Method for preparing zirconium iron pink pigment from electrically-melted zirconium oxide

A technology of fused zirconia and zirconia powder, which is applied in the field of producing zirconium-iron red material by fused zirconia, can solve the problems of high content, low reactivity, and insufficient composition and activity, so as to reduce production costs and improve Reactivity, the effect of removing the influence of reaction impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

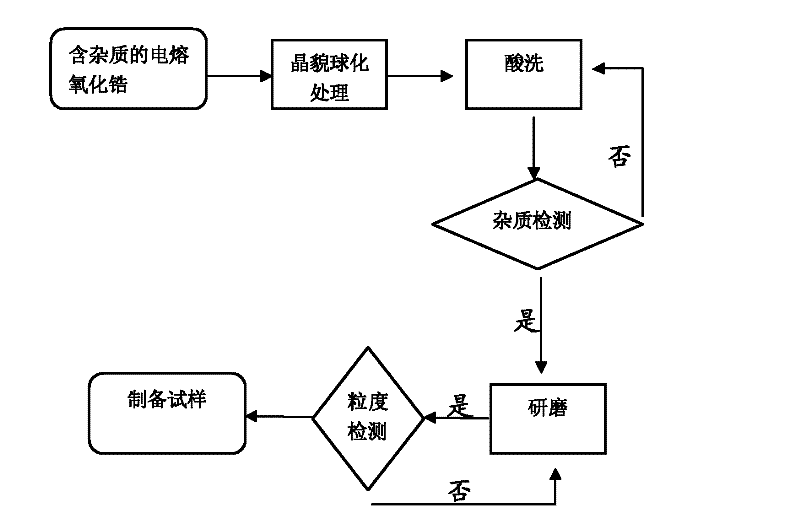

[0017] see process flow figure 1 , the method for producing zirconium-iron red material by electric fusion zirconia of the present invention comprises the following steps:

[0018] 1): Crystal appearance modification treatment: the ordinary fused zirconia powder is subjected to spheroidization treatment by a special device, so that the morphology of fused zirconia tends to be close to a spherical state;

[0019] 2) Remove impurities: wash the product obtained in step 1) with dilute acid, which can be 1% (mass) dilute sulfuric acid or dilute hydrochloric acid, and pickle until the impurity Al in the fused zirconia 2 o 3 , Fe 2 o 3 , SiO 2 ,P 2 o 5 Each content is less than 0.1% (mass), and some samples are taken in the process and pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com