A method and device for controlling tailing of roll-assisting rollers

A control method and technology of a control device, which are applied in rolling mill control devices, manufacturing tools, metal rolling, etc., can solve the problems of indentation, increase roll consumption of auxiliary rolls, etc., so as to reduce roll consumption, reduce manpower, avoid The effect of roller wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

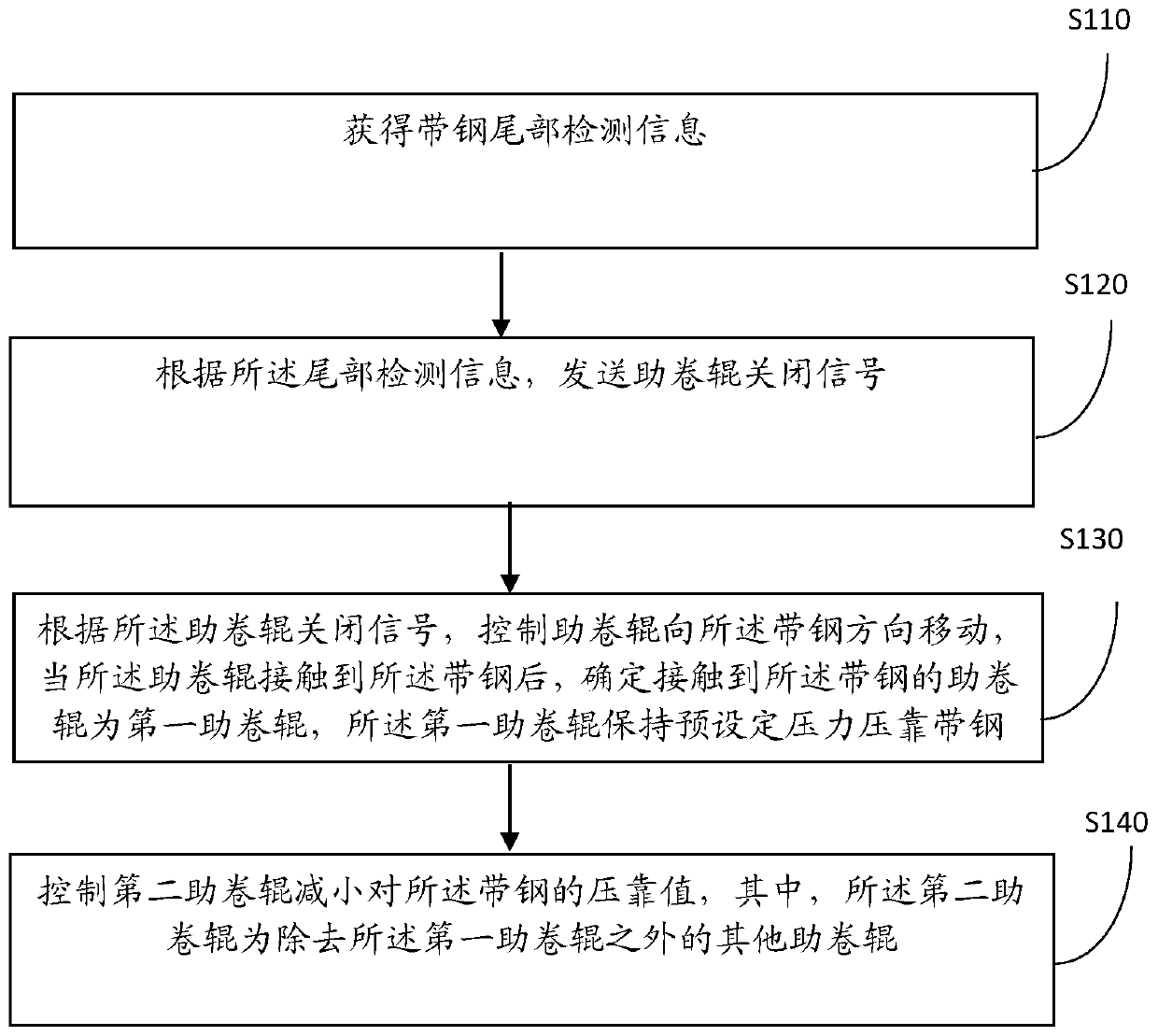

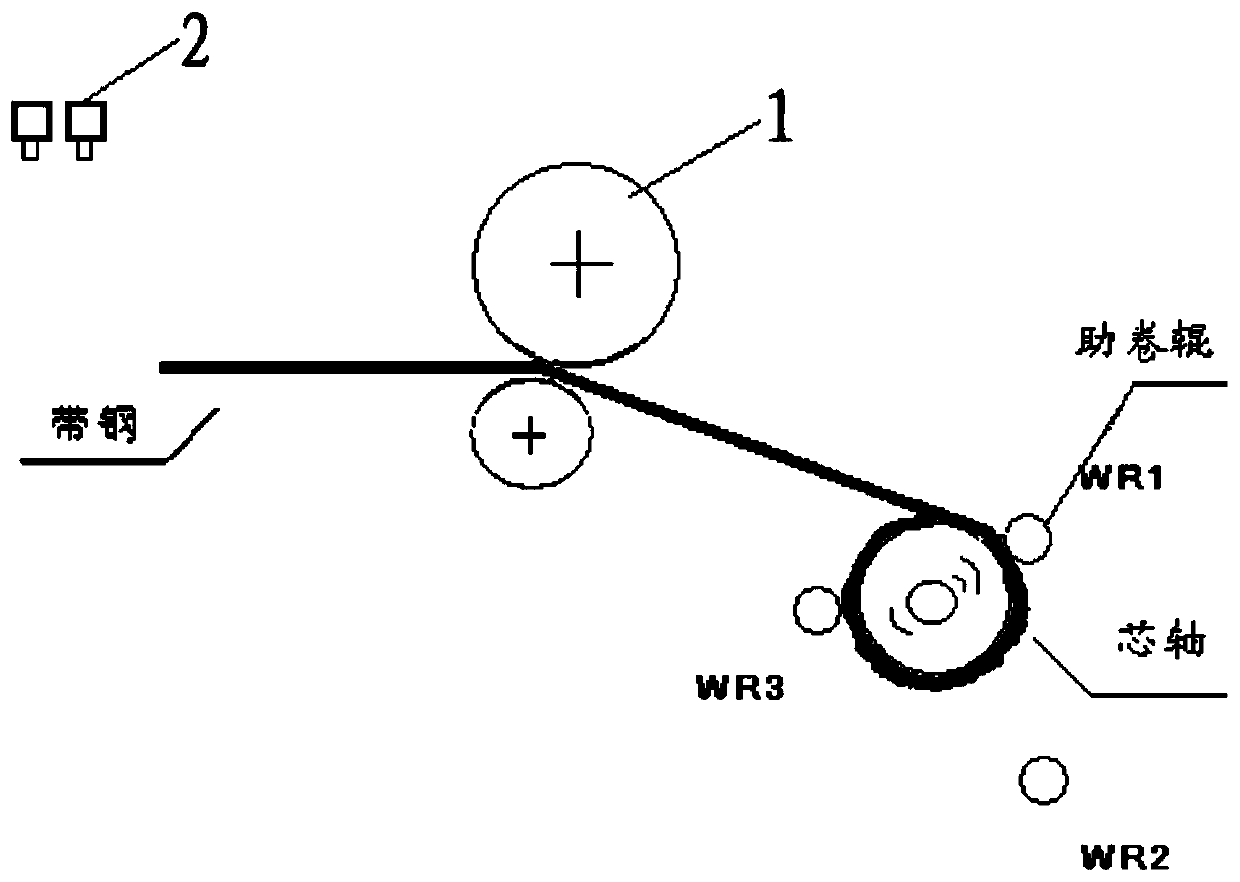

[0054] figure 1 It is a schematic flow chart of a method for controlling the tailing of the winding-assisting roller in the embodiment of the present invention. Such as Figure 1-3 As shown, the embodiment of the present invention provides a method for controlling the tailing of the winding-assisting roller, which is applied to a coiler. There are position sensors and pressure sensors, and there is a metal detector 2 at the front 5 meters of the pinch roller 1 of the coiler, and the method includes:

[0055] Step 110: Obtain detection information of the strip tail.

[0056] Specifically, the strip steel is detected in real time by the metal detector 2 arranged in front of the pinch roller 1, and when the tail of the strip leaves the detection range of the metal detector 2, it indicates that the When the strip steel has completely entered the working range of the coiler, it is necessary to carry out tail pressing work. After the metal detector 2 detects the loss, that is, wh...

