Preparation method of three-dimensional MXene

A three-dimensional, inert gas technology, applied in chemical instruments and methods, tungsten/molybdenum carbides, inorganic chemistry, etc., can solve the problems of restricting large-scale production and application, easy pollution of the environment, harsh conditions, etc., to achieve favorable ion Transmission and electron conduction, green and pollution-free cost, simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

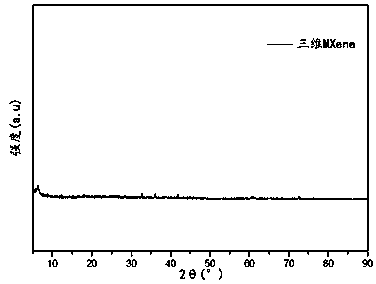

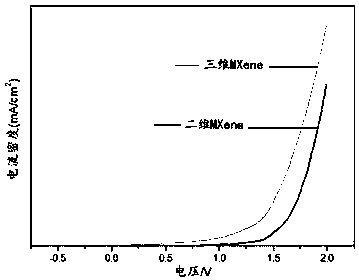

[0020] A three-dimensional Ti 3 C 2 The preparation method, under the protection of inert gas argon, 0.4g of two-dimensional Ti 3 C 2 The powder was placed in boiled 100mL deionized water, and ultrasonically dispersed for 30min with a cell pulverizer to form a two-dimensional Ti 3 C 2 Dispersion liquid, ultrasonically dispersed two-dimensional Ti 3 C 2 Pour the dispersion liquid into the plate that has been protected by argon for 30 minutes before, continue to pass argon for about 10 minutes, and pour the prepared liquid nitrogen on the Ti 3 C 2 The surface of the dispersion liquid is instantly frozen, and the frozen material is wrapped with tin foil and then placed in a freeze dryer and dried at minus 40°C for 150 hours to obtain a three-dimensional Ti 3 C 2 .

[0021] The Ti used in this example 3 C 2 It was prepared with reference to Zhang C, Anasori B, Seral‐Ascaso A, et al. Transparent, Flexible, and Conductive 2D Titanium Carbide (MXene) Filmswith High Volumet...

Embodiment 2

[0024] A three-dimensional Ti 2 The preparation method of C, under the protection of inert gas argon, 0.6g commercially available two-dimensional Ti 2 C powder was placed in boiled 100mL deionized water, and ultrasonically dispersed for 60min with an ultrasonic cleaner to form two-dimensional Ti 2 N dispersion liquid, ultrasonically dispersed two-dimensional Ti 2 Pour the C dispersion into the plate that has been protected by argon for 30 minutes before, continue to pass argon for about 10 minutes, and pour the prepared liquid nitrogen on the Ti 2 The surface of the dispersion of C is instantly frozen, and the frozen material is wrapped with tin foil and then placed in a freeze dryer and dried at minus 35°C for 100 hours to obtain a three-dimensional Ti 2 c.

Embodiment 3

[0026] A three-dimensional Mo 2 The preparation method of C, under the protection of inert gas nitrogen, 1.0g commercially available two-dimensional Mo 2 C powder was placed in 100mL ethanol deoxygenated, and ultrasonically dispersed with an ultrasonic cleaner for 90min to form two-dimensional Mo 2 C dispersion liquid, ultrasonically dispersed two-dimensional Mo 2 C dispersion is poured into the PTFE beaker that has been protected by nitrogen gas for 30 minutes before, continue to pass nitrogen gas for about 10 minutes, seal the beaker and put it in a refrigerator at minus 80°C for rapid freezing. The frozen material is wrapped with tin foil and then placed. Dry in a freeze dryer at minus 50°C for 60 hours to obtain three-dimensional Mo 2 c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com