Method for preparing TiCxOy and/or TiC through carbon-added hydrogen reduction

A technology of titanium carbide and titanium carbide, which is applied in the field of preparation of titanium carbide or/and titanium carbide by the reduction of carbon and hydrogen, can solve the problems of low production efficiency, high preparation temperature of production process, high cost, etc., so as to improve efficiency and increase Reduction, energy cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

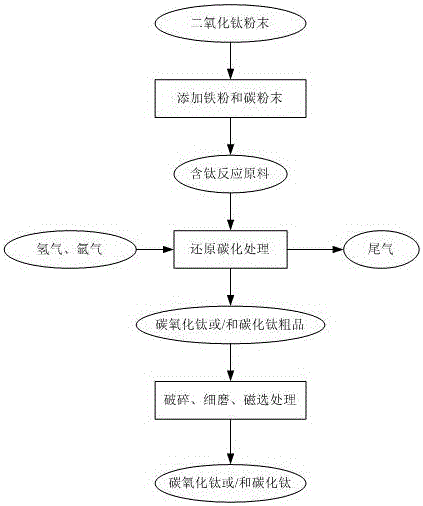

[0056] This embodiment adopts TiO 2 The rutile with a content of 96% is used as titanium dioxide raw material powder to prepare titanium carbide or / and titanium carbide. The specific steps are as follows:

[0057] (1) TiO 2 The rutile powder with a content of 96% is sieved to obtain a sufficient amount of titanium dioxide powder, and the particle size of the sieved titanium dioxide powder is required to be 48 mesh to 200 mesh.

[0058] (2) Add an appropriate amount of carbon powder to the obtained titanium dioxide powder, so that the molar ratio of carbon powder to titanium dioxide powder is 1.7:1, and add a certain amount of iron powder at the same time. The amount of iron powder added is the carbon powder and titanium dioxide powder. 8.2% of the total weight, the titanium-containing material is mixed as the titanium-containing reaction material.

[0059] (3) Put the obtained titanium-containing reaction raw materials into an MgO crucible, then put them into a tube furnace,...

example 2

[0064] This embodiment adopts TiO 2 Titanium dioxide powder with a content of 99% is used as titanium dioxide raw material powder to prepare titanium carbide or / and titanium carbide. The specific steps are as follows:

[0065] (1) TiO 2 The titanium dioxide powder with a content of 99% is screened to obtain a sufficient amount of titanium dioxide powder, and the particle size of the titanium dioxide powder obtained by screening is required to be 48 mesh to 200 mesh.

[0066] (2) Add an appropriate amount of carbon powder to the obtained titanium dioxide powder, so that the molar ratio of carbon powder to titanium dioxide powder is 3:1, and add a certain amount of iron powder at the same time. The amount of iron powder added is the carbon powder and titanium dioxide powder. 8.2% of the total weight, the titanium-containing material is mixed as the titanium-containing reaction material.

[0067] (3) Put the obtained titanium-containing reaction raw materials into an MgO crucible...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com