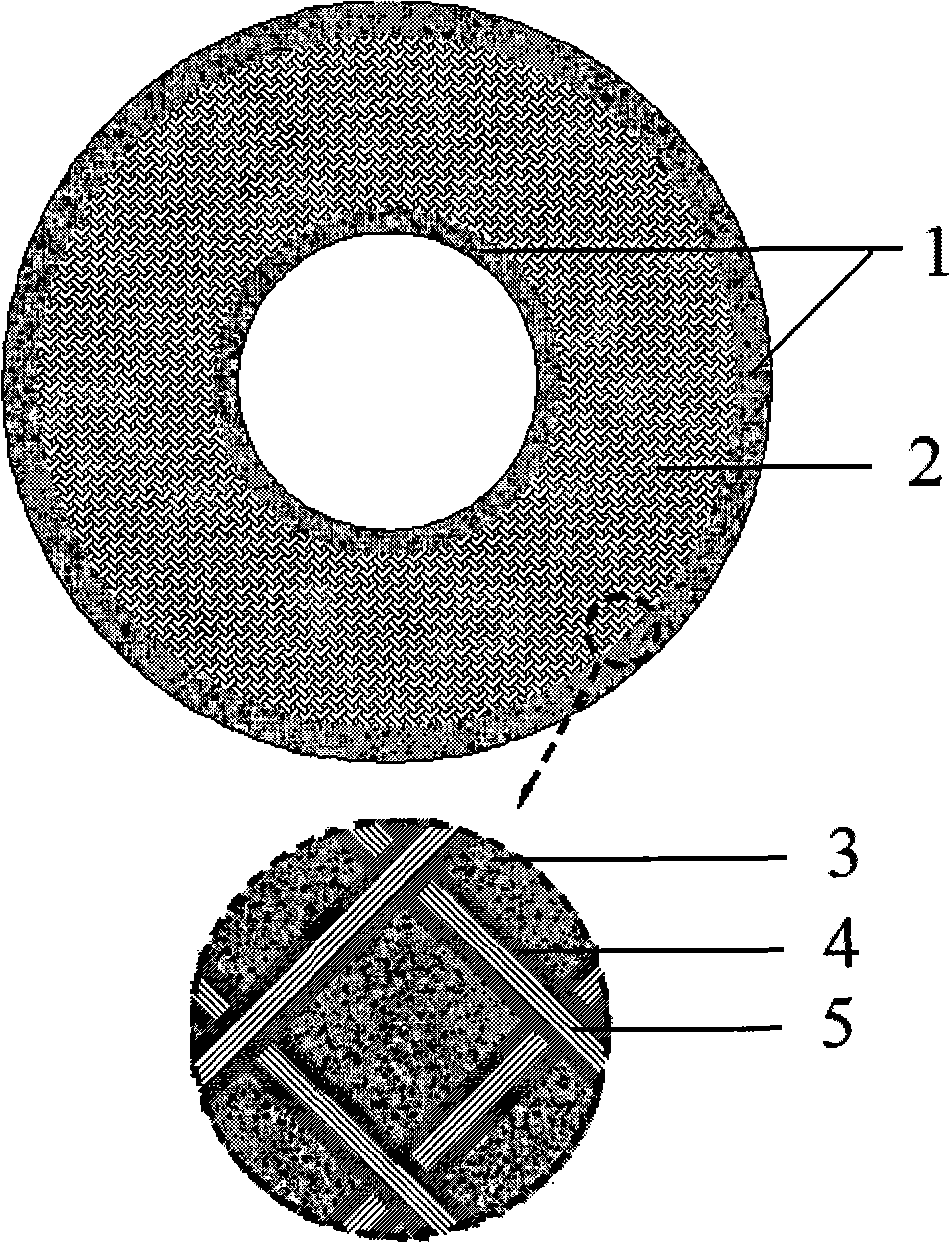

Preparation method of polyvinylidene fluoride hollow fiber composite microporous film with strong interface binding power

A polyvinylidene fluoride, interfacial adhesion technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. The problem of low strength is to achieve the effect of strong hydrophilicity and anti-pollution, good hydrophilicity and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

