Interconnection structure made of redirected carbon nanotubes

a technology of redirected carbon nanotubes and interconnection structures, which is applied in the direction of cable junctions, cable terminations, basic electric elements, etc., can solve the problems of difficult control of catalyst deposition and cnt growth, difficult to completely eliminate copper, and difficult to use copper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

I / First Embodiment of the Invention

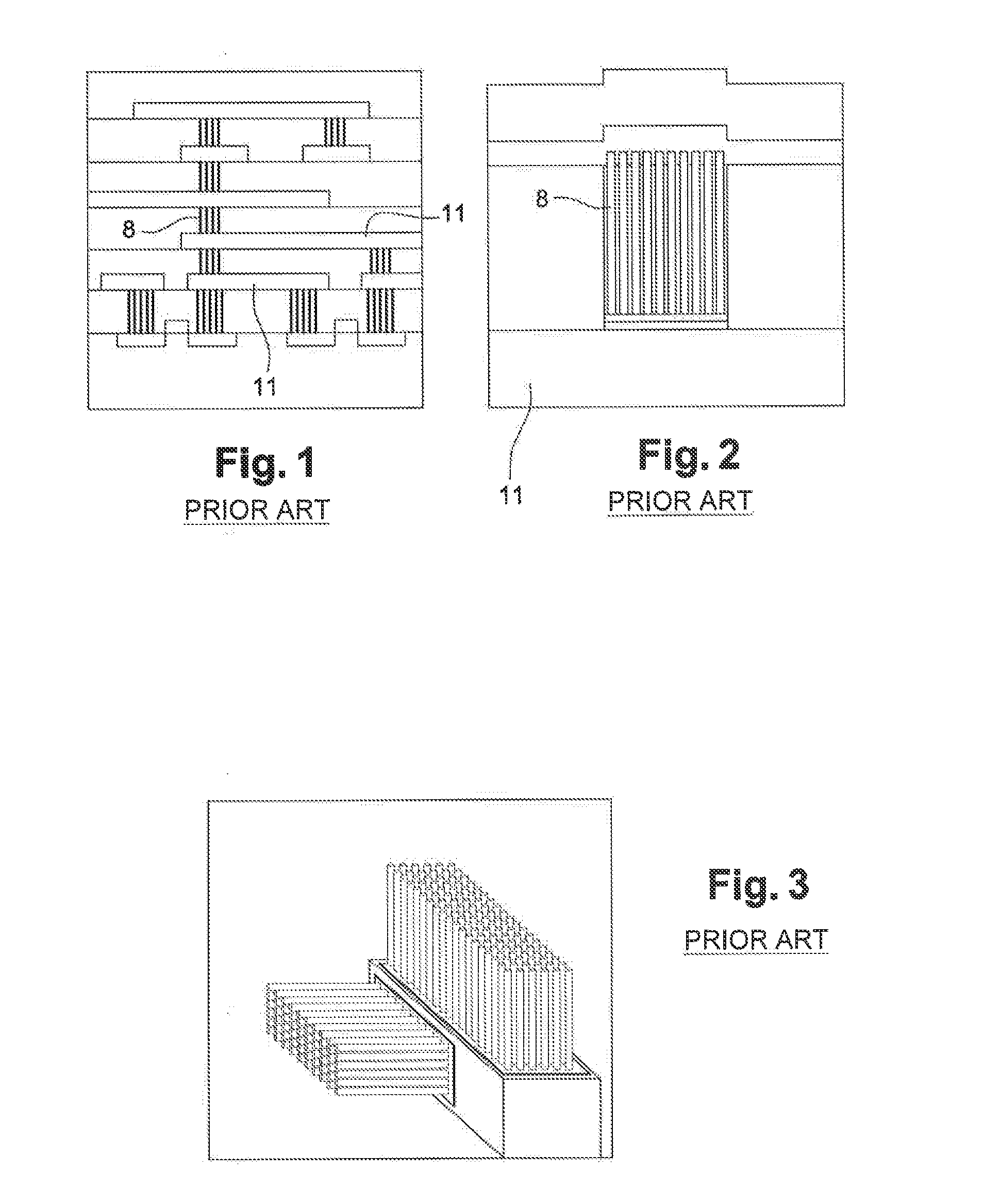

[0079]As already mentioned, this first embodiment by overlapping of vertical CNT bundles is illustrated in FIGS. 5A and 6A, respectively.

