Synchronous detection test device for multi-item parameters of linear TBM hobs

A technology of synchronous detection and testing equipment, which is applied in the directions of measuring equipment, testing wear resistance, and testing machinability, etc., can solve the problems of rock breaking process and test data distortion that do not meet the requirements of full-section hard rock roadheader hob, and achieve The effect of shortening the development and design cycle, improving the design quality, and accurate data of the rock breaking test of the hob

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

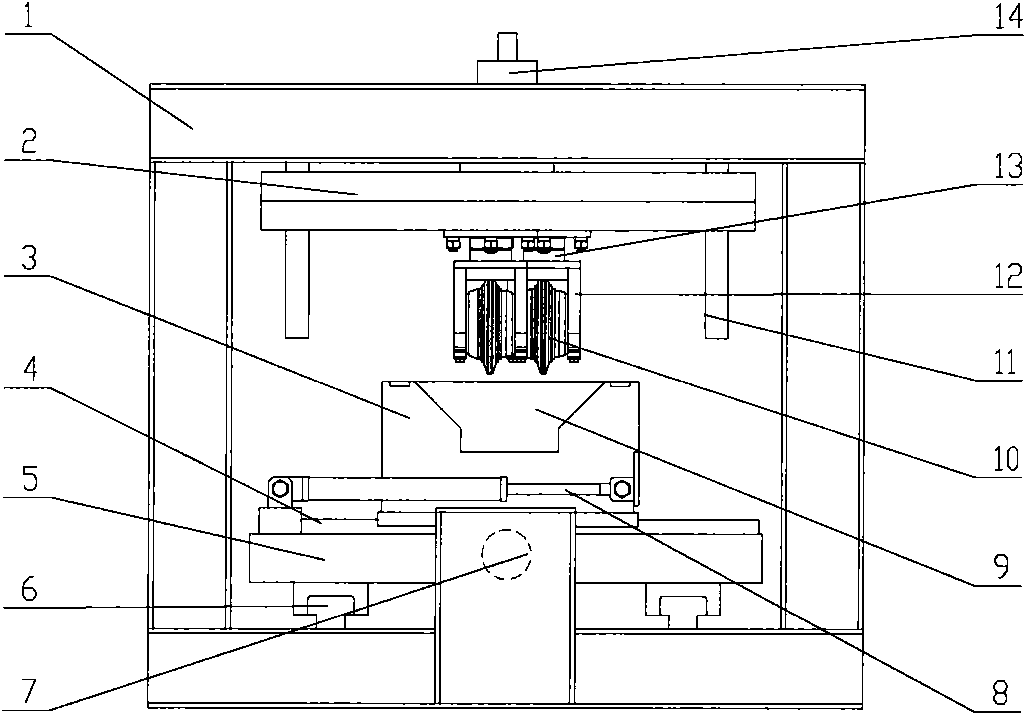

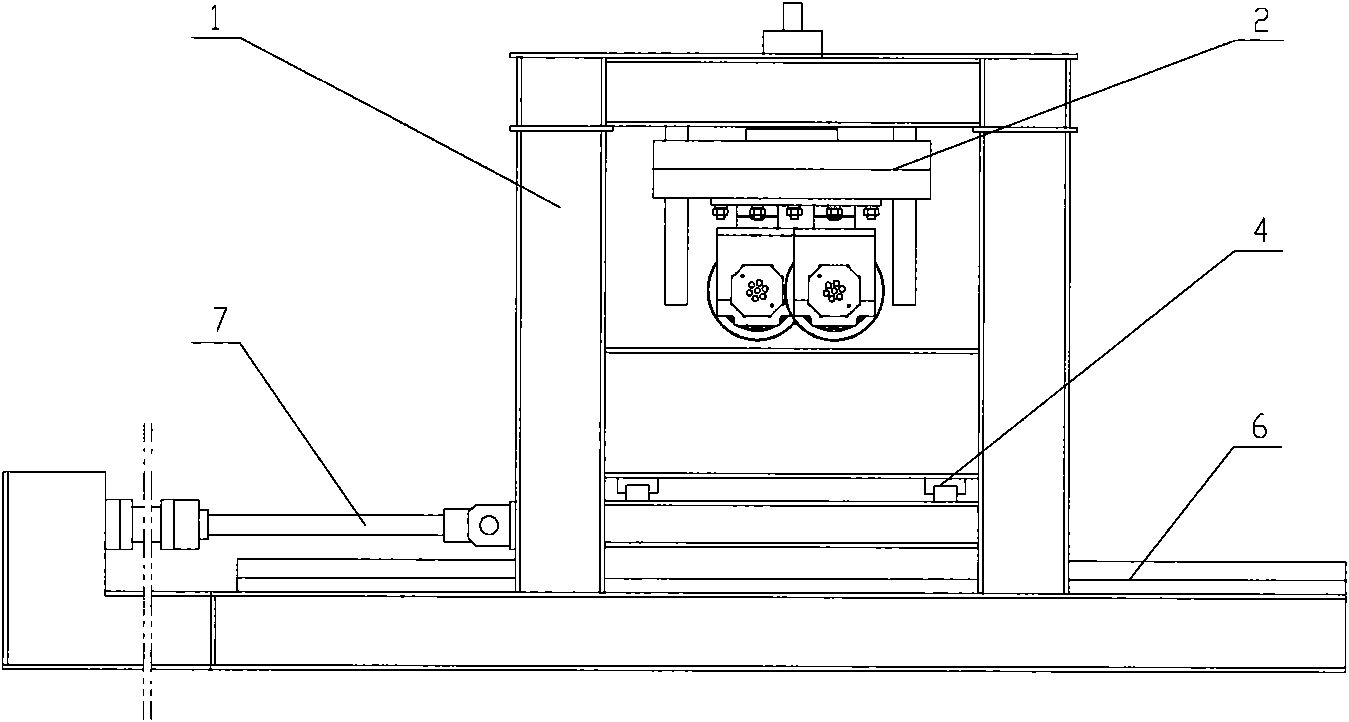

[0010] Referring to the accompanying drawings, a linear type TBM hob multi-parameter synchronous detection test device, the whole device consists of a self-reflexive force frame 1, an adjustment tool holder 2, an X-direction mobile table 3, an X-direction linear guide rail 4, and a Y-direction movement. Table 5, Y-direction linear guide rail 6, Y-direction hydraulic cylinder 7, X-direction hydraulic cylinder 8, rock sample 9, hob 10, four-bar guide mechanism 11, hob seat 12, three-direction pressure sensor 13, Z-direction hydraulic cylinder 14, the rock sample 9 lateral movement direction is set as the X axis, the axis direction of the hob 10 is set as the Y axis, and the direction perpendicular to the broken surface of the rock sample 9 is set as the Z axis. The rock sample 9 is fixed on the trolley, the adjusting tool holder 2 is installed on the four-bar guide mechanism 11, the X-direction moving table 3 and the Y-direction moving table 5 are installed on the horizontal line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com