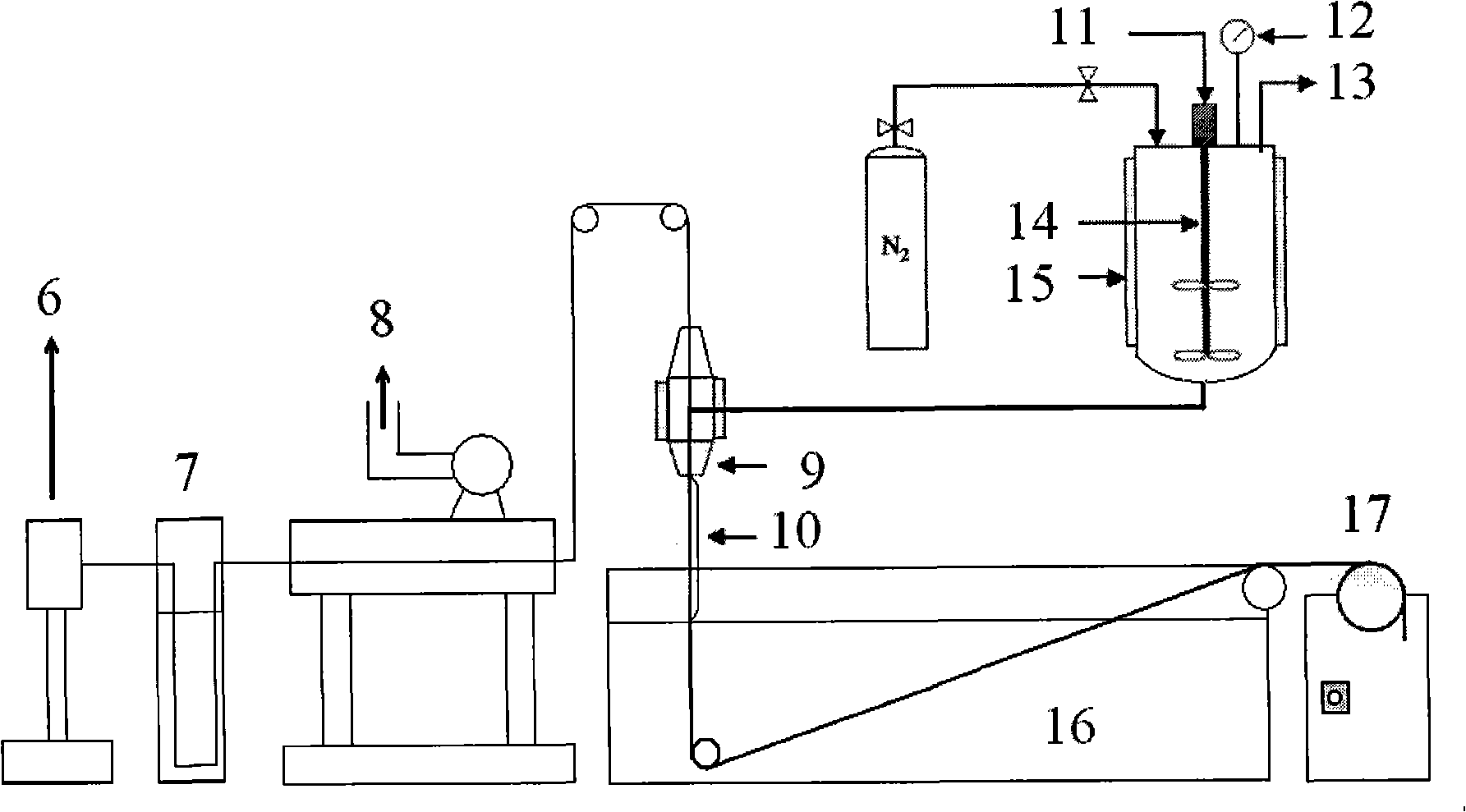

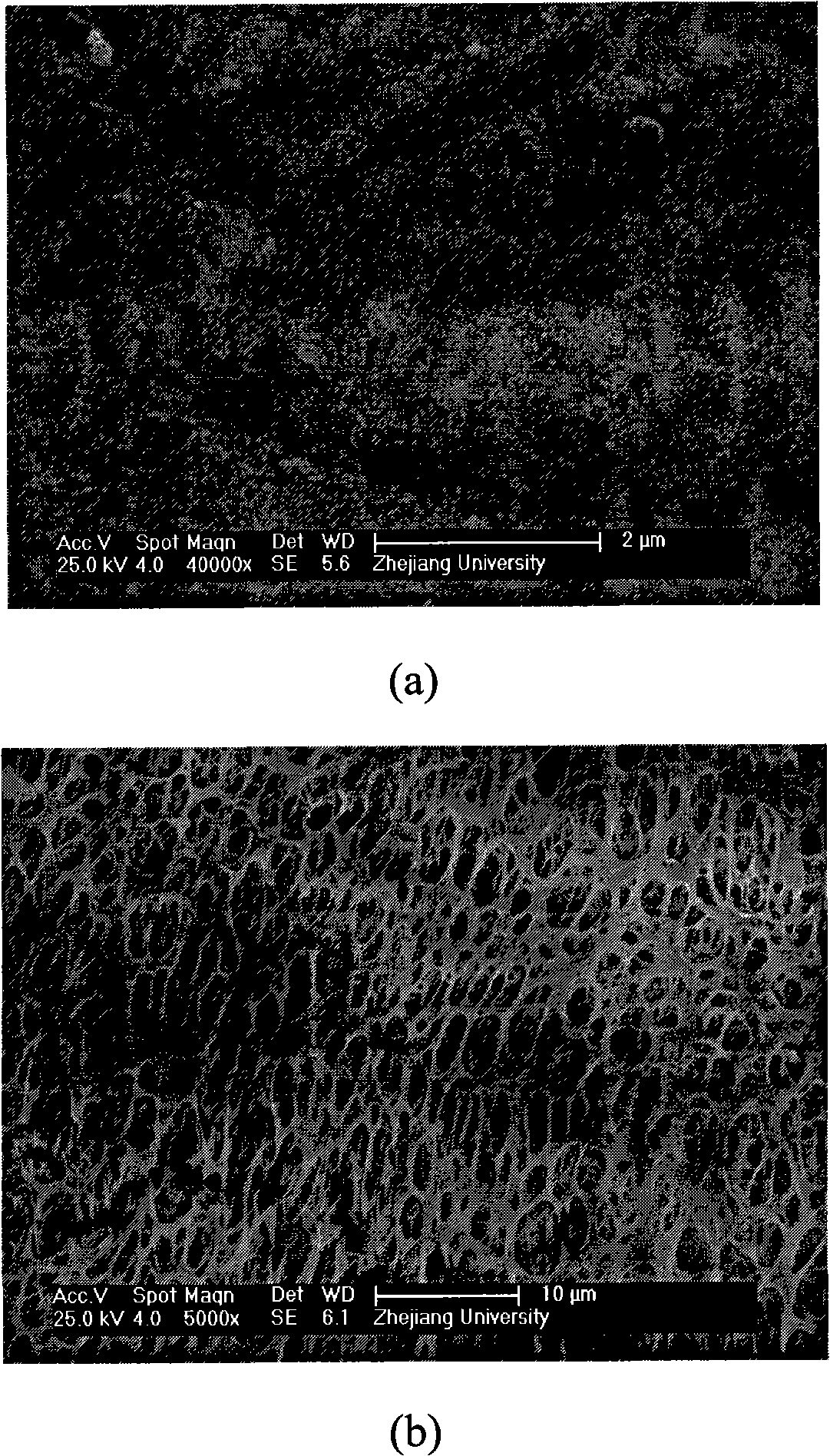

Method used

Image

Examples

Embodiment 1

[0036] 1) dissolving trifluoropropyltrimethoxysilane in absolute ethanol to obtain a dilute solution of trifluoropropyltrimethoxysilane with a concentration of 5% by weight;

[0037] 2) Blend polyvinylidene fluoride, poly(methyl methacrylate-monomethyl ether polyoxyethylene methyl methacrylate), additives, non-solvent and solvent, stir at 80°C for 24 hours, filter, vacuum remove Bubble, obtain film casting liquid, each component of film casting liquid and its concentration are as follows:

[0038] The number average molecular weight of polyvinylidene fluoride is 2.1×10 5 , the weight percent concentration is 10%;

[0039] The number average molecular weight of poly(methyl methacrylate-monomethyl ether polyoxyethylene methyl methacrylate) is 2.8×10 4 , the weight percent concentration is 2%;

[0040] The additives are: polyvinylpyrrolidone with a number average molecular weight of 30,000 and a concentration of 0.5% by weight; polyethylene glycol with a number average molecul...

Embodiment 2

[0053] Embodiment 2 preparation steps are the same as embodiment 1.

[0054]

Embodiment 3

[0055] Embodiment 3 preparation steps are the same as embodiment 1.

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com