Method for processing graphene-carbon nanotube FET device

A graphene nanoribbon and carbon nanotube technology, applied in nanotechnology, semiconductor devices, electrical components and other directions, can solve the problems of easily contaminated samples, low precision, harsh operating environment, etc., and achieve low cost, high precision, and robustness. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

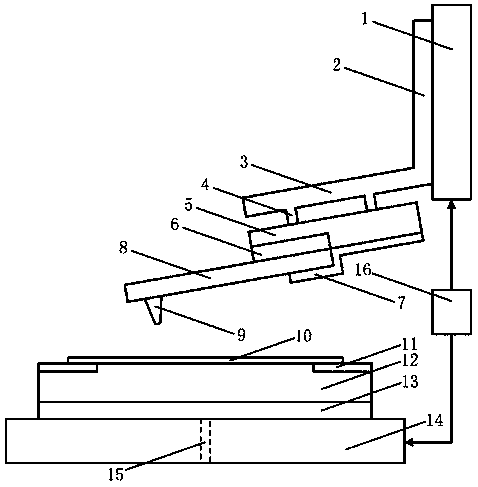

[0044] Such as Figure 1-Figure 6 Shown, the processing method of graphene-carbon nanotube FET device of the present invention, comprises the following steps,

[0045] (1), assembling the graphene sheet 10 on the cutting processing system;

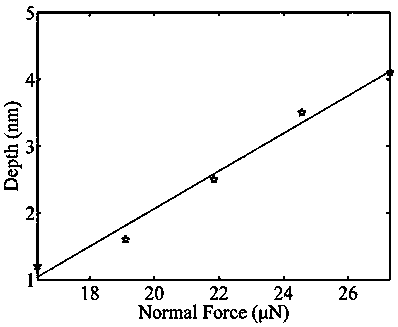

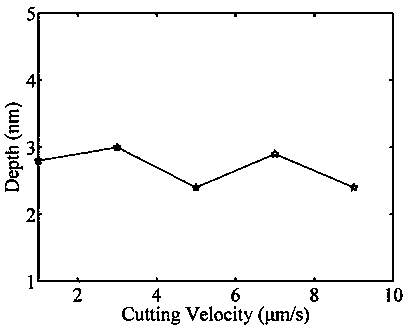

[0046] (2) Set the cutting force, cutting speed and cutting path for the cutting processing system;

[0047] (3) Start the cutting and processing system to cut and process the graphene sheet 10 into graphene nanoribbons 19;

[0048] (4), cutting off the graphene nanoribbon 19, and processing the graphene nanoelectrode whose electrode front end width and electrode pair gap are nanoscale;

[0049] (5) Establish a force model of single-walled carbon nanotubes in a non-uniform electric field;

[0050] (6) Remove the graphene nano-electrode from the cutting processing system and place it on the circular sample platform 24 and fix it under negative pressure, titrate the single-walled carbon nanotube solution after the graphene nano-electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com