Method for modifying polyvinylidene fluoride ultrafiltration membrane by amphiphilic co-polymer

An amphiphilic copolymer, polyvinylidene fluoride membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. Control stability, repeatability, hydrophilicity and anti-pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

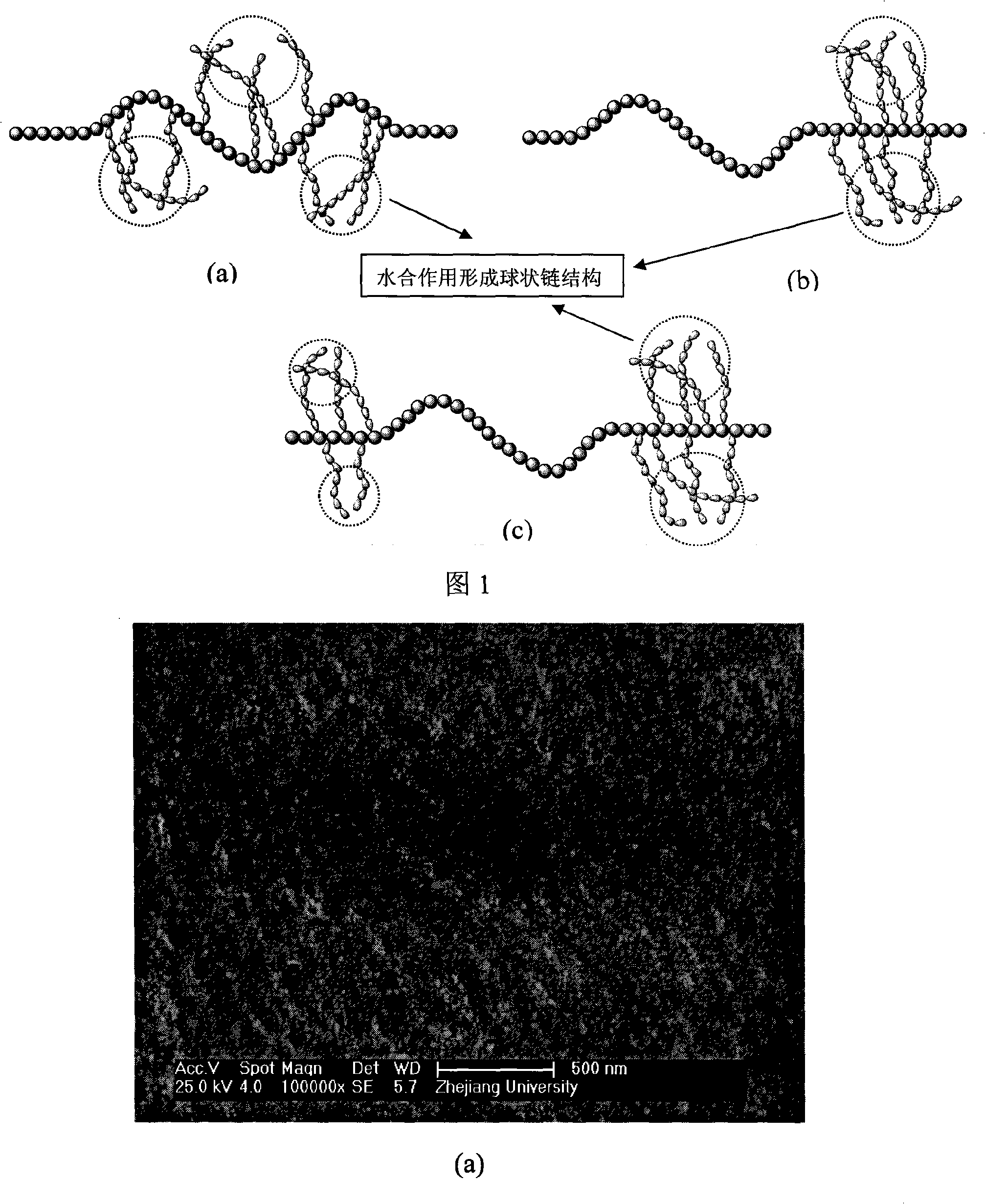

Problems solved by technology

Method used

Image

Examples

Embodiment 1

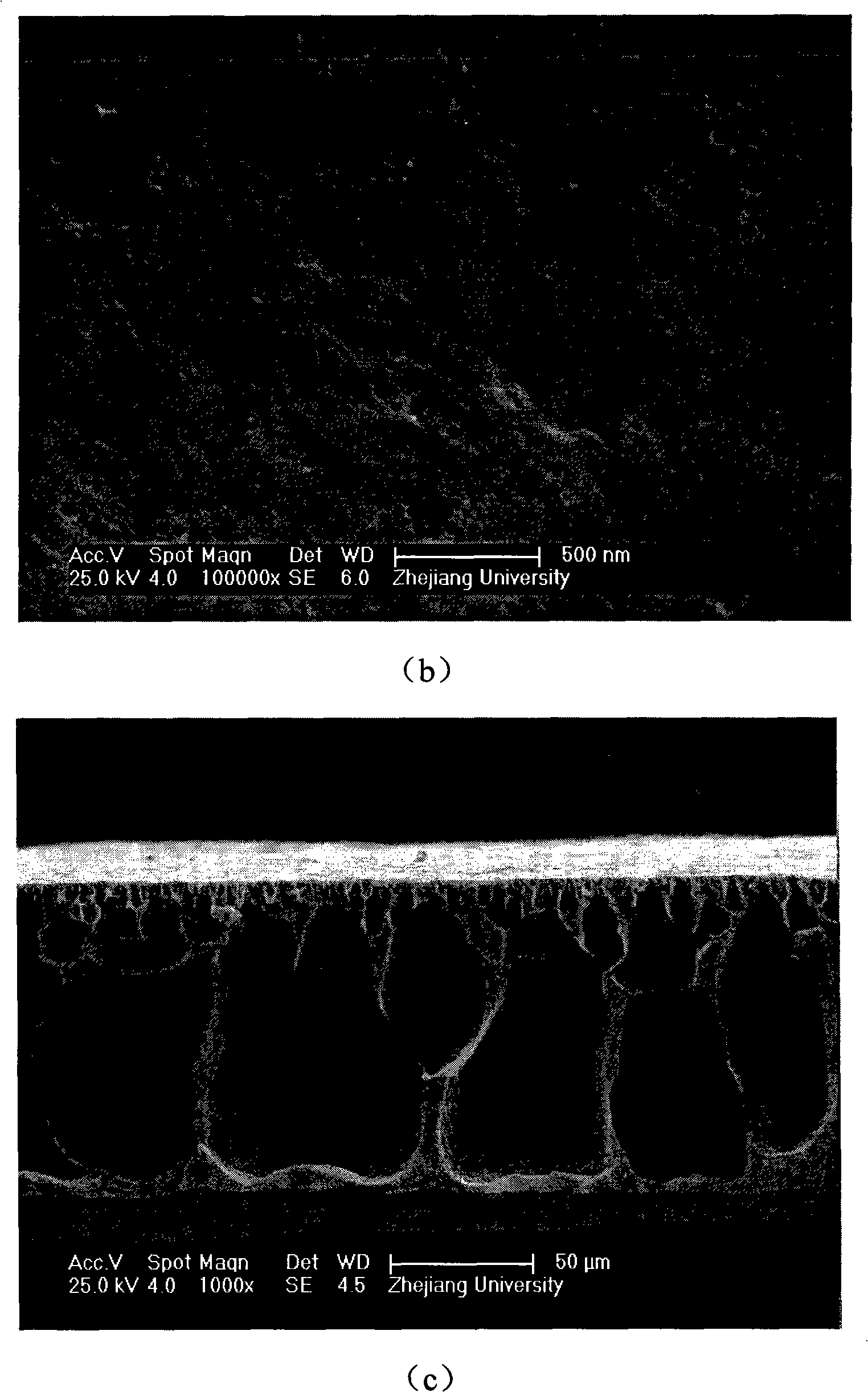

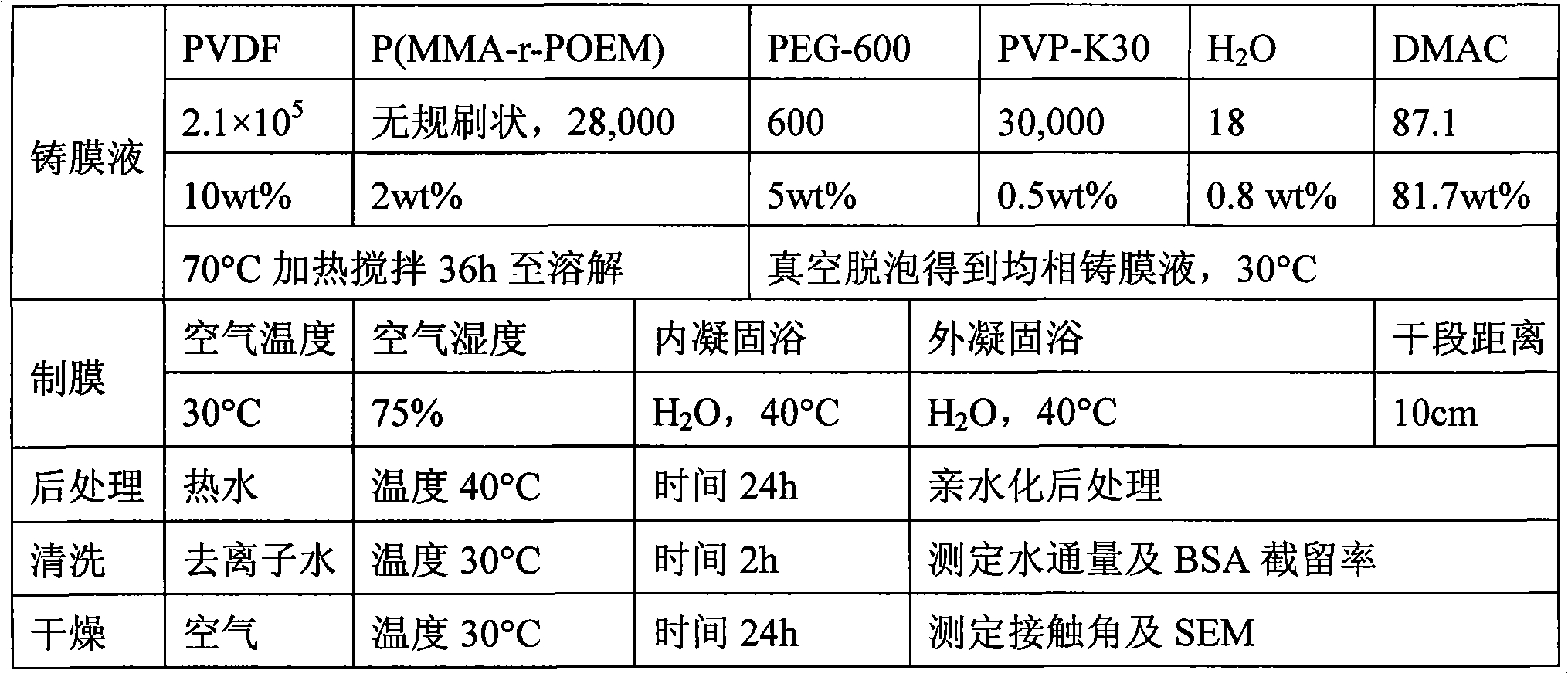

[0049] Embodiment 1 preparation steps are as follows:

[0050] 1) Blend polyvinylidene fluoride, poly(methyl methacrylate-r-monomethyl ether polyoxyethylene methyl methacrylate), additives, non-solvent and solvent, stir at 70°C for 36 hours, filter, Vacuum degassing to obtain the casting solution, the components and concentrations of the casting solution are as follows:

[0051] The molecular weight of polyvinylidene fluoride is 2.1×10 5 , the concentration is 10wt%;

[0052] The molecular weight of poly(methyl methacrylate-r-monomethyl ether polyoxyethylene methyl methacrylate) is 2.8×10 4 , the concentration is 2wt%;

[0053] The additives are: polyvinylpyrrolidone with a molecular weight of 30,000 and a concentration of 0.5 wt%; polyethylene glycol with a molecular weight of 6×10 2 , the concentration is 5wt%;

[0054] The solvent is: N,N-dimethylacetamide, the concentration is 81.7wt%;

[0055] The non-solvent is: H 2 O, concentration is 0.8wt%; Each component distr...

Embodiment 2

[0062] Embodiment 2 preparation steps are the same as embodiment 1.

[0063]

Embodiment 3

[0064] Embodiment 3 preparation steps are the same as embodiment 1.

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com