Lithium ion battery cathode material

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor cycle stability, many uncertain factors, and difficulty in mass production, and achieve excellent processing performance and long battery life , the process is easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

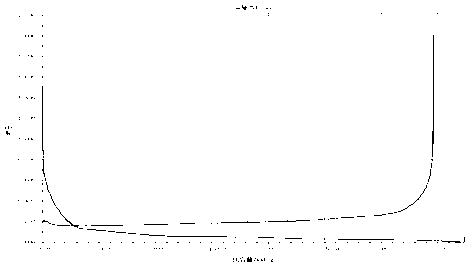

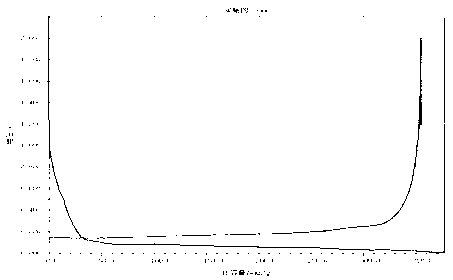

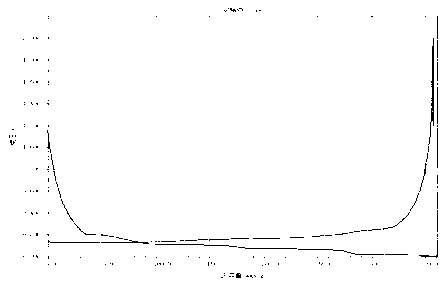

Image

Examples

Embodiment 1

[0034] Embodiment 1 (comparative example):

[0035] ①Material preparation: Weigh 150g of coal coke and 10g of asphalt, ready for use;

[0036] ②Feeding: Dissolve the prepared raw materials in the organic solvent carbon disulfide, alternately add them into the pressure vessel while stirring, continue to stir for 3 hours, and then add 9% of the total weight of beetroot oil within 20 minutes;

[0037] ③Heating up: Then heat up and heat up, within 6 hours, the temperature rises to 500°C for surface modification treatment; when the temperature rises for 3 hours, negative pressure extracts the volatiles in the above substances;

[0038] ④Keep constant temperature: keep constant temperature at 500°C for 4 hours, and extract volatile matter at the same time;

[0039] ⑤ Natural cooling to room temperature;

[0040] ⑥High temperature 3000℃, after 24 hours of graphitization treatment, then cool naturally.

[0041] Nitrogen or hydrogen gas is fed into the heat treatment process for pro...

Embodiment 2

[0046] Present embodiment ①~⑥ steps are completely identical with example 1;

[0047] ⑦Add 5g of carbon nanotubes for ultrasonic dispersion, pass the obtained powder through a 200-mesh sieve, and the sieved powder is the modified carbon powder sample;

[0048] Nitrogen or hydrogen gas is fed into the heat treatment process for protection, and other inert gases such as argon or its mixed gas can also be fed.

[0049] The obtained carbon modified material is spherical or ellipsoidal, with an average particle size D50 of 19.2 μm, a tap density of about 1.0 g / cc, and a BET specific surface area of 2.0 m 2 / g or so, the real density is about 1.25g / cc, and there are a lot of nanopores inside, the pore diameter is 0.2~0.6nm.

[0050] Other parts of this embodiment are identical to Embodiment 1.

[0051] The first discharge capacity of the material is 352.2mAh / g, and the first charge and discharge efficiency is 94.5%.

Embodiment 3

[0053] ①Material preparation: Weigh 120g of coal coke and 12g of asphalt and prepare for use;

[0054] ②Feeding: Dissolve the prepared raw materials in the organic solvent carbon disulfide, alternately add them into the pressure vessel while stirring, continue to stir for 2 hours, and then add 3% of the total weight of beetroot oil within 10 minutes;

[0055] ③Heating up: Then heating up, within 7 hours, the temperature rises to 500°C for surface modification treatment; when the temperature rises for 2 hours, negative pressure extracts the volatiles in the above substances;

[0056] ④Keep constant temperature: keep constant temperature at 500°C for 5 hours, and extract volatile matter at the same time;

[0057] ⑤ Natural cooling to room temperature;

[0058] ⑥High temperature 2800℃, after graphitization treatment for 48 hours, then cool naturally.

[0059] ⑦ Add 6g of carbon nanotubes for ultrasonic dispersion, pass the obtained powder through a 200-mesh sieve, and the sieve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com