Method for preparing MXenes and derivative nanosheets by electrochemical process

A derivative, nanosheet technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, carbides, etc., can solve problems such as long etching time, health hazards, environmental pollution, etc. The effect of low preparation cost and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

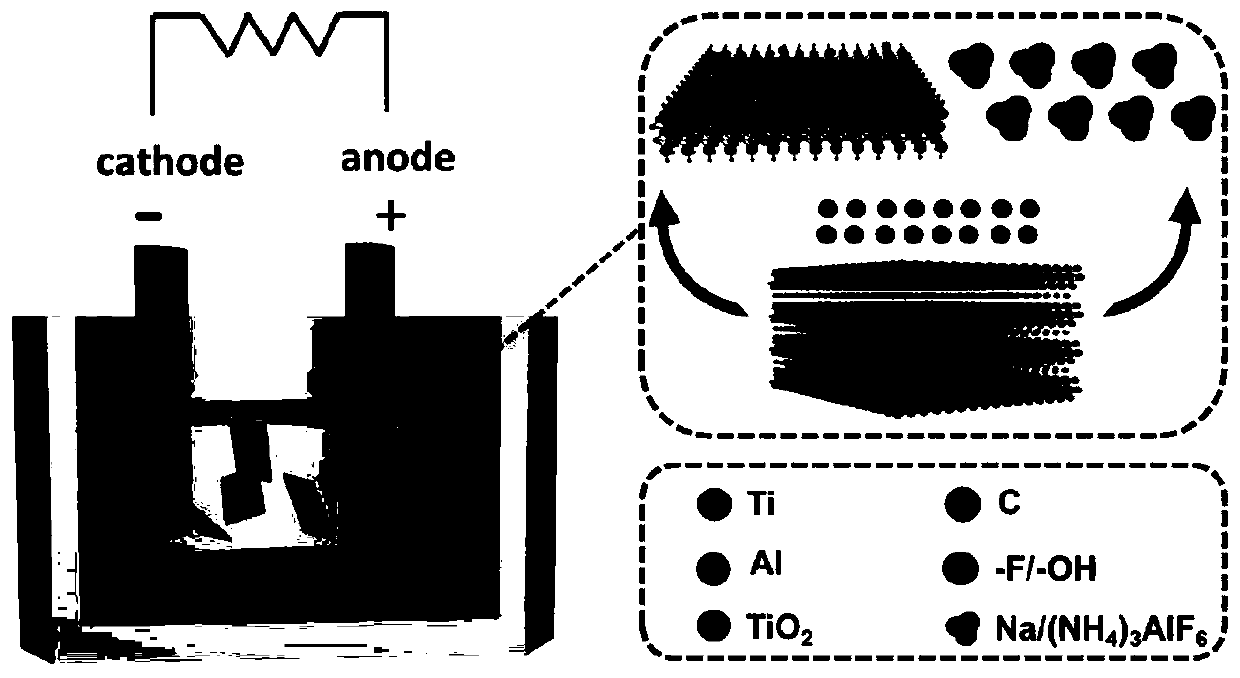

[0019] The process steps of the method for electrochemically preparing MXenes and derivative nanosheets thereof involved in this embodiment are as follows:

[0020] S1. Weigh 1.43g of powder and put it in a 50mL beaker, add 50mL of deionized water into the beaker containing the powder, and put it on a magnetic stirrer to completely dissolve the ammonium bifluoride powder;

[0021] S2, put the big Ti 3 AlC 2 MAX is fixed on the clip electrode as an anode, Pt sheet electrode (area>1.0cm 2 ) as the cathode, and apply a DC constant voltage of 3V, and react for 6-24 hours;

[0022] S3. After the reaction, take out the electrolyte in the beaker and put it into the centrifuge tube, place the centrifuge tube symmetrically in the centrifuge, centrifuge at a speed greater than 7000 rpm for more than 10 minutes, take the supernatant, and after centrifugation The electrolyte changed from colorless to light yellow to dark brown and then to light yellow.

