Composite oxide carrier and preparation method thereof

A composite oxide and carrier technology, which is applied in catalyst carriers, chemical instruments and methods, chemical/physical processes, etc., can solve the problems that the carrier is difficult to satisfy the high specific surface, uneven distribution of zirconia, and high preparation cost at the same time. Pore volume, acidity and alkalinity can be adjusted, and the preparation cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

[0047] According to experiment number 1 carrier raw material ratio and operating conditions, add mixed surfactant 4 when gelling, it is composed of: mixed surfactant 2: polyvinyl alcohol 150000=1:1 (weight ratio), wherein ammoniacal liquor: mixed Surfactant 4=5:1 (weight ratio). The composite oxide carrier was obtained, and its main properties are listed in Tables 1 and 2.

[0048] Experiment number 12: Example 5

[0049] According to experiment number 2 carrier raw material ratio and operating conditions, add mixed surfactant 5 when forming a gel, and it is composed of: mixed surfactant 1: polyvinyl alcohol 20000: polyvinyl alcohol 50000: polyvinyl alcohol 150000=1: 1:1:1 (weight ratio), wherein ammonia: mixed surfactant 5=20:1 (weight ratio). The composite oxide carrier was obtained, and its main properties are listed in Tables 1 and 2.

Embodiment 6

[0051] According to experiment number 2 carrier raw material ratio and operating conditions, add mixed surfactant 6 when forming a gel, and its composition is: mixed surfactant 2: methylcellulose 50000: methylcellulose 100000=5:1:1 (weight ratio), wherein ammoniacal liquor: mixed surfactant 5=20:1 (weight ratio). The composite oxide carrier was obtained, and its main properties are listed in Tables 1 and 2.

[0052] Experiment No. 14: Example 7

[0053] According to experiment number 2 carrier raw material ratio and operating conditions, add mixed surfactant 7 when forming gel, it is composed of: mixed surfactant 2: hydroxypropyl methylcellulose 150000: hydroxypropyl methylcellulose 100000 : Propyl cellulose 100000=3:1:1:1 (weight ratio), wherein ammonia: mixed surfactant 5=20:1 (weight ratio). The composite oxide carrier was obtained, and its main properties are listed in Tables 1 and 2.

[0054] Experiment No. 15: Example 8

[0055] According to experiment number 4 carri...

Embodiment 9

[0057] According to experiment number 7 carrier raw material ratio and operating conditions, add mixed surfactant 9 when aging, it is composed of: mixed surfactant 1: polyvinyl alcohol 20000: caproyl acetone = 1:25:5 (weight ratio) , wherein the addition of tensio-active agent is 10% (weight ratio) of ammoniacal liquor. The composite oxide carrier was obtained, and its main properties are listed in Tables 1 and 2.

[0058] Table 1 Proportion of each oxide in the composite oxide support (mass percentage)

[0059] serial number SiO 2 % ZrO 2 % Al 2 o 3 % 1 37 10 53 2 16 6 78 3 16 6 78 4 30 9 61 5 30 9 61 6 12.5 2.5 85 7 70 2 28 8 12.5 2.5 85 9 12.5 2.5 85 10 12.5 2.5 85 11 37 10 53 12 16 6 78 13 16 6 78 14 16 6 78 15 30 9 61 16 70 2 28

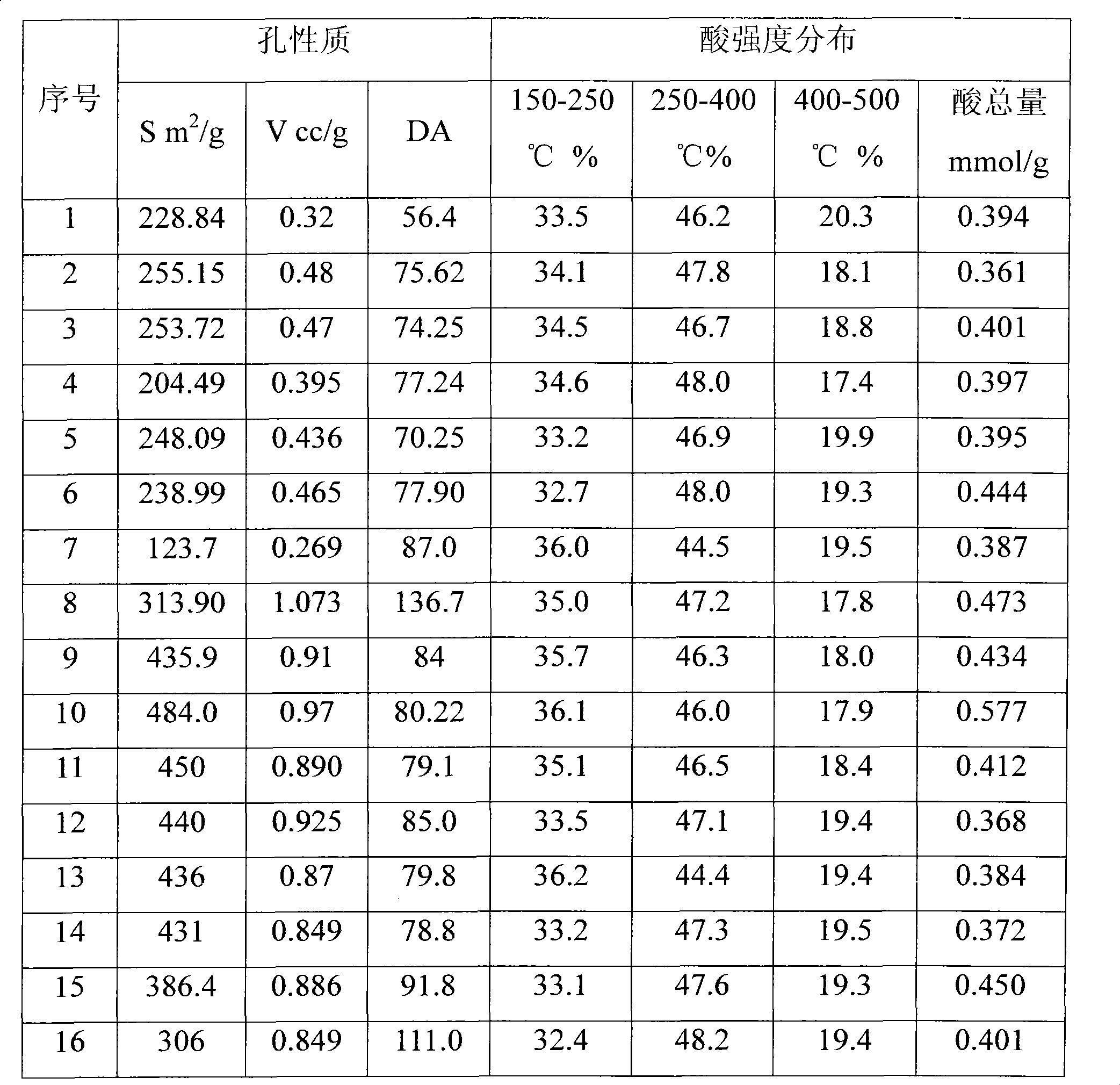

[0060] Table 2 Physical properties of composite oxide supports

[0061]

[0062] Note: 1. DA is the aver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com