Method for producing polymer fine particle

A manufacturing method and polymer technology, applied in transportation, packaging, and thin material processing, etc., can solve problems such as clear description of specific methods, deterioration of productivity, and many types of solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0283] Example 1

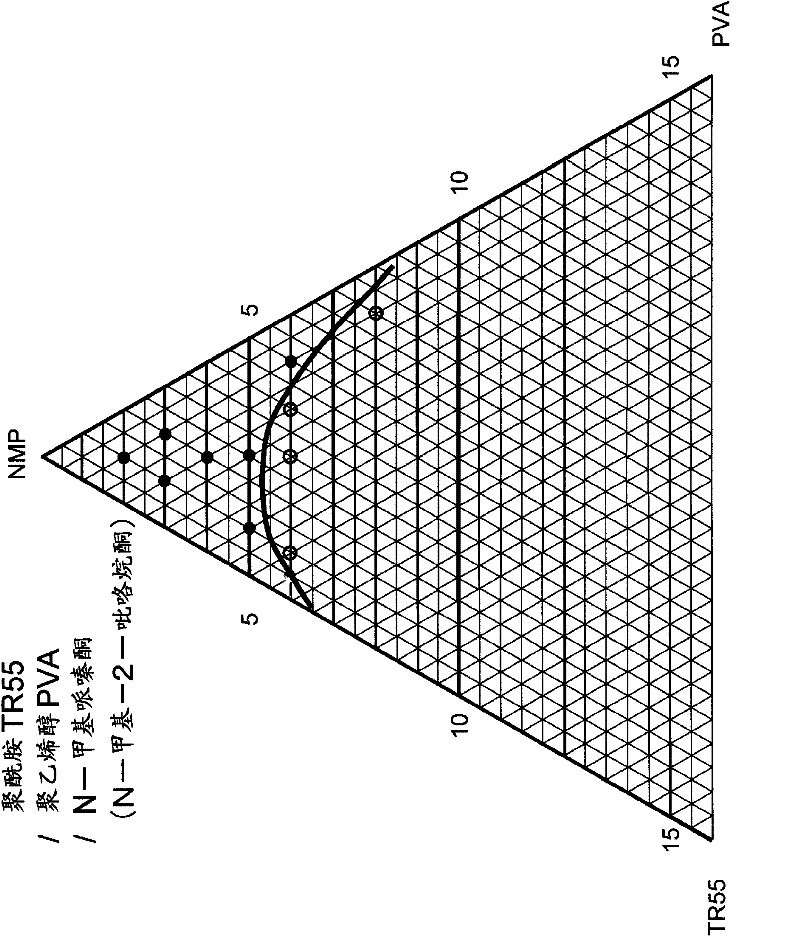

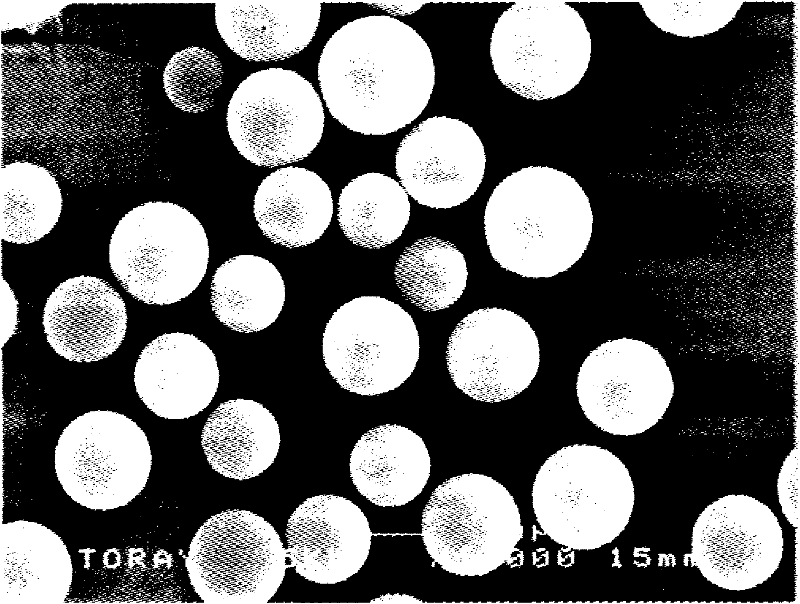

[0284] Into a 100 ml 4-necked flask were charged 2.5 g of polyethersulfone (weight average molecular weight: 67,000 Sumitomo Chemical Co., Ltd. “Sumica Exel (registered trademark)” 5003P) as polymer A, and N-methyl-2- 45 g of pyrrolidone, polyvinyl alcohol as the polymer B (Nippon Synthetic Chemical Industry Co., Ltd. "Goosenol (registered trademark)" GL-05, weight average molecular weight 10,600, SP value 32.8 (J / cm 3 ) 1 / 2 ) 2.5 g, heated to 80° C., and stirred until the polymer was dissolved. The temperature of the system was returned to room temperature, and then 50 g of ion-exchanged water as a poor solvent was added dropwise at a rate of 0.41 g / min via an infusion pump while stirring at a rate of 450 rpm. After adding about 12 g of ion-exchanged water, the system turned white. Stir for 30 minutes after all the water has been added, filter the resulting suspension, wash with 100 g of ion-exchanged water, filter, and vacuum-dry the filtrate at 80°C f...

Embodiment 2

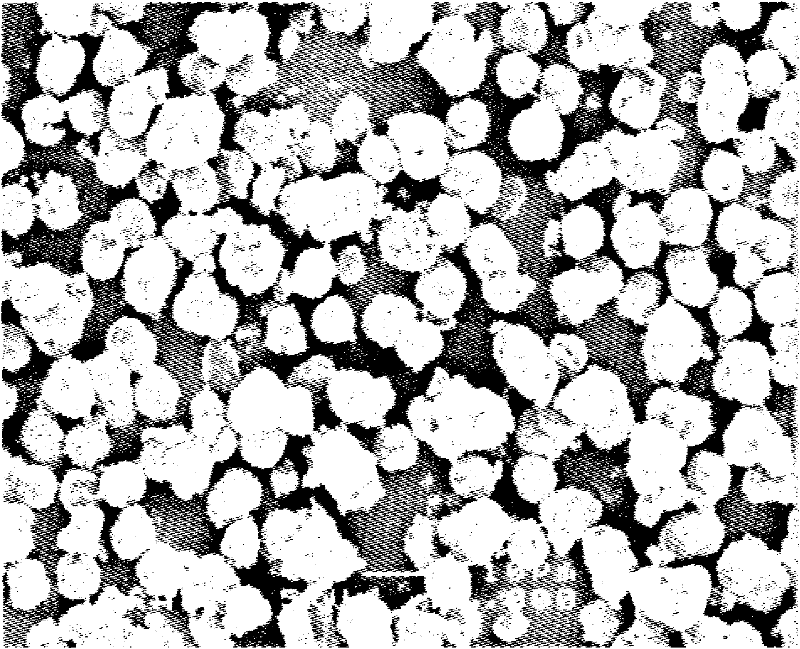

[0285] Example 2

[0286] Into a 100 ml 4-necked flask were charged 2.5 g of polyethersulfone (weight average molecular weight: 67,000 Sumitomo Chemical Co., Ltd. “Sumica Exel (registered trademark)” 5003P) as polymer A, and N-methyl-2- 46.5 g of pyrrolidone, 1.0 g of polyvinyl alcohol as