Preparation method of sulfonated two-dimensional titanium carbide nanosheet

A two-dimensional titanium carbide and nanosheet technology, which is applied in the fields of titanium carbide, chemical instruments and methods, carbon oxides/sulfur carbides, etc., to achieve the effects of low production cost, high dispersion, and simple and controllable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

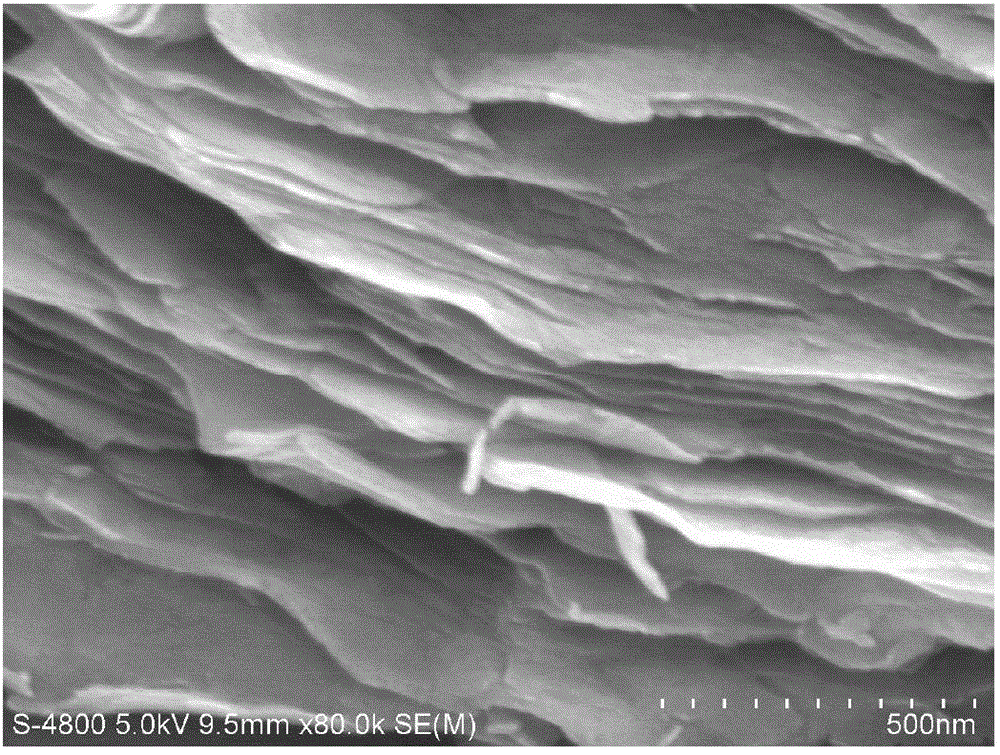

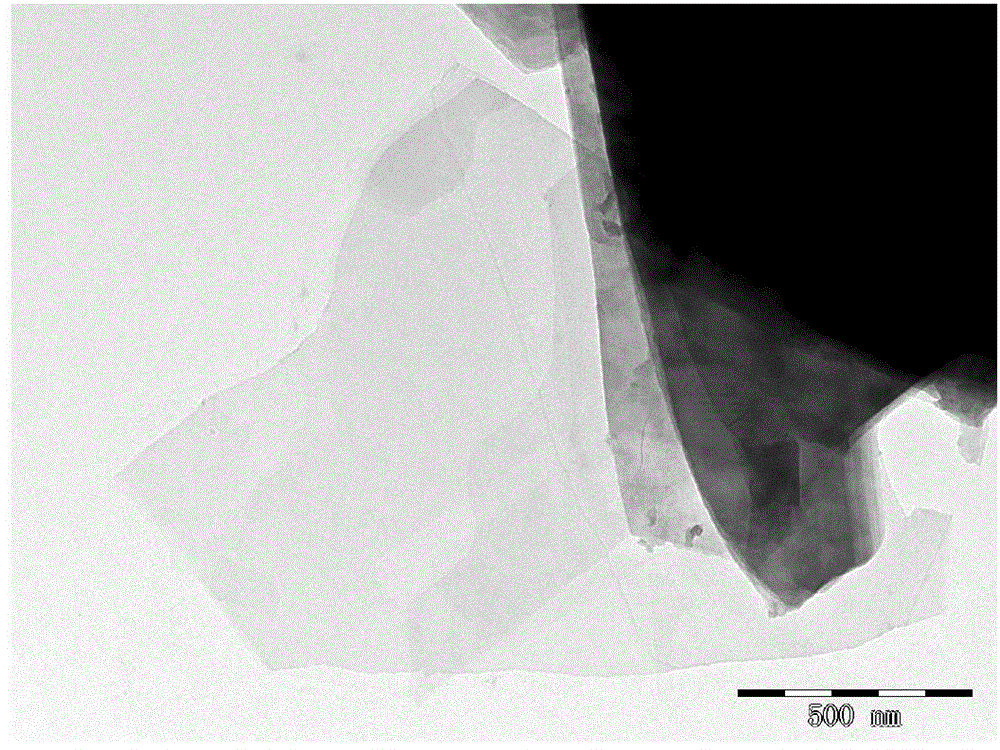

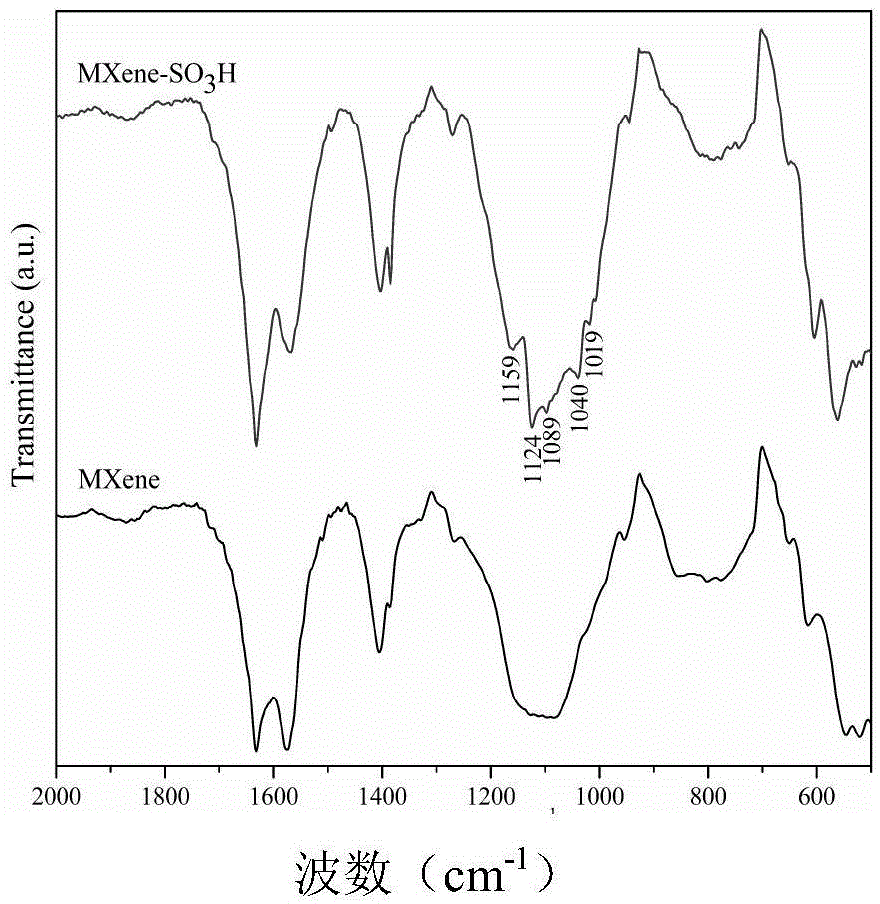

[0022] Example 1 Preparation of sulfonated two-dimensional titanium carbide nanosheets.

[0023] (1) 0.1 g of Ti 3 AlC 2 Soak the powder in 20mL of 50wt% HF aqueous solution at 25°C, and react with magnetic stirring at a speed of 1500r / min for 8 hours to obtain a suspension; filter and wash the obtained suspension repeatedly until the pH value is neutral After centrifugation at 6000 rpm for 10 minutes, a two-dimensional titanium carbide precipitate was obtained;

[0024] (2) Redisperse the above precipitated product in 10ml of water and ultrasonic for 30 minutes, add 10ml of p-aminobenzenesulfonic acid diazonium salt solution dropwise under ice bath conditions, and react for 2h under magnetic stirring. This is the sulfonation process, and the sulfonation Two-dimensional titanium carbide solution;

[0025] (3) The above-mentioned sulfonated two-dimensional titanium carbide solution was separated and precipitated by centrifugation at 4000 rpm for 10 minutes, washed repeatedly...

Embodiment 2

[0026] Example 2 Preparation of sulfonated two-dimensional titanium carbide nanosheets.

