Catalyst carrier and preparation method thereof

A technology of catalyst support and alumina support, which is applied in the direction of catalyst support, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of small surface modification of alumina, unguaranteed co-precipitation conditions, and high preparation costs. Achieve the effects of easy regulation of acidity and alkalinity, improved performance and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 7

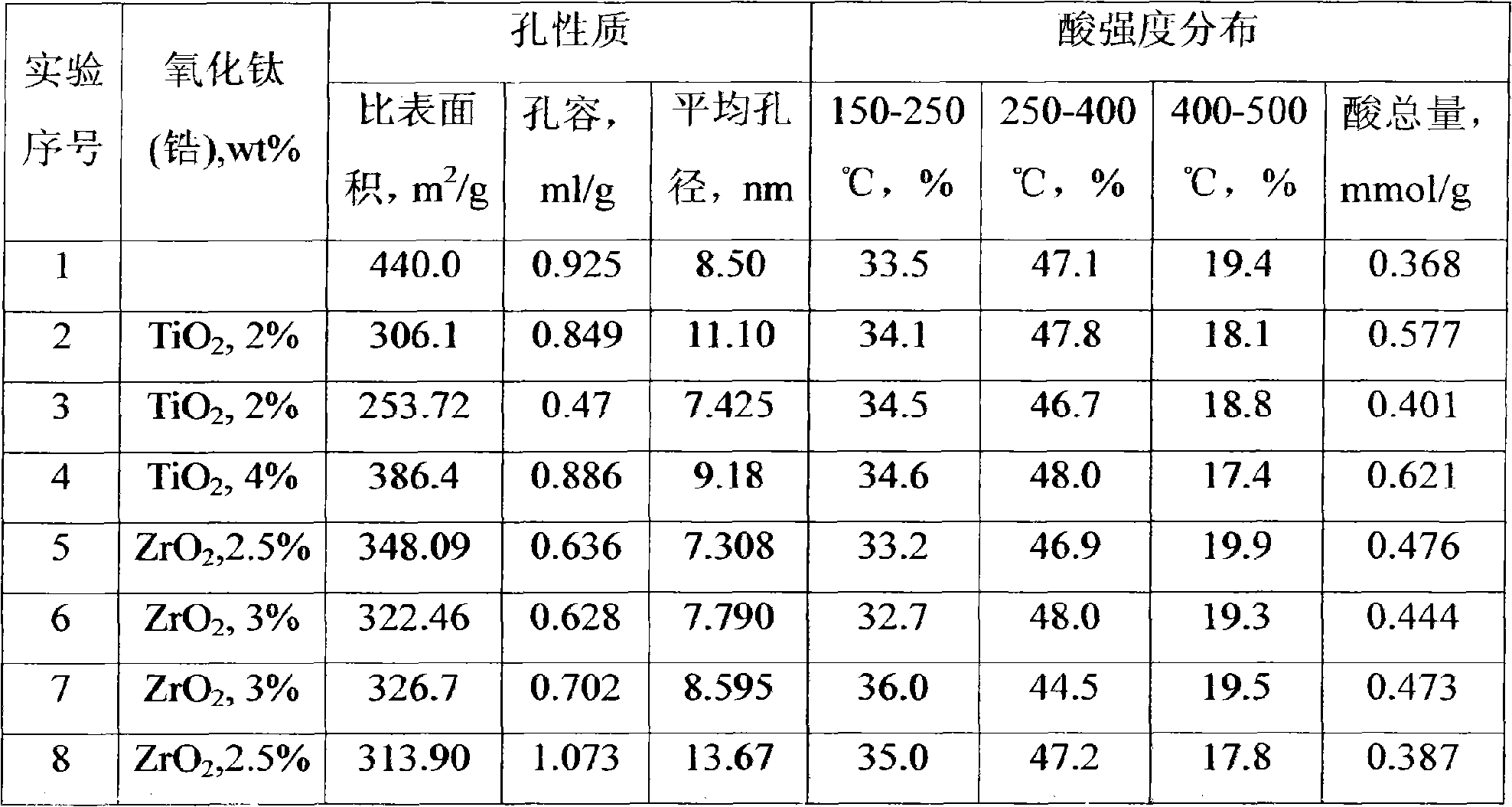

[0045] According to the volume ratio of 1:3, 0.20mol / L ZrOCl 2 ·8H 2 The O aqueous solution is dropped into 0.5mol / L ammonia solution, and the resulting precipitate is washed and filtered to obtain ZrO(OH) 2 Hydrogels. Disperse the gel in deionized water, add a mixture of polyglycerol 600 and polyvinyl alcohol, the weight ratio of polyglycerol 600: polyvinyl alcohol is 1:1, and the amount of organic additives added is 10% of the total volume of the sol. Two hours. The alumina carrier of Example 1 was put into it, dipped for 10 minutes, taken out and dried at room temperature for 8 hours, and calcined at 500° C. for 3 hours to obtain a composite oxide carrier. Its main properties are listed in Table 1.

[0046] Experiment No. 8: Comparative Example 1

[0047] Combine 1000ml 2mol / L aluminum nitrate, 1000ml 0.05mol / L zirconium nitrate and 120ml silica gel (containing SiO 2 25%), add the mixed solution of ammonia water and polyglycerol 2000 (average molecular weight 2000), wherein amm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com