Preparation method and device of metal foam material

A metal foam and metal aluminum technology, which is applied in the field of the preparation of closed-cell metal foam materials, can solve the problems of poor product reproducibility, prolonged cooling time, and reduced product yield, etc. The effect of reducing pore size gradient and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

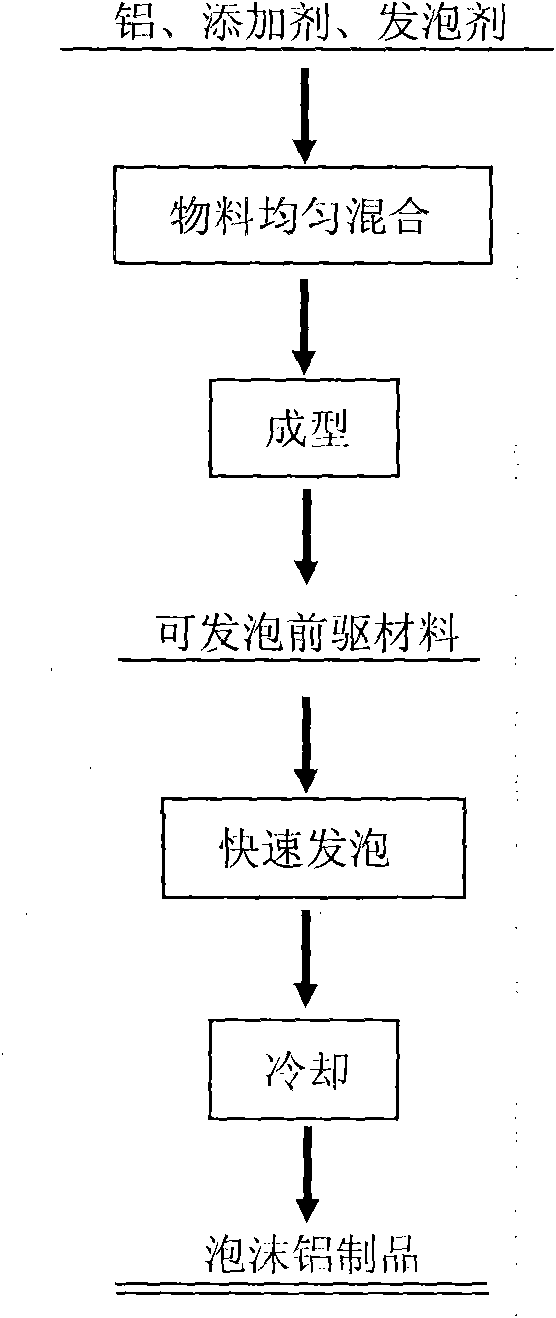

[0046] Embodiment 1: a kind of preparation method of metal foam material is as follows:

