Patents

Literature

36results about How to "Does not occupy effective space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

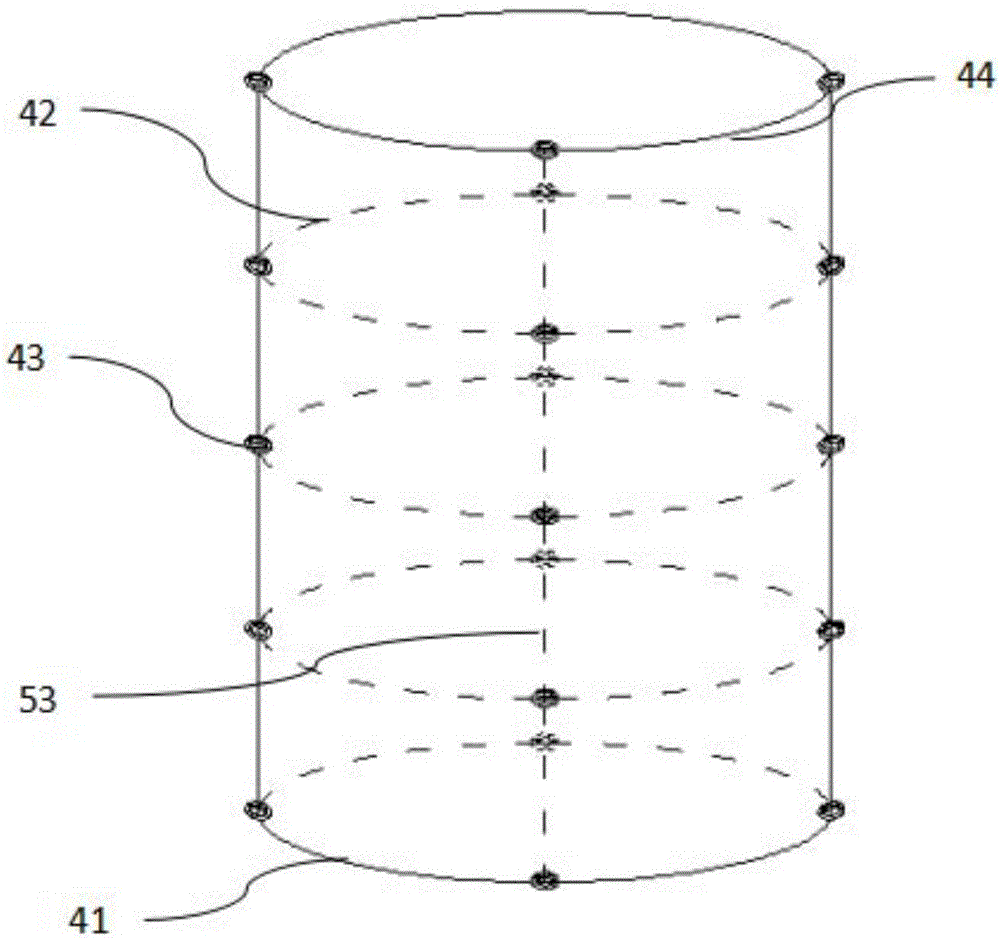

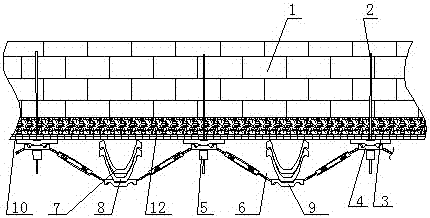

Integrated water purifying equipment for concurrent inclined plate precipitation

ActiveCN103172155ACompact structureSmall footprintWater/sewage treatment by flocculation/precipitationTreatment effectEngineering

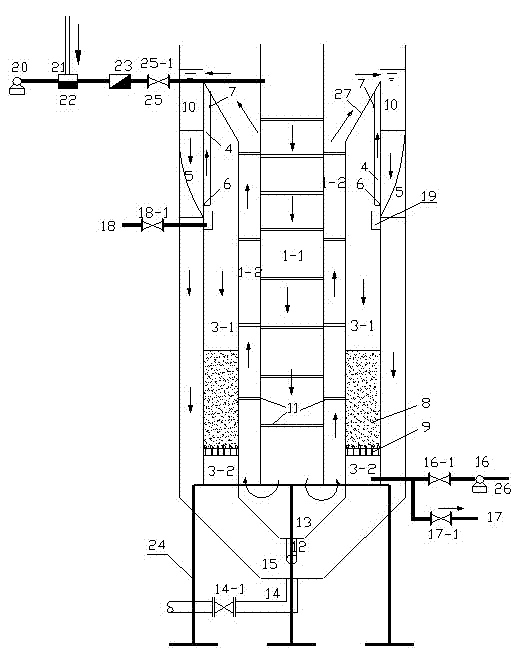

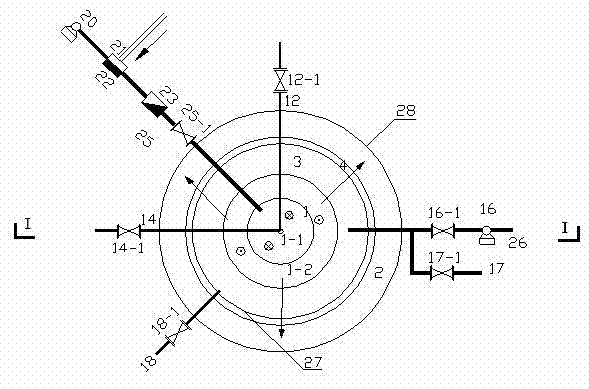

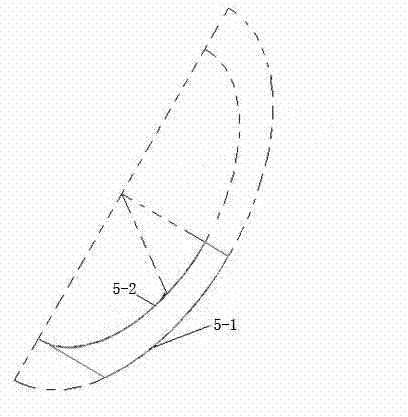

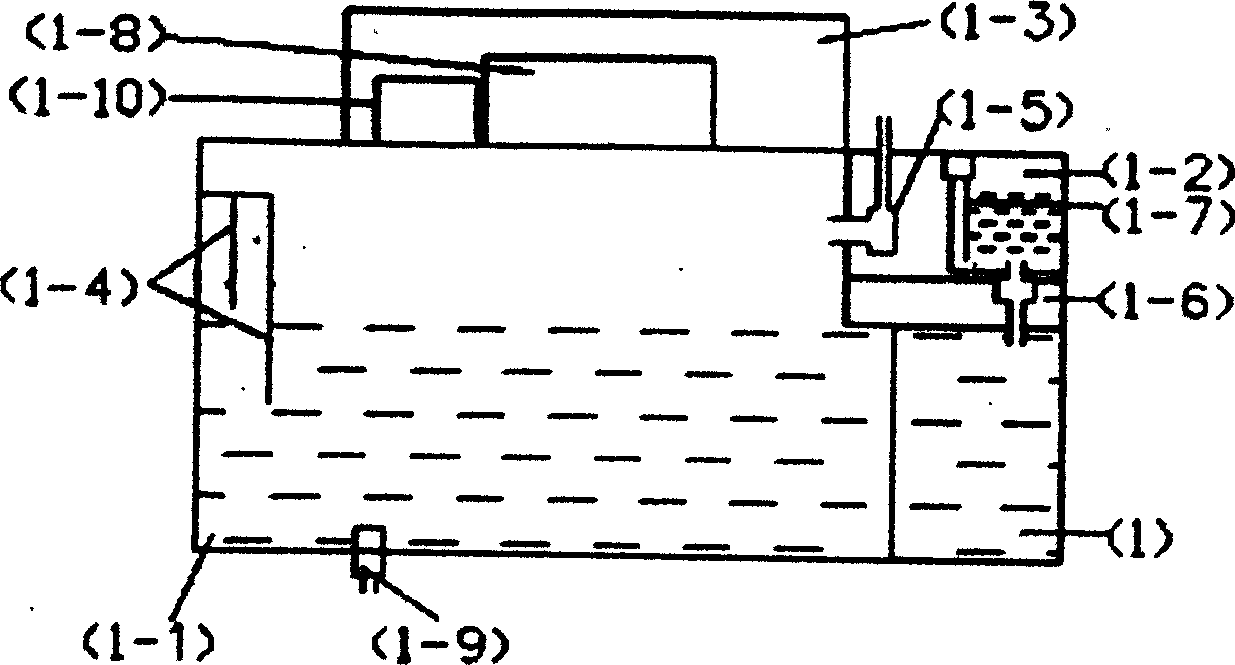

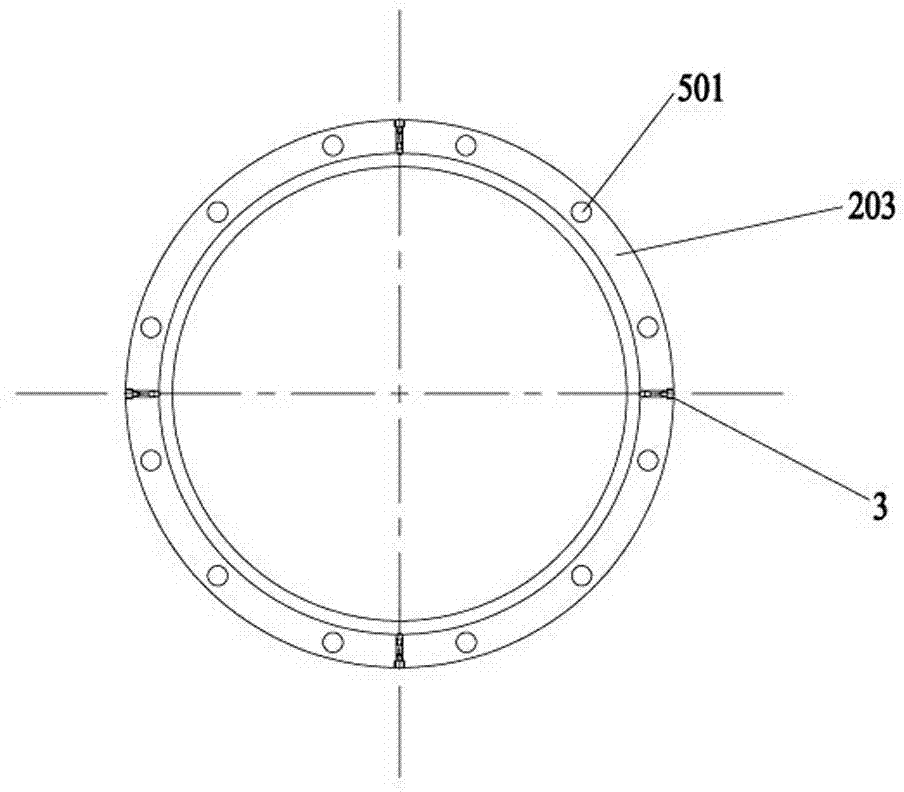

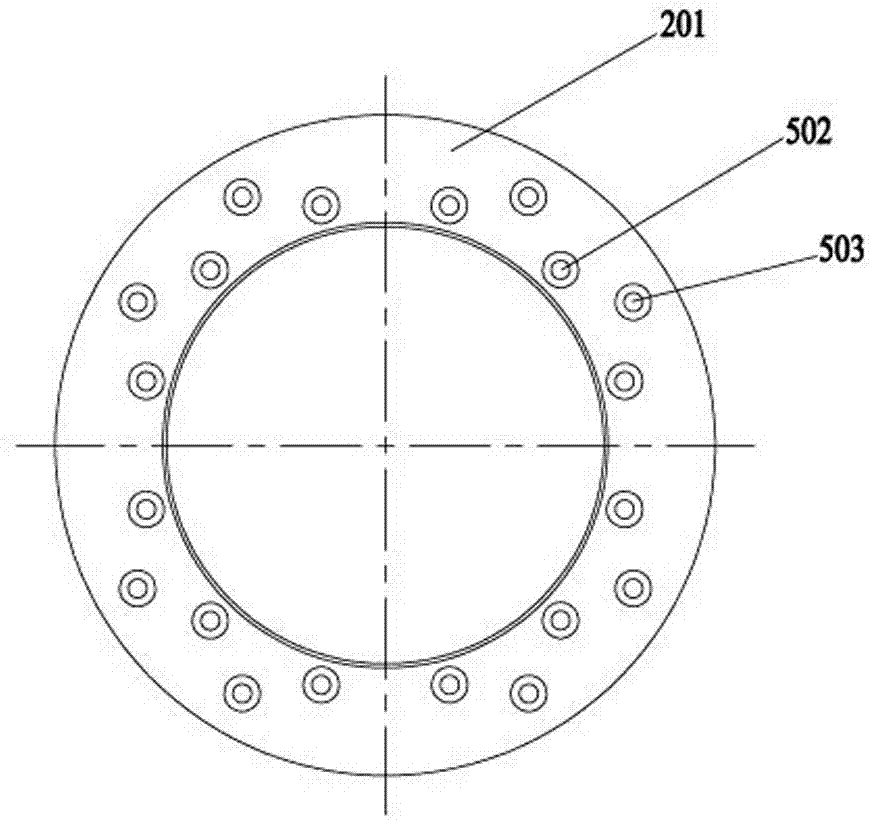

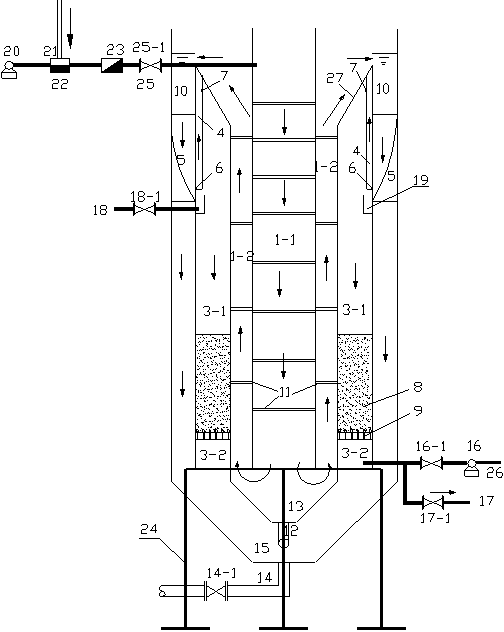

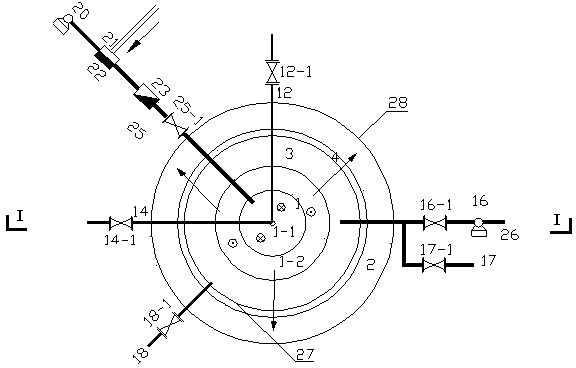

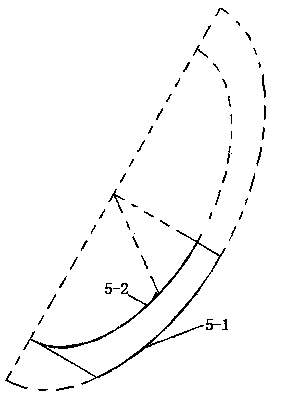

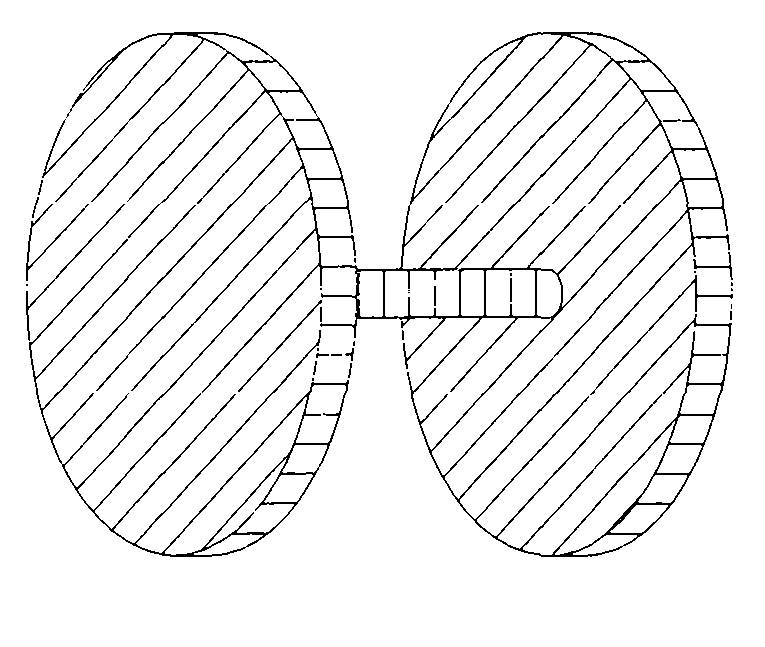

The invention relates to integrated water purifying equipment for concurrent inclined plate precipitation. A main body is concentrically partitioned into inner, middle and outer cylinders, which are respectively a flocculation zone, a filter zone and a concurrent inclined plate precipitation zone, wherein a water distributing zone is arranged at the upper segment of the concurrent inclined plate precipitation zone; an inclined plate group zone is arranged at the middle segment; a sludge concentrating chamber is arranged at the lower end; a water collecting zone is arranged between the water distributing zone, the inclined plate group zone and the filter zone; the bottom part of the water collecting zone is respectively communicated with the inclined plate group zone and the filter zone through pores; a circle of inclined plates are evenly distributed in the inclined plate group zone; the inclination angles theta of the inclined plates are 30-45 degrees; and the pores are arranged at the positions between the tail ends of two adjacent inclined plates at the bottom part of the water collecting zone and are communicated with the inclined plate group zone and the water collecting zone. The concurrent inclined plate precipitation technique is applied to the integrated water purifying equipment; flocculation, concurrent inclined plate precipitation and filtering are combined together; and the treatment process is independently and synergetically finished, so that the flocculation, concurrent inclined plate precipitation and filtering fully develop the advantages; and the integrated water purifying equipment is good in treatment effect, compact and reasonable, small in floor area, and convenient to install.

