Intelligent control method of loading machine

An intelligent control, loader technology, applied in the direction of earthmoving machine/shovel, construction, etc., can solve the problems of easy fatigue, complex loading site, and high labor intensity of loader drivers, so as to reduce labor intensity and promote high efficiency. The effect of healthy development and improving the working state of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The patent of the present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

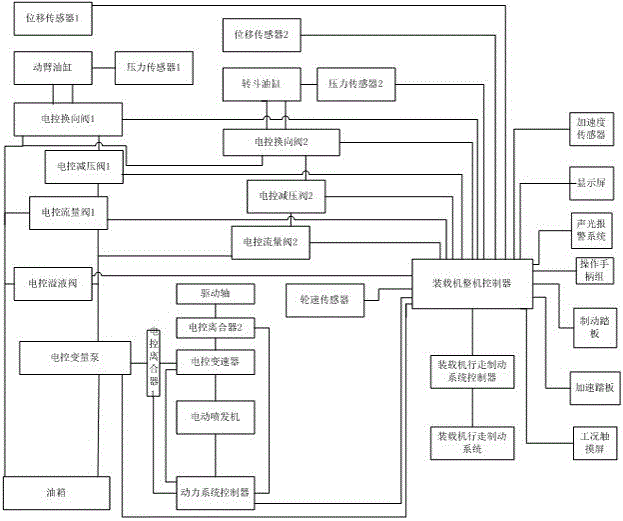

[0008] see figure 1 , the present invention relates to a loader intelligent control method, providing an intelligent control system, the system includes a complete machine controller, the complete machine controller is respectively connected with the power system controller, the travel brake system controller, the electronic control variable Pump, electric control overflow valve, first electric control flow valve, second electric control flow valve, first electric control decompression valve, second electric control decompression valve, first electric control reversing valve, second electric control The reversing valve, the first pressure sensor, the second pressure sensor, the first displacement sensor, the second displacement sensor, and the wheel speed sensor are connected; The clutch is connected to the second electronically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com