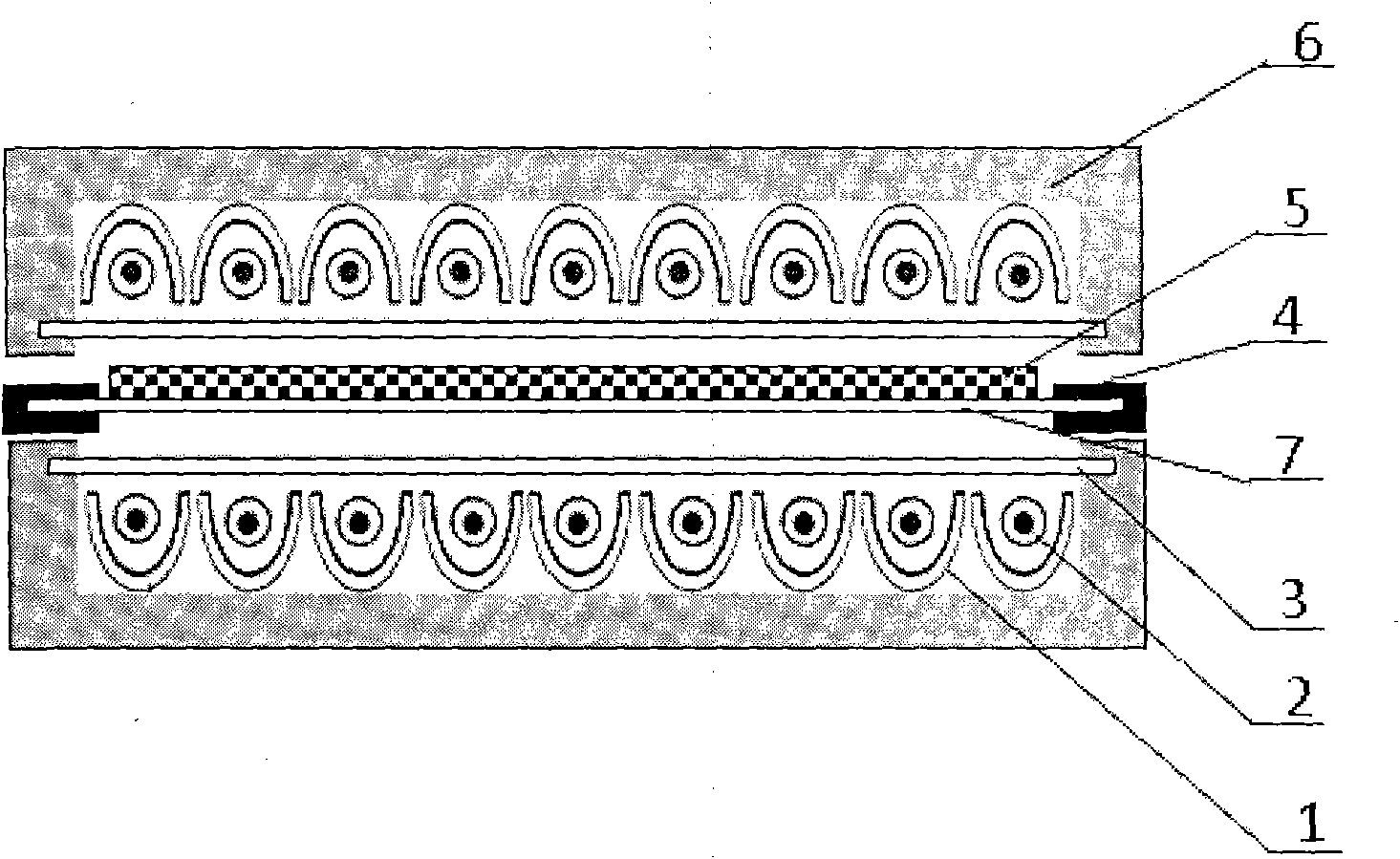

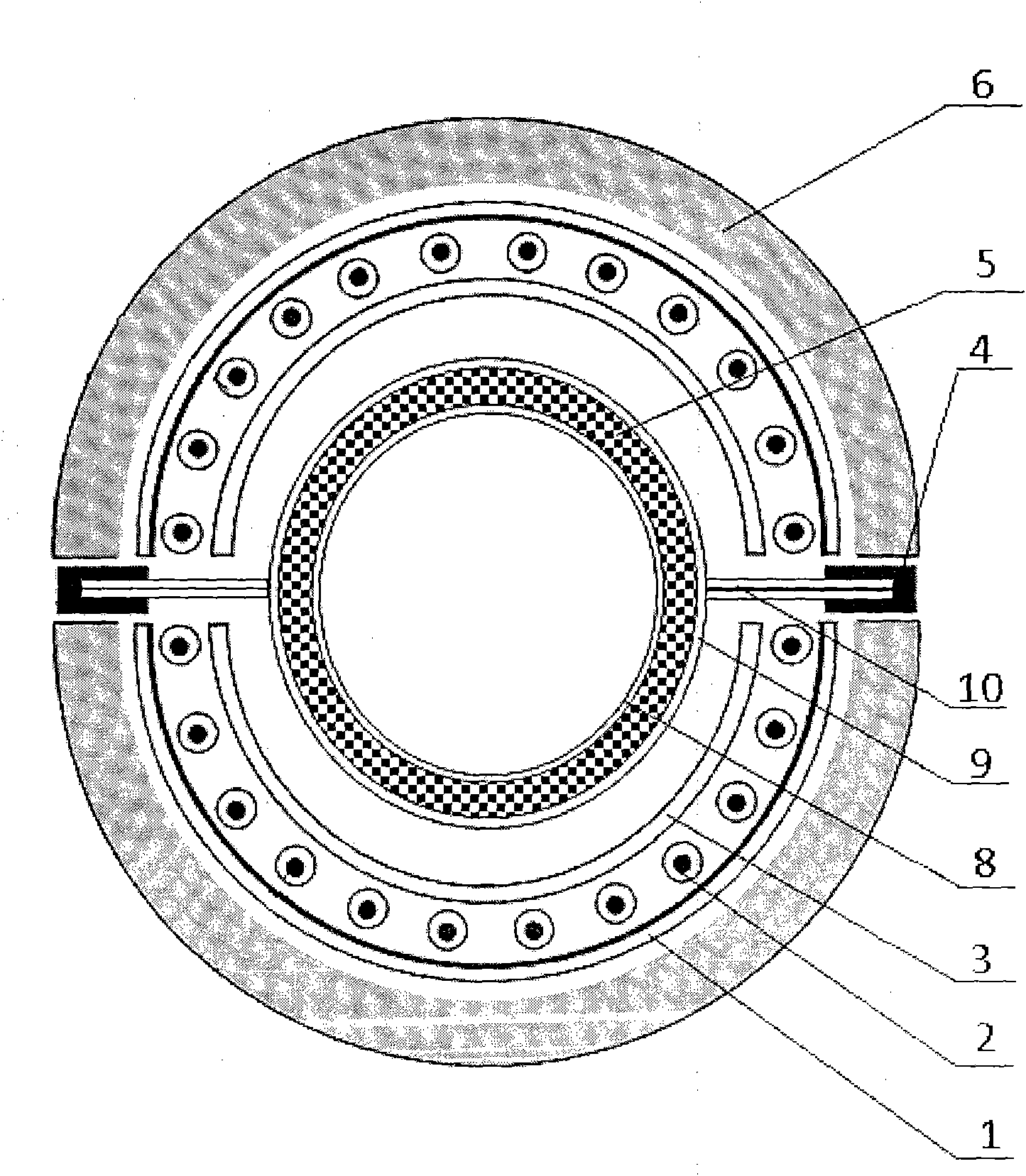

[0047] Take 850g of pure aluminum and melt it at 800°C-850°C, add 120g of metal silicon and 30g of metal calcium respectively to prepare Al-12%Si-3%Ca alloy melt, stir evenly and cool down to 600°C-650°C, add Titanium hydride accounting for 0.5-1.5% of the mass of the aluminum alloy melt and stirred evenly, the particle size of titanium hydride is 250-300 mesh and oxidized at 500°C for 1 hour, the stirring speed is 1000-3000r / min, and the stirring time is 3-5min. The aluminum alloy melt containing titanium hydride is poured into a flat ingot and cut into a 5mm thick plate, which is the foamable precursor 5, and the output voltage of the thyristor in the temperature control device is adjusted to change the temperature of the infrared radiator. Transmit power so that the temperature between the upper and lower heating mantles is at a certain temperature between 800°C and 1100°C, the distanc...

Embodiment 2

[0048] Embodiment 2: a kind of preparation method of metal foam material is as follows:

[0049] Take 497.5g of aluminum powder and 2.5g of magnesium powder for preliminary mixing, then take titanium hydride powder with a mass fraction of 0.5-1.0% of the mixed powder and pour them into the mixing tank together, seal the mixing tank and place it in the electric mixing tank Rotate and mix on the rollers of the machine, the mixing time is 0.5-1.5h, then pour the uniformly mixed material into the mold and compress it