Owner:CHONGQING UNIV

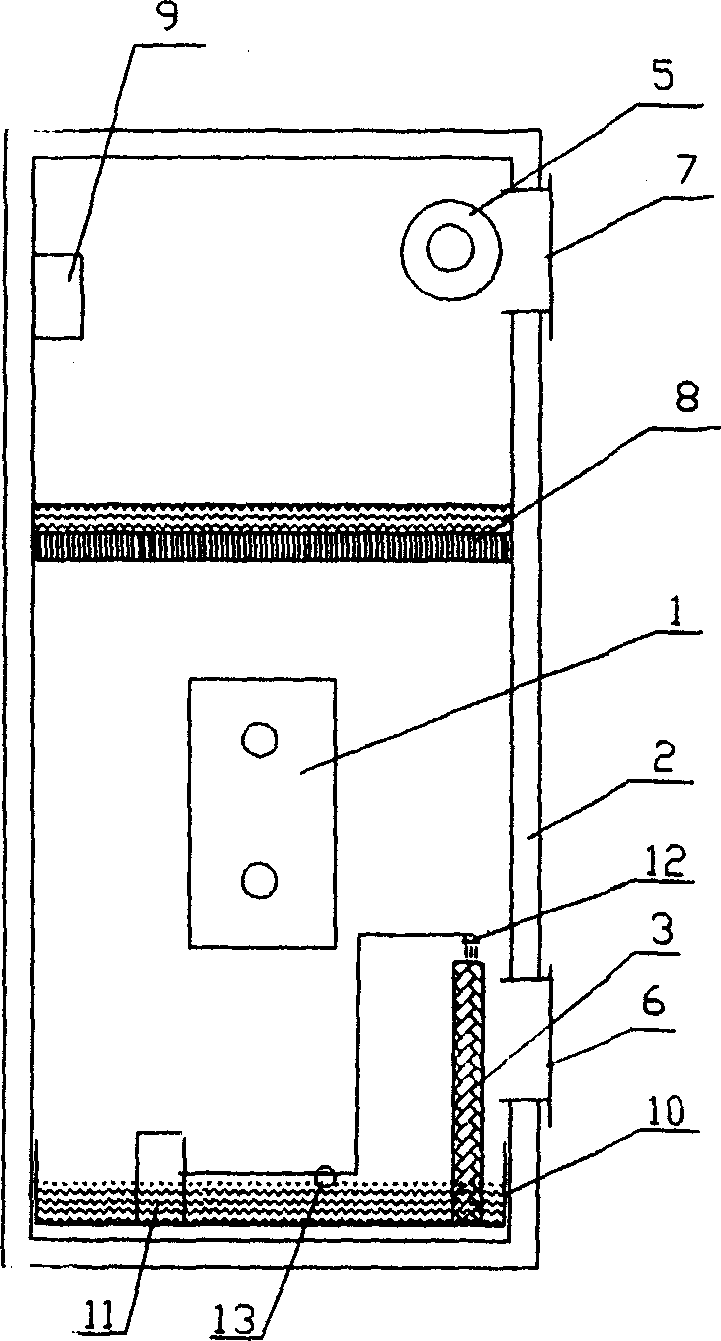

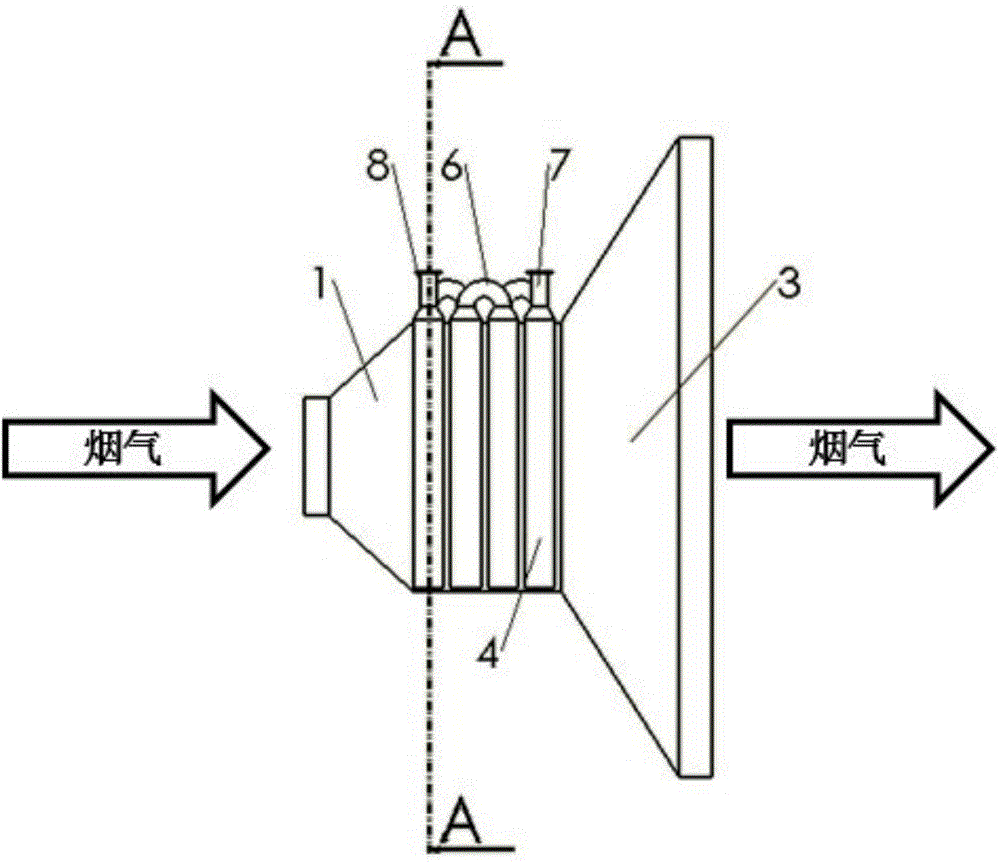

Multifunction counter-flow radiator

InactiveCN1580653ALow costDoes not occupy effective spaceLighting and heating apparatusSpace heating and ventilation detailsBreatherEngineering

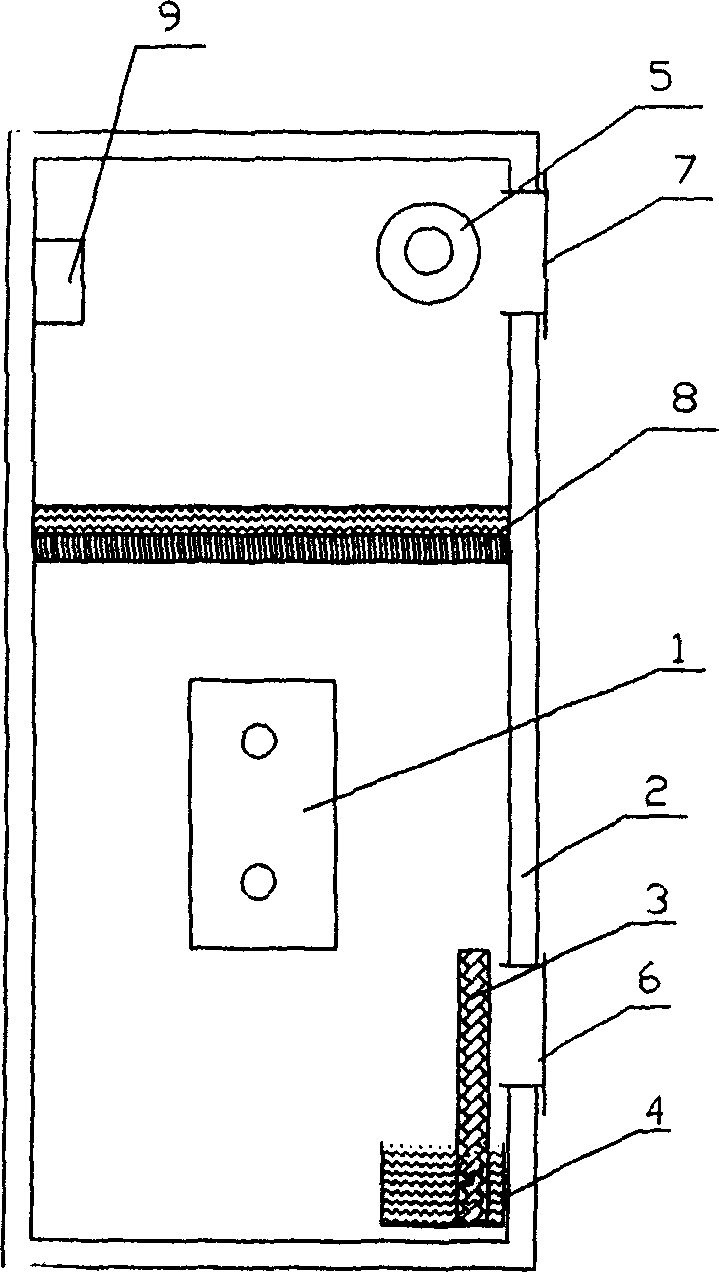

This is a multi-functional convection radiator. It fully uses the chimney-effect of the convection radiator and air blower, humidification device, and air purification device are added. Its technologic scheme is: around the radiator there is convective cover, on the upper part and down part of this cover there are inlet and outlet air breather, between the air-breather and radiator elements, wet-membrane wetting device and air purification device and air blower are added. So that in winter may purify air by wetter and heating, in summer may use the steam to wet the air, and refrigerate.