Embodiment 2

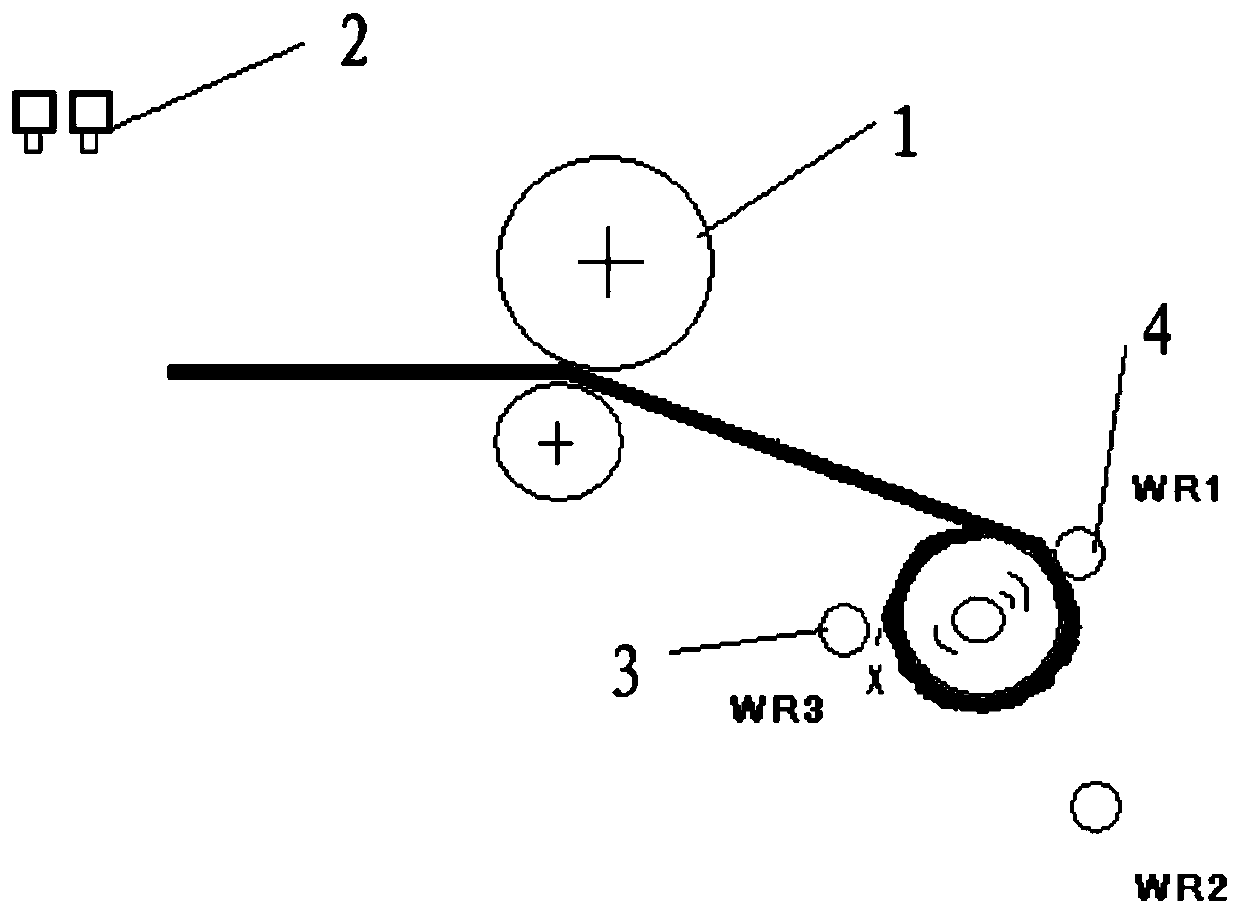

[0074] Based on the same inventive idea as the method for controlling the tailing of the roll-assisting roller in the foregoing embodiments, the present invention provides a control device for the tailing of the roll-assisting roll, which is applied to a coiler, and the coiler has two More than one roll-assisting roll, position sensors and pressure sensors are installed in the hydraulic cylinder of the roll-assisting roll, and a metal detector 2 is arranged at the front 5 meters of the pinch roll 1 of the coiler, such as Figure 4 As shown, the device includes:

[0075] A first obtaining unit 11, the first obtaining unit 11 is used to obtain strip tail detection information;

[0076] A first sending unit 12, the first sending unit 12 is configured to send a winding-assisting roller closing signal according to the tail detection information;

[0077] The first determining unit 13, the first determining unit 13 is used to control the winding-assisting roller to close toward the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com