High-speed precision punching machine

A precision punching, high-speed technology, applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve the problems of easy deformation caused by eccentric force of guide column assembly tolerance, low stamping precision, difficult adjustment of ball head clearance, etc., to overcome stamping precision Low, stable operation, and compact structure of the punching machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

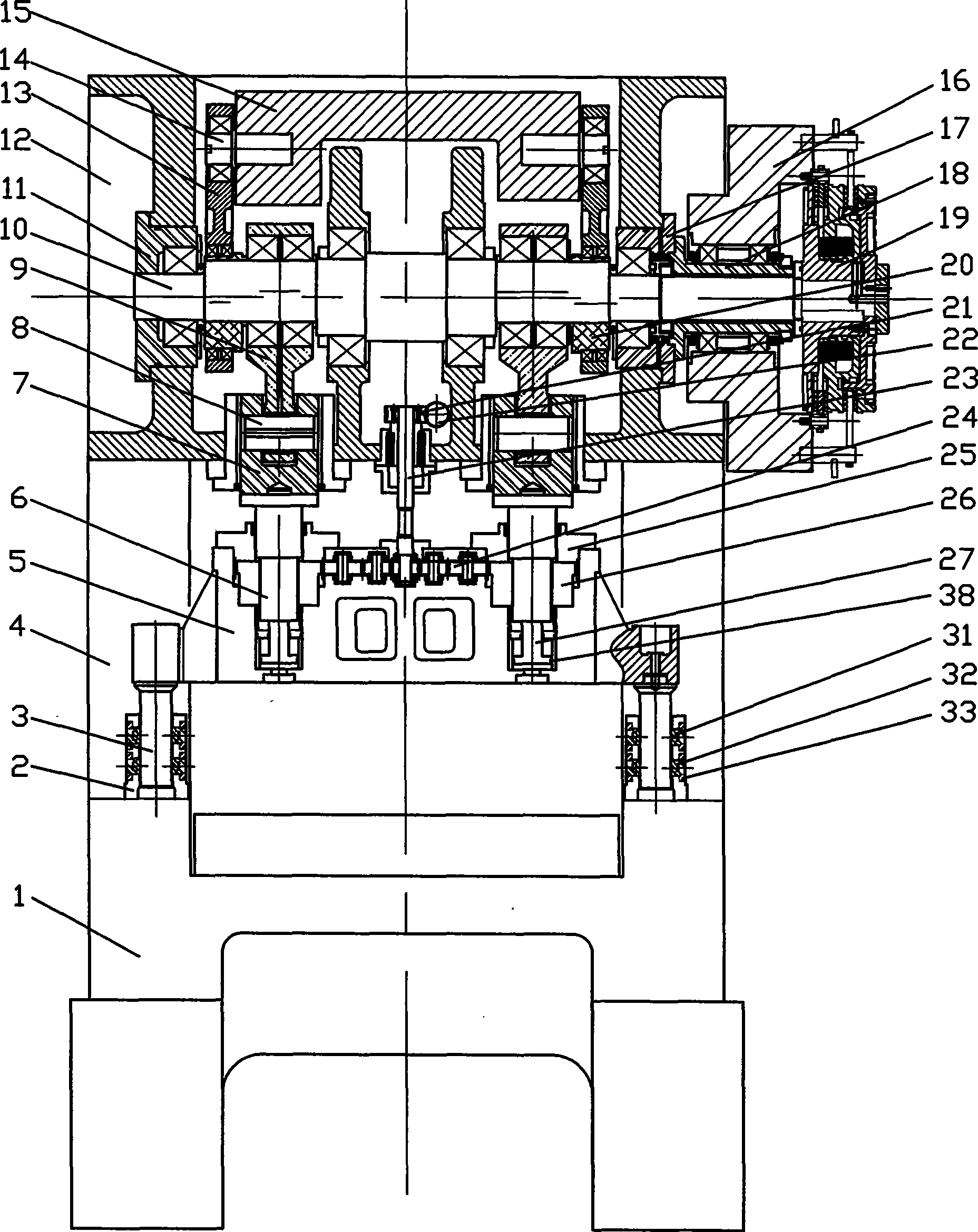

