belt technology, applied in the detection field, can solve the problems of high cost, increased risk factors of belt damage, and high false alarm rate, so as to improve safety and economy, reduce the risk of being torn, and facilitate installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The specific embodiments described below by referring to the figures are exemplary and are for explanatory purposes only rather than limiting the present invention.

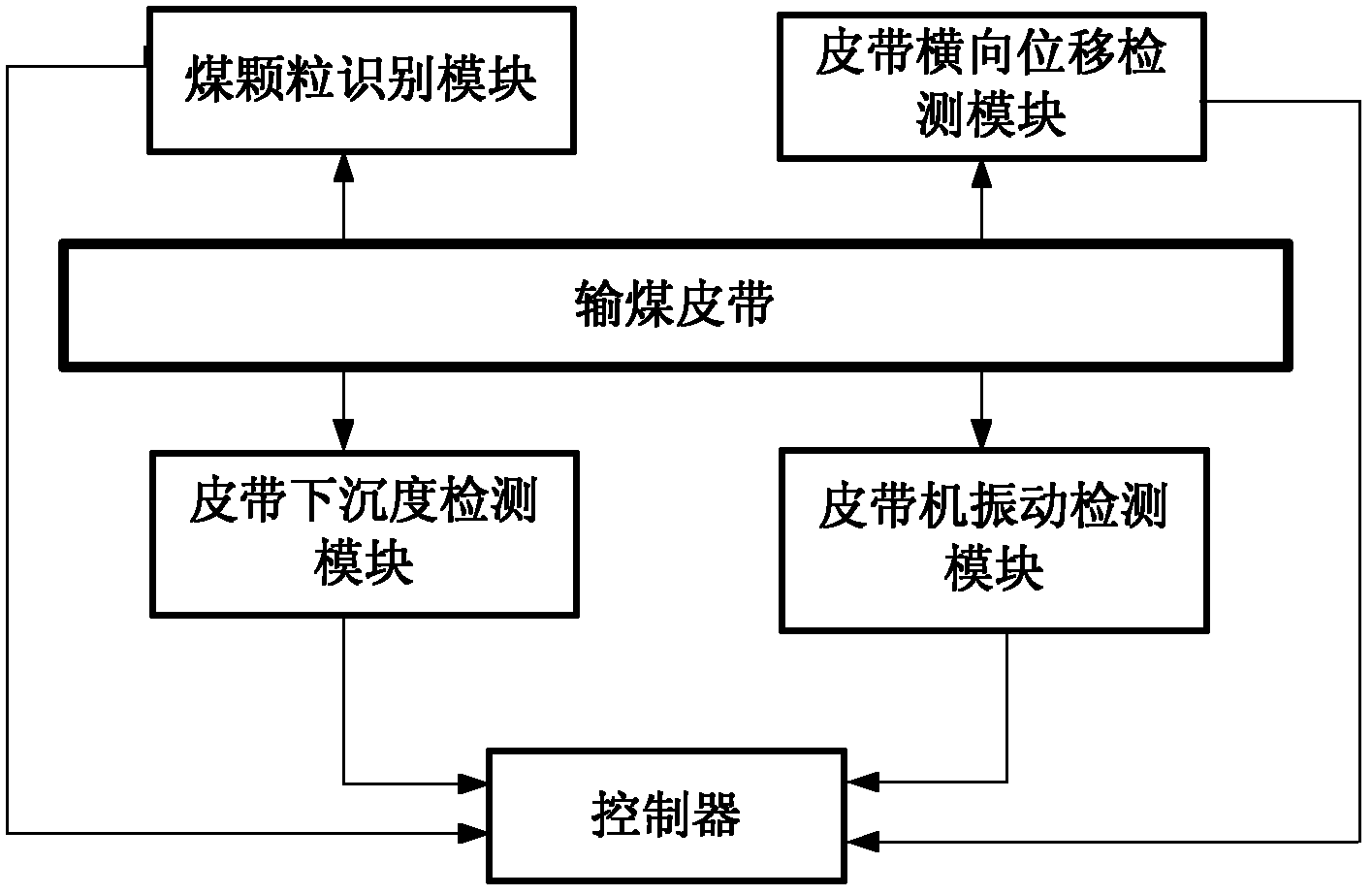

[0026] figure 1 A schematic block diagram of the intelligent monitoring system for the coal conveyor belt of the present invention is shown. The intelligent monitoring system includes a coal particle identification module, a belt sinking degree detection module, a belt lateral displacement detection module, a belt conveyor vibration detection module and a controller. The controller is connected with each functional module in a wired or wireless manner.

