Preparation method for mesopore-micropore core-shell composite molecular sieve catalyst

A composite molecular sieve and catalyst technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of insufficient performance of macromolecular catalytic functions, hydrothermal stability, acid stability and poor strength, etc. problems, to achieve the effect of low price, simple operation, and simple equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

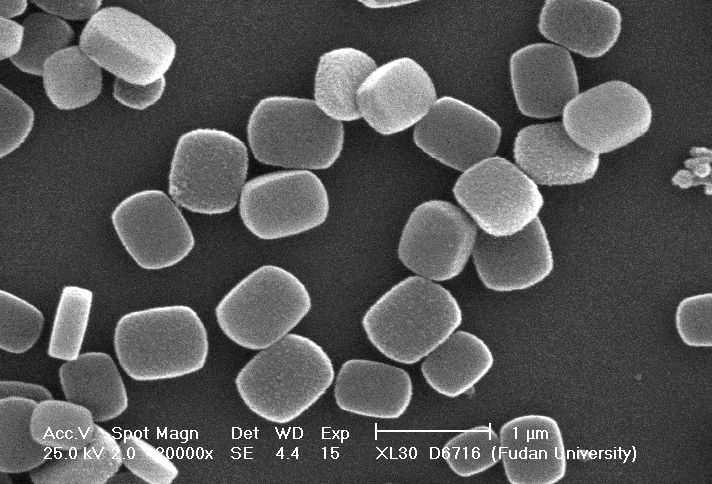

[0041] Preparation of ZSM-5 zeolite molecular sieve with a size of 700 nm: Add 4.9 g of tetrapropylammonium hydroxide aqueous solution with a mass percentage concentration of 50% dropwise to 69.0 g of deionized water, stir well until the solution is clear, and then add ethyl orthosilicate 2.5 g, continued to stir for 12 hours, and the reaction solution was transferred to a hydrothermal kettle and heated for 24 hours at 180 °C. After hydroheating, the product was washed with a large amount of deionized water to neutrality, dried at 100°C for 5 hours, and roasted in an air atmosphere at 550°C for 5 hours in a muffle furnace to obtain the product. Scanning electron microscopy showed that the size of the resulting zeolite was around 700 nm, see figure 1 .