Owner:宋伟增

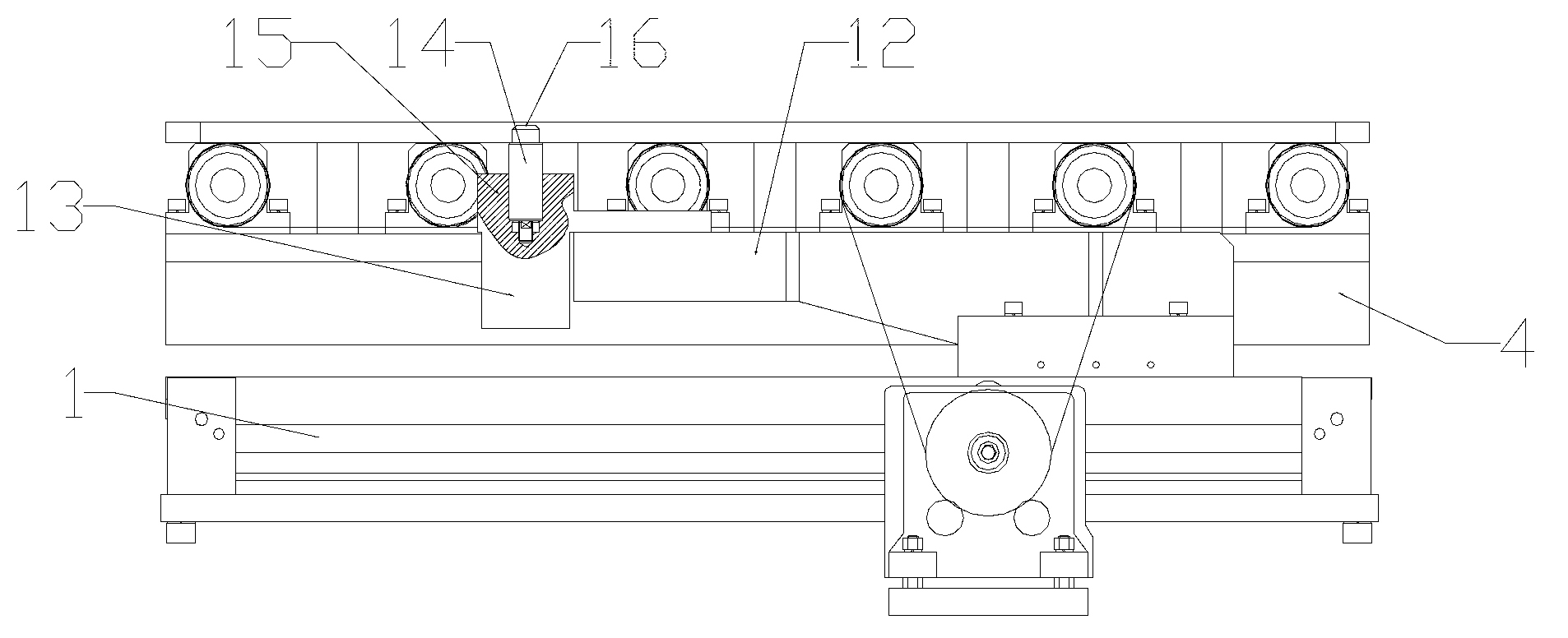

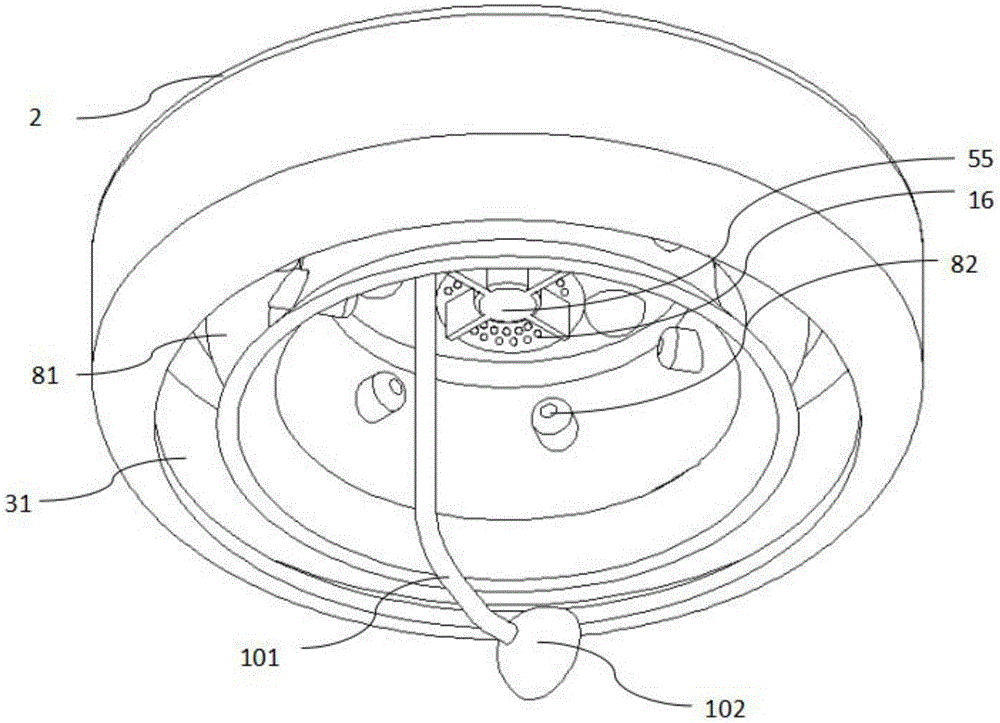

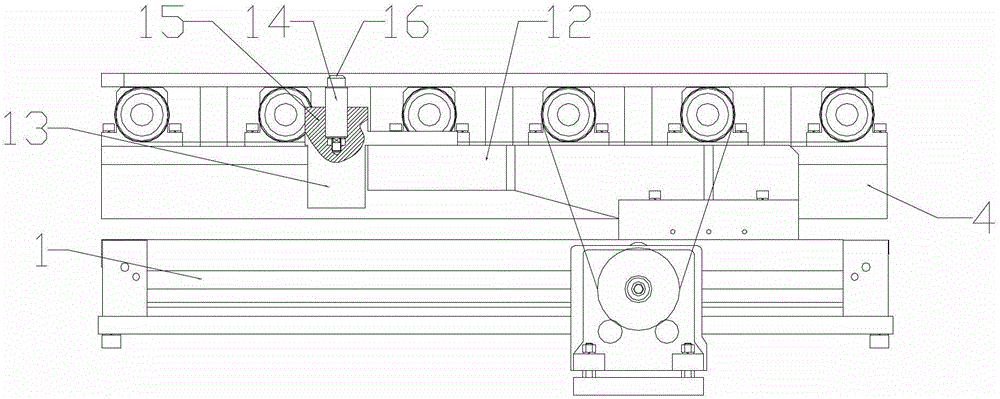

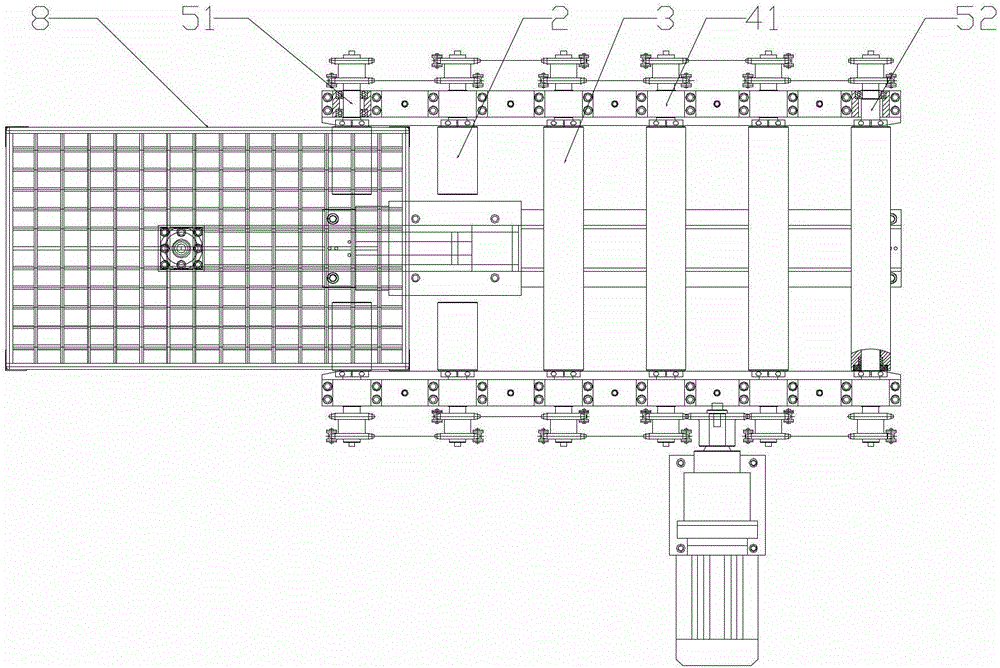

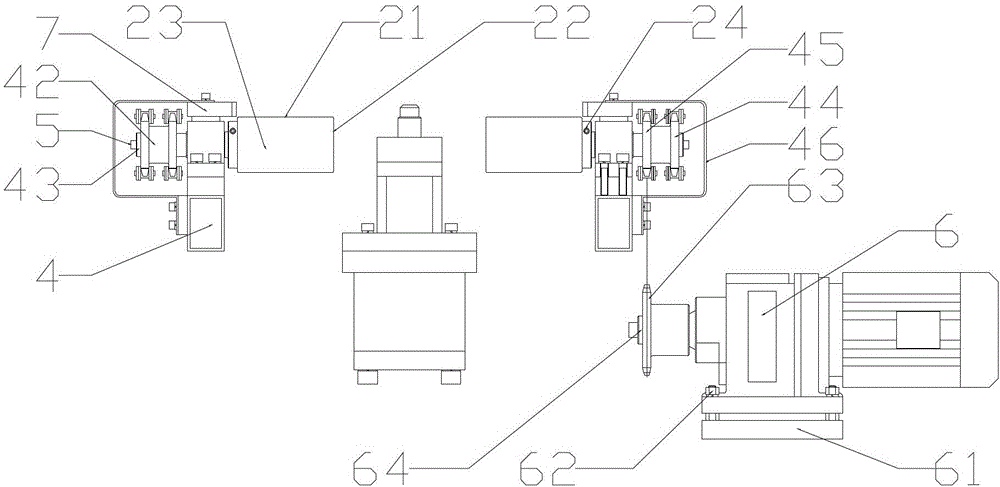

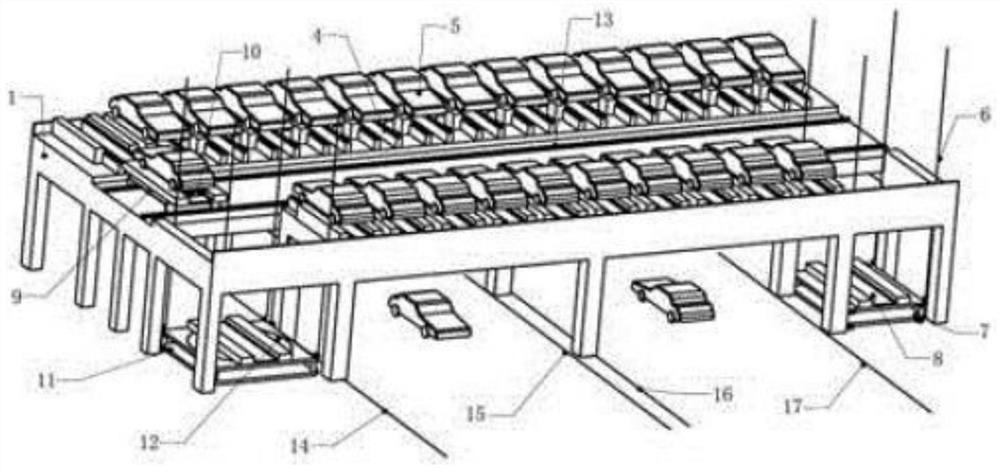

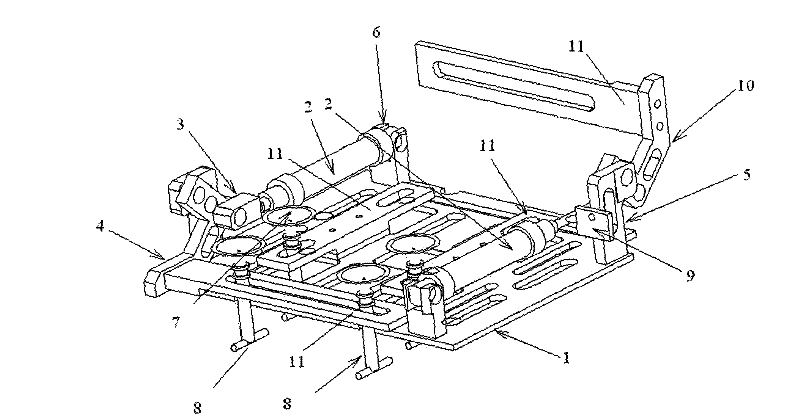

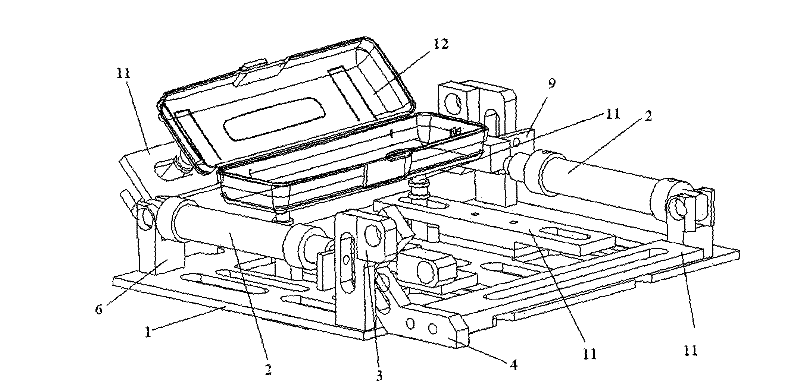

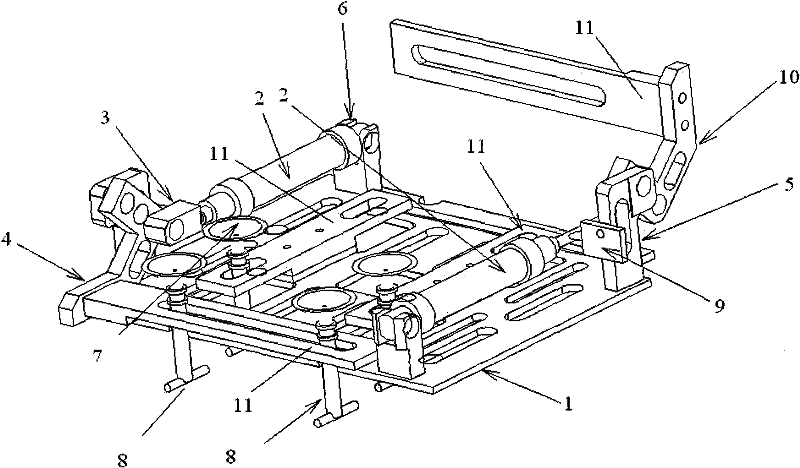

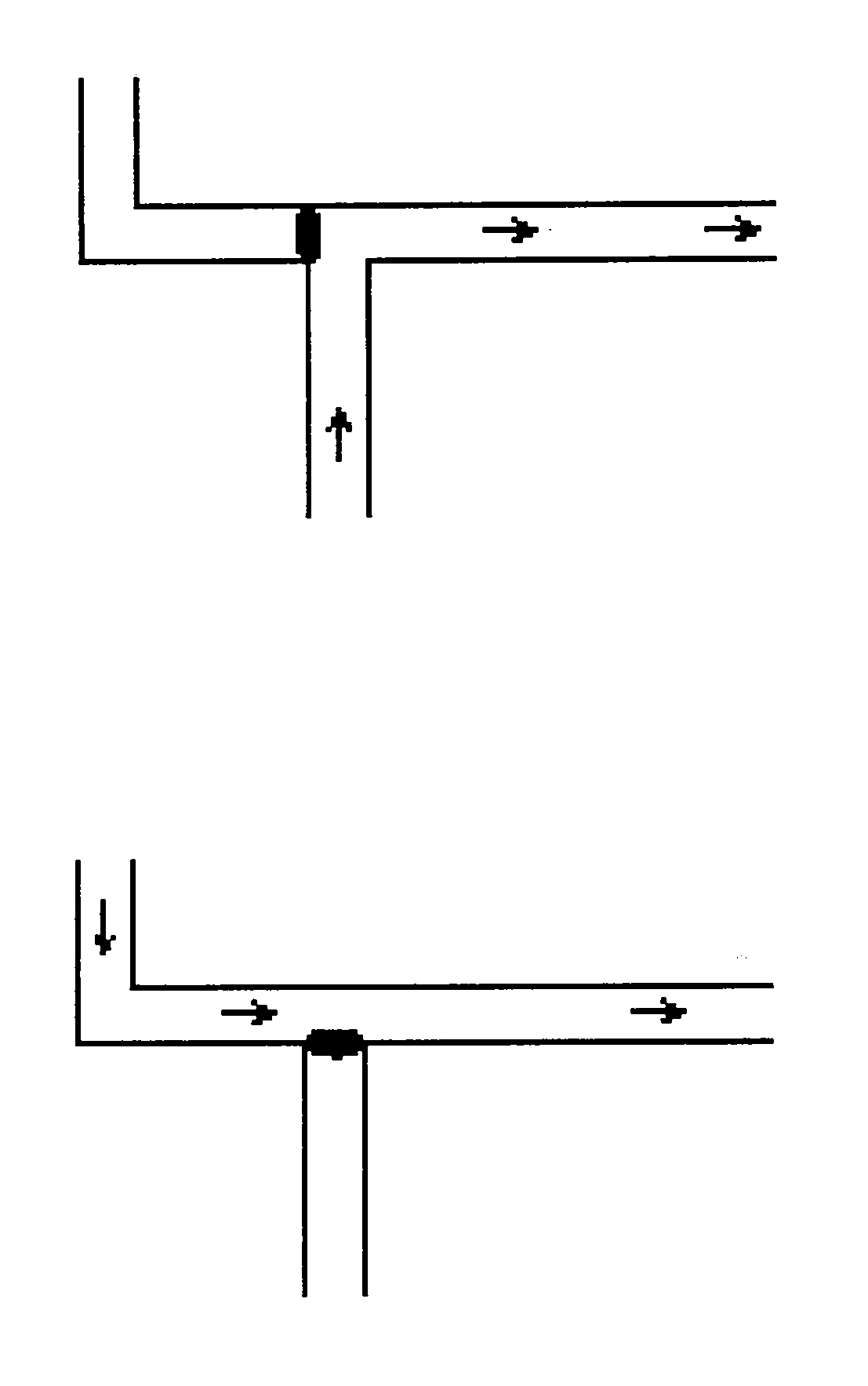

Automatic feeding and discharging roller conveyor

ActiveCN103010730ASolve problems such as poor transition and raceway damageHigh degree of automationConveyor partsRoller-waysPush pullEngineering

The invention discloses an automatic feeding and discharging roller conveyor, which comprises a raceway, a power device and a rack. The automatic feeding and discharging roller conveyor is significantly characterized in that a feeding and discharging device is arranged under one end of the raceway and comprises a rodless cylinder, a cylinder pad plate arranged on the lower part of the rodless cylinder and a push-pull rod connected with a piston sliding block on the upper part of the rodless cylinder, the right part of the push-pull rod is provided with a push-pull pin guide seat, a push-pull pin is arranged in the push-pull pin guide seat, a transmission roller comprises two half rollers and an overall roller, and a gap is arranged between the two corresponding half rollers. The automatic feeding and discharging roller conveyor has the beneficial effects of transition between two power raceways can be realized, transition between a material platform and the conveyor can also be realized, and the problems of non-smooth transition and damage to the raceway can be solved effectively. Moreover, automatic feeding and discharging roller conveyor has the advantages of high degree of automation, smooth and orderly transition, compact and reasonable structure and less occupied space.

Owner:WUXI BAOHE MACHINERY EQUIP

Modern ecological combined system of lavatorial appliance capable of controlling foam by digital system

InactiveCN1485507ADoes not occupy effective spaceFlushing devicesBathroom coversEngineeringProduct gas

A digital control foam lavatory ecological integrated system, wherein disinfection foam is generated by means of a digital controller, and the top and lower liquid level are also controlled, for continuous depth filling crouching and suspension closet, the toilet seat is sterilized and cleaned before use, realizing a multiple flush-free, foam, water accumulation and water bag smell stopping system. The system by the invention can substantially reduce the management, cleaning and transportation cost.

Owner:李福清

Ship safety selfhelp device

A high-safety self-saving device for ship features that a rolled (or foldded) air bag is communicated via control valve and pipeline to compressed air cylinder and after said control valve is turned on, the air bag is inflated and developed to make it close to the ship hull. Its advantages are simple structure, low cost and high reliability.

