Device and method for preparing activated carbon material for electrochemical capacitor

An activated carbon and capacitor technology, which is applied in the field of devices for preparing activated carbon materials for electrochemical capacitors, can solve the problems of unstable microwave activation process, increase the cost of activated carbon products, secondary pollution of waste water, etc. The effect of speeding up the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

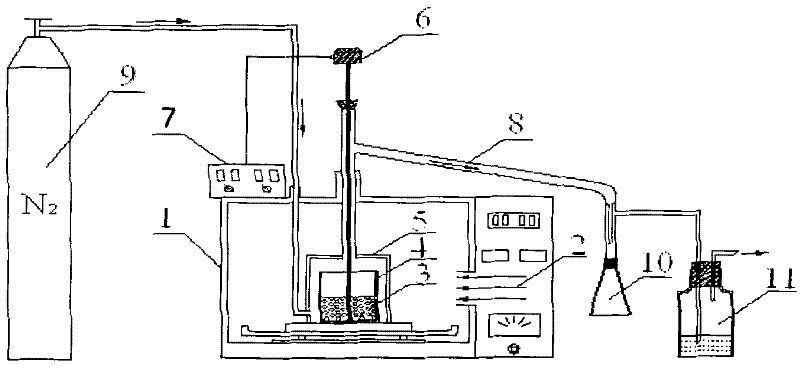

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: Taking bituminous coal as raw material, the specific preparation process is as follows:

[0023] (1) Add 500mL of hydrochloric acid (6M) to 100g of 180 mesh bituminous coal, then add 2mL of absolute ethanol, stir and ultrasonically vibrate the mixture for 30min; heat the mixture in a constant temperature water bath at 55-60°C for 1h, wash with hot distilled water until neutral , and dried under vacuum at 110°C for 2h. Divide the above coal sample into two parts and place them in plastic beakers, add 400mL of 40% hydrofluoric acid and 2mL of absolute ethanol, stir and ultrasonically vibrate the mixture for 30min; heat in a constant temperature water bath at 55-60°C for 1h, Wash with hot distilled water until neutral, and dry in vacuum at 110°C for 2 hours. Divide the above coal sample into two parts and place them in a glass beaker, add 500mL of 2M nitric acid, then add 2mL of absolute ethanol, stir and ultrasonically vibrate the mixture for 30min; Neutra...

Embodiment 2

[0026] Embodiment 2: Taking bituminous coal as raw material, the specific preparation process is as follows:

[0027] (1) Raw coal and the processing method of raw coal are the same as (1) in embodiment 1, and the ash content of coal is less than 0.2%.

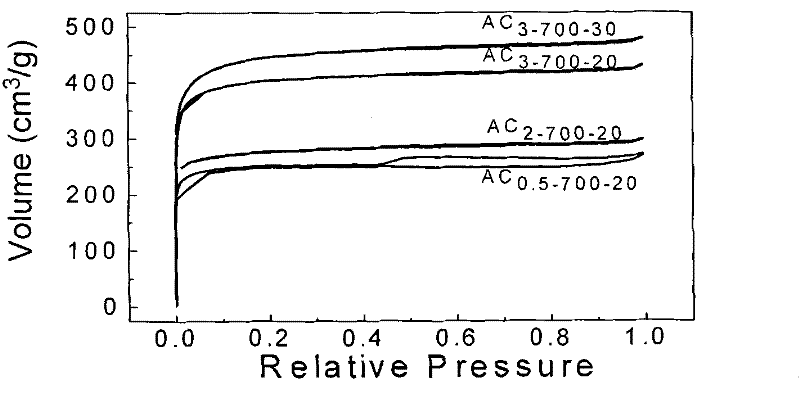

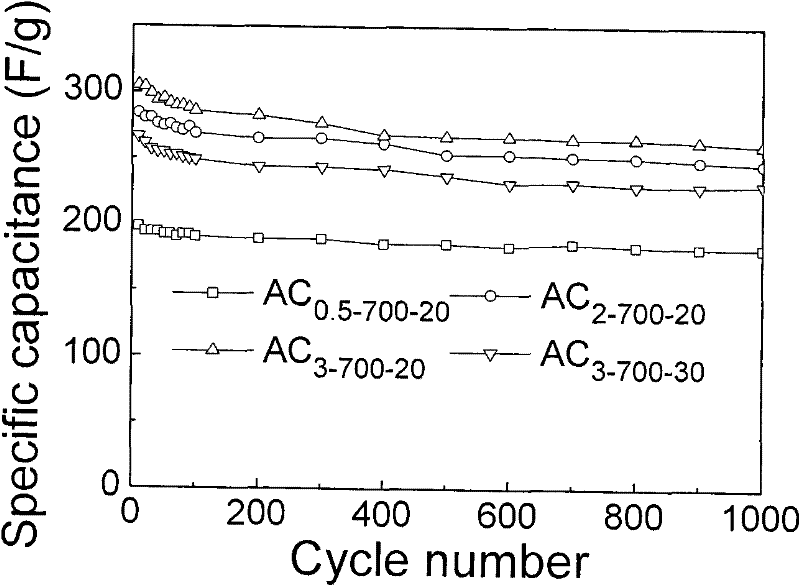

[0028] (2) Dissolve 12g of deashed coal and 24g of potassium hydroxide obtained in step (1) in 30mL of deionized water, stir rapidly with a glass rod and place in water to cool until returning to normal temperature; then add 5mL of absolute ethanol, and use Stir with a glass rod; heat and stir the mixture on a magnetic heating stirrer until a paste is formed; transfer the paste to a ceramic mortar, dry it under vacuum at 110°C for 1 h, and transfer the mixture to corundum in the crucible. The corundum crucible was placed in the quartz protective cover in the microwave chemical reactor, and activated carbon was prepared by microwave-assisted heating and activation under the condition of 700W and 20min; it was naturally cooled ...

Embodiment 3

[0030] Embodiment 3: using bituminous coal as raw material, the specific preparation process is as follows:

[0031] (1) Raw coal and the processing method of raw coal are the same as (1) in embodiment 1, and the ash content of coal is less than 0.2%.

[0032] (2) Dissolve 12 g of deashed coal and 36 g of potassium hydroxide obtained in step (1) into 30 mL of deionized water, stir rapidly with a glass rod and place in water to cool until returning to normal temperature; then add 5 mL of dehydrated ethanol, and use Stir with a glass rod; heat and stir the mixture on a magnetic heating stirrer until a paste is formed; transfer the paste to a ceramic mortar, dry it under vacuum at 110°C for 1 h, and transfer the mixture to corundum in the crucible. The corundum crucible was placed in the quartz protective cover in the microwave chemical reactor, and activated carbon was prepared by microwave-assisted heating and activation under the condition of 700W and 20min; it was naturally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com