Metal-based composite material as well as preparation method and application thereof

A composite material and metal-based technology, applied in the direction of nitrogen and non-metallic compounds, nitrogen-metal/silicon/boron binary compounds, non-metallic elements, etc., can solve problems such as no corresponding MXene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

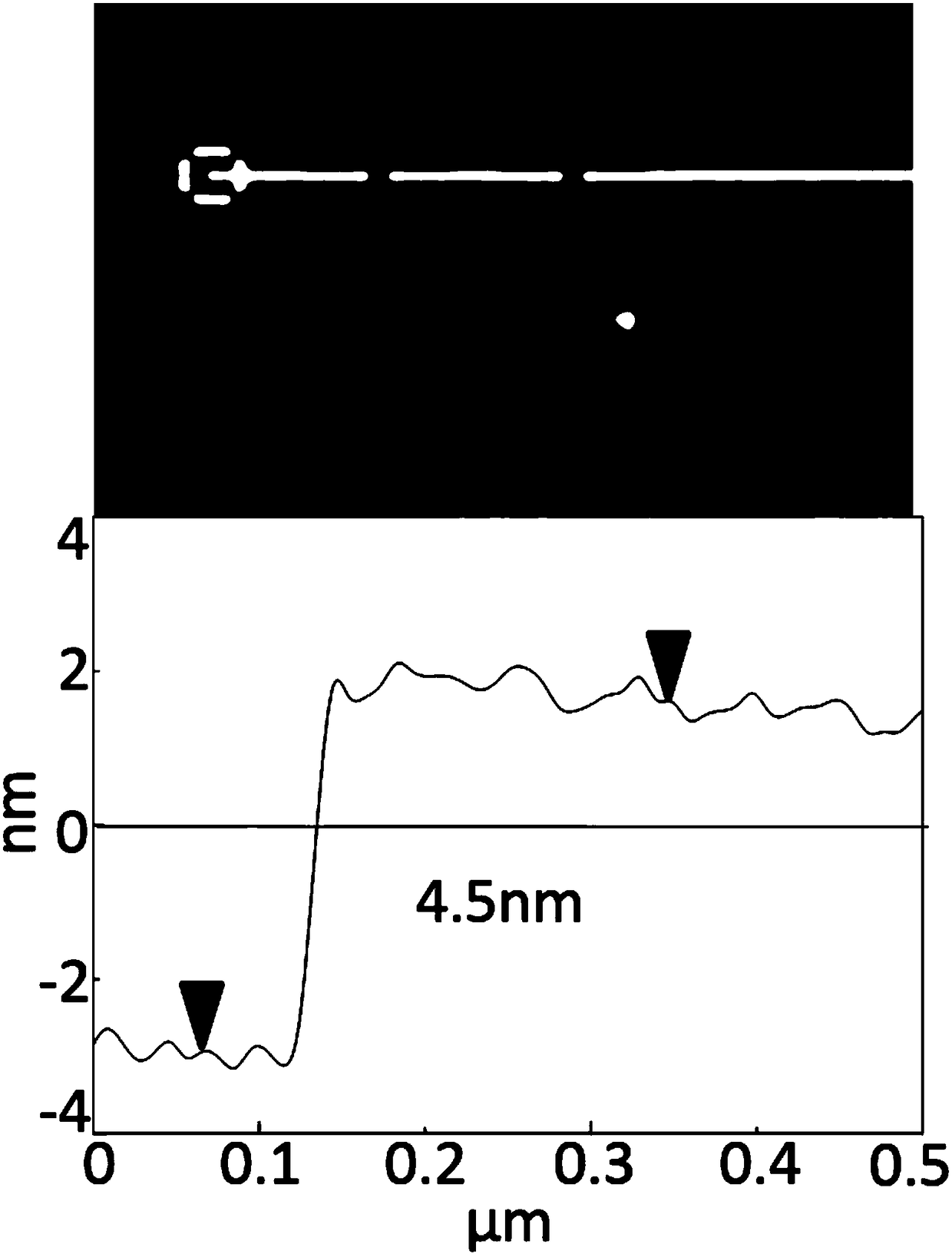

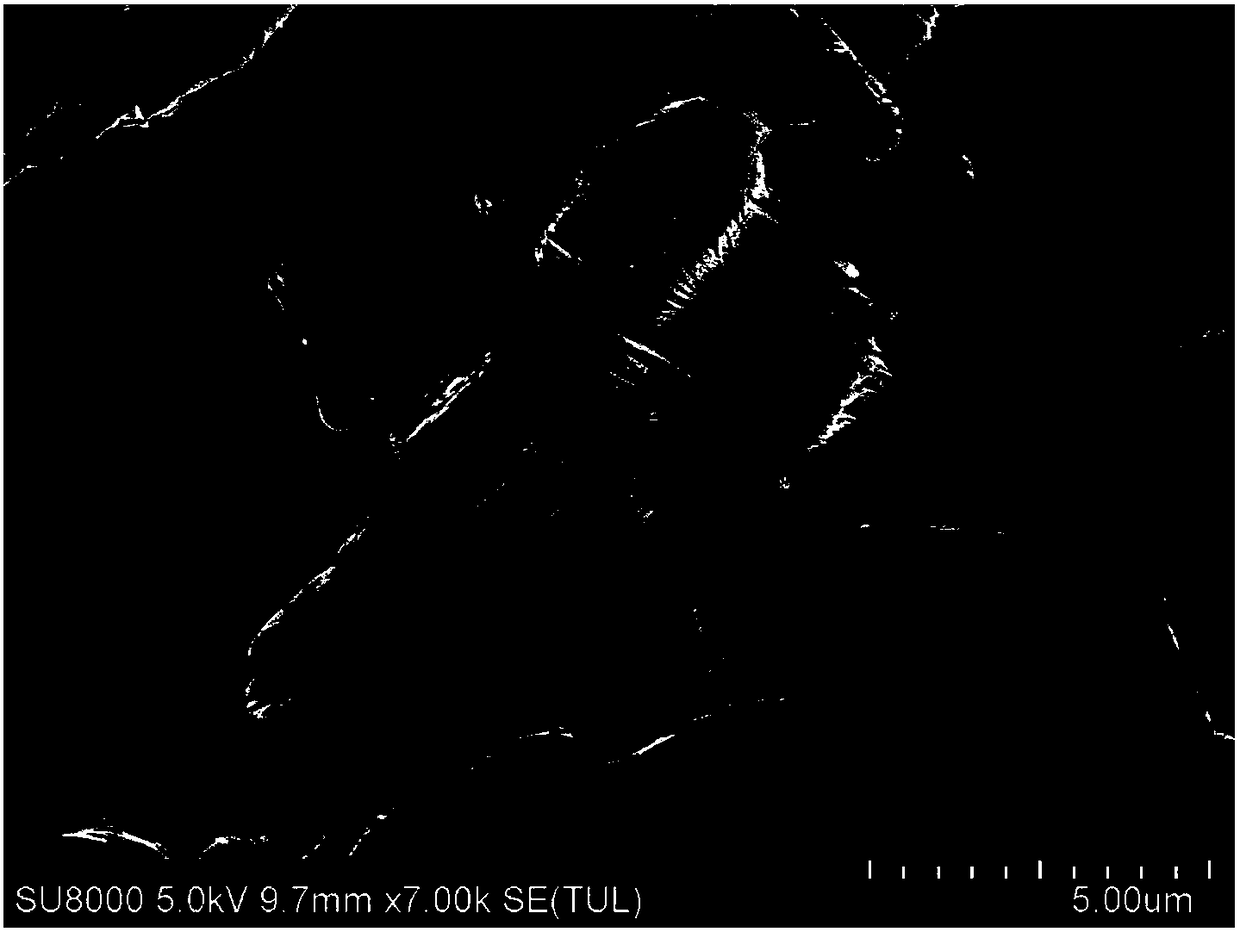

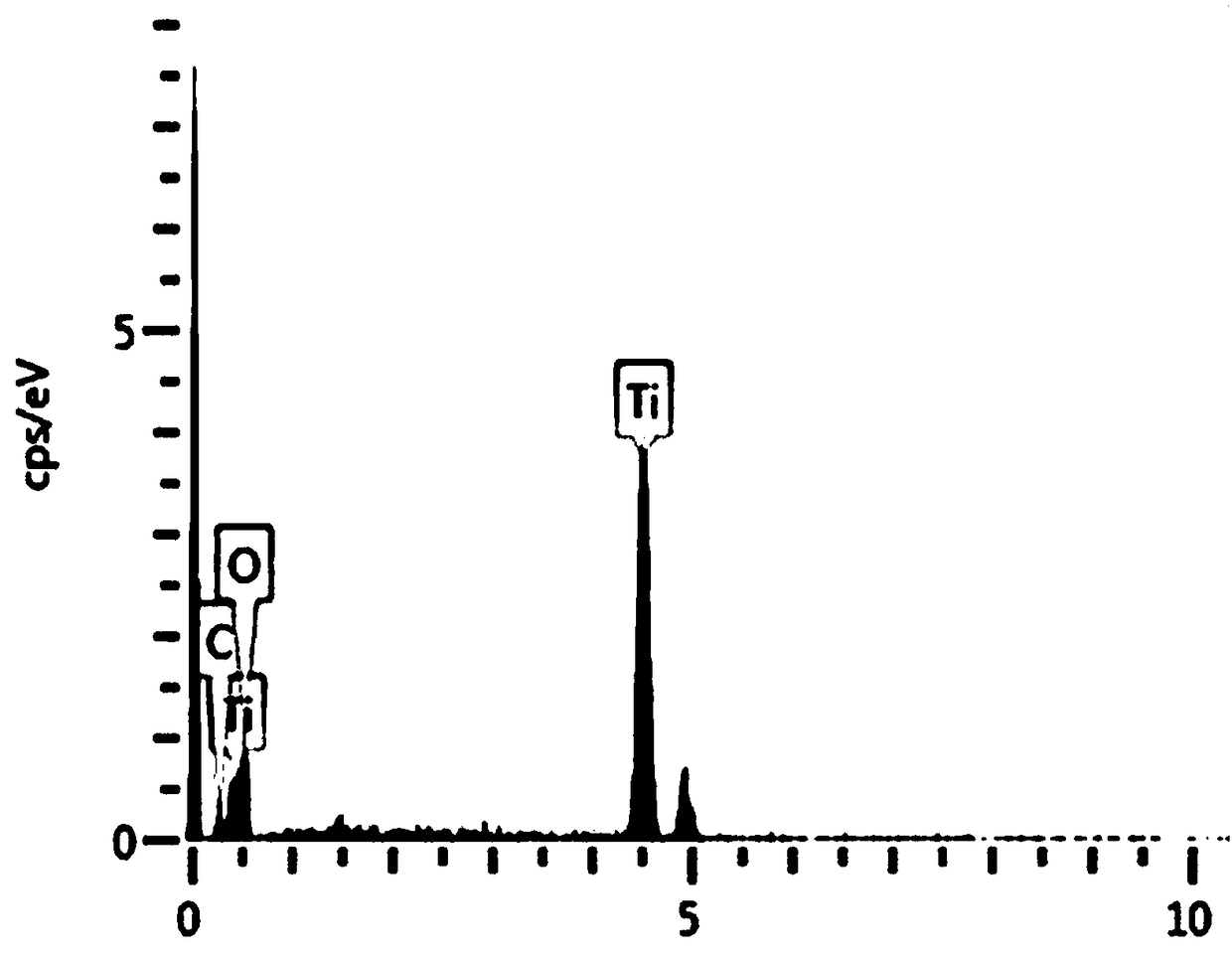

[0062] The metal matrix composite material 1 was prepared by the following steps:

[0063] Step (1), use a ball mill to convert 10g of structural formula into Ti 3 AlC 2 The compound is pulverized and ground to a particle size of 80 μm, then placed in a corrosion-resistant polytetrafluoroethylene