Antistatic PEEK resin material and preparation method thereof

A resin material and antistatic technology, applied in the field of antistatic PEEK resin material and its preparation, can solve the problems of limited improvement of the mechanical properties of PEEK resin, affecting the surface resistance of the material, uneven distribution of carbon fibers, etc., so as to improve the mechanical properties and reduce the Effect of surface resistance and wear resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The preparation method of this antistatic PEEK resin material, its step comprises:

[0016] A. Dissolve sulfonated PEEK in water, add carbon nanotubes, suction filter after stirring, dry and pulverize, wherein the mass ratio of sulfonated PEEK to carbon nanotubes is 1:50;

[0017] B. Place the chopped carbon fiber in a 500°C environment for 6 hours;

[0018] C, 68 parts of PEEK powder and 2 parts of carbon nanotube powder prepared in step A, 30 parts of chopped carbon fiber prepared in step B are added in ethanol, fully stirred so that all materials are evenly blended;

[0019] D. Suction filtration, ethanol recovery, put the mixed material into the cavity of a hot-pressing mold at 395-400°C, and after melting, mold it under a pressure of 10Mpa, and cool and demould;

[0020] E. The material after demoulding is kept at 250° C. for 60 minutes, and the pressure of the whole heat preservation process is 4 Mpa to obtain a finished product.

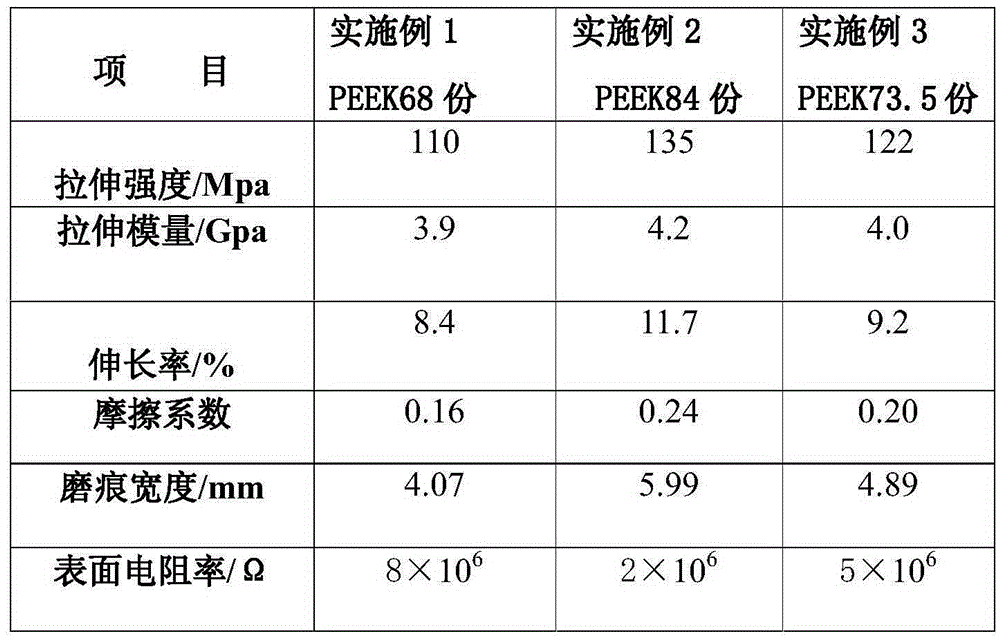

[0021] The performance test wa...

Embodiment 2

[0023] The steps of the preparation method of the antistatic PEEK resin material are basically the same as those in the examples, the difference being: 84 parts of PEEK, 1 part of carbon nanotube, 15 parts of chopped carbon fiber, and the processing time of chopped carbon fiber is 8 hours.

[0024] The performance test was carried out on the prepared antistatic PEEK resin material, and the test results are shown in Table 1.

Embodiment 3

[0026] The steps of the preparation method of the antistatic PEEK resin material are basically the same as those in the examples, the difference being: 73.5 parts of PEEK, 1.5 parts of carbon nanotubes, 25 parts of chopped carbon fibers, and the processing time of chopped carbon fibers is 7 hours.

[0027] The performance test was carried out on the prepared antistatic PEEK resin material, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com