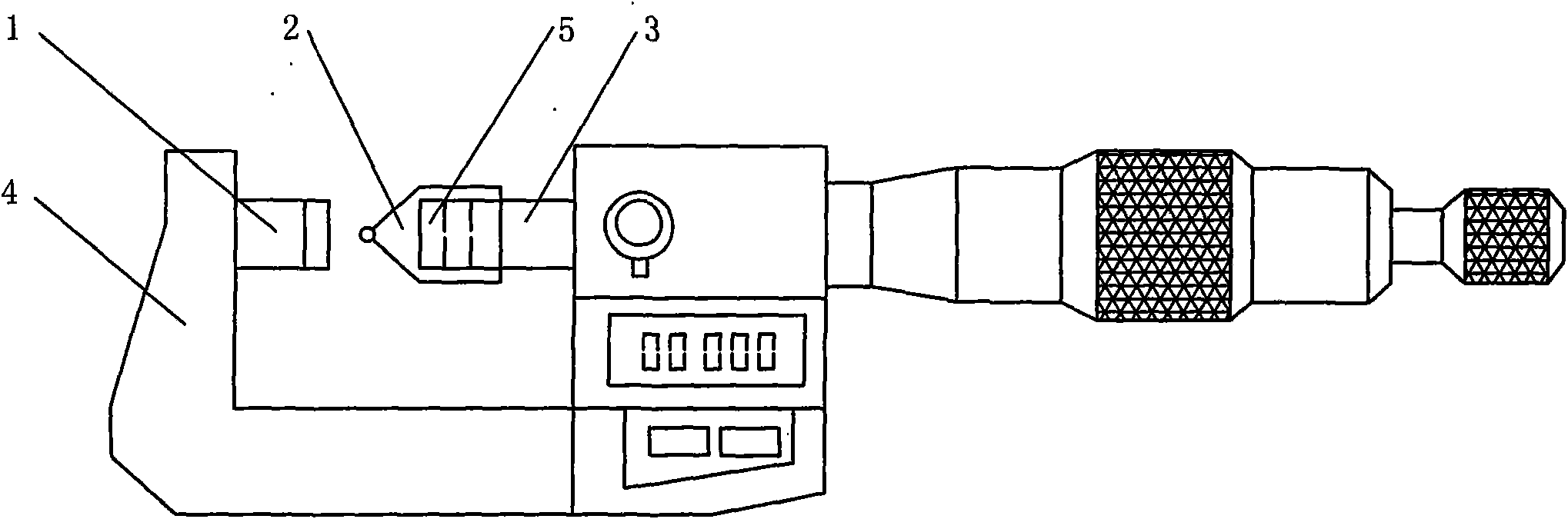

Multifunctional digital micrometer

A digital micrometer multi-function technology, applied in micrometer, mechanical diameter measurement and other directions, can solve the problems of increased manufacturing cost, small end face, limited movement range of mobile micrometer screw, etc., to achieve the effect of expanding functions and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

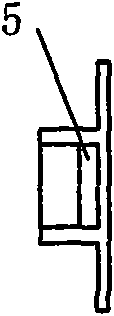

[0016] Multifunctional digital display micrometer, including digital display micrometer, is characterized in that a measuring head is installed on the measuring anvil and / or moving micrometer screw rod of the digital display micrometer, and one end of the measuring head is made to cooperate with the measuring anvil and the moving micrometer screw rod. , Install the magnetic sheet in the inner hole.

[0017] The measuring head is composed of a cone section and a cylinder section, an inner hole is made in the cylinder section, a magnetic sheet is installed in the inner hole, and a sphere is made at the tip of the cone section.

[0018] The measuring head is composed of cylindrical sections at both ends and a cone section in the middle. The cylindrical section connected to the large-diameter end of the cone section is made with an inner hole, and a magnetic sheet is installed in the inner hole. The cylindrical section connected to the small-diameter end of the cone section The en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com