the polymer B (manufactured by Nippon Synthetic Chemical Industry Co., Ltd., "Goisenol (registered trademark)" GL-05), heated to 80° C., and stirred until the polymer was dissolved . The temperature of the system was returned to room temperature, and then 50 g of ion-exchanged water as a poor solvent was added dropwise at a rate of 0.41 g / min via an infusion pump while stirring at a rate of 450 rpm. After adding about 12 g of ion-exchanged water, the system turned white. Stir for 30 minutes after all the water has been added, filter the resulting suspension, wash with 100 g of ion-exchanged water, filter, and vacuum-dry the filtrate at 80°C for 10 hours to obtain 2.1 g of a white solid . ...

Embodiment 3

[0287] Example 3

[0288] Into a 100 ml 4-necked flask were charged 2.5 g of polyethersulfone (weight average molecular weight 67,000 Sumitomo Chemical Co., Ltd. "Sumica Exel (registered trademark)" 5003P) as polymer A, 45 g of dimethyl sulfoxide as an organic solvent, and 2.5 g of polyvinyl alcohol of the polymer B (Nippon Synthetic Chemical Industry Co., Ltd. "Goosenol (registered trademark)" GL-05) was heated to 80° C. and stirred until the polymer was dissolved. The temperature of the system was returned to room temperature, and then 50 g of ion-exchanged water as a poor solvent was added dropwise at a rate of 0.41 g / min via an infusion pump while stirring at a rate of 450 rpm. After adding about 12 g of ion-exchanged water, the system turned white. Stir for 30 minutes after all the water has been added, filter the resulting suspension, wash with 100 g of ion-exchanged water, filter, and vacuum-dry the filtrate at 80°C for 10 hours to obtain 2.2 g of a white solid . Ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com