Embodiment 2

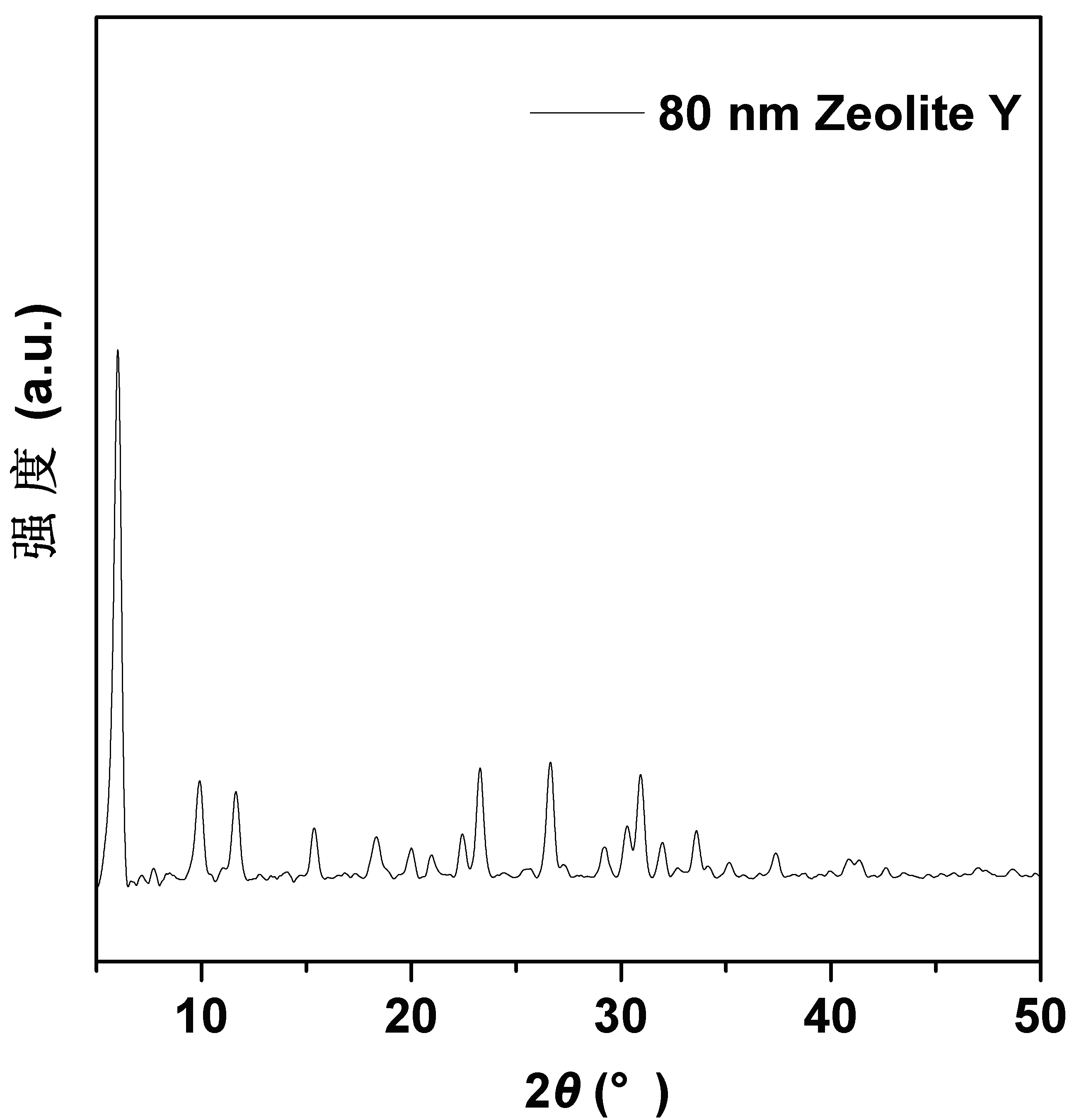

[0043] Preparation of nano-Y zeolite molecular sieve with a size of 80 nm: Add 12.0 g of tetramethylammonium hydroxide aqueous solution with a mass percentage concentration of 25% dropwise to 40.0 g of deionized water, stir well until the solution is clear, and then add 2.5 g of aluminum isopropoxide After stirring for 5 hours, 5.0 g of tetraethyl orthosilicate was added, the stirring was continued for 12 hours, and 6.0 g of aqueous sodium hydroxide solution with a mass percentage of 0.4% was added. This solution was reacted in an oil bath at 100 °C for 7 days. The resulting product was centrifuged at high speed and washed with a large amount of deionized water until neutral. Finally, freeze-dry to obtain nano Y zeolite with a size of 80 nm. The XRD spectrum proves that the obtained nano-Y zeolite molecular sieve is a pure faujasite phase with high crystallinity. See the wide-angle XRD spectrum figure 2 .

