Method for preparing hydrophilic polyvinyl chloride alloy ultrafiltration membrane

A polyvinyl chloride, hydrophilic technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the inevitable damage to membrane structure and strength, poor thermal and chemical stability of PVC, difficult Realize problems such as industrialized production, and achieve the effects of controllable and stable structure, strong hydrophilicity and anti-pollution, and repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of hydrophilic polyvinyl chloride alloy ultrafiltration membrane comprises the following steps:

[0037] 1) Synthesis of amphiphilic graft copolymer: 15g polyvinyl chloride is dissolved in 150ml nitrogen methyl pyrrolidone, add 75ml hydrophilic monomer polyethylene glycol monomethyl ether methacrylate (PEGMA) (molecular weight is 475g / mol), 0.12g cuprous bromide, 0.048g cupric bromide, 0.39g pentamethyldiethylenetriamine, stirred evenly, moved to 95°C oil bath, protected by high-purity argon, and carried out atom transfer radical polymerization , reacted for 3 hours, then precipitated with a mixture of methanol and water, the volume ratio of methanol and water was 3:7, to obtain amphiphilic graft copolymer polyvinyl chloride-g-polyethylene glycol monomethyl ether methyl Acrylate (PVC-g-PEGMA).

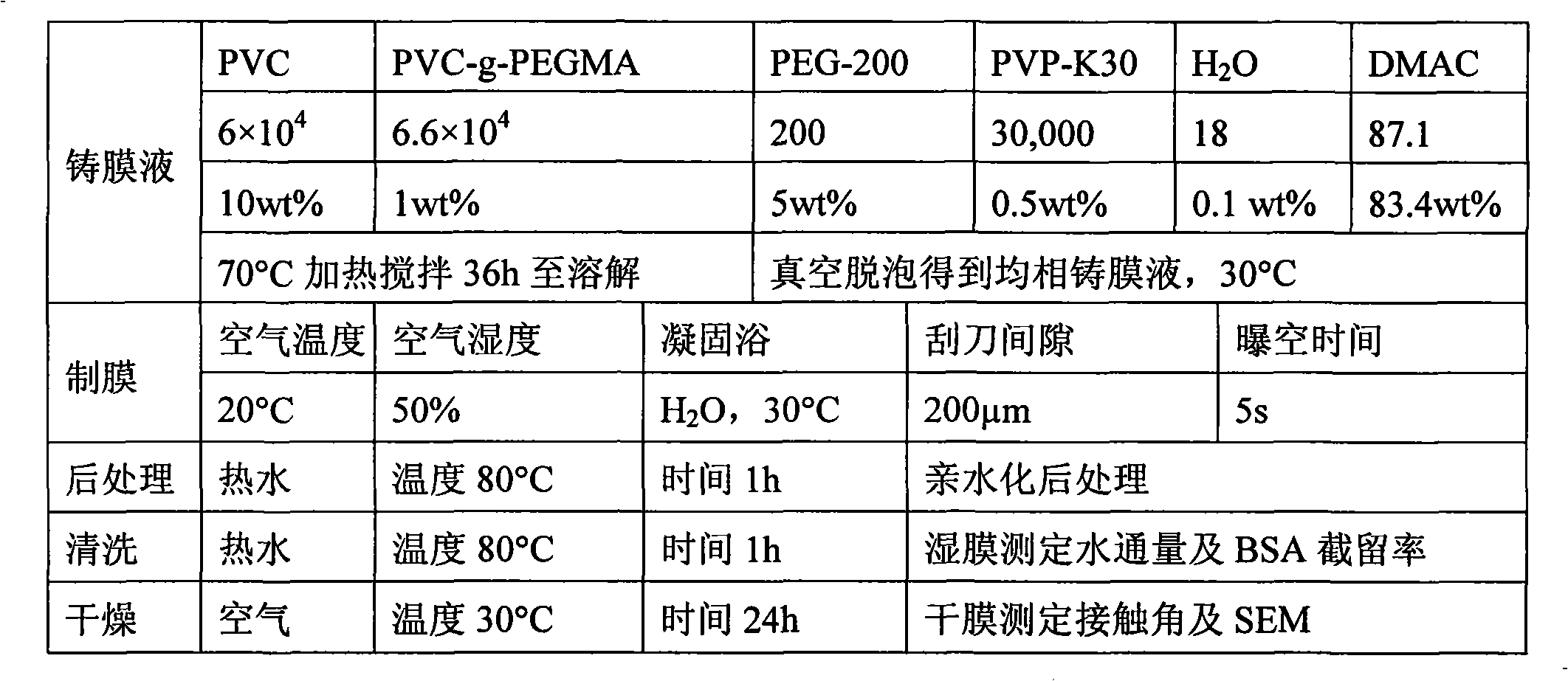

[0038] 2) Preparation of casting solution: 10-30wt% of polyvinyl chloride, 1-10wt% of amphiphilic graft copolymer, 5.5-26wt% of additives, 0.1-2wt% of no...

Embodiment 1

[0045] Embodiment 1 preparation steps are as follows:

[0046] 1) Synthesis of amphiphilic graft copolymer: 15g polyvinyl chloride is dissolved in 150ml nitrogen methyl pyrrolidone, add 75ml hydrophilic monomer polyethylene glycol monomethyl ether methacrylate (PEGMA) (molecular weight is 475g / mol), 0.12g cuprous bromide, 0.048g cupric bromide, 0.39g pentamethyldiethylenetriamine, stirred evenly, moved to 95°C oil bath, protected by high-purity argon, and carried out atom transfer radical polymerization , reacted for 3 hours, then precipitated with a mixture of methanol and water, the volume ratio of methanol and water was 3:7, to obtain amphiphilic graft copolymer polyvinyl chloride-g-polyethylene glycol monomethyl ether methyl Acrylate (PVC-g-PEGMA).

[0047] 2) Preparation of casting solution: 10wt% of polyvinyl chloride, 1wt% of amphiphilic graft copolymer, 0.5wt% of additive polyvinylpyrrolidone; 5wt% of polyethylene glycol; 0.1wt% of non-solvent are blended with solvent...

Embodiment 2

[0053] Embodiment 2 preparation steps are the same as embodiment 1.

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com