Method for manufacturing vacuum glass

A technology of vacuum glass and manufacturing method, which is applied in the field of glass product manufacturing, and can solve problems such as manual operation of air extraction, inability to use tempered glass, poor edge sealing process, etc., and achieve simple and easy production process and strong displacement ability , Strong effect of vacuum glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

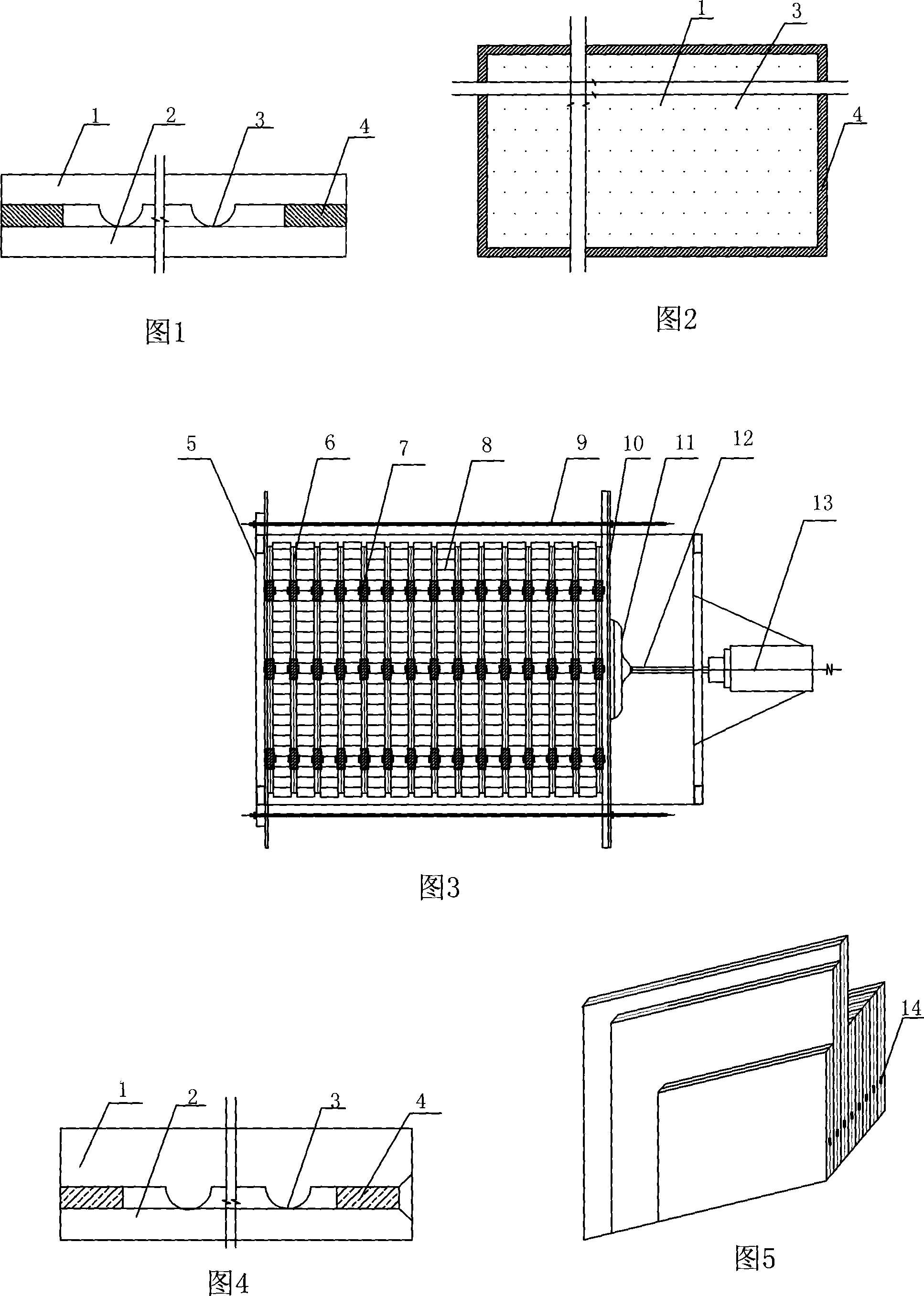

[0024] The main glass is made of 3mm or 5mm float glass original products, and the surface is cleaned by decontamination. UV ink is used for screen printing on the surface of the main glass. After being irradiated by a UV light curing device, the ink is cured to form bumps 3 Or use sintered glass color glaze printing material to screen print on the main glass surface, put it into a heating furnace and sinter at a temperature of about 600° C. for 1 to 2 minutes to form bumps 3 . The height of bumps 3 can be selected according to their distribution density and the thickness of the main glass, and the ratio to the thickness of the main glass is generally 1:10-1:3. Using this ratio range to set the height of the bump can make the support more stable and the glass strength higher. The produced bump glass 1 is cut according to size requirements and directly used for making vacuum glass. It is also possible to use sintered glass color glaze printing material to screen print on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com