container, and 500 g of acidic etching solution containing 40 wt % lithium fluoride and hydrogen chloride is added to the container, wherein lithium fluoride and hydrogen chloride The molar ratio is 1:4, etched at 80°C for 12h, the Al element in the compound is completely removed, and the accordion-shaped Ti 3 C 2 The multilayer MXene material of the structural formula;

[0064] In step (2), the multilayer MXene material obtained in step (1) was rinsed with N-methylpyrrolidone containing 5wt% sodium cholate to remove residual impurities, and then it was vacuum-dried, and then dispersed in a layer containing 10wt% In the petroleum ether of sodium p-butylbenzene sulfonate, obtain mu...

Embodiment 2

[0069] The metal matrix composite material 2 was prepared by the following steps:

[0070] The only difference with Example 1 is that the structural formula of the compound added in the step (1) is Ti 3 AsCN, the obtained multilayer MXene material has Ti 3 The structural formula of CN.

[0071] Example 2 A metal matrix composite material 2 was obtained.

Embodiment 3

[0073] The metal matrix composite material 3 was prepared by the following steps:

[0074] The only difference with Example 1 is that the structural formula of the compound added in step (1) is Nb 2 AlC, the resulting multilayer MXene material has Nb 2 For the structural formula of C, the amount of the acidic etching solution added is 100 g and the acidic etching solution is a hydrofluoric acid solution with a concentration of 20 wt%.

[0075] Example 3 A metal matrix composite material 3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com