Embodiment 3

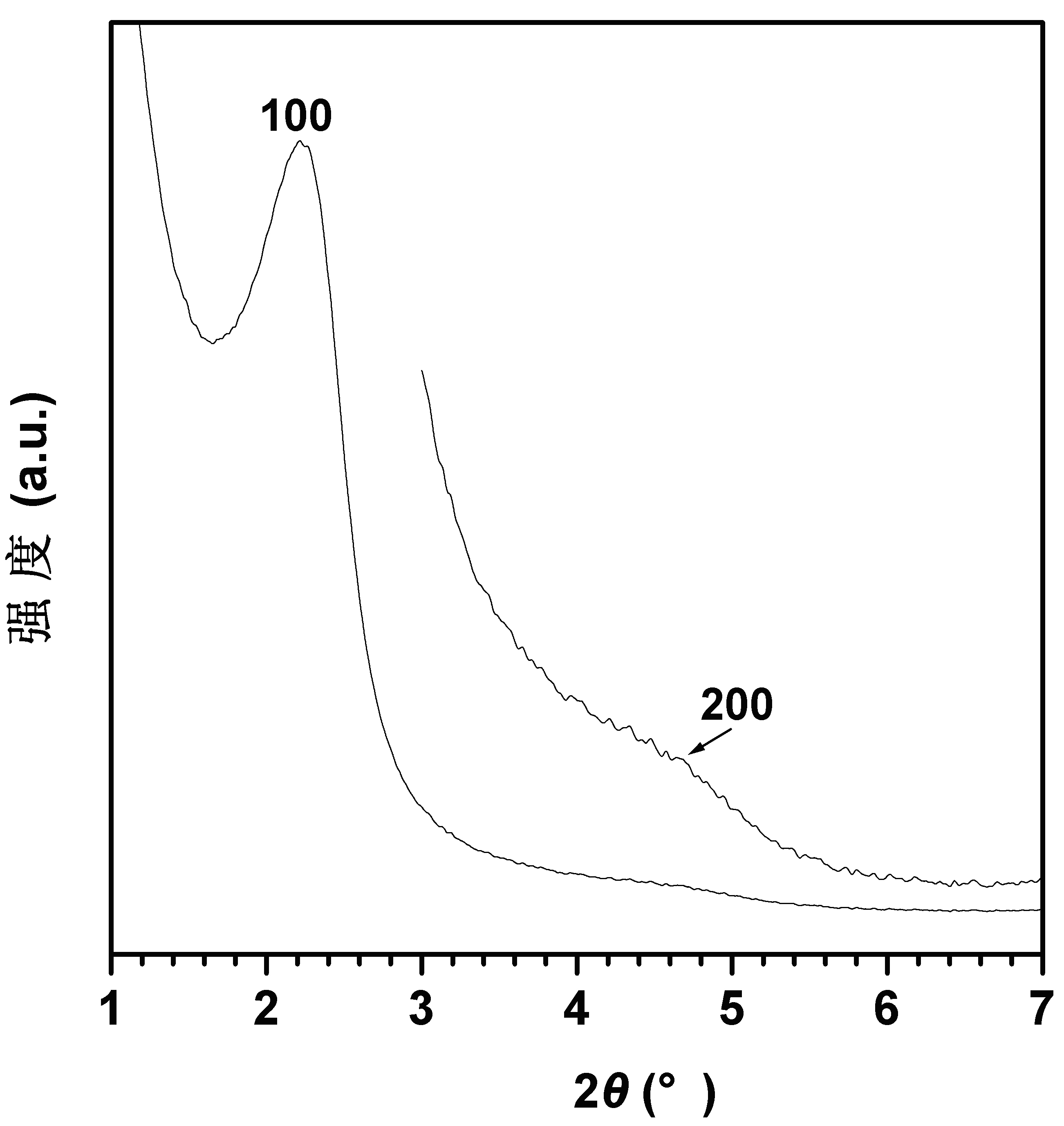

[0045] Using ZSM-5 with a particle size of 700 nanometers as the core, two-dimensional hexagonal p 6 mm Preparation of core-shell composite molecular sieves with mesoporous silica as the shell and a shell thickness of 75 nm: 0.05 g of cationic surfactant cetyltrimethylammonium bromide (CTAB) was dissolved in 10 g of water, In the mixed solution of 6.0 g ethanol and 0.12 g ammonia water, after stirring until the solution becomes clear, disperse 0.05 g ZSM-5 zeolite molecular sieve under the action of 200 W ultrasound, and after the dispersion is uniform, add 0.05 g tetraethyl orthosilicate. After reacting at 25 °C for 4 hours, the product was centrifuged and washed to neutrality, and dried at 100 °C for 5 hours. Then in the muffle furnace at 550 ° C, the air atmosphere was roasted for 5 hours to obtain the product. The XRD spectrum proves that the shell channel space symmetry of the obtained core-shell composite molecular sieve material is p 6 mm , XRD spectrum see imag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com