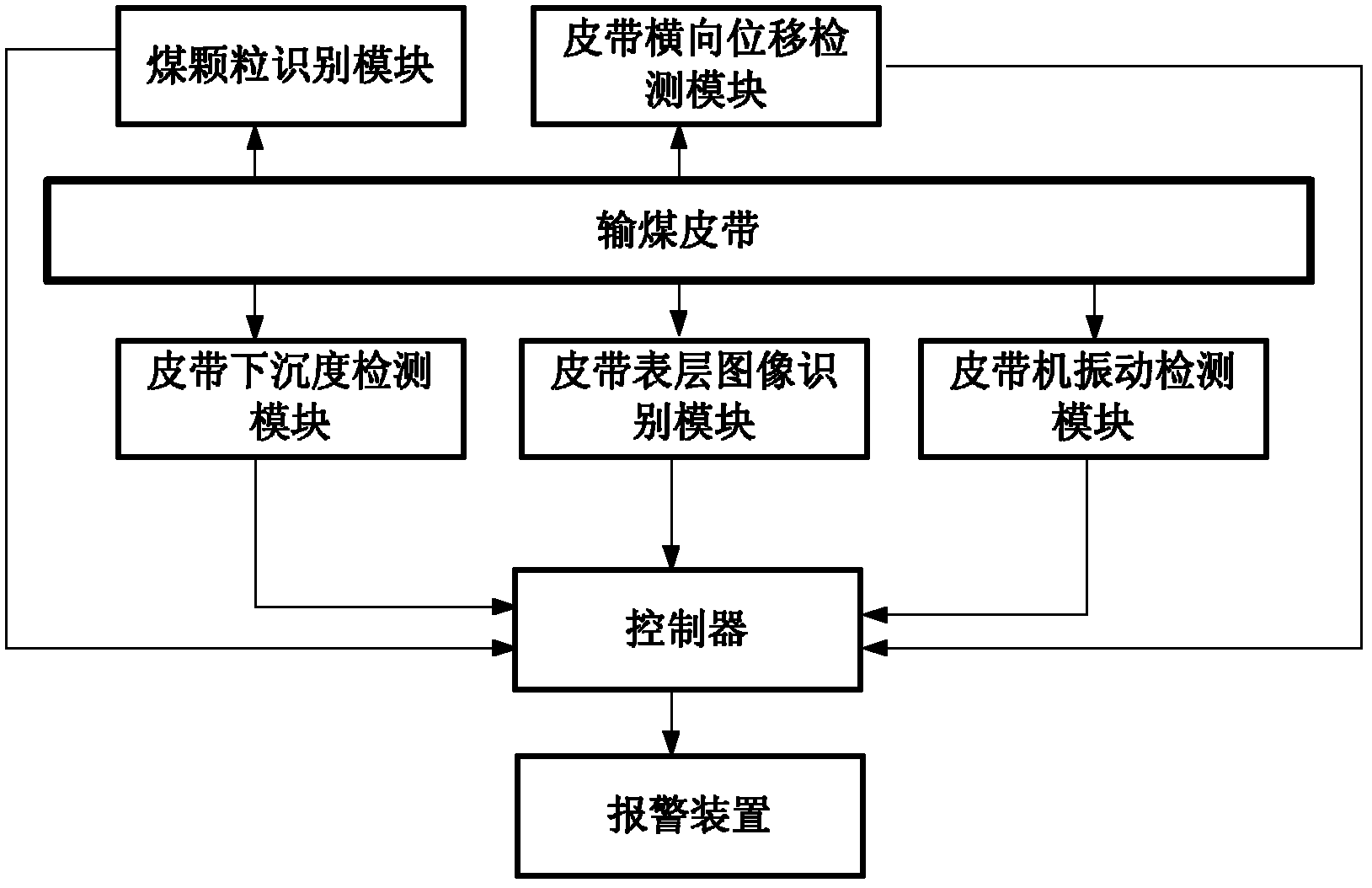

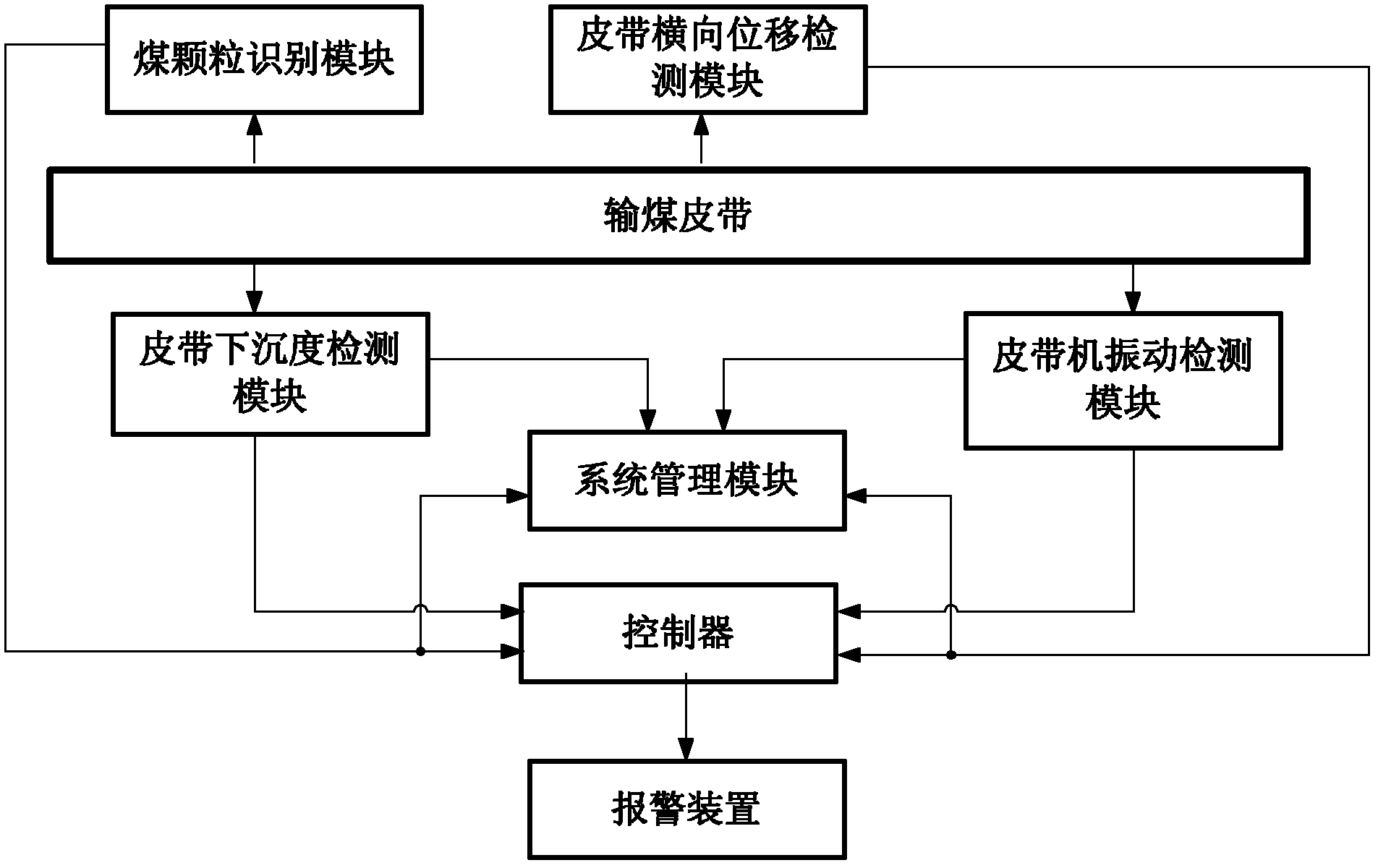

[0027] In addition, the intelligent monitoring system of the present invention may also include a belt surface image recognition module and / or a system management module and / or an alarm device, such as figure 2 and image 3 shown.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com