Substrate supporting mechanism

A technology for a substrate and a holding surface, applied in the field of manipulators, can solve the problems of transporting the substrate to the correct position, unable to obtain the substrate W to slide, unable to crack the substrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Next, an embodiment of the present invention will be described. In this embodiment, a substrate (wafer size: 300 mm) is used for a transfer test using a substrate transfer robot, and the positional deviation of the substrate relative to the end effector is measured. .

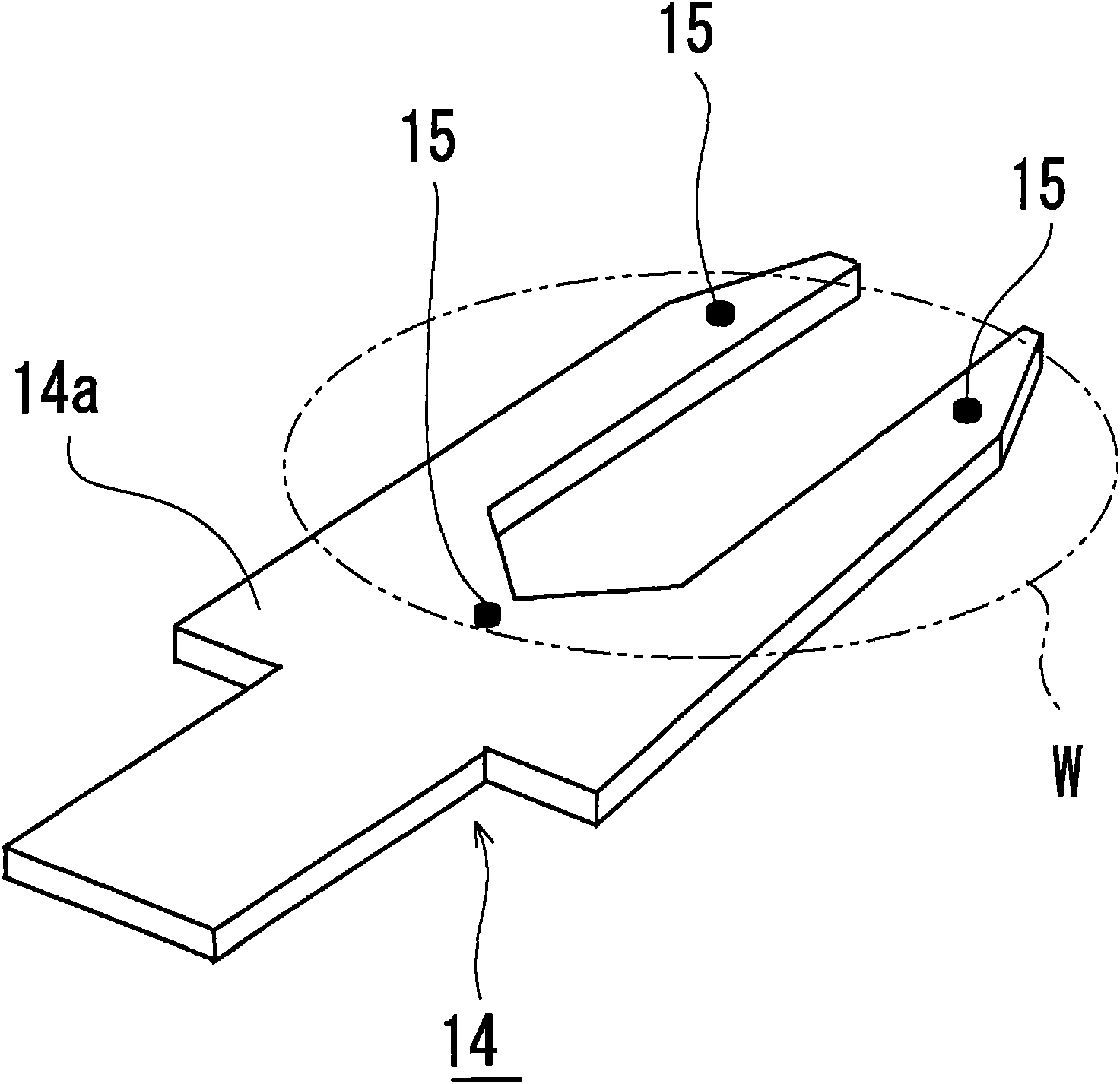

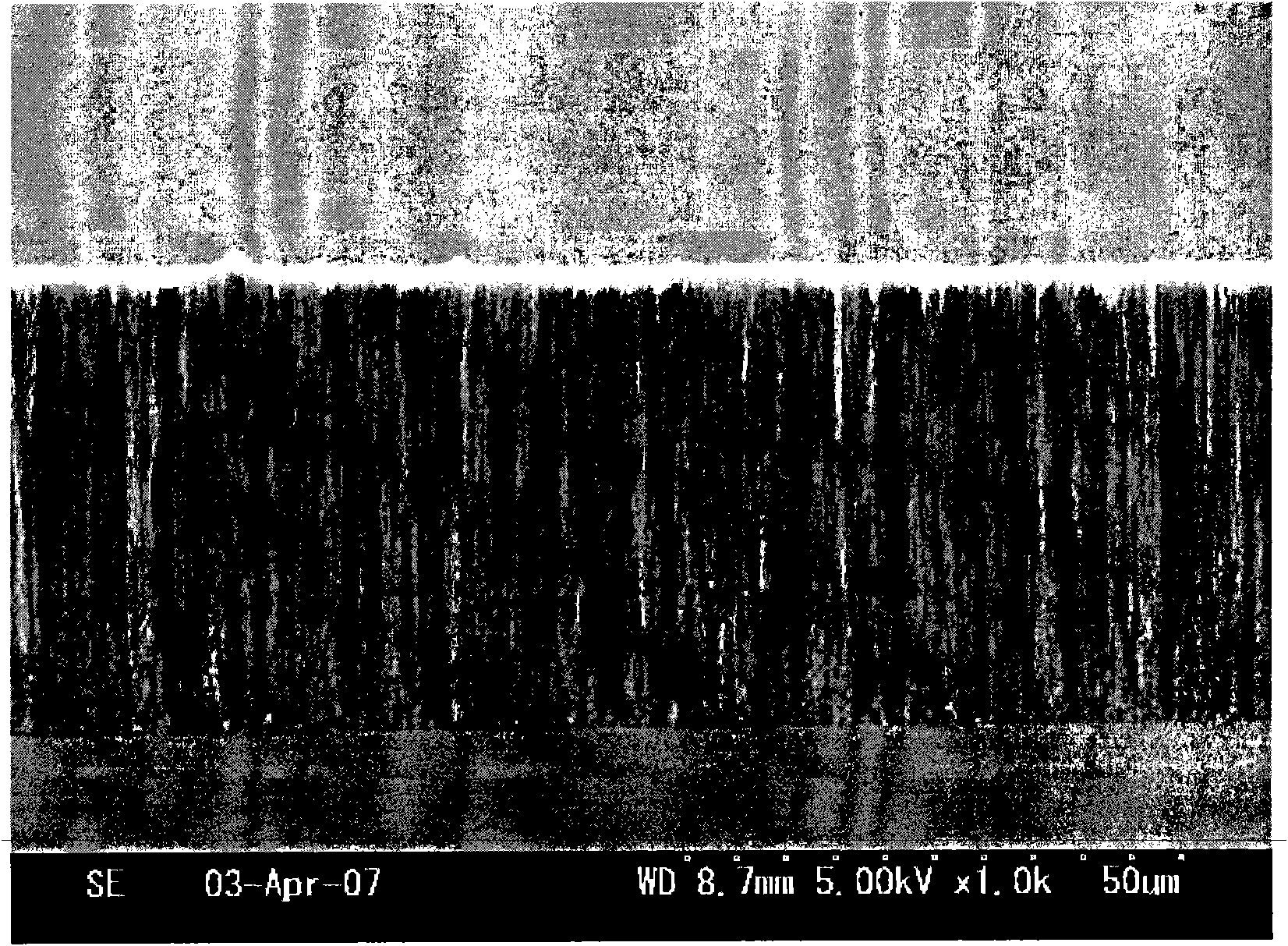

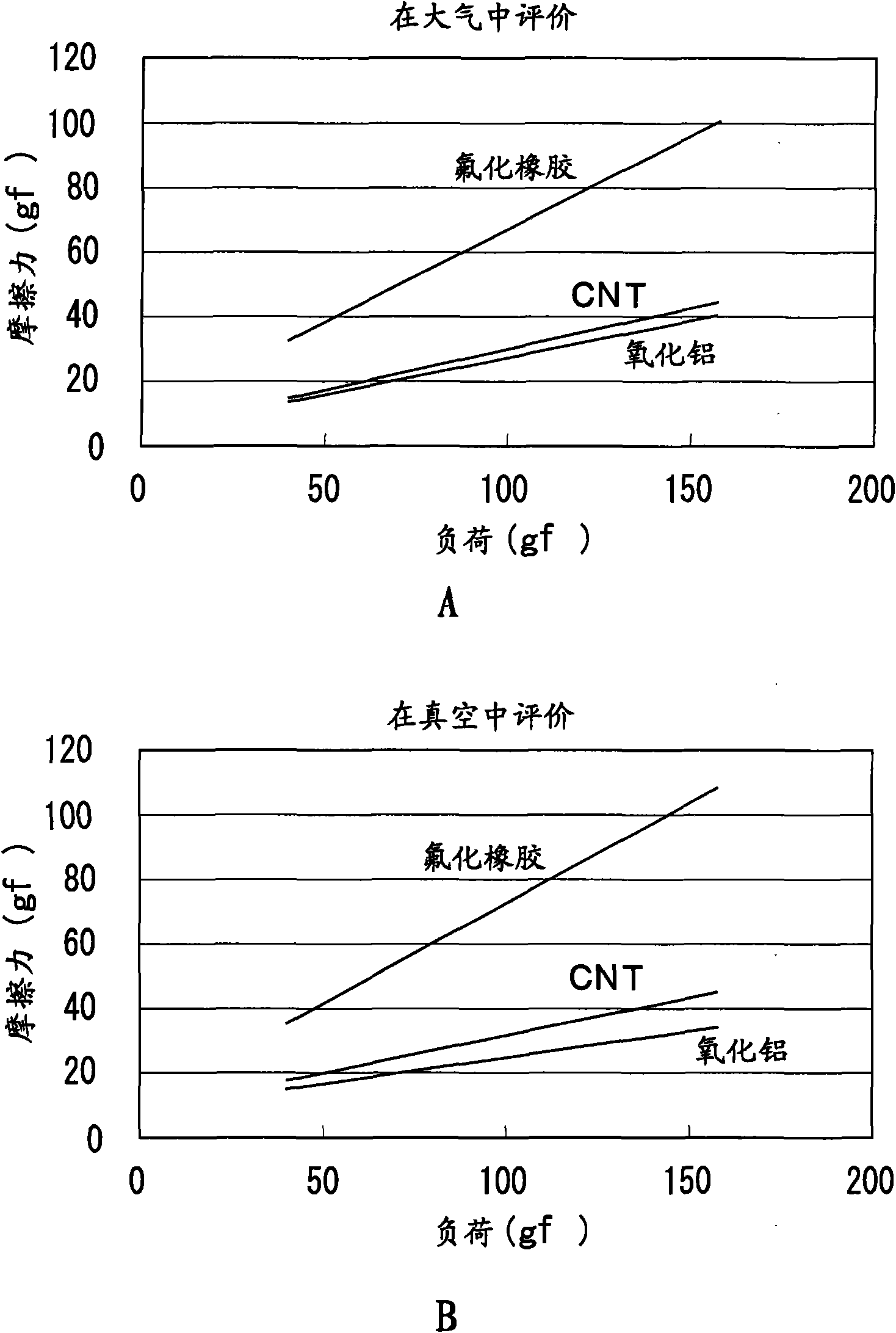

[0040] The end effector is made of aluminum oxide, and its upper surface is mounted with figure 1 and figure 2 The carbon nanotube holding part 15 shown in , the installation position of the holding part is figure 1 The 3 locations shown are 2 locations at the tip of the bifurcation and one location at the base of the bifurcation. The holding part adopts a structure in which carbon nanotubes are grown on a silicon wafer, and the growth conditions of the carbon nanotubes are the same as those of figure 2 The samples shown were grown under the same conditions. The total area of the holding part is 11.5cm 2 .

[0041] The handling test is to let the robot repeatedly perform the following actions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com