Electronic control component of fuel system and fuel system control method

A technology of fuel system and electronic control components, which is applied in the field of vehicles and can solve the problems of inability to exhaust, poor versatility, and high equipment complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

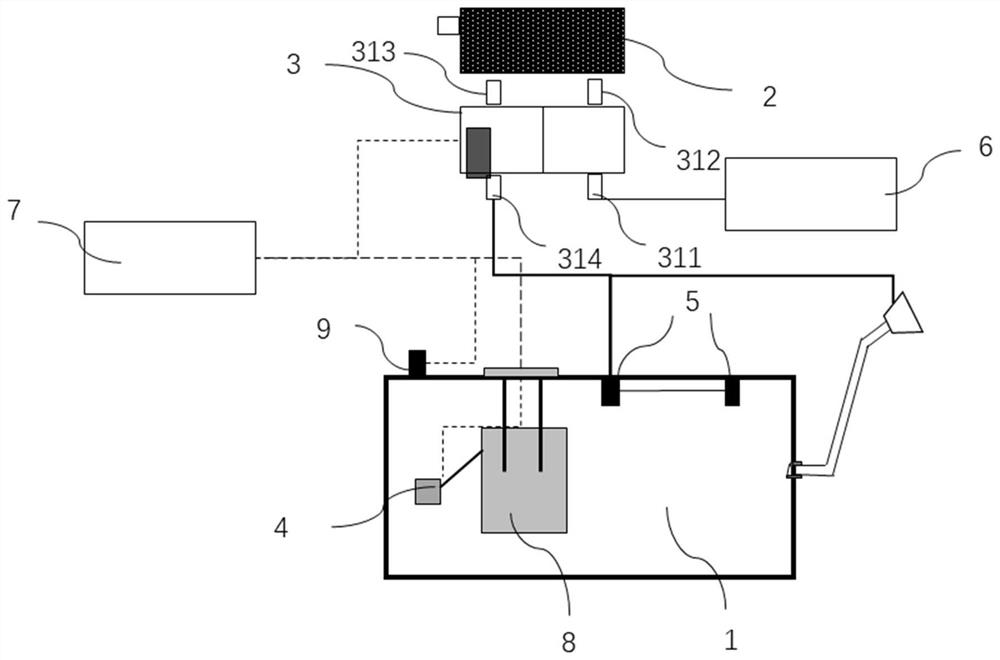

[0051] like figure 1 As shown, the fuel system provided by this application includes a fuel tank 1 , a carbon canister 2 , an electronic control component 3 , a liquid level sensor 4 , an exhaust port 5 , an air filter 6 , a microcontroller 7 , an oil pump 8 and a pressure sensor 9 . The oil pump 8 and the liquid level sensor 4 are arranged in the oil tank 1 , and the pressure sensor 9 is arranged on the side wall of the oil tank 1 . The microcontroller 7 is connected to the electronic control component 3 , the liquid level sensor 4 and the pressure sensor 9 .