Owner:李斌

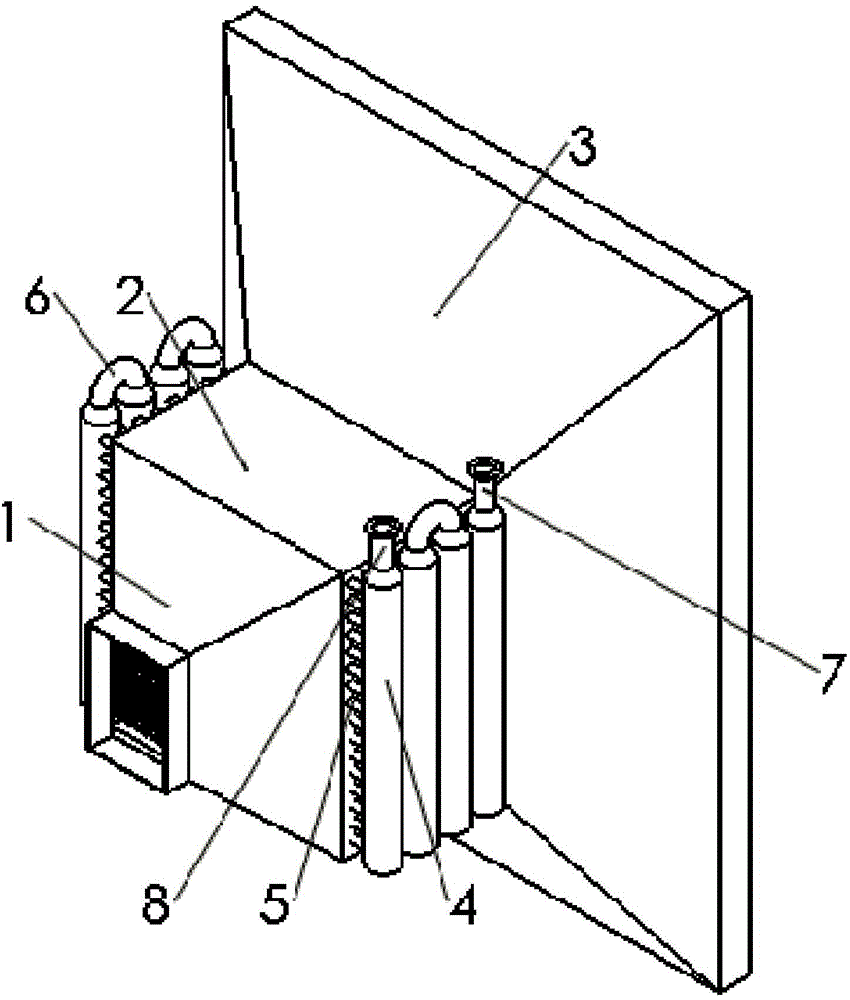

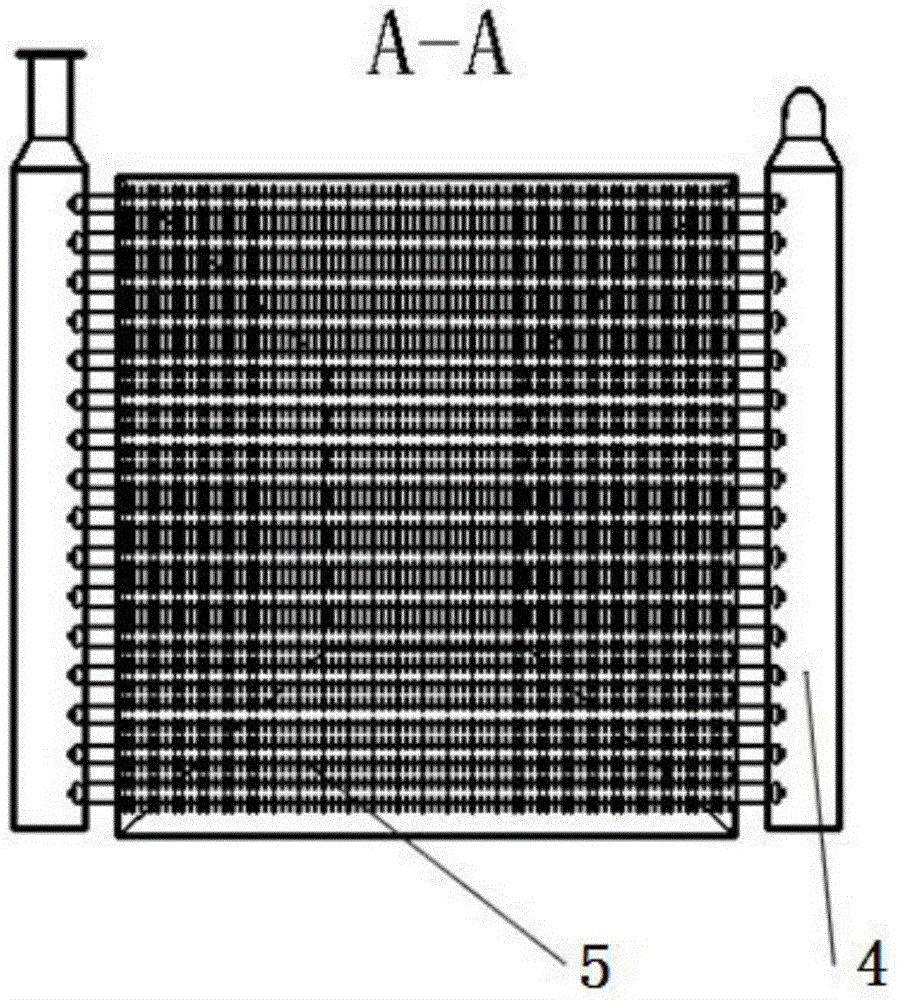

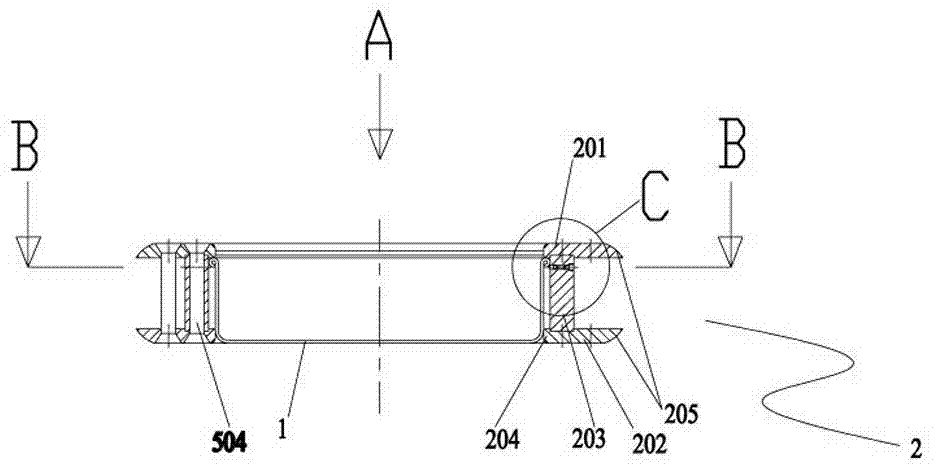

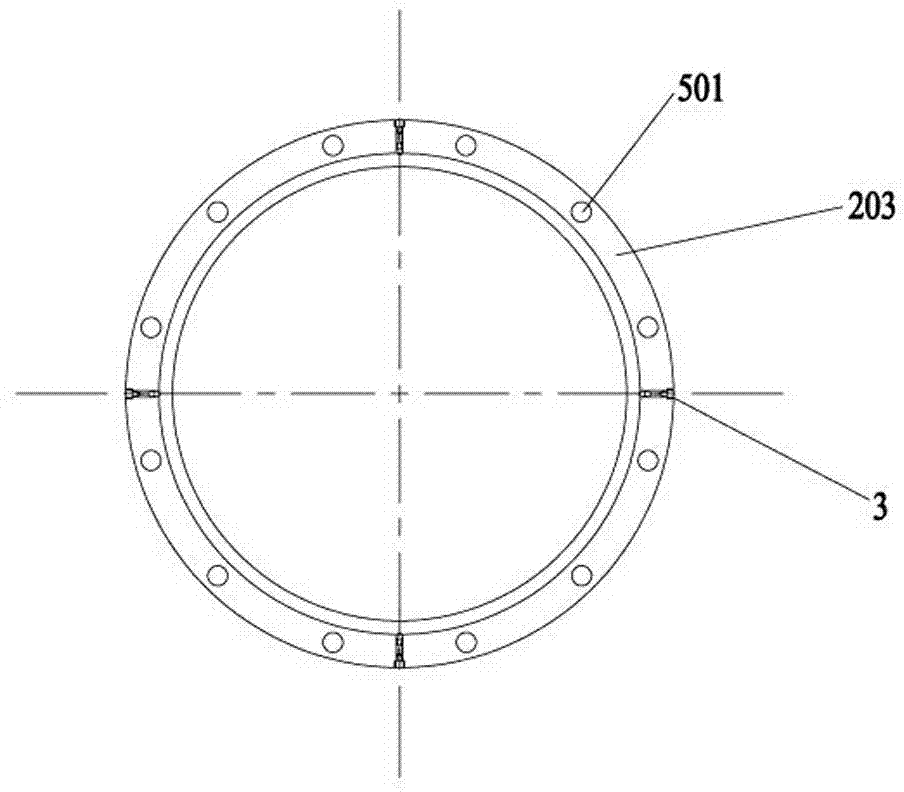

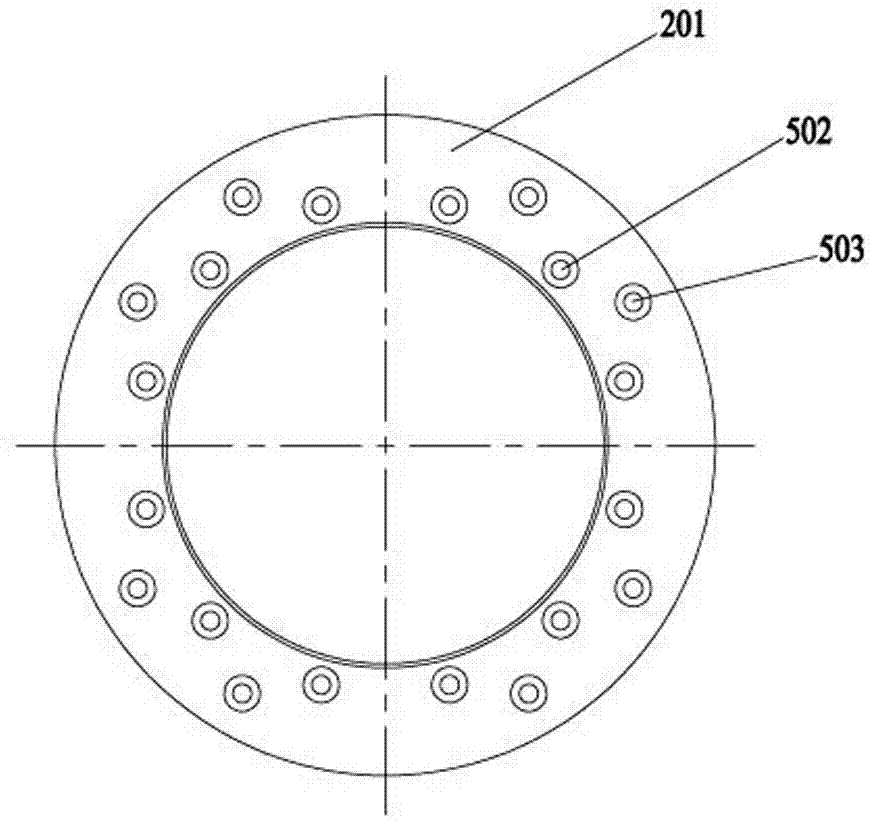

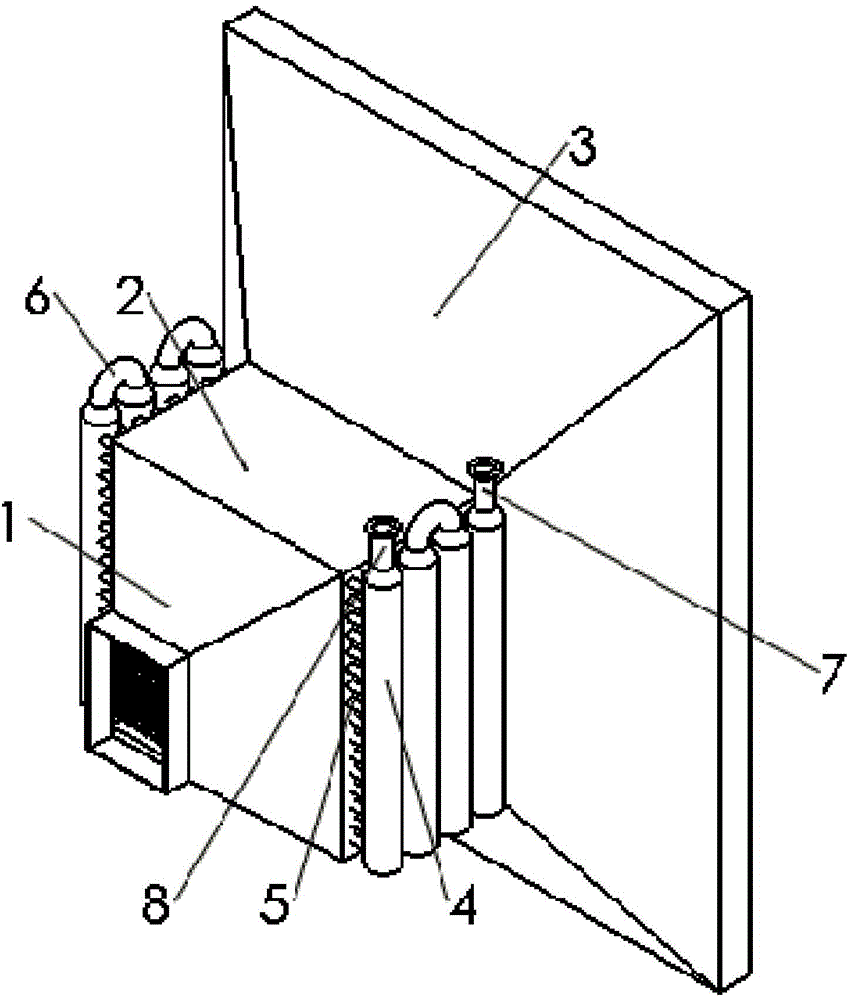

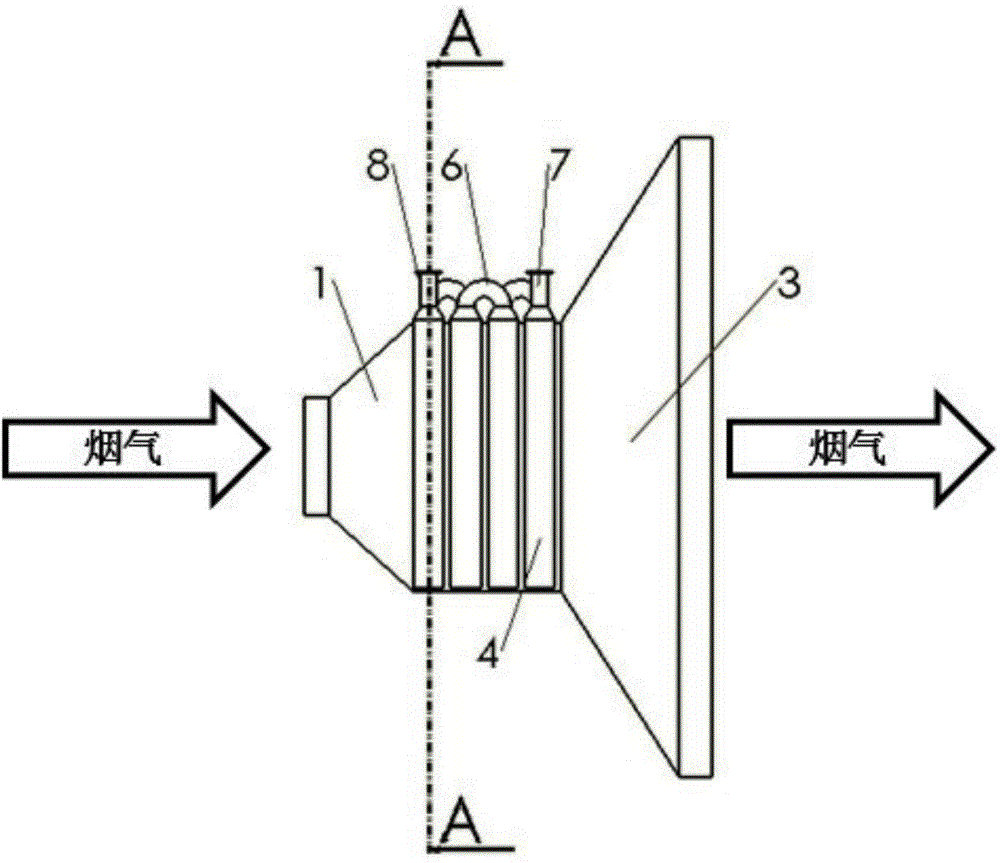

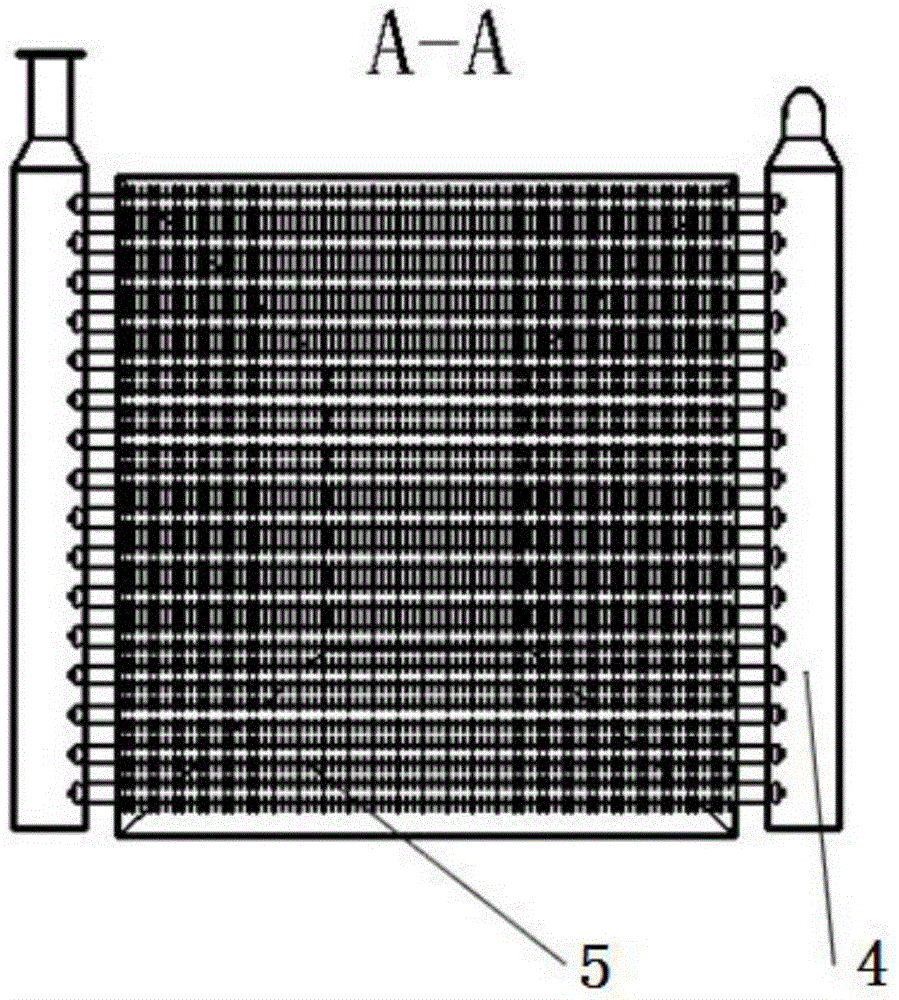

Novel tube panel type water tube heat exchanger integrated with electrostatic precipitator

ActiveCN103604113AMake full use of the flue spaceSmall footprintCombustion technology mitigationFeed-water heatersElectrical resistance and conductancePlate heat exchanger

A novel tube panel type water tube heat exchanger integrated with an electrostatic precipitator consists of a plurality of rows of tube panels, wherein each row of tube panels consists of heat exchanger headers at two ends and a plurality of heat exchanging tube bundles which are connected with the heat exchanger headers at the two ends; tube ends of the heat exchanger heads at the two ends of each of the adjacent tube panels are connected to one another through large-diameter elbows, so that working media of the adjacent tube panels are connected to one another; and heat exchanging tube bundles of each tube panel are arranged in a flue structure in a middle section of an extension section of an inlet of the precipitator. The heat exchanger does not occupy the other effective space in front of the inlet of the electrostatic precipitator; the waste heat of the smoke can be reasonably used; and the specific resistance of the soot is reduced, so that the efficiency of the electrostatic precipitator is improved. The novel tube panel type water tube heat exchanger integrated with the electrostatic precipitator has the advantages that the structure is simple and compact, modular production and modular assembly can be realized, and field installation is quite convenient.

Owner:CENT SOUTHERN CHINA ELECTRIC POWER DESIGN INST CHINA POWER ENG CONSULTING GROUP CORP +1

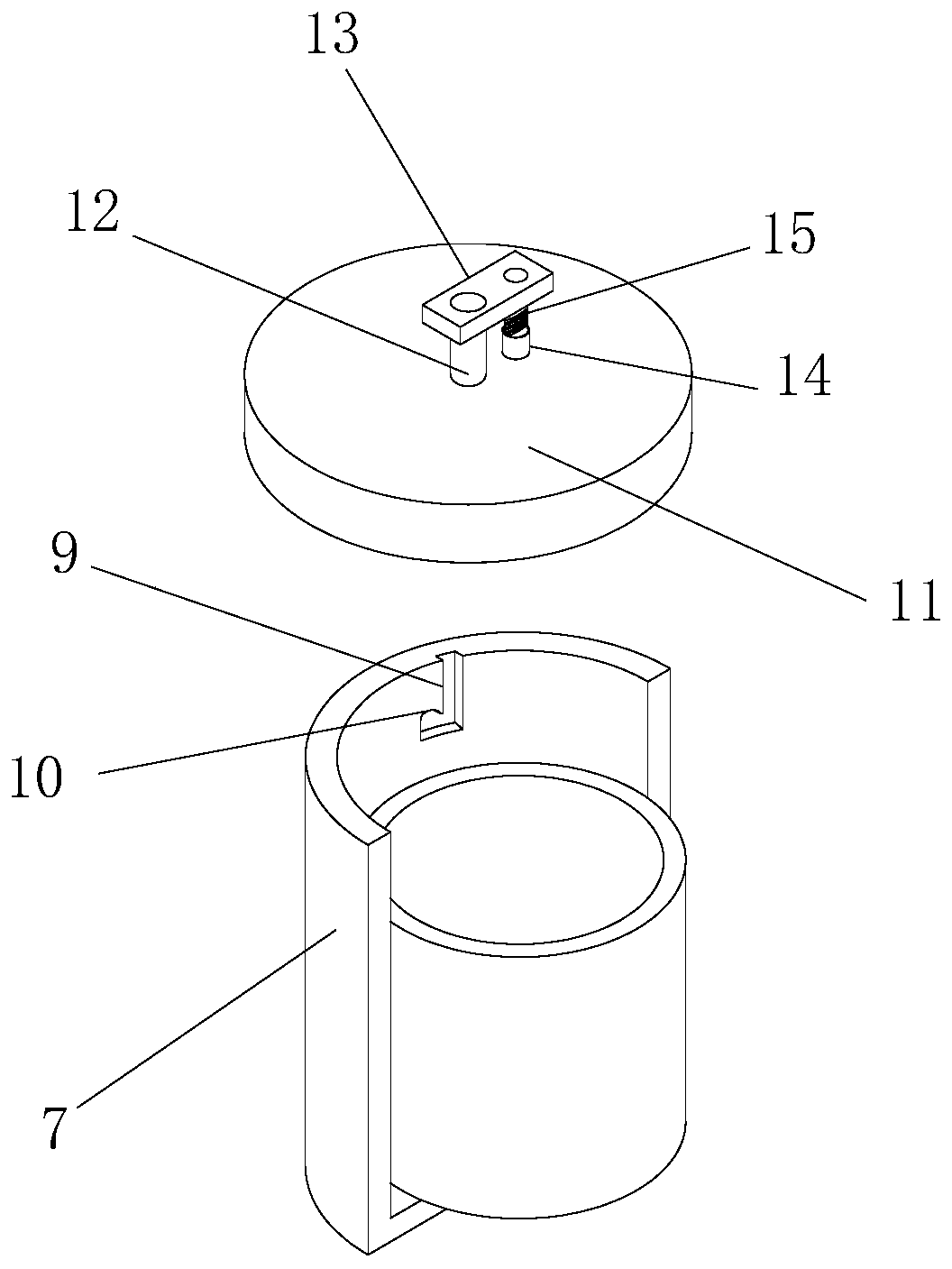

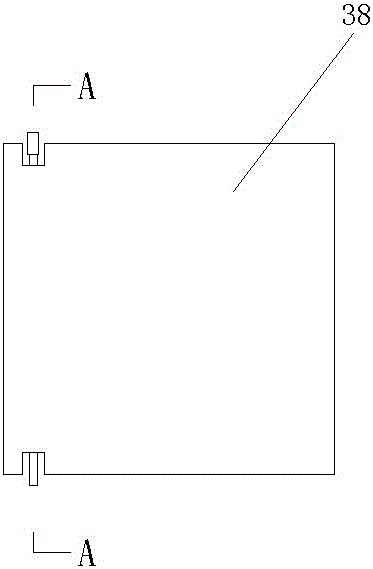

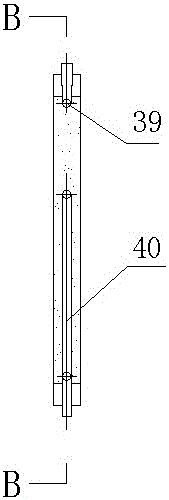

Retractable cup saucer

The invention relates to a retractable cup saucer which comprises a vertically retractable cup saucer body and a fixing assembly. The fixing assembly is used for fixing the cup saucer body onto an outer plate and comprises an upper fixing plate, a lower fixing plate and a collar, the collar is positioned between the upper fixing plate and the lower fixing plate, and the cup saucer body is nested in the collar; the edge of an opening in the upper end of the cup saucer body is turned out to form a flange; elastic parts and a boss are arranged on the inner wall of the collar, and the relative retraction position of the cup saucer body can be constrained by the elastic parts and the boss. Compared with the prior art, the retractable cup saucer has the advantages that the placing depth of a cup can be effectively increased, so that the placing stability of the cup can be improved, the cup is not easy to topple over, and the retractable cup saucer not only is generally applicable to dining tables, but also is applicable to commercial office tables with requirements; the cup saucer extends downwardly, so that an effective service space can be saved for a user, and the cup saucer can be collected when not used; the retractable cup saucer is fixed by the aid of rivets and accordingly is firm; components of the retractable cup saucer are simple in structure, and accordingly additional casting moulds can be omitted.