Embodiment 2

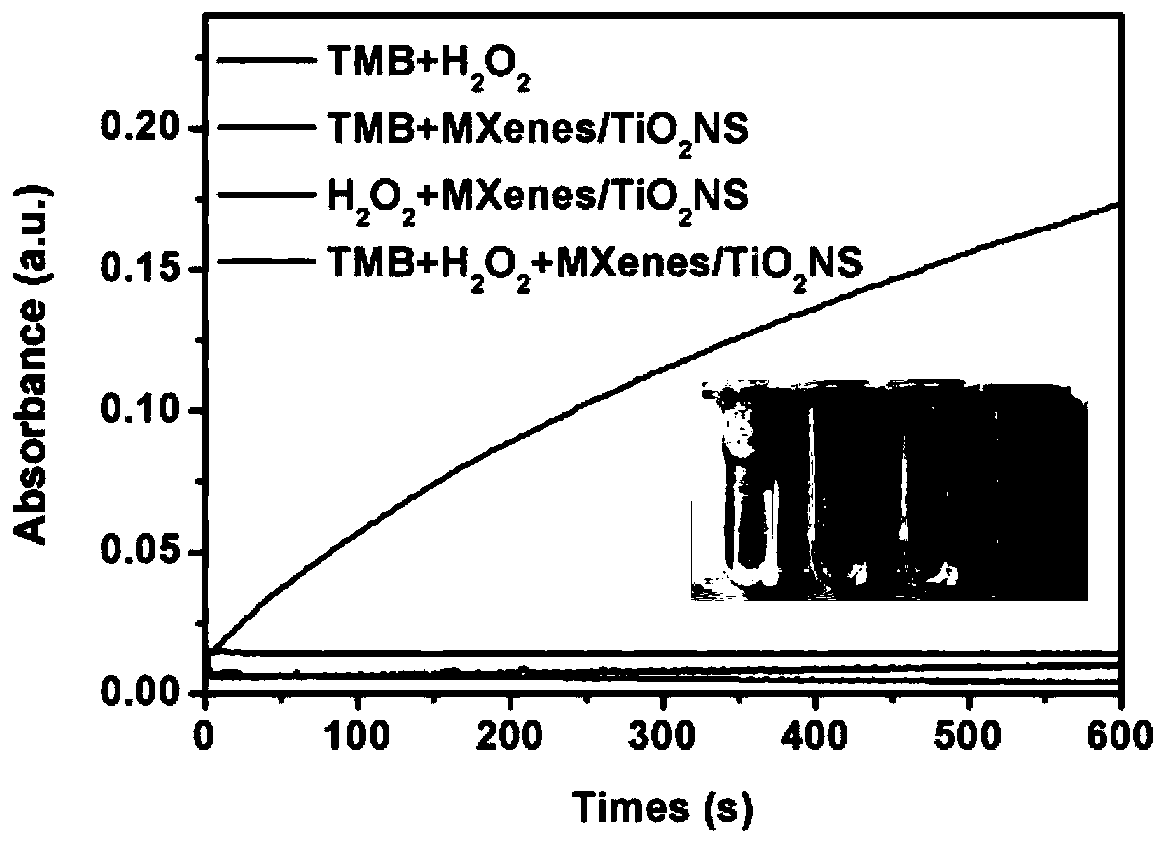

[0024] The Ti prepared in this embodiment to embodiment 1 3 C 2 T x In different reaction systems of MXene and its derivative nanosheets, the UV absorbance of 3,3',5,5'-tetramethylbenzidine at a wavelength of 652nm was measured as a function of time, as shown in image 3 As shown, in the system containing 3,3',5,5'-tetramethylbenzidine, hydrogen peroxide and nanosheets, the reaction solution gradually turns blue, which proves that the nanosheets have peroxidase activity .

Embodiment 3

[0026] The Ti prepared in this embodiment to embodiment 1 3 C 2 T x MXene and its derivative nanosheets eliminate superoxide radicals, such as Figure 4 As shown in A, adding nanosheets to the mixed solution containing riboflavin, methionine and nitro blue tetrazolium, under the condition of light irradiation, its ultraviolet absorbance at 560nm decreased, indicating that it eliminated the ultra-violet Oxygen free radicals; such as Figure 4 As shown in B, with the increase of the concentration of nanosheets, the ultraviolet absorbance at 560nm gradually decreases, indicating that the content of eliminating superoxide radicals gradually increases, proving that the nanosheets have the activity of superoxide dismutase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com