Device and method for measuring air permeability of isolation material

A gas permeability and barrier material technology, which is applied in the field of devices for measuring gas permeability of barrier materials to achieve the effect of reducing the background gas pressure value and reducing the leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

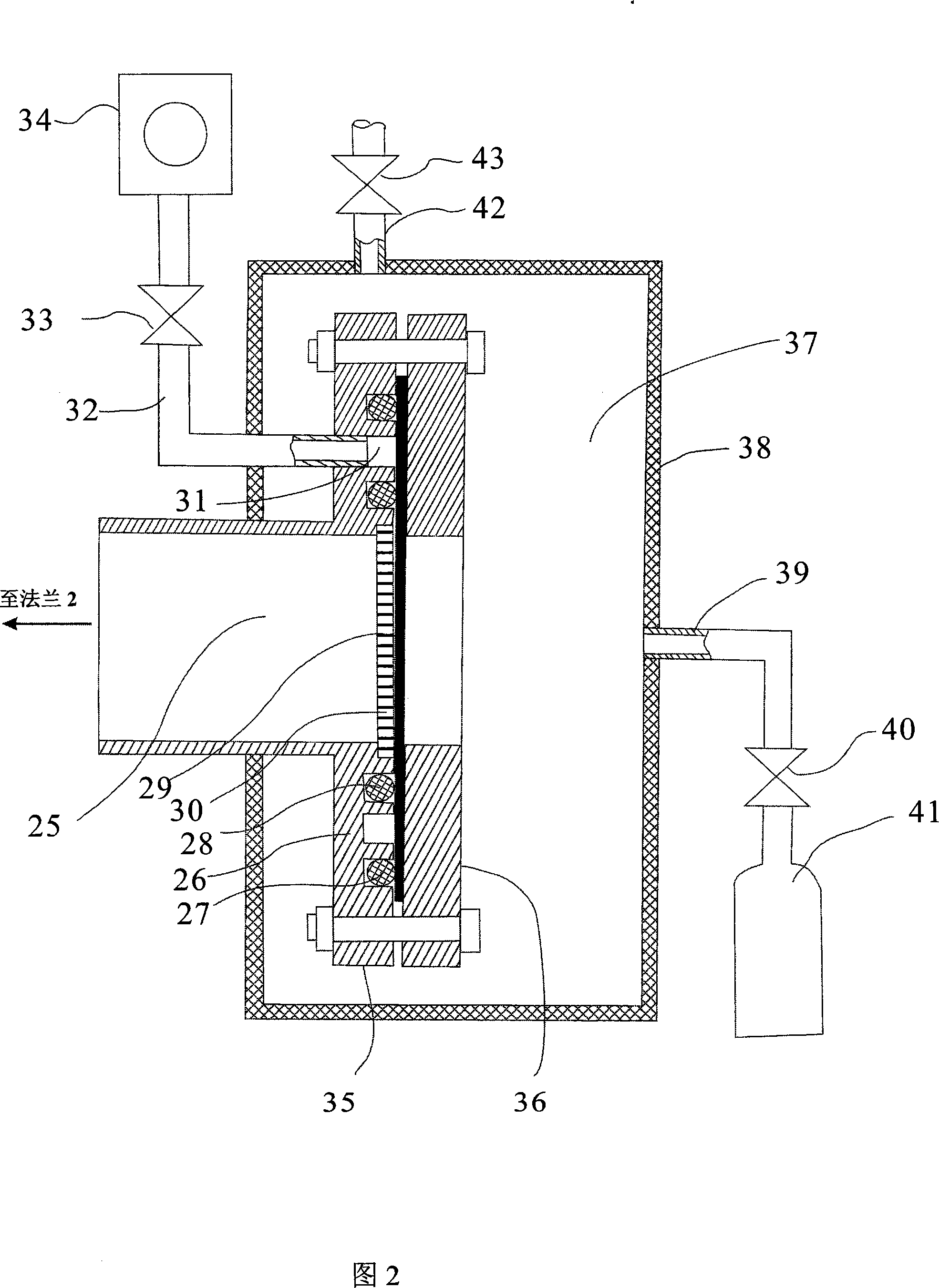

[0056] The double-vacuum sealing structure of the barrier material to be tested and the vacuum chamber seal is shown in Figure 2, using the vacuum chamber flange 26, the gas chamber flange 36, and the inner and outer sealing rings (28, 27) of the vacuum chamber flange and the gas chamber The flange 36 compresses and seals the measured barrier material film or sheet 29 between the vacuum chamber 25 and the gas chamber 37, and a vacuum channel is arranged between the inner and outer sealing rings (28, 27) of the vacuum chamber flange 26 31. The vacuum chamber flange 26 and the gas chamber flange 36 are connected and pressed by connecting bolts 35, so that the measured barrier material clamped between the vacuum chamber flange 26 sealing rings (28, 27) and the gas chamber flange 36 The film or sheet 29 is sealed between the vacuum chamber 25 and the gas ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com