Owner:阮建军

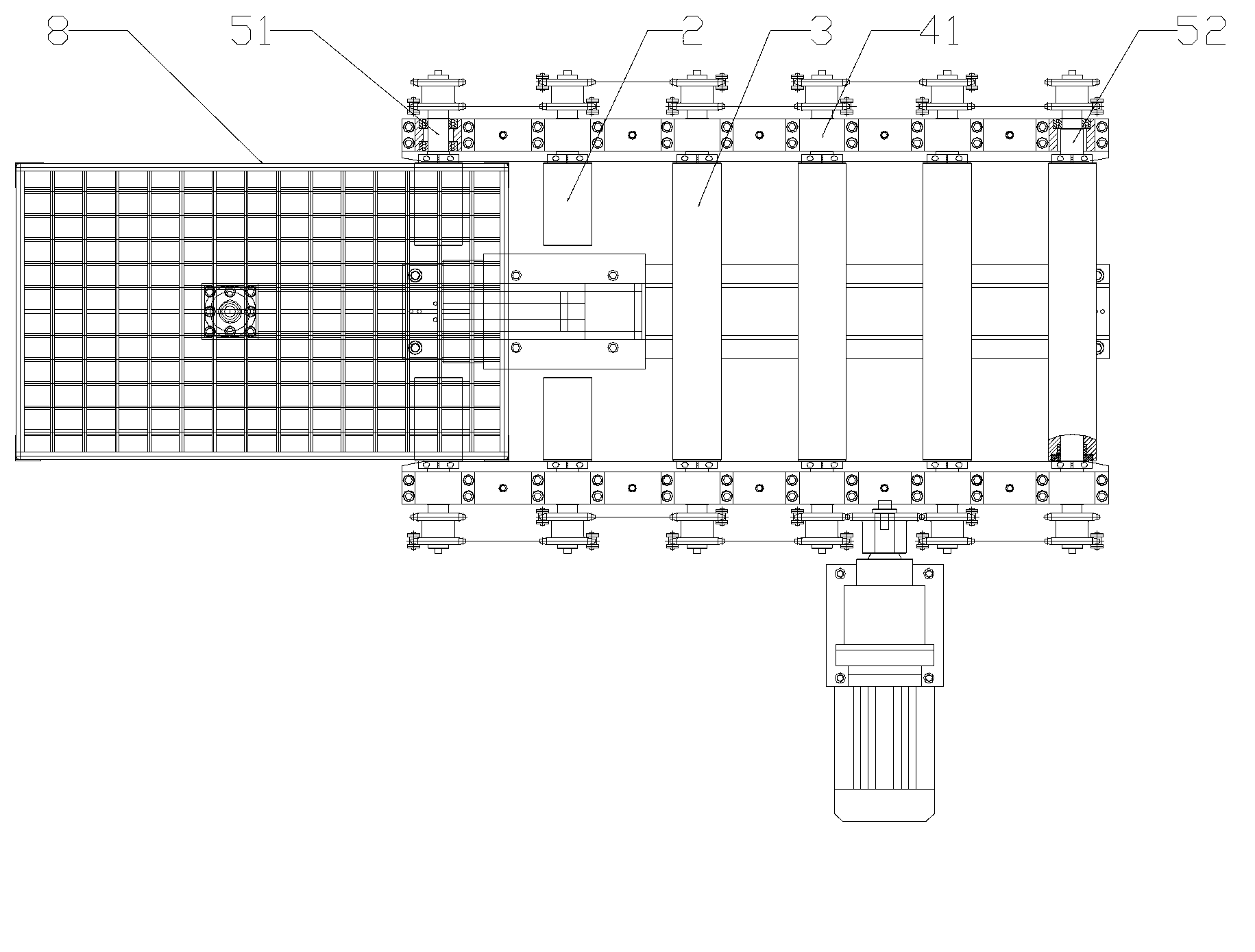

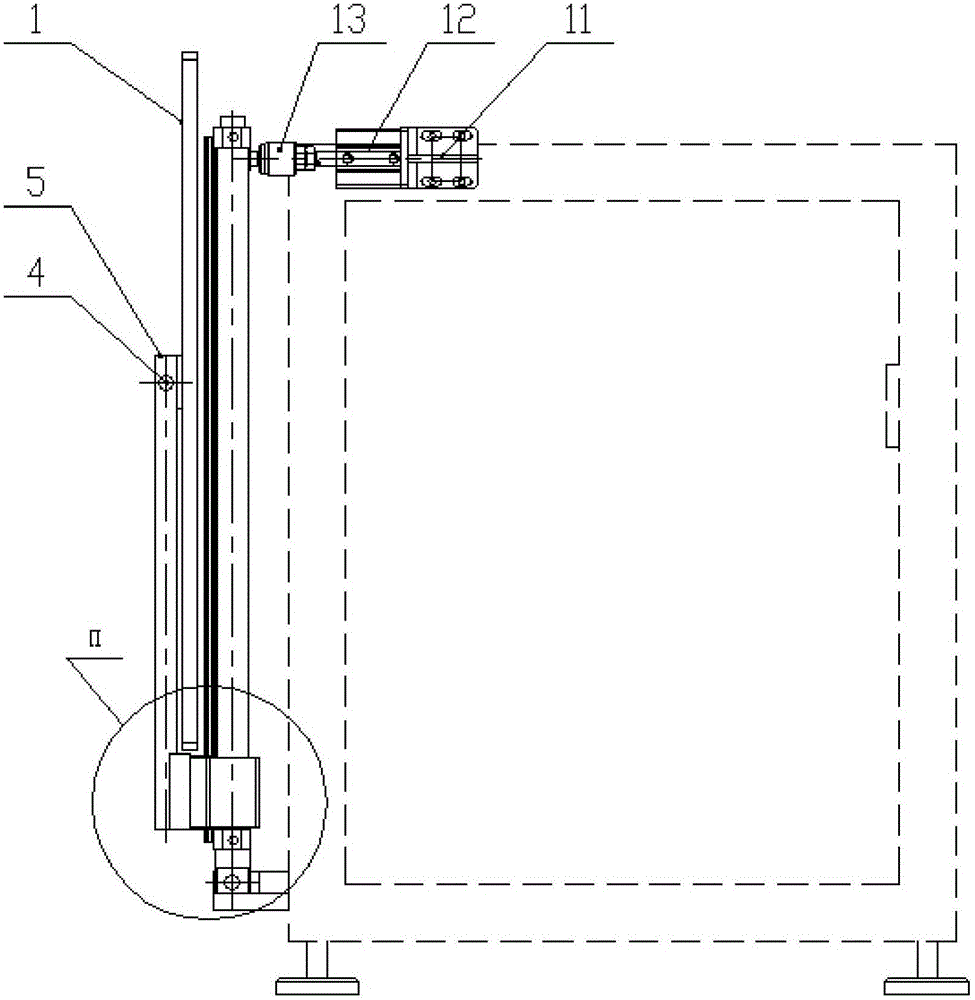

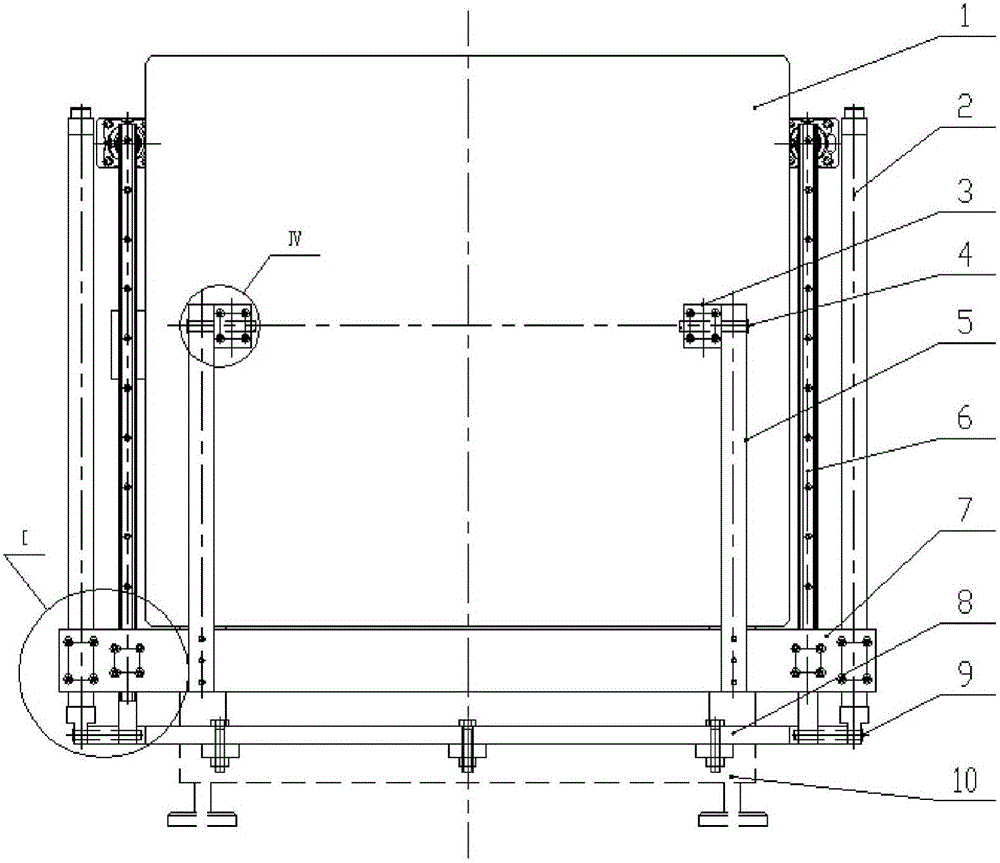

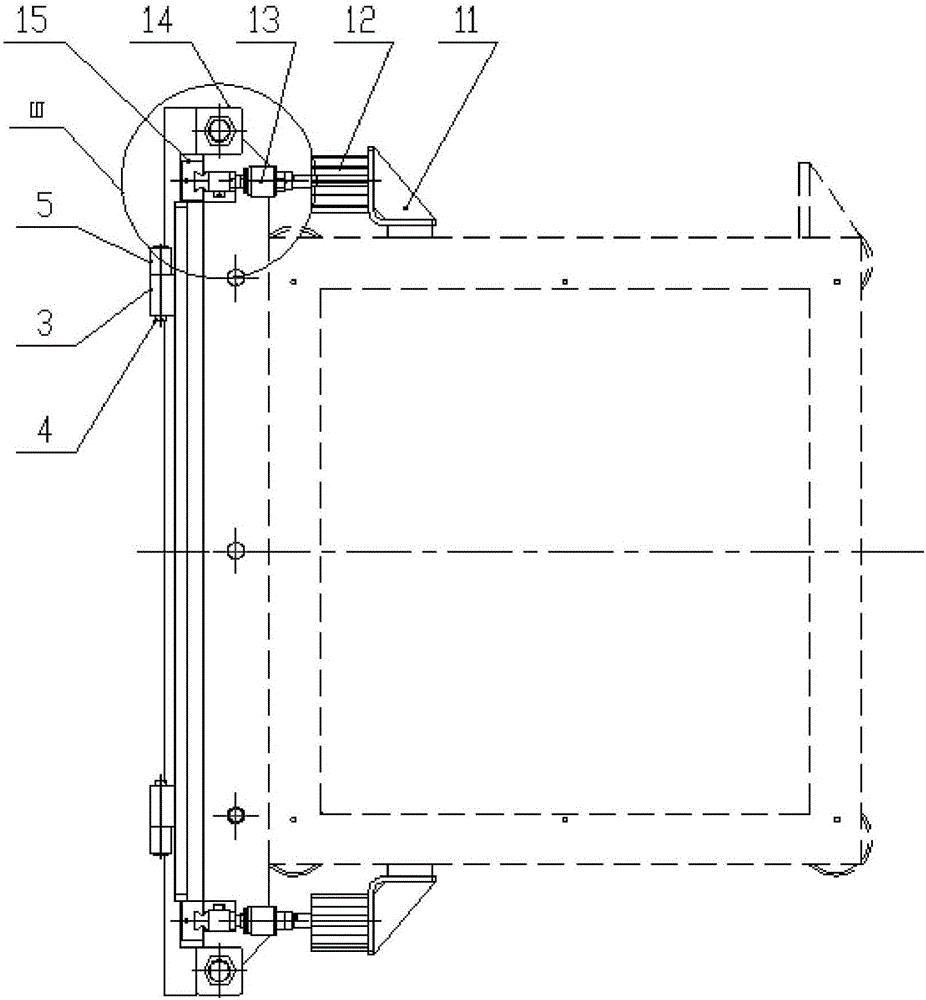

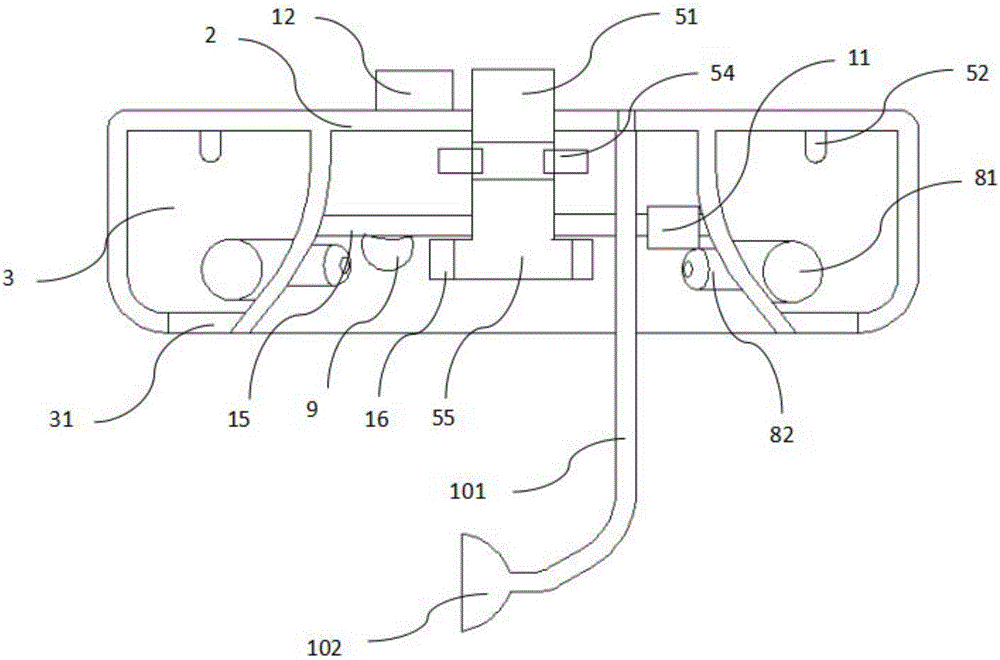

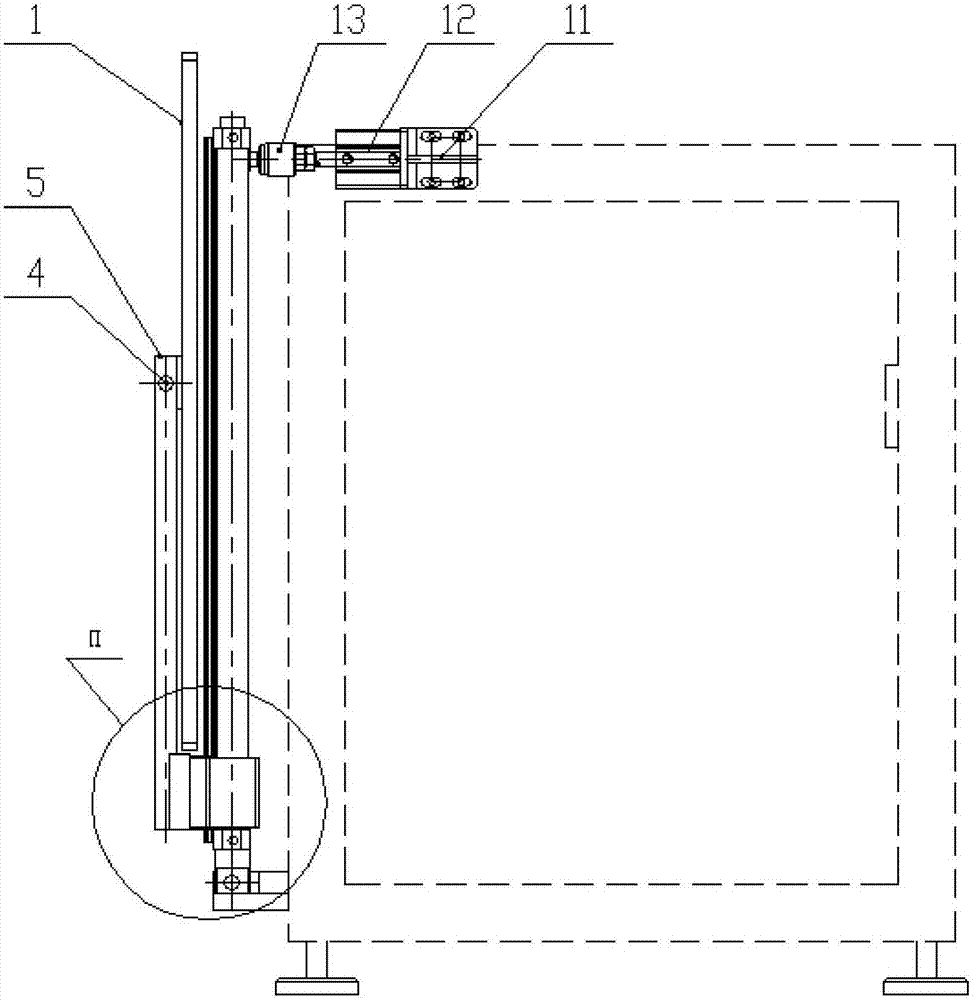

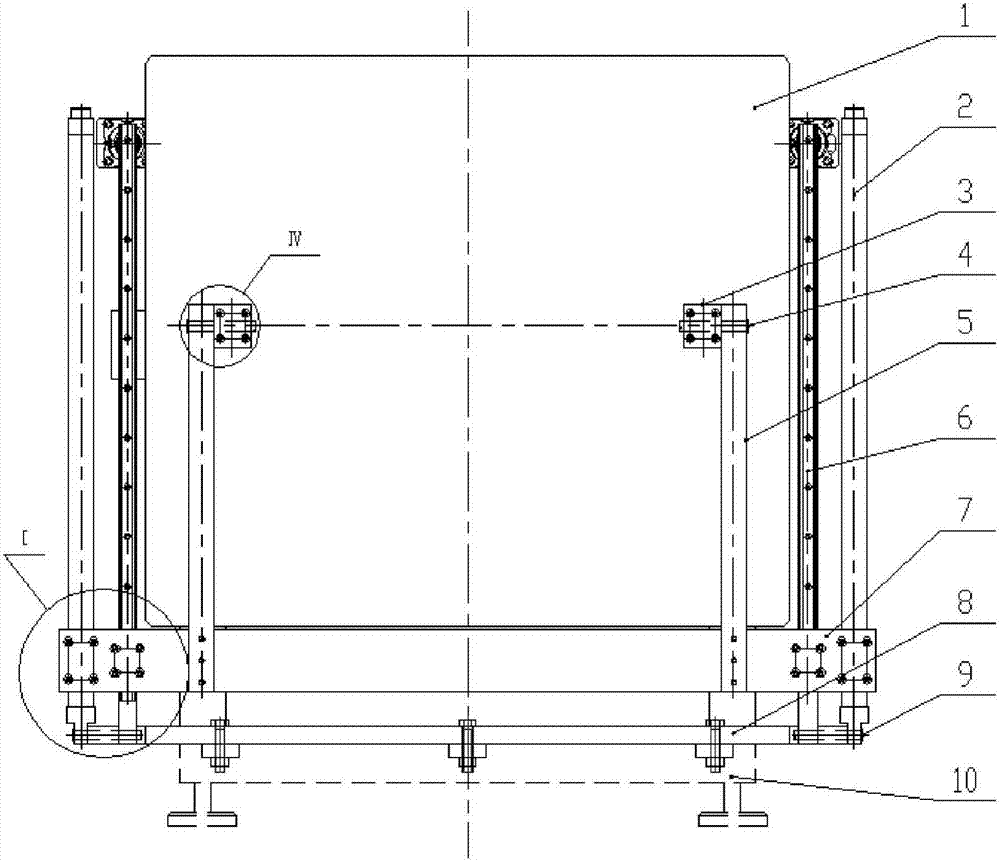

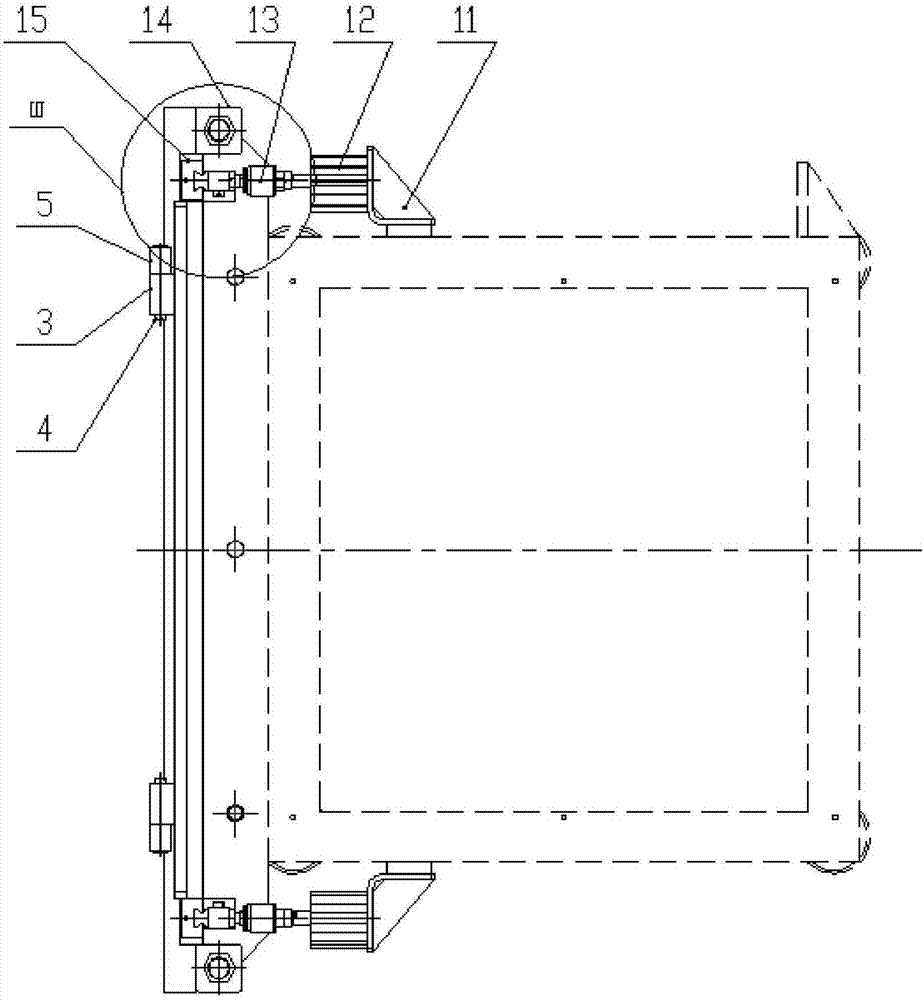

Entrance/exit end door of continuous vacuum production line

ActiveCN105758186ALow costLow machining accuracy requirementsFurnace componentsPower-operated mechanismProduction lineEngineering

The invention discloses an entrance / exit end door of a continuous vacuum production line. The continuous vacuum production line comprises a stander. The entrance / exit end door is characterized by adopting a push away-closing type. The end door is arranged at the lower part of the stander at a port of the vacuum production line. The entrance / exit end door has the benefits that 1, no expensive gate valve is adopted, so that the cost is greatly reduced; 2, the whole structure is arranged at a free space position of the stander at the front lower side of the production line, so that no effective space is occupied; 3, by the adoption of the push away-closing type openable furnace door structure, the requirement on the processing precision is low, mounting and maintenance are facilitated, and the manufacturing cost is low.

Owner:DONGGUAN HUICHENG VACUUM TECH

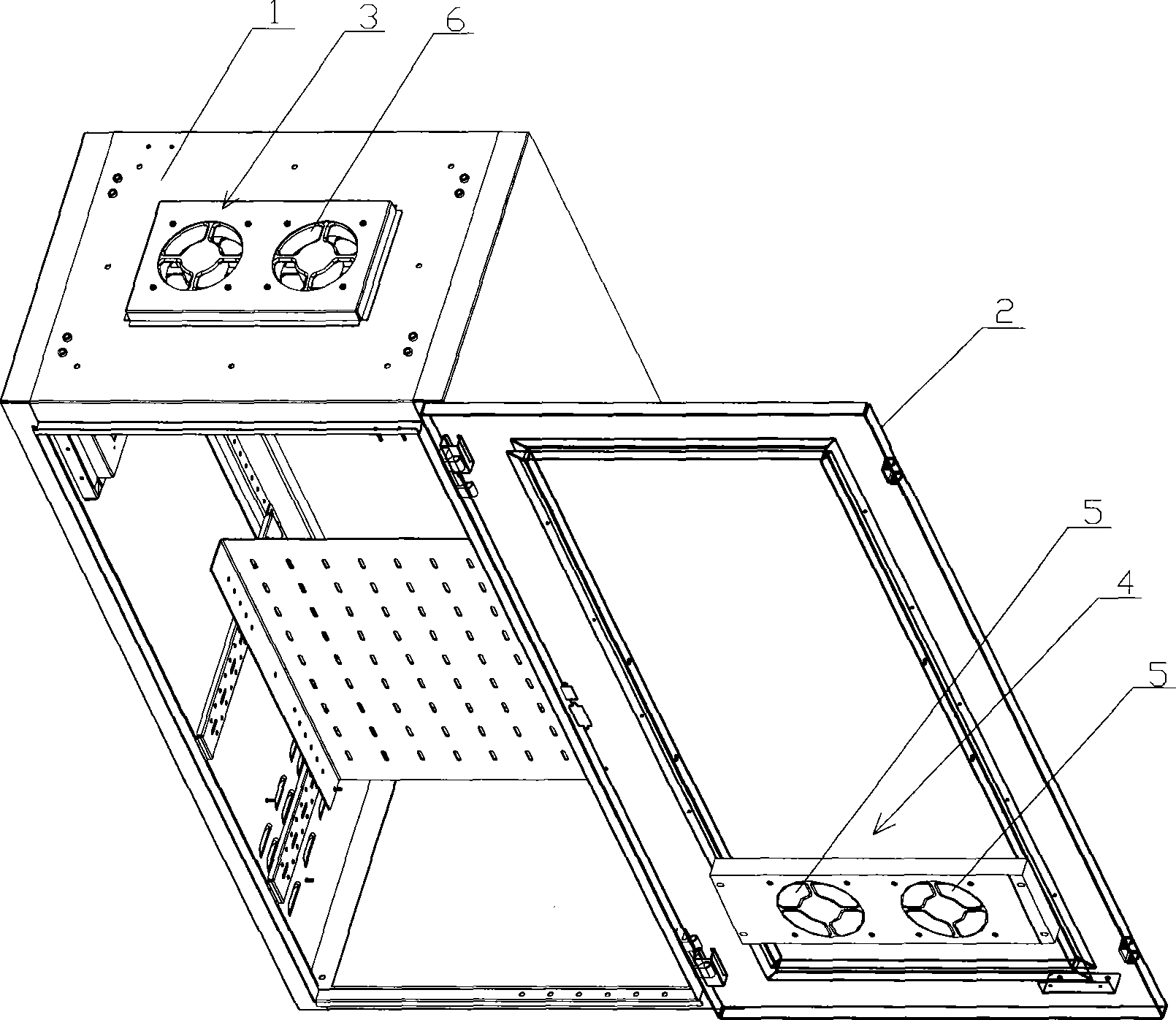

Signal cabinet

InactiveCN101448377AHas the function of "breathing"Stable jobCooling/ventilation/heating modificationsElectrical apparatus casings/cabinets/drawersEngineeringOperating environment

The invention provides a signal cabinet with a forcible exhaust air system, aiming to solve the problem, in the prior art, that the heat generated inside the cabinet can not be discharged as quickly as possible because of a one-way circulating exhaust air system in the signal cabinet. A suction device and a temperature sensor and a humidity sensor connected with a main control module are arranged inside the cabinet, the main control module receives the temperature signal and the humidity signal transmitted from the temperature sensor and the humidity sensor to control the starting-up / shutting-down of the suction device and an air exhausting device, so as to form a forcible airflow circulation system which can discharge the heat generated from the equipment inside the cabinet, such as a hardware system, an industrial controller and a power supply, out of the cabinet as quickly as possible, thereby ensure long-term stable operation of the modules inside the cabinet. The temperature sensor and the humidity sensor can keep the operating environment inside the cabinet within a specified temperature and humidity range.

