Two stage Fischer-Tropsch synthesis method

A technology of Fischer-Tropsch synthesis and synthesis gas, which is applied in the recovery of liquid hydrocarbon mixtures and the petroleum industry. It can solve the problems of low CO utilization rate and high methane production rate, and achieve the goal of improving conversion rate, high oil yield and improving activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

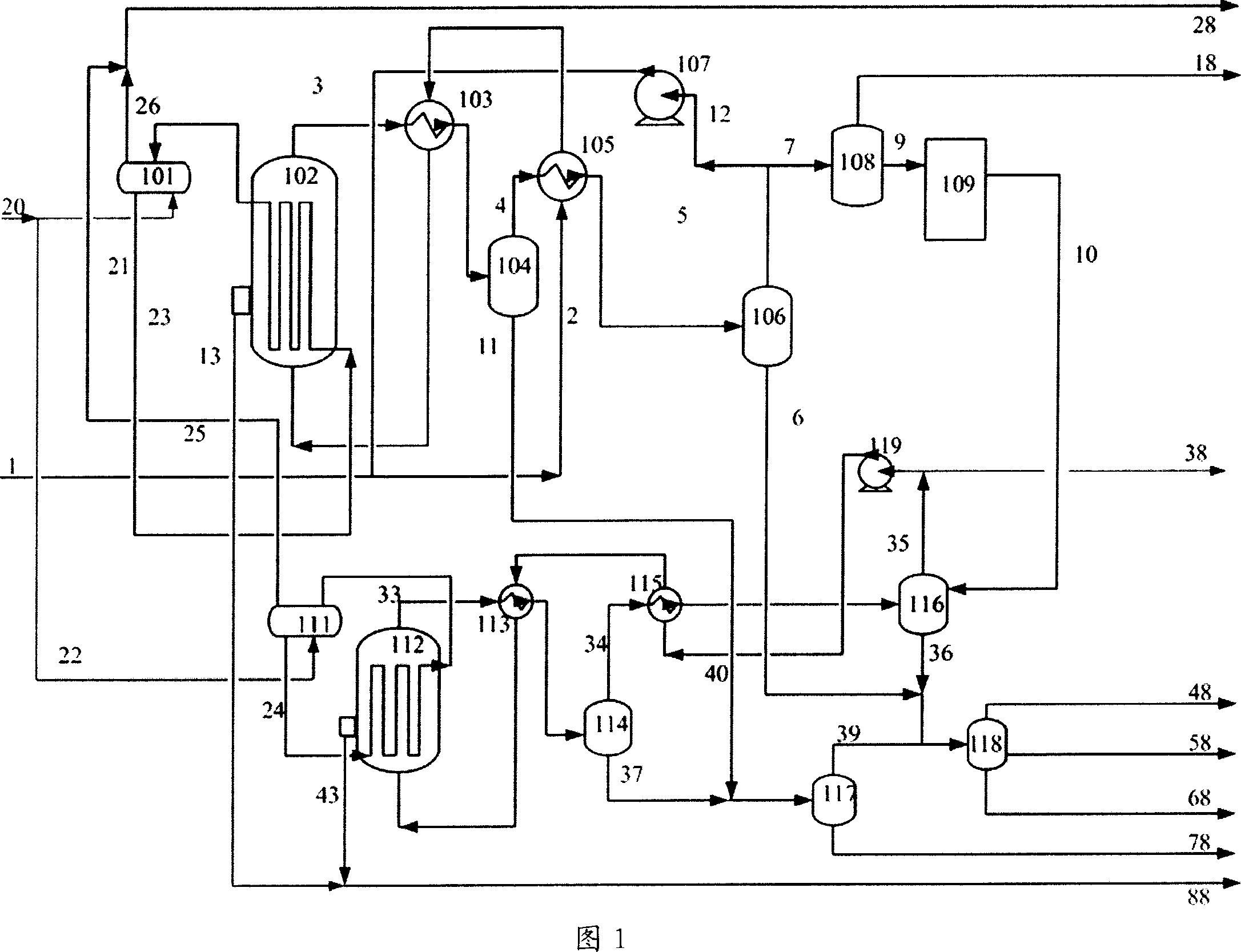

[0032] This embodiment adopts the technological process shown in Fig. 1, and the fresh feed gas is the H obtained through purification and water-gas shift after coal gasification. 2 The specific composition of syngas with a volume ratio of 1.6 to CO is shown in Table 1.

[0033] Element

[0034] Both stages of this embodiment adopt iron-based catalysts, and the weight composition of the catalysts is 100Fe: 5Cu: 5K 2 O: 25SiO 2 . The preparation method is to mix the ferric nitrate and copper nitrate solutions in proportion to form a mixed solution, and then add NaCO after heating to boiling. 3 The solution was precipitated, then filtered and washed free of alkali; the filter cake was beaten, and a quantitative amount of K 2 SiO 3 , and join the HNO 3 Wash off excess potassium ions, wash and filter, beat the filter cake and spray dry to obtain catalyst particles with a particle size range of 60-90 microns, which can be used as qualified iron-based catalysts after...

Embodiment 2

[0039] The present embodiment adopts the process flow shown in Figure 1, but removes CO removal 2 device 108 . The fresh raw gas is H2 obtained after gasification of natural gas and purification 2 The specific composition of syngas with a volume ratio of 2 to CO is shown in Table 3.

[0040] Element

[0041] Both stages of this embodiment adopt cobalt-based catalysts, and the weight composition of the cobalt catalysts is 15Co: 5Zr: 100Al 2 o 3 . The preparation method is to first pour zirconium nitrate aqueous solution into the alumina that has been roasted at 500 °C in the air in advance according to the method of incipient wetness, then use a drum to evaporate, dehydrate and dry, and then add Co(NO 3 ) 2 6H 2 O aqueous solution, after drying, impregnate the aqueous solution of cobalt nitrate again, repeat the above three times in total, until the cobalt content in the catalyst precursor meets the requirements, add a certain amount of binder, form, dry, roast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com