Ti3C2Tx-TiO2 composite material as well as preparation method and application thereof

A composite material, H2O2 technology, applied in the direction of analyzing materials, electrochemical variables of materials, chemical instruments and methods, etc., can solve the problems of complicated preparation process, complicated process flow, lack of stability, etc., and achieve low cost and simplified process flow , the effect of good photocurrent response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

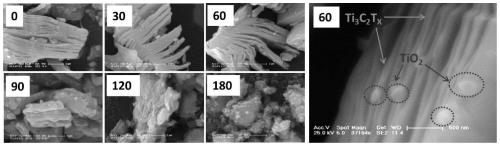

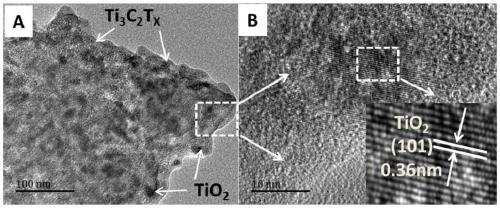

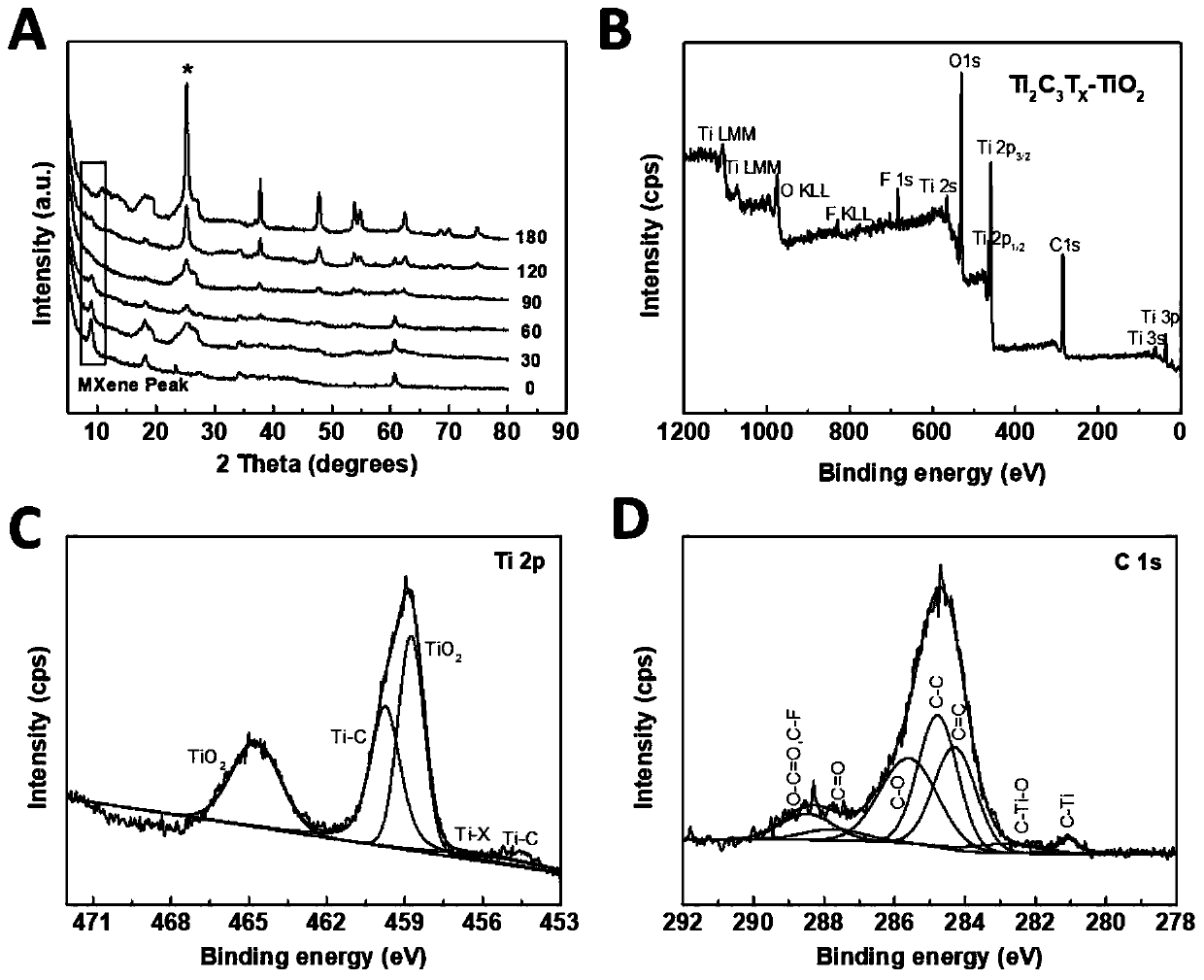

[0037] A preparation of Ti based on oxidized titanium carbide MXene 3 C 2 T x -TiO 2 The method of composite material, concrete steps are as follows:

[0038] 1) Layered Ti 3 C 2 T x Preparation of MXene: synthesized by acid etching, using HF (49%) to stir at room temperature for 4 hours, then sonicated, washed with deionized water and then dried.

[0039] 2) Ti 3 C 2 T x -TiO 2 Preparation: First, disperse 0.1 g of the above-prepared MXene powder into 10 mL of deionized water, stir magnetically at room temperature, and then add 30 wt% H 2 o 2 (The volumes are 30 μL, 60 μL, 90 μL, 120 μL, and 180 μL, and the obtained samples are named as HM 30, HM 60, HM 90, HM 120, HM 180, and HM 0 are MXene samples that have not been treated with hydrogen oxide) at 100 ° C Stir magnetically for 2h. Then the reacted mixture was ultrasonicated (room temperature, power 100W, 30 minutes), washed with deionized water and ethanol, and then dried in a vacuum oven at 40°C for 12 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com