[0027] (1) 0.3 g of Ti 3 AlC 2 Soak the powder in 40mL of 40wt% HF aqueous solution at 40°C, and react with magnetic stirring at a speed of 1500r / min for 4 hours to obtain a suspension; filter and wash the obtained suspension repeatedly until the pH value is neutral After centrifugation at 6000 rpm for 10 minutes, a two-dimensional titanium carbide precipitate was obtained;

[0028] (2) Redisperse the above-mentioned precipitated product in 30ml of water, ultrasonicate for 30 minutes, add 20ml of p-aminobenzenesulfonic acid diazonium salt solution dropwise under ice bath conditions, and react for 6h under magnetic stirring. This is the sulfonation process to obtain sulfonate two-dimensional titanium carbide solution;

[0029] (3) The above-mentioned sulfonated two-dimensional titanium carbide solution was separated and precipitated by centrifugation at 4000 rpm for 10 minutes, washed r...

Embodiment 3

[0030] Example 3 Preparation of sulfonated two-dimensional titanium carbide nanosheets.

[0031] (1) 0.2 grams of Ti 3 AlC 2 Soak the powder in 30mL of 40wt% HF aqueous solution at 50°C, and magnetically stir the reaction at a speed of 1500r / min for 2 hours to obtain a suspension; filter and wash the obtained suspension repeatedly until the pH value is neutral After centrifugation at 6000 rpm for 10 minutes, a two-dimensional titanium carbide precipitate was obtained;

[0032] (2) Redisperse the above-mentioned precipitated product in 20ml of water, ultrasonicate for 30 minutes, add dropwise 30ml of p-aminobenzenesulfonic acid diazonium salt solution under ice bath conditions, and react for 3h under magnetic stirring. This is the sulfonation process, and sulfonate two-dimensional titanium carbide solution;

[0033] (3) The above-mentioned sulfonated two-dimensional titanium carbide solution was separated and precipitated by centrifugation at 4000 rpm for 10 minutes, washed re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com