axially, the pressure is 300-500MPa, and the green body obtained is cut into thicknesses of 5mm foamable precursor 5, adjust the output voltage of the thyristor in the temperature control device and then change the emission power of the infrared radiator, so that the temperature between the upper and lower heating mantles is at a certain temperature between 800°C and 1100°C Next, the distance between the two heating mantles is 60 mm, and the prepared precursor 5 is pl...

Embodiment 3

[0050] Embodiment 3: a kind of preparation method of metal foam material is as follows:

[0051] Take a total of 500g of titanium hydride powder and aluminum powder accounting for 0.6 to 1.2% of the total mass and pour them into the mixing tank together, seal the mixing tank and place it on the rollers of the electric mixer for rotation and mixing. The mixing time is 0.5~1.5h, then pour the uniformly mixed material into the mold for cold pressing, the pressure is 200~300MPa, then heat the obtained cold compact at 300~500℃ and extrude, the pressure is 200~400MPa, finally Cut the obtained columnar green body into a foamable precursor 5 with a thickness of 5 mm, adjust the output voltage of the thyristor in the temperature control device and then change the emission power of the infrared radiator, so that the temperature between the upper and lower heating covers is at 800 Under a certain temperature between ℃~1100℃, the distance between two heating mantles is 60mm. Place the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com