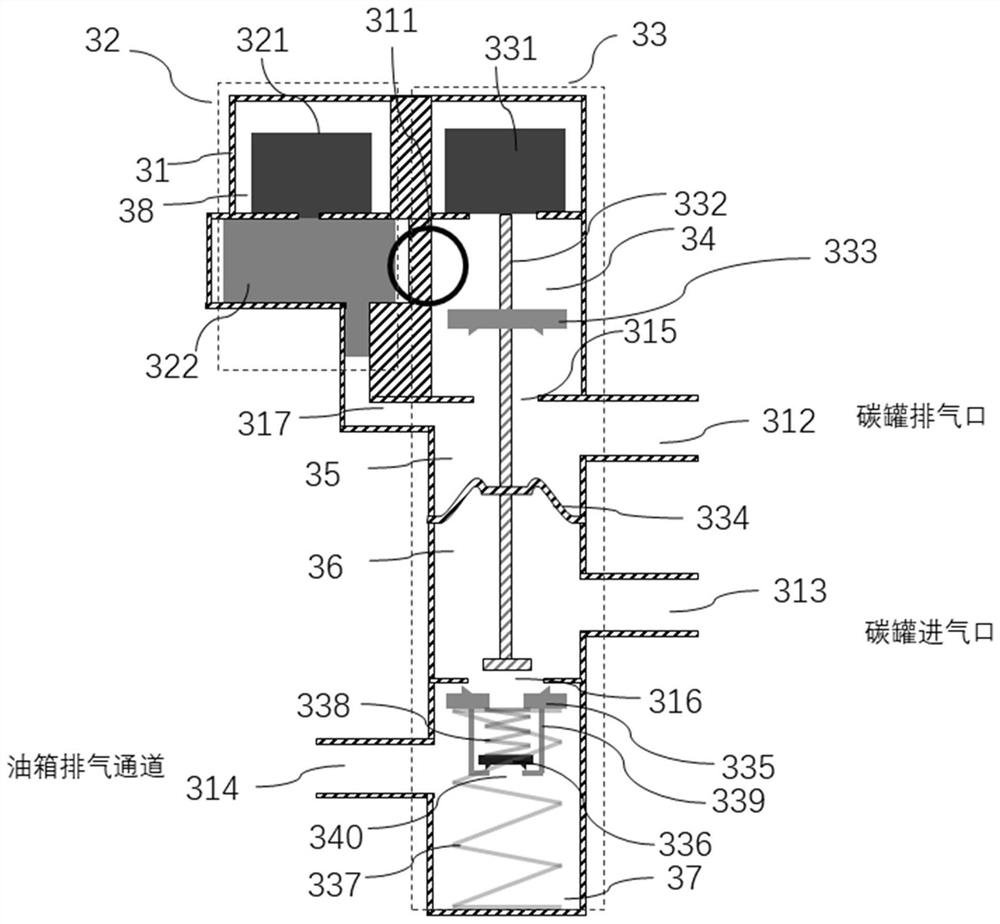

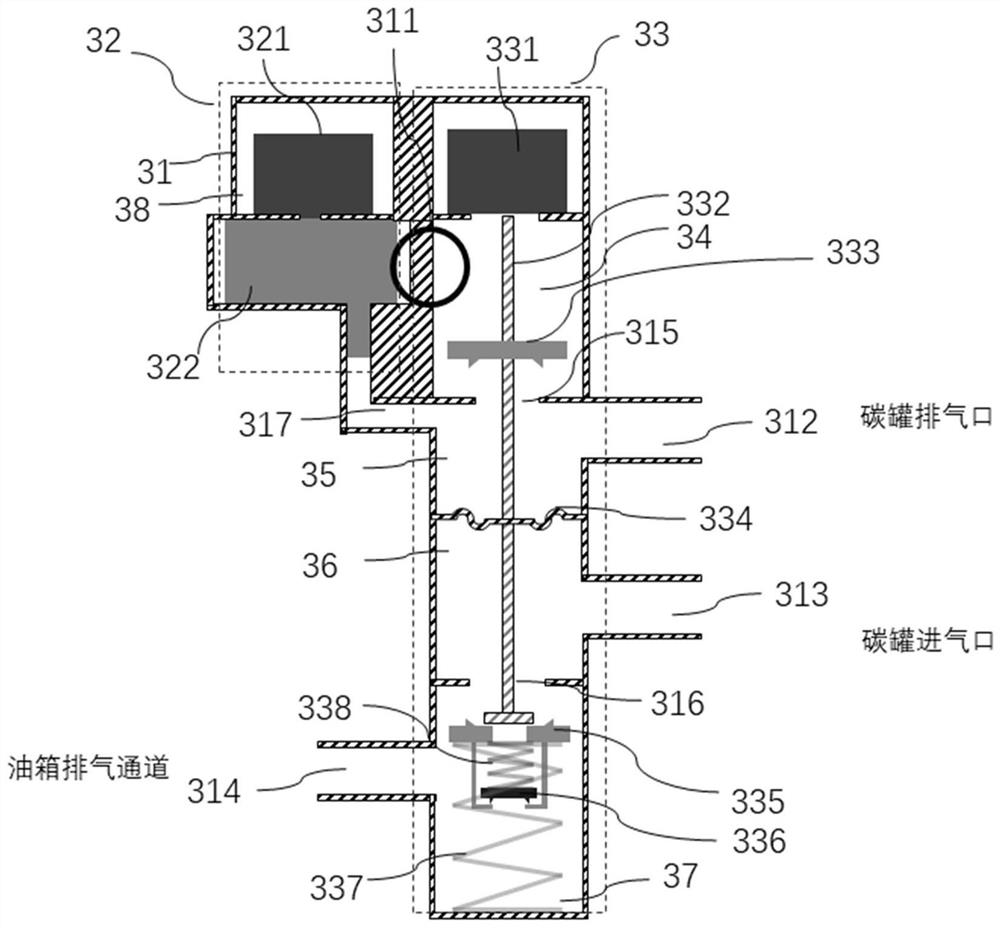

[0052] combine figure 1 and figure 2 As shown, the electronic control component 3 includes a housing 31 , a first valve core 333 and a second valve core 335 , and the housing 31 is provided with four ports.

[0053] The first port 311 of the housing 31 communicates with the atmosphere through the air filter 6 , and a first channel 315 and a first valve core 333 are provided between the first port 311 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com