Owner:QINGDAO HISENSE TRANS TECH

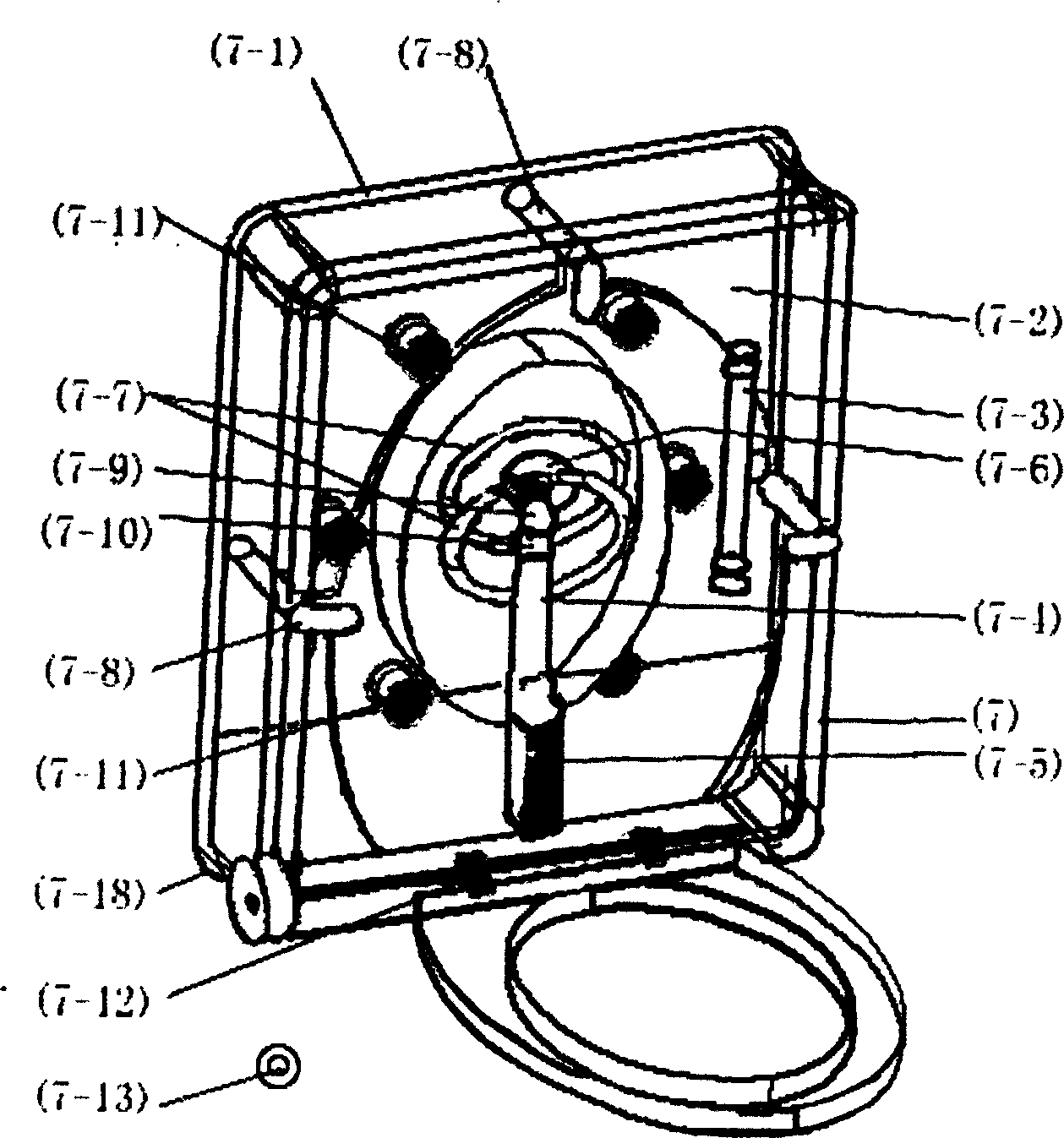

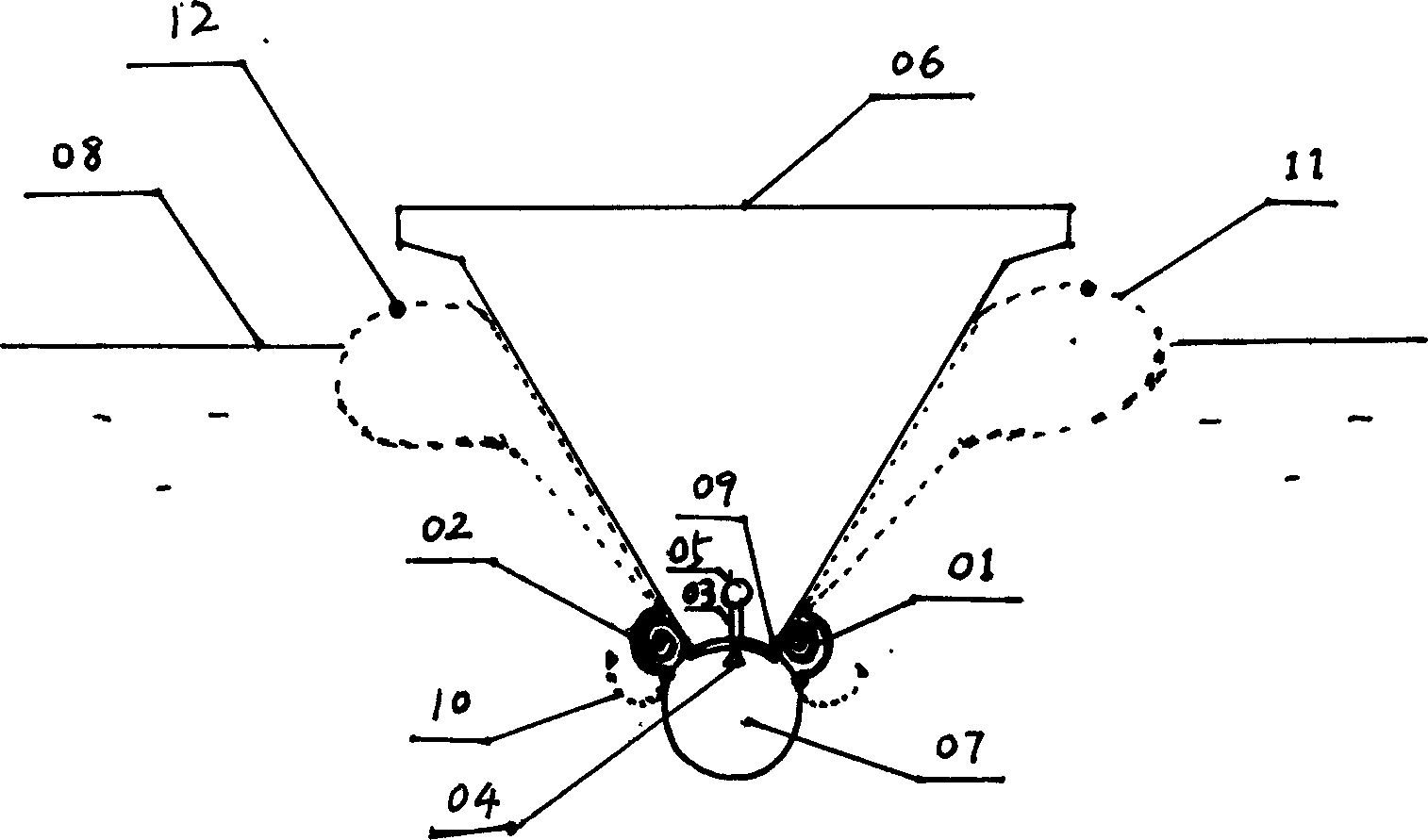

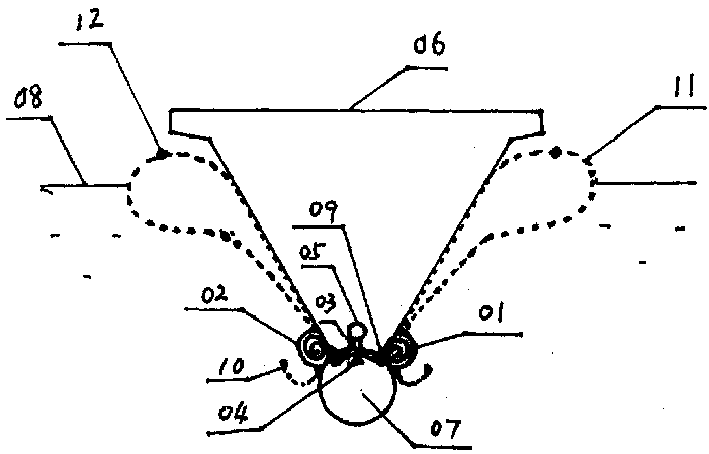

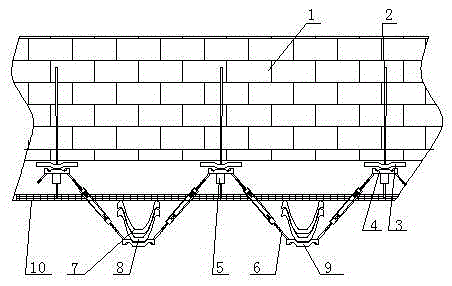

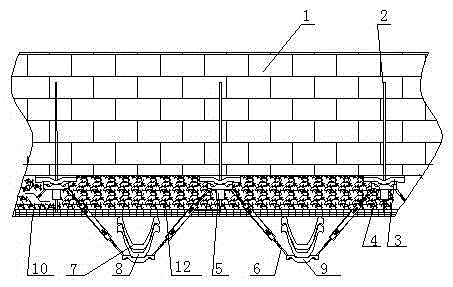

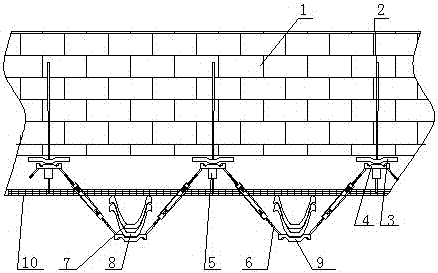

Anchor cable and metal support uniting complementing support device and method

InactiveCN105201526ACapable of deformingGood deformabilityUnderground chambersTunnel liningStructural engineeringMetal

The invention relates to an anchor cable and metal support uniting complementing support device for sinking and driving engineering and a method. The support device comprises U-shaped metal supports, and the openings thereof are fastened on a metal net; short beams of the metal supports and load transfer beams of the metal supports are arranged outside the metal supports in sequence; anchor cables are arranged between two adjacent metal supports; one end of each anchor cable is located in the surrounding rock, and the other end of the anchor cable is located outside the surrounding rock and is provided with trays, anchor cable load transfer beams and anchor gears in sequence; diagonal draw bars are connected between the load transfer beams of the metal supports and the load transfer beams of the anchor cables; a V-shaped anchor fixing system is continuously formed on the installation surface of the metal net. In the invention, the anchor cables directly reinforce the surrounding rock through the trays, a tensile component directly reinforces weak parts of the metal supports which independently support the surrounding rock, the supporting area of the anchor cables is remarkably increased by the connection of the tensile component with the supports, and the organic united complementation of the metal supports with the anchor cables is realized. The anchor cable and metal support uniting complementing support device provided by the invention can be used for any roadways of shed supporting, and can be recycled and reused if used for mining roadways.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Adjustable cup stand

InactiveCN104490228ADeepen the depthDoes not occupy effective spaceKitchen equipmentDomestic articlesEngineeringRivet

The invention relates to an adjustable cup stand, which comprises a cup stand body, a fixing element, an elastic element and a lug boss, wherein the cup stand body can realize the vertical telescopic effect, the fixing element is used for fixing the cup stand body onto an external plate body, and comprises an upper fixing plate, a lower fixing plate and a sleeve ring positioned between the upper fixing plate and the lower fixing plate, the cup stand body is sleeved in the sleeve ring, an open edge of the upper end of the cup stand body is outwards folded to form a flanging, and the elastic body and the lug boss which are used for limiting the relative telescopic position of the cup stand body are arranged on the inner wall of the sleeve ring. Compared with the prior art, the adjustable cup stand has the following advantages that 1, the placing depth is effectively increased, and the stability for placing a cup is improved, so that the cup cannot easily fall down, and in addition, the adjustable cup stand is generally applicable to dinner tables and can also be used for business desks with needs; 2, the cup stand is downwards expanded, the effective use space of a user is saved, and the adjustable cup stand can be folded when being not used; 3, rivets are used for fixing, and the firmer effect is realized; 4, the structure of each part is simple, and the additional mold casting is not needed.