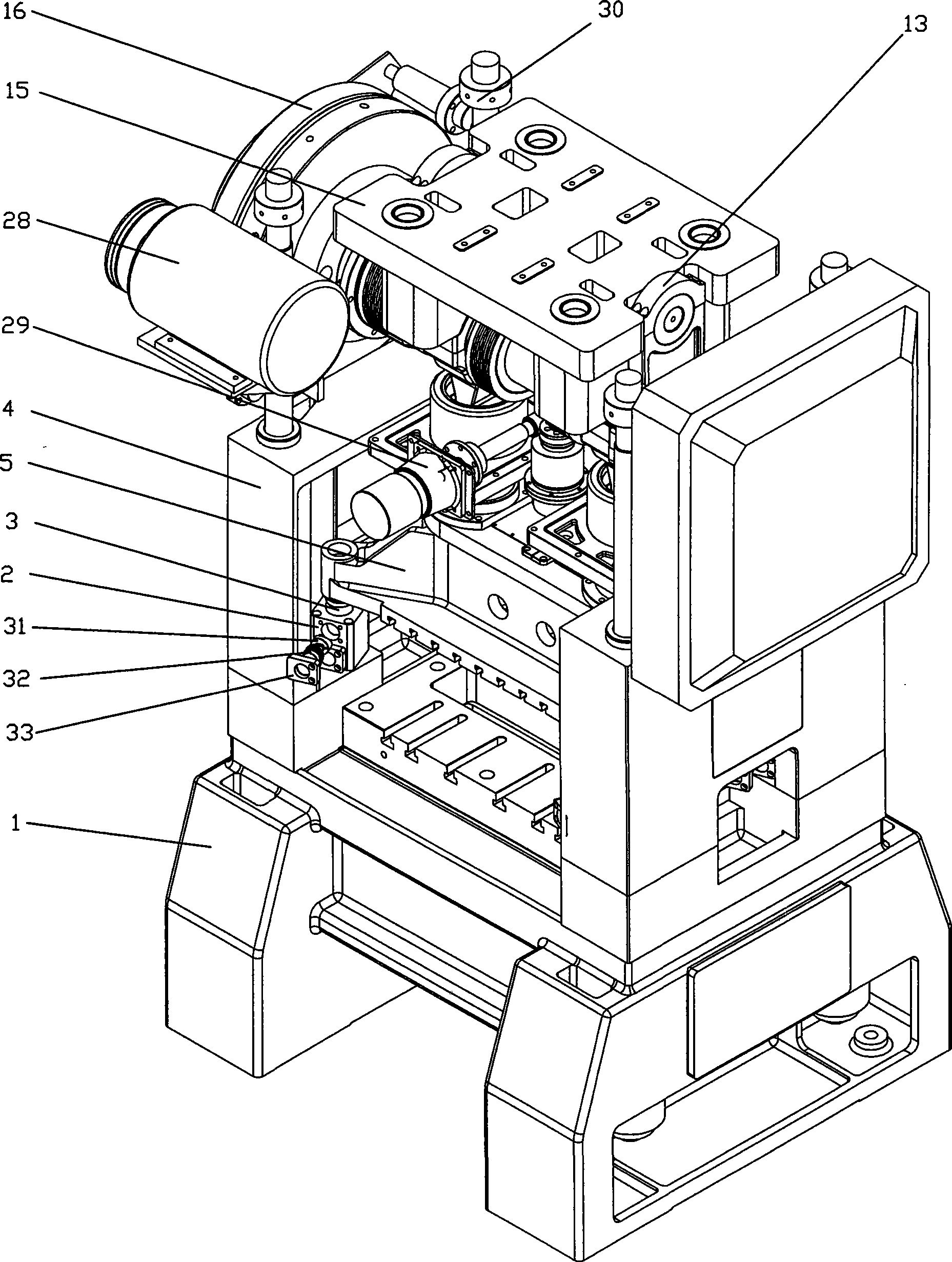

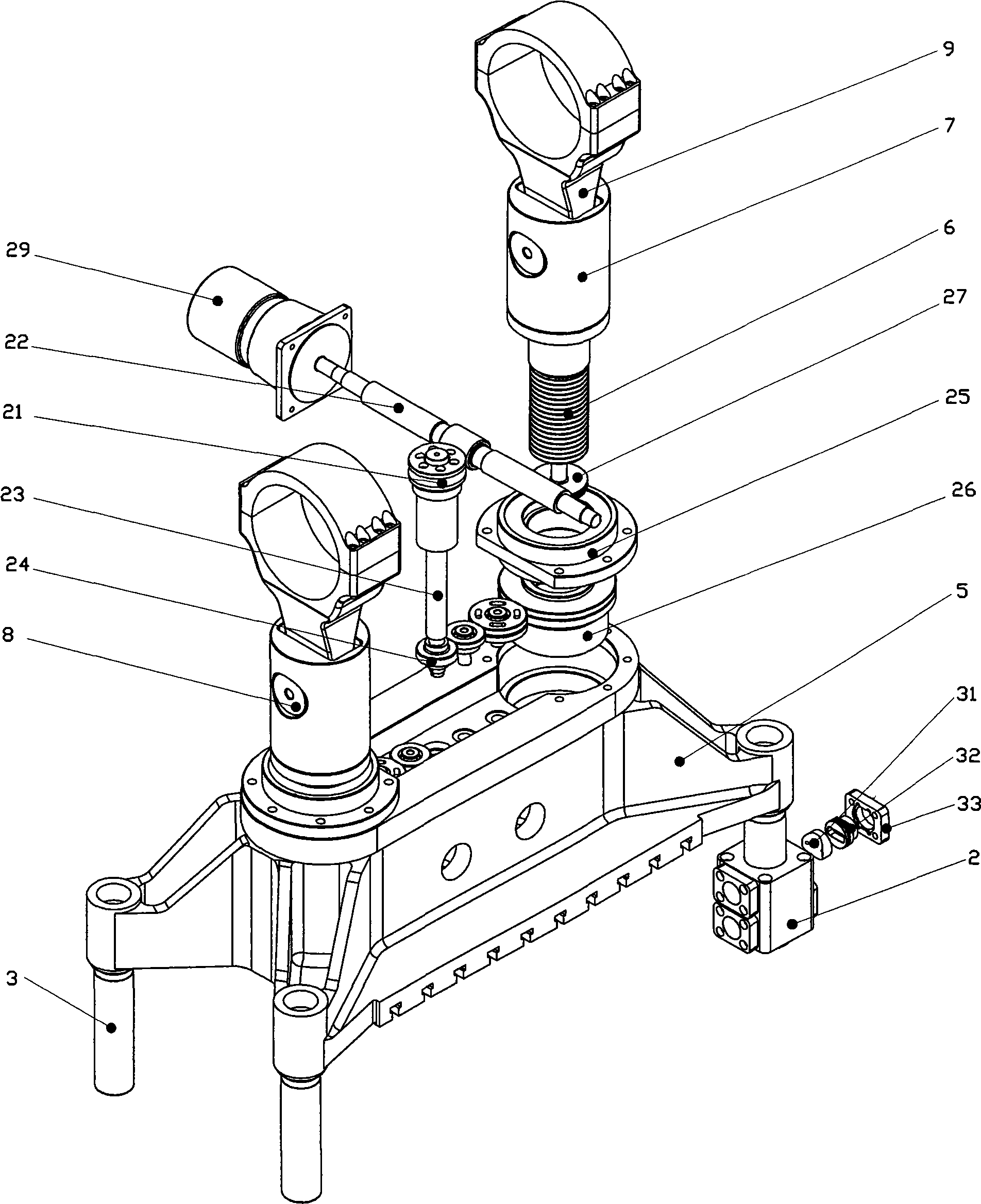

[0013] The dynamic balance part adopts a double-link mechanism. Since the crankshaft 10 is an eccentric shaft device, the eccentric force generated during the movement will cause left and right swings during the stamping process, so two sets of eccentric shafts are installed at both ends of the crankshaft. The collar 20 makes it opposite to the eccentric direction of the crankshaft 10, and is close to the end surface of the eccentric section of the crankshaft, and is connected to the two ends of the dynamic balance weight 15 through the double connecting rod 13 connected to it on both sides, the bearing, and the pin 14 , through the up and down movement of the dynamic balance weight 15 connected by two sets of eccentric collars 20 to offset the eccentric force generated by the crankshaft movement, thereby ensuring that the punching machine can work in bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com