[0080]More specifically, its forming method is illustrated in FIG. 8. It should be noted that steps A to F are schematically shown in end views, that is, perpendicular to groove 3, FIGS. 8G and 8H corresponding to views parallel to the direction of groove 3.

[0081]A / Forming of the Base Structure:

[0082]An insulating layer 1, made of silica or of a low-K material of microelectronics is deposited on conductive layer 2. Conductor 2 typically is aluminum.

[0083]B / Etching of the Groove:

[0084]Within insulator 1, groove 3, which will become future line 4, is formed by conventional lithography methods.

[0085]C / TiN Deposition:

[0086]A TiN layer 5, having a thickness of approximately 50 nanometers, is deposited in groove 3, if possible by means of a conformal deposition method. TiN has the function of inhibiting the growth o...

second embodiment

II / Second Embodiment of the Invention

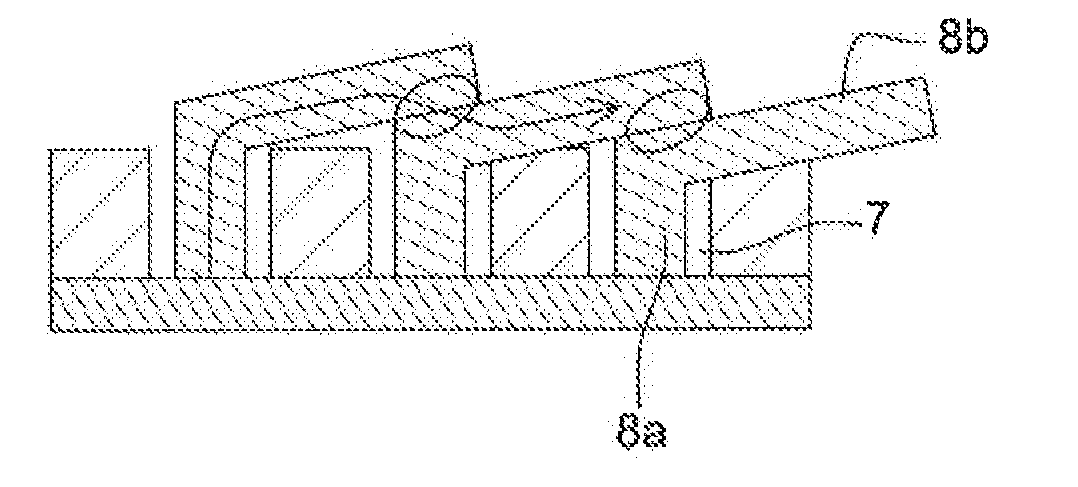

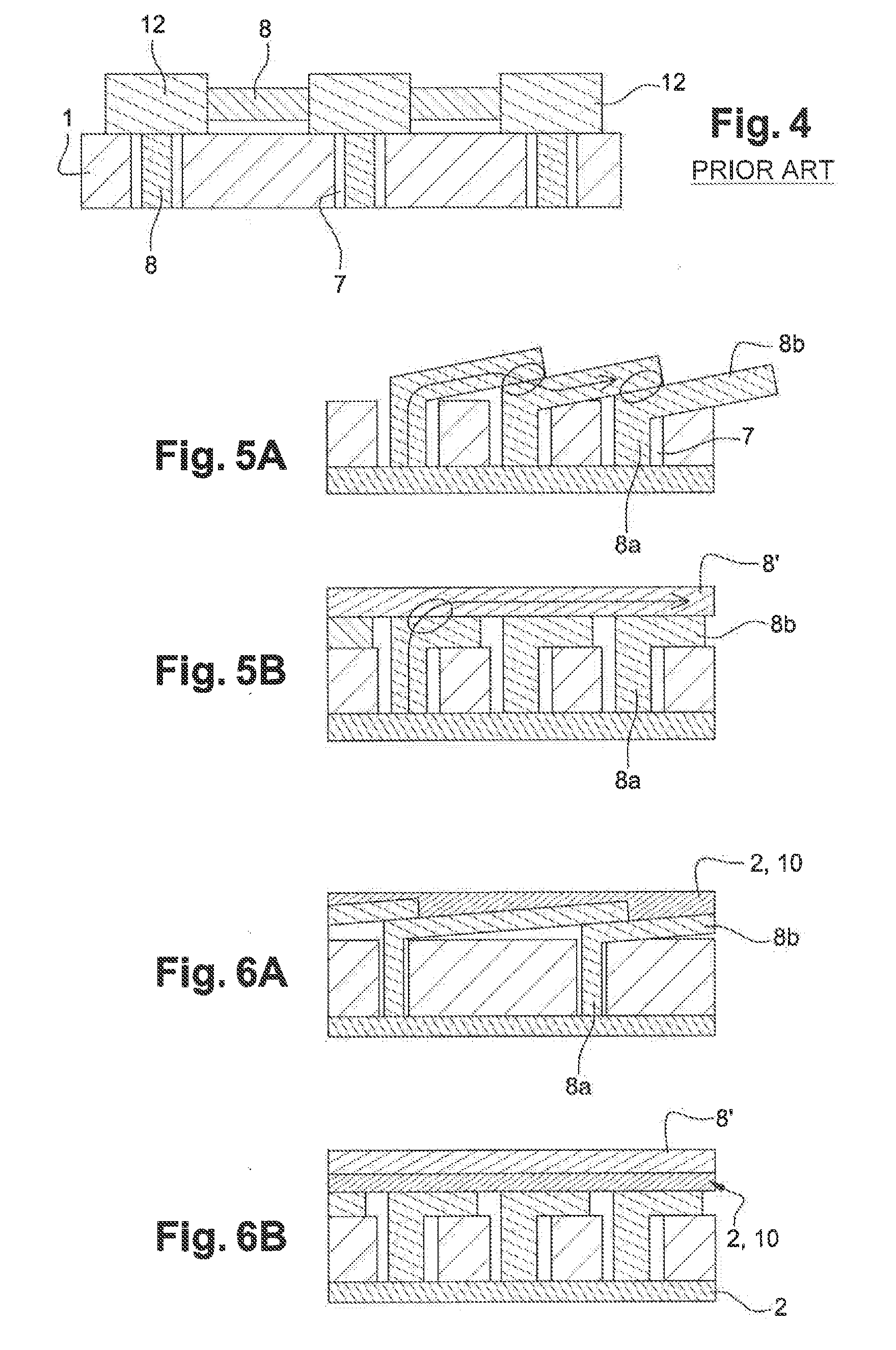

[0105]This second embodiment is illustrated in FIGS. 5B, 6B, 7, 9, and 10,

[0106]FIG. 5B illustrates the fact that the line resistance is lower than in the first embodiment since there is only one interface resistance left.

[0107]FIG. 7 is a drawing illustrating the principle of this second embodiment according to which the substantially perpendicular interconnects, respectively vias 7 and lines 4, come from at least two different bundles of nanotubes, advantageously formed simultaneously. It should be noted that the diagrams of the left-hand portion show cross-section views while the right-hand diagrams are top views.

[0108]Further, the embodiment implying the simultaneous growth of nanotubes 8 and 8′ from line 4 and vias 7 is illustrated in FIG. 9, which is derived from FIG. 8.

[0109]Steps A to C are similar to those of FIG. 8.

[0110]However, before the opening of vias 7, an additional step is carried out (FIG. 9D′): an opening 9 of TiN 5 is formed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| electric resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com