Owner:罗志良

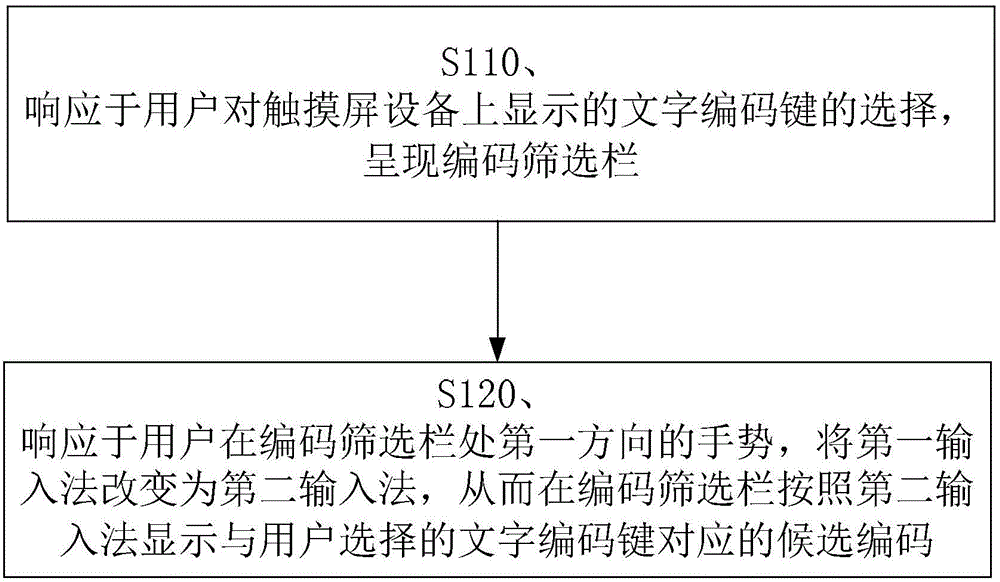

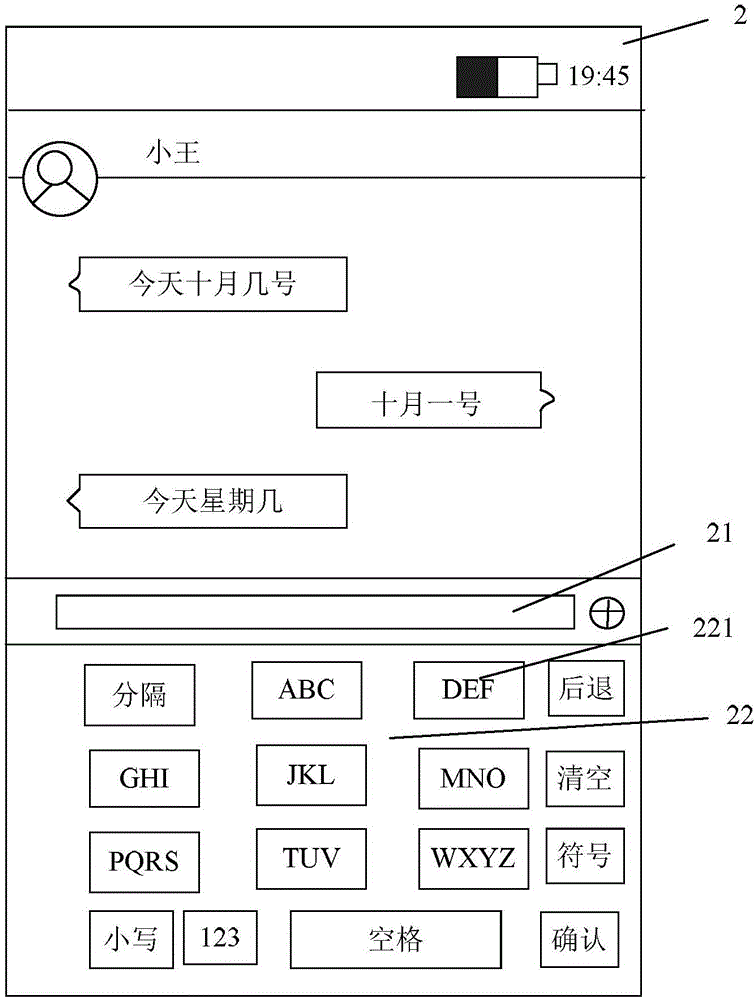

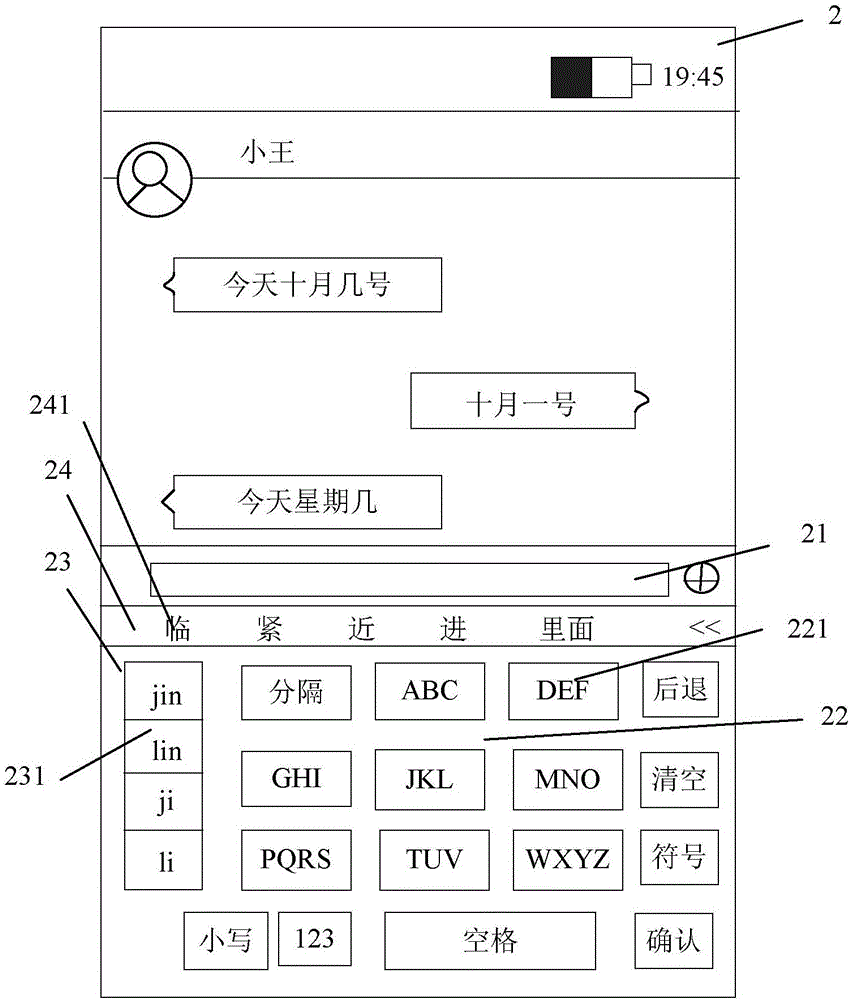

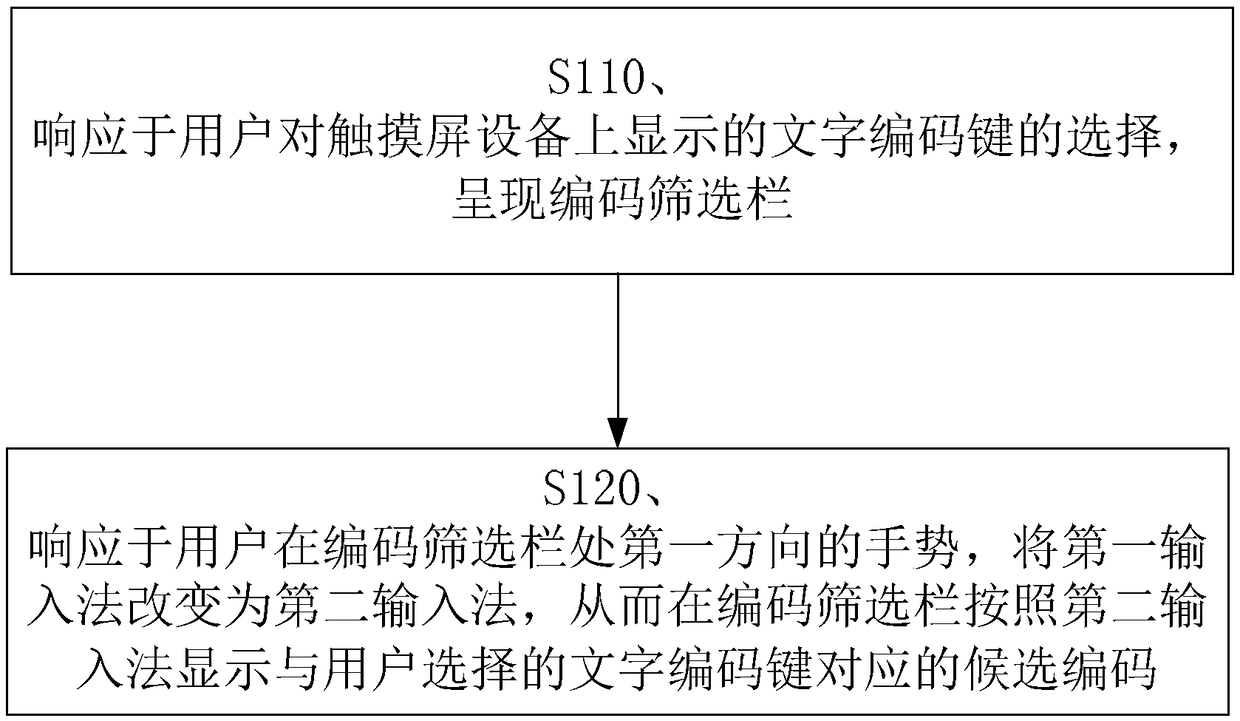

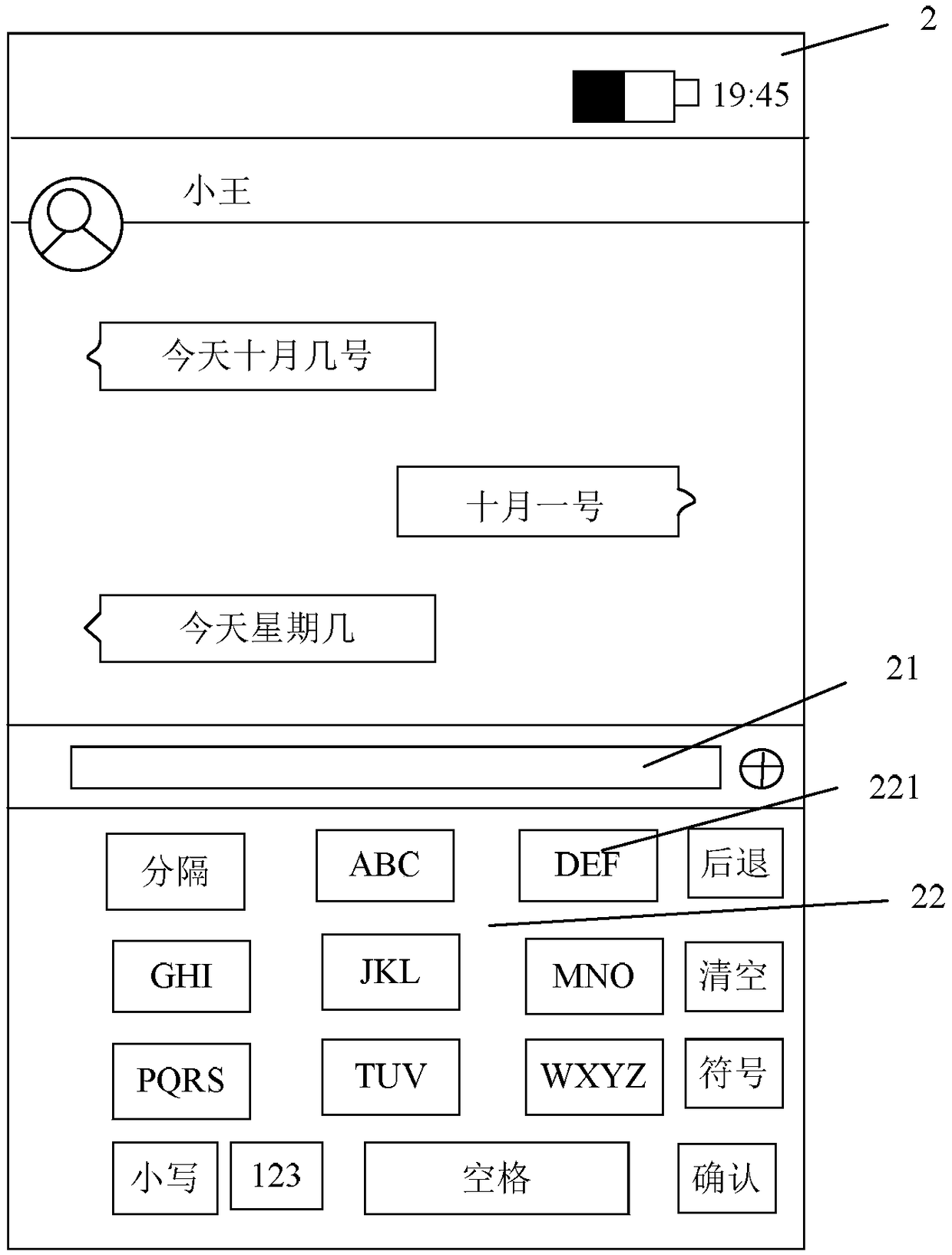

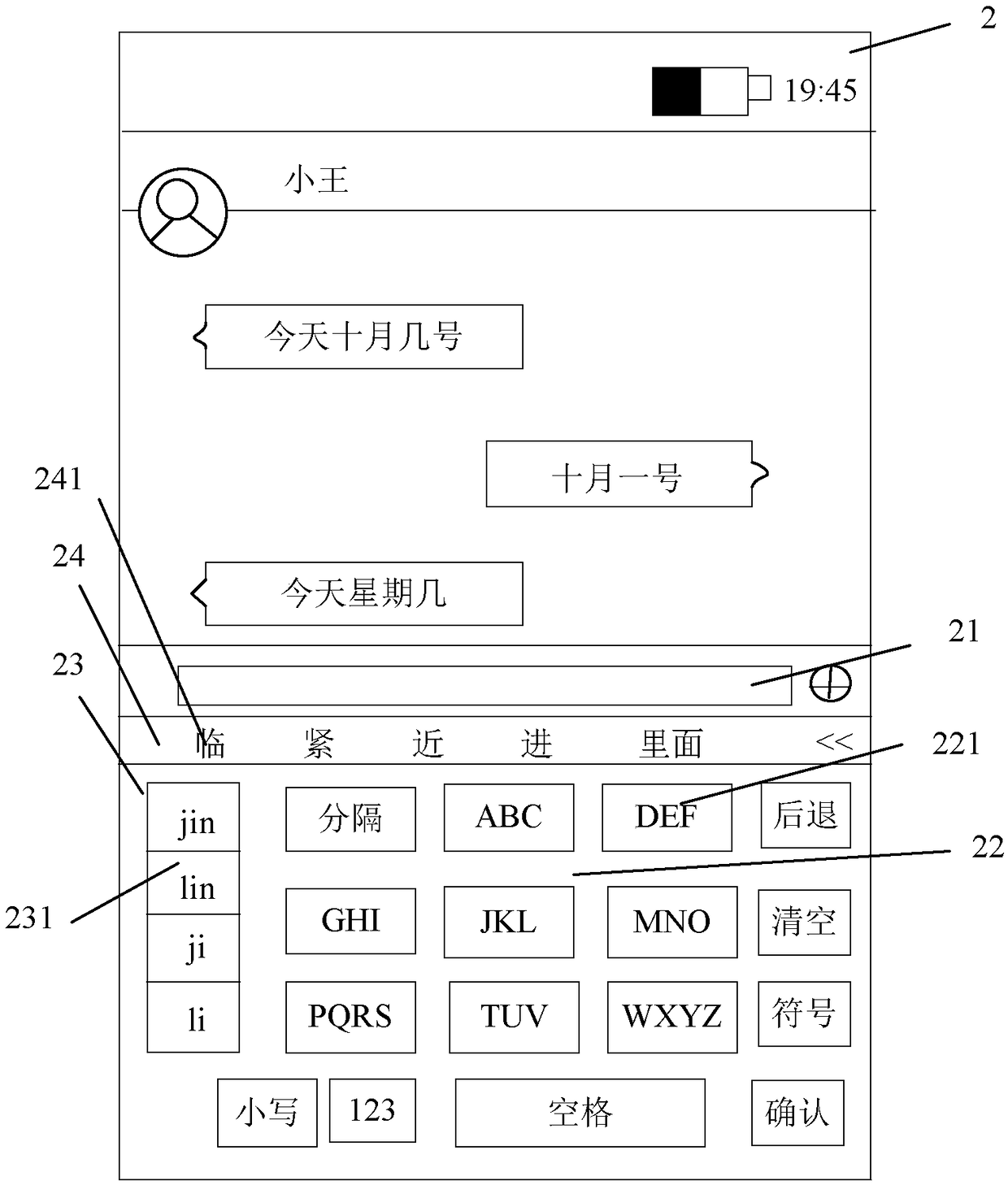

Method and device for switching user input method on touch screen device

ActiveCN106406567ADoes not occupy effective spaceReduce misuseInput/output processes for data processingUser inputTouchscreen

The invention provides a method and device for switching a user input method on a touch screen device. The method comprises the steps of displaying a code screening field in response to selection of a user for a text coding key displayed on the touch screen device, wherein the code screening filed is used for displaying candidate codes corresponding to the text coding key selected by the user according to a first input method; and changing the first input method into a second input method in response to a gesture of the user at the position of the code screening field in a first direction, thereby displaying the candidate codes corresponding to the text coding key selected by the user in the code screening field according to the second input method. The invention also provides a scheme for switching the input method rapidly and accurately on the premise of not occupying an effective space of a touch screen.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

Household steam sauna device and integrated bathroom

The invention provides a household steam sauna device and an integrated bathroom, and relates to the technical field of steam sauna products. The steam sauna device comprises an integrated base top, a steam generating system and a fixing supporting system. The integrated base top is connected with the steam generating system through the fixing supporting system; the technical problems that in the prior art, the occupied area is large, and using is inconvenient are solved; the technical effects that the structure is simple, installing is convenient, the functions are complete, effective space is not occupied, using is convenient, the appearance is attractive, and the steam sauna device has the health-care treating effect are achieved. The integrated bathroom comprises the steam sauna device and a shower, and has the advantages that the steam sauna function and the showering function are integrated, effective space is not occupied, and using is convenient.

Owner:连保东

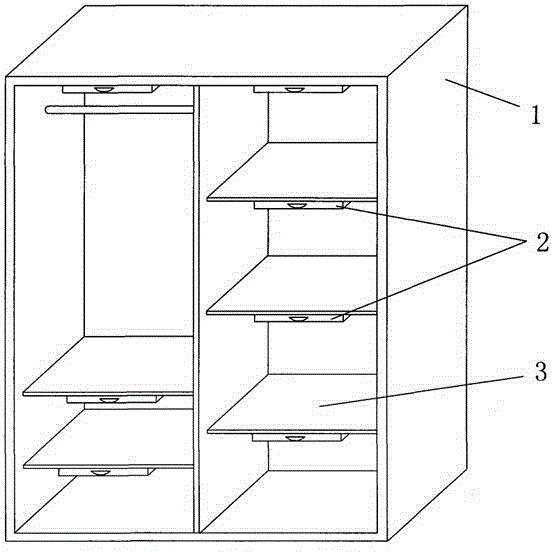

Environment-friendly furniture

InactiveCN105310288AEasy to take outEasy to take out the eco-friendly container for replacementWardrobesChestsHazardous substanceAir cleaning

The invention discloses environment-friendly furniture. The environment-friendly furniture comprises a box body 1, wherein an environment-friendly container 2 is arranged on the inner wall face of the box body, the wall body of the environment-friendly container is provided with a channel, and air cleaning agents are placed in the environment-friendly container. According to the environment-friendly furniture, the environment-friendly container containing the air cleaning agents can be arranged in all kinds of furniture box bodies, an inner cavity of the environment-friendly container can be communicated with a cavity of the furniture box body via through holes or through grooves formed in the wall body of the environment-friendly container, harmful substances contained in gas in the furniture box body can be removed effectively and quickly by means of adsorption, and therefore cleanliness of indoor air and environmental protection are guaranteed.

Owner:李素梅

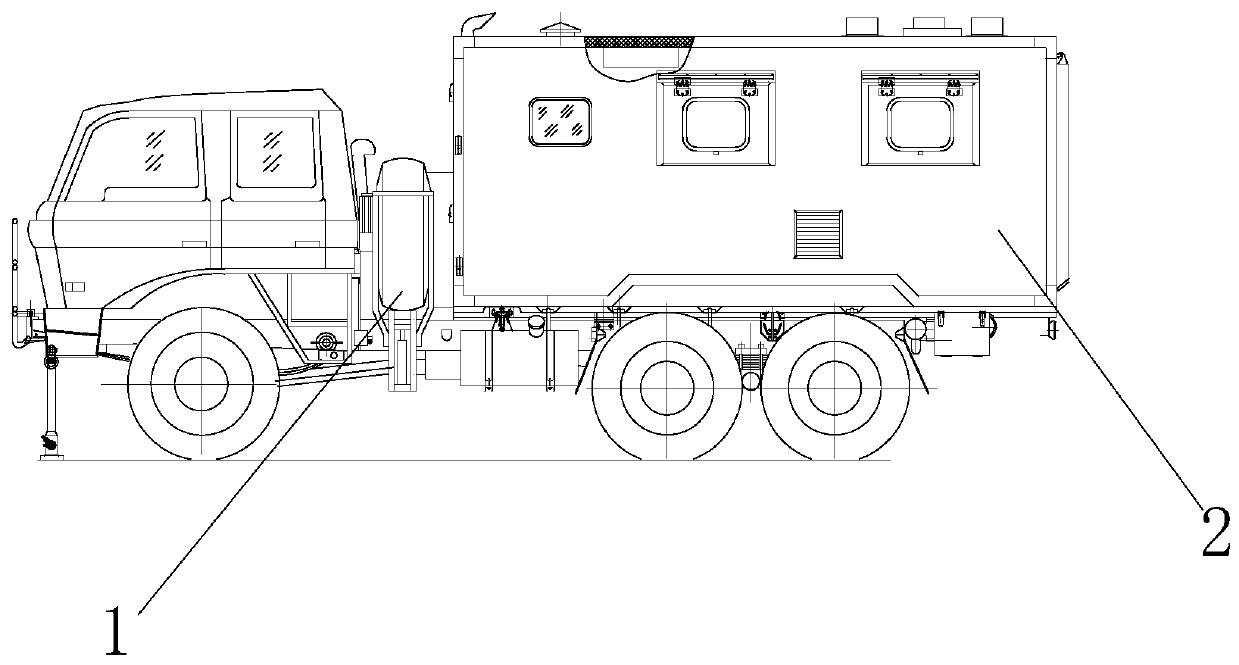

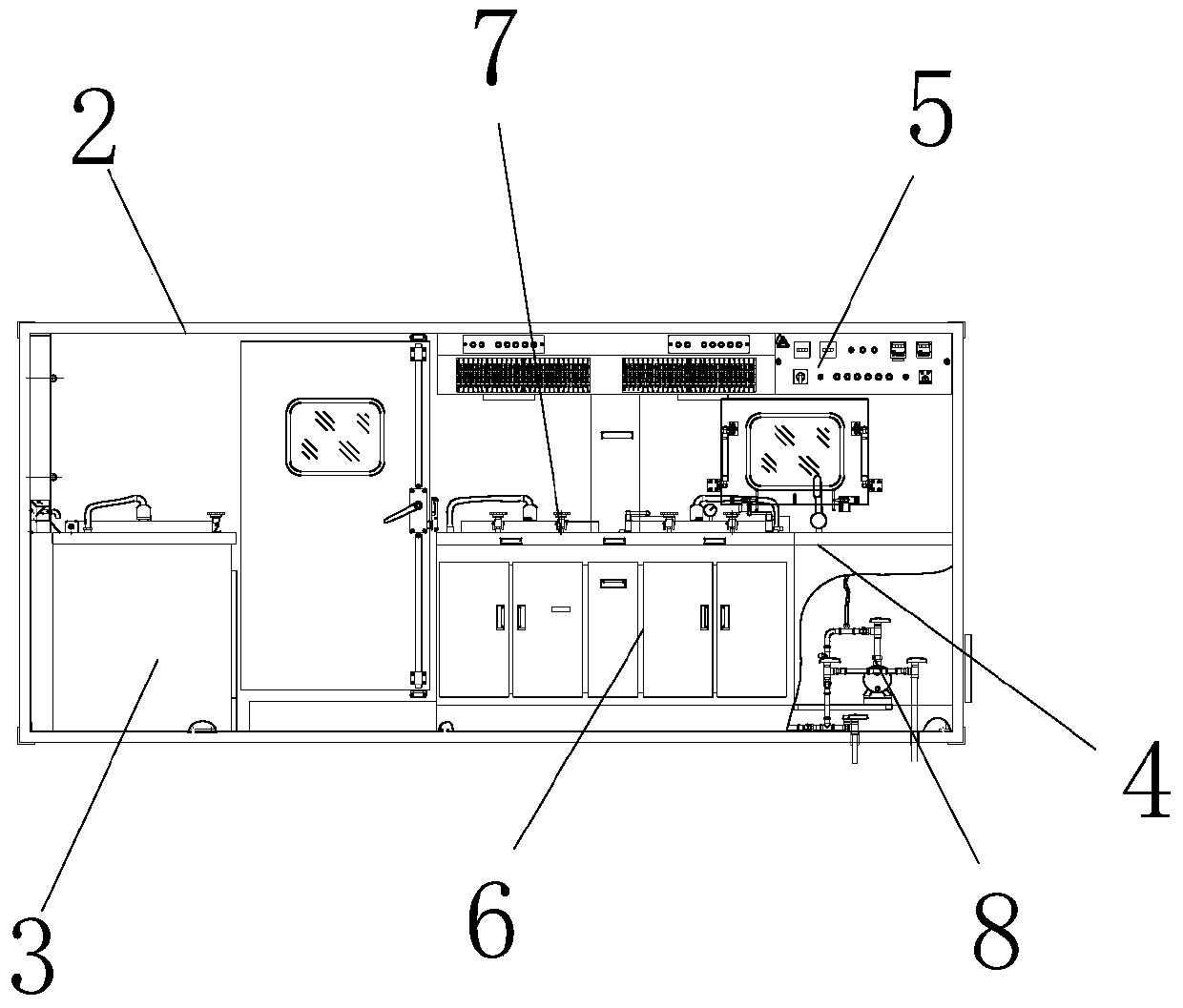

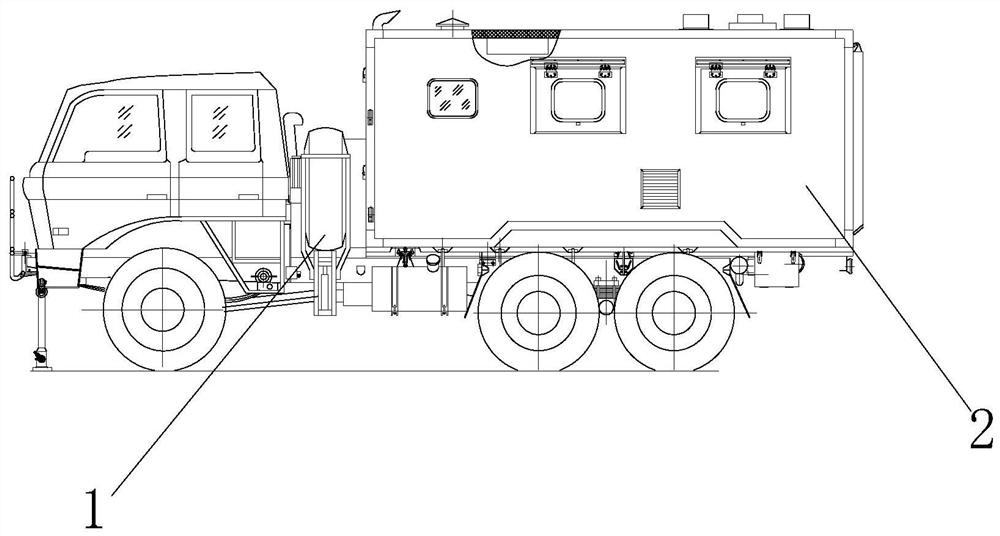

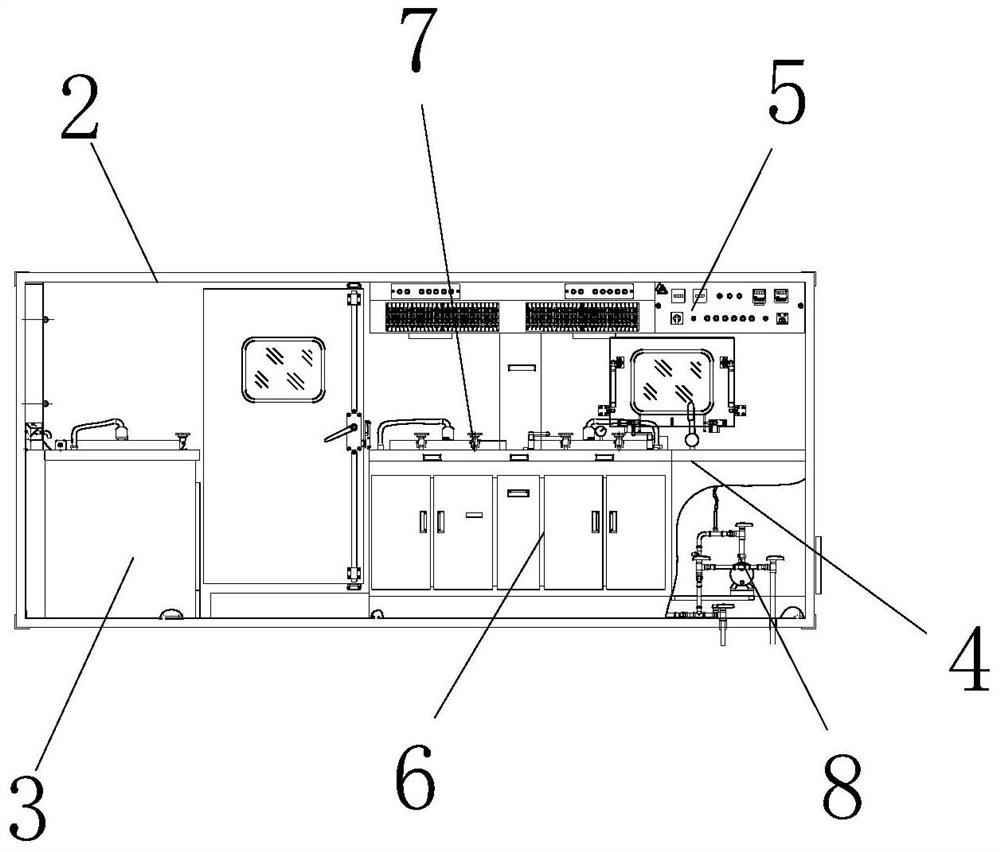

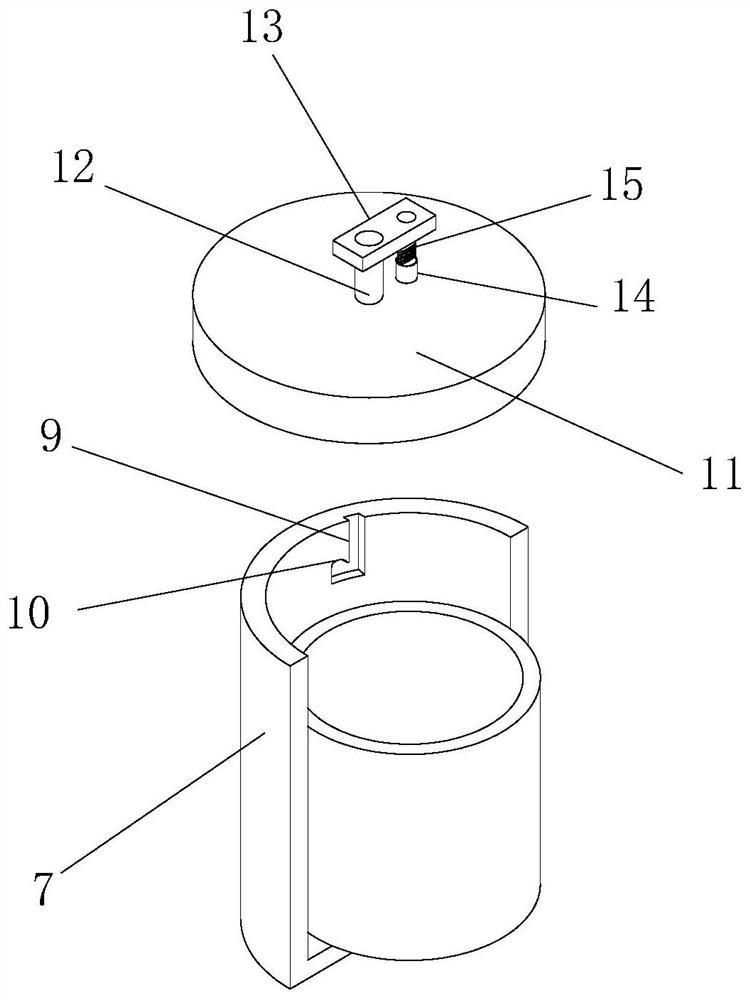

Plateau type kitchen vehicle

ActiveCN111016769AImprove sealingQuick cookCooking-vessel materialsDomestic stoves or rangesRubber ringPressure cooking

The invention, which relates to the technical field of plateau cooking, discloses a plateau type kitchen vehicle comprising a kitchen vehicle body. A carriage is fixedly mounted on the rear side of the kitchen vehicle body; the carriage is a rectangular hollow box; a vegetable washing sink is fixedly mounted in the kitchen vehicle body; an operating platform is fixedly mounted in the middle insidethe carriage in parallel; an equipment box is fixedly installed at the top end of the interior of the carriage; a storage cabinet is fixedly installed at the lower end of the operating platform and aheating pipeline is fixedly installed on the right side of the storage cabinet; pressure cookers are fixedly installed in the operating platform and are cylindrical hollow barrels, two sets of vertical grooves are vertically formed in the inner wall of each pressure cooker, and the vertical grooves are rectangular grooves. According to the invention, a fixing sleeve can downwards extrude the cooker cover to enable the cooker cover to be tightly attached to the pressure cooker, the cooker cover extrudes the rubber ring to enable the interior of the pressure cooker to have good sealing performance; the air pressure in the pressure cooker is manually changed through a fixing block according to the plateau air pressure condition, so that food can be rapidly cooked to be well-done when the kitchen vehicle is used on the plateau.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA

An automatic feeding and discharging roller conveyor

ActiveCN103010730BHigh degree of automationSmooth and orderly transitionConveyor partsRoller-waysPush pullEngineering

The invention discloses an automatic feeding and discharging roller conveyor, which comprises a raceway, a power device and a rack. The automatic feeding and discharging roller conveyor is significantly characterized in that a feeding and discharging device is arranged under one end of the raceway and comprises a rodless cylinder, a cylinder pad plate arranged on the lower part of the rodless cylinder and a push-pull rod connected with a piston sliding block on the upper part of the rodless cylinder, the right part of the push-pull rod is provided with a push-pull pin guide seat, a push-pull pin is arranged in the push-pull pin guide seat, a transmission roller comprises two half rollers and an overall roller, and a gap is arranged between the two corresponding half rollers. The automatic feeding and discharging roller conveyor has the beneficial effects of transition between two power raceways can be realized, transition between a material platform and the conveyor can also be realized, and the problems of non-smooth transition and damage to the raceway can be solved effectively. Moreover, automatic feeding and discharging roller conveyor has the advantages of high degree of automation, smooth and orderly transition, compact and reasonable structure and less occupied space.

Owner:WUXI BAOHE MACHINERY EQUIP

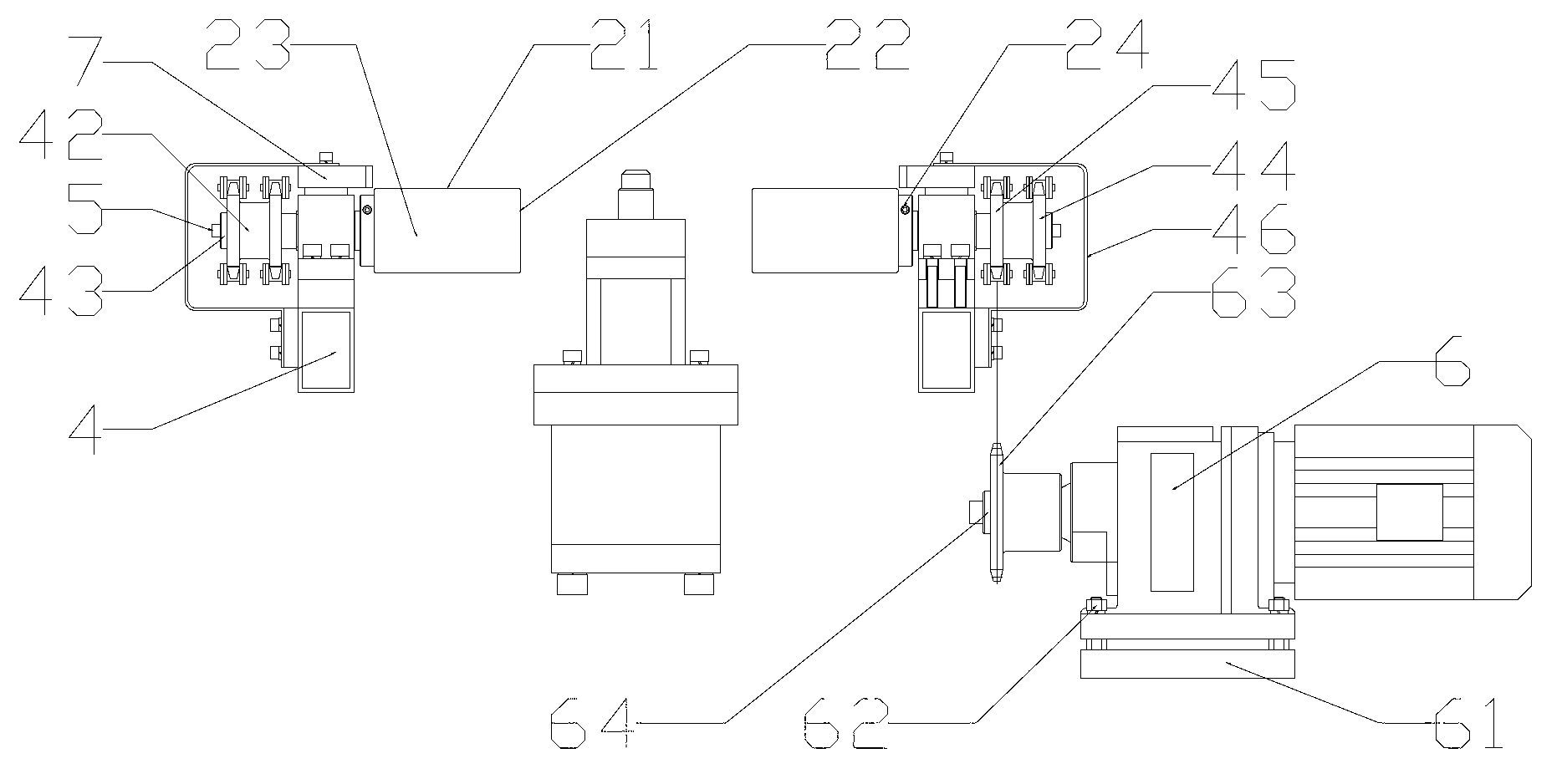

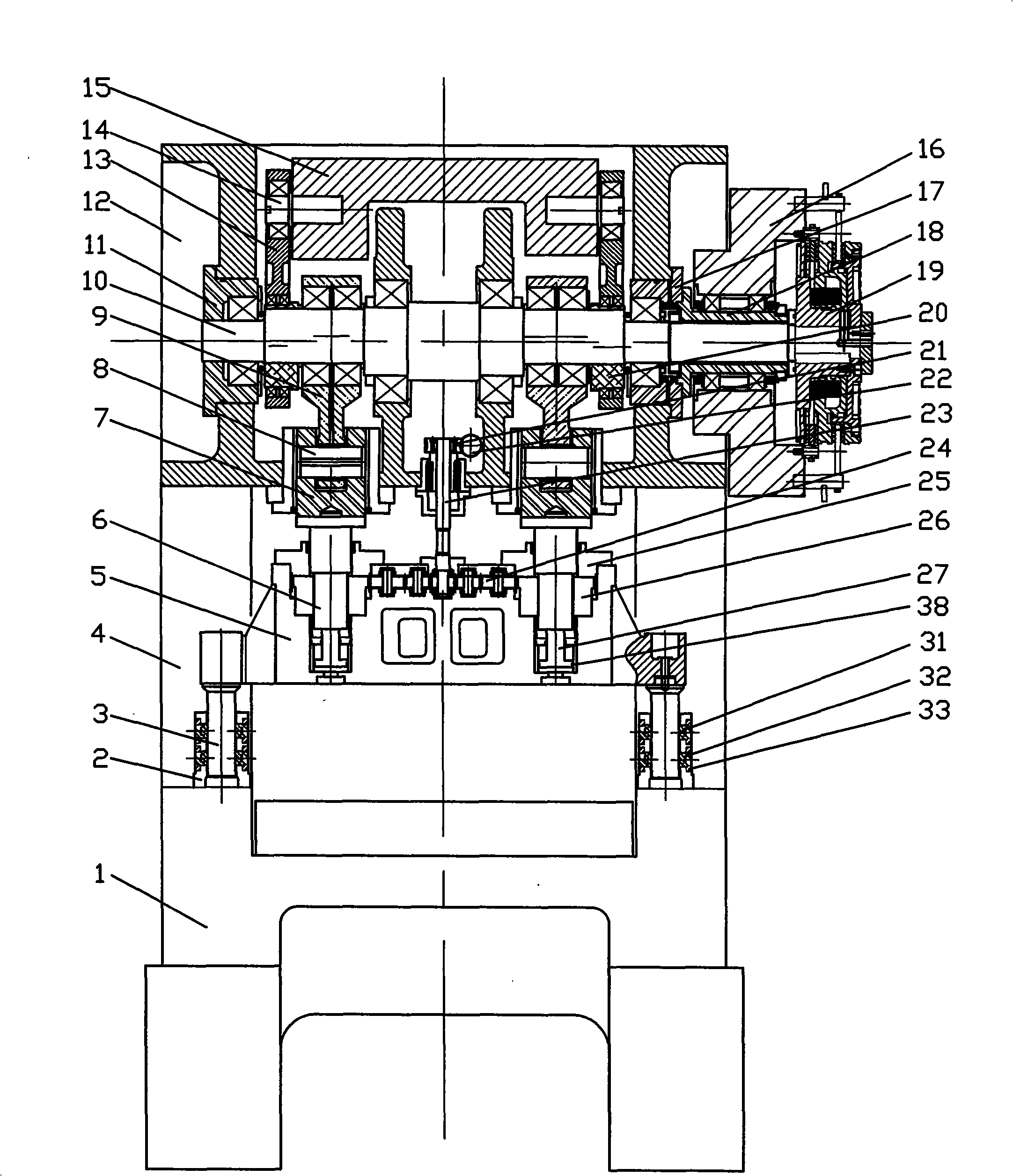

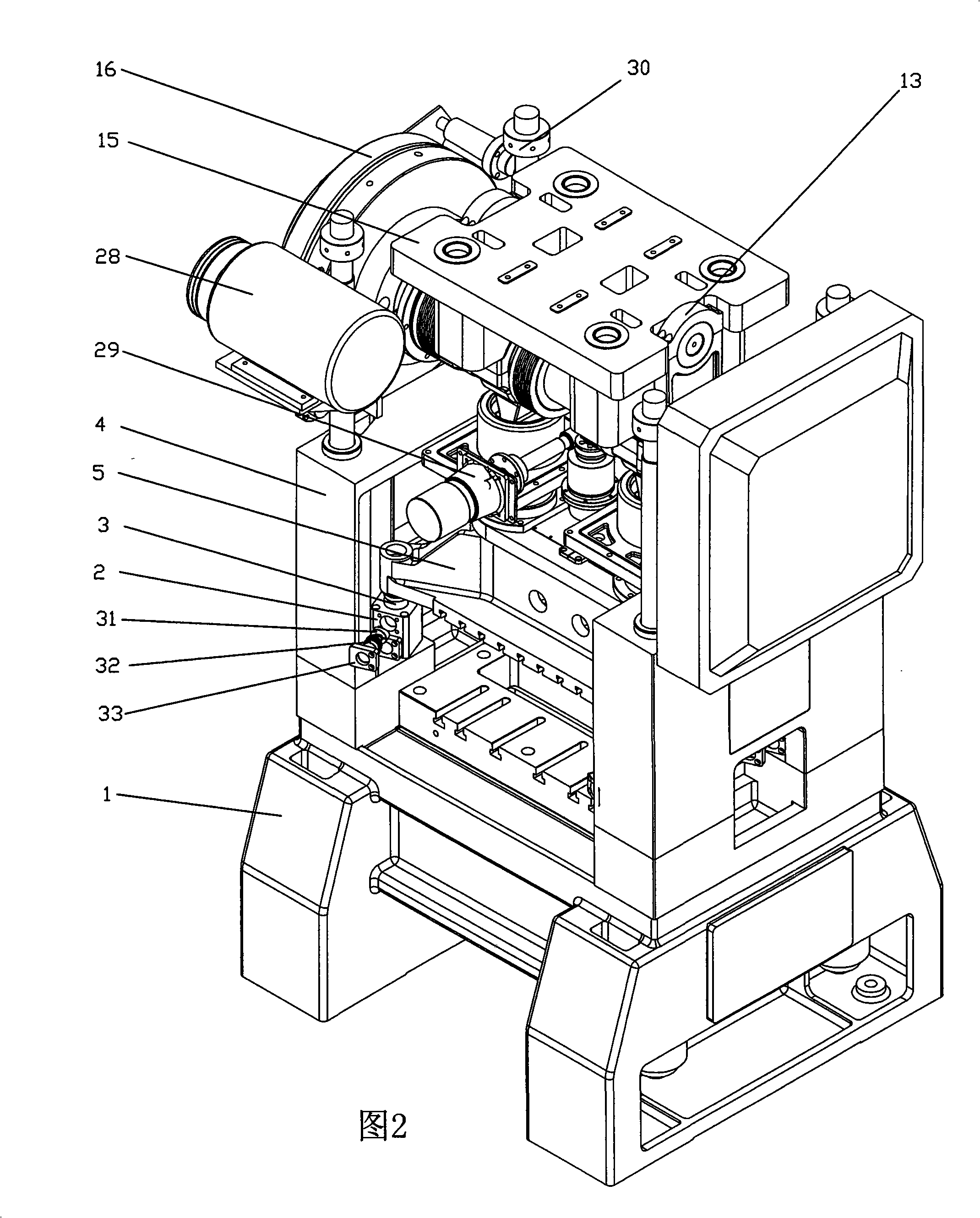

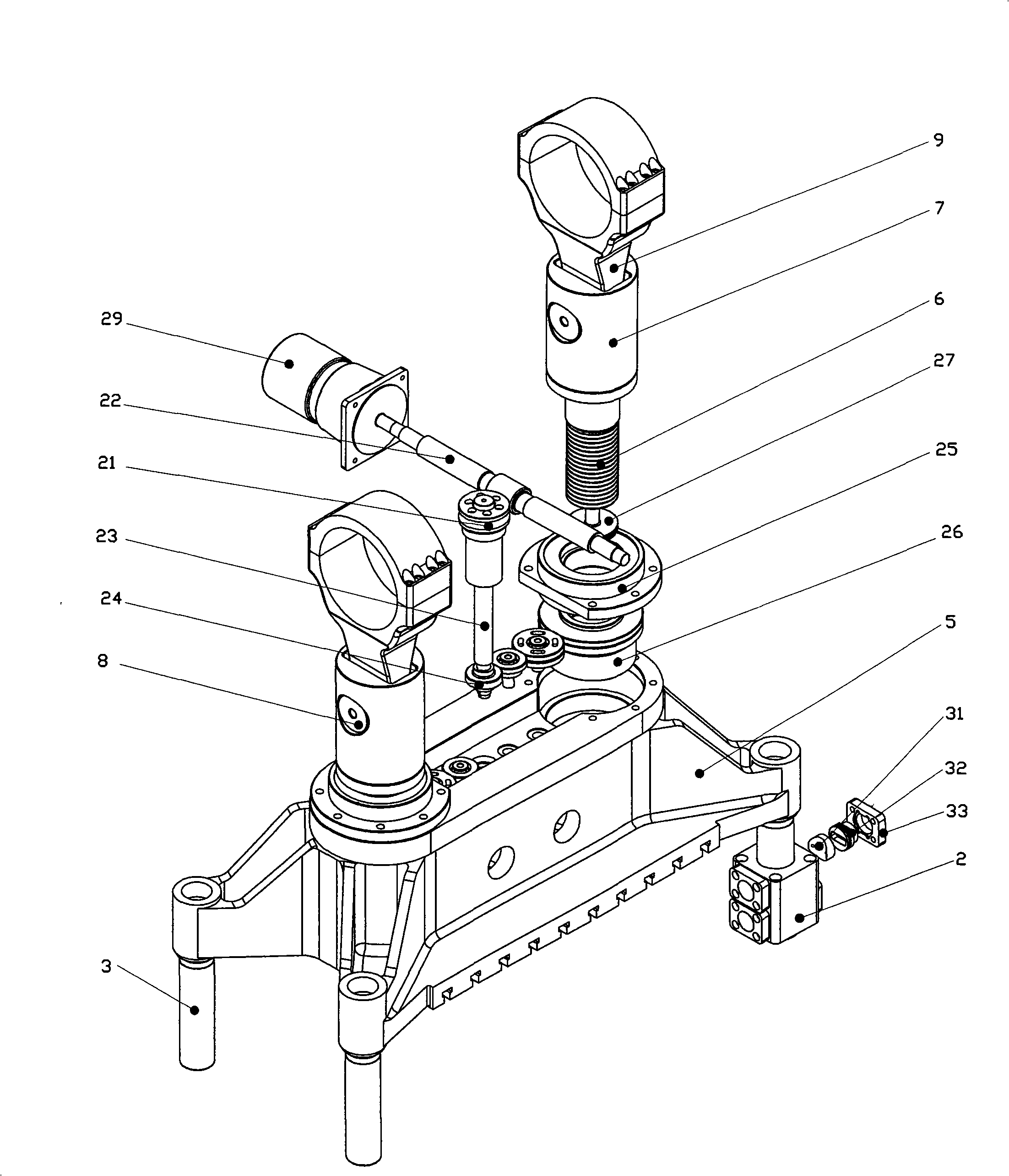

High-speed precision punching machine

The invention relates to a dieing machine, which comprises a pedestal and an abutment body. A crankshaft transmission part is provided with a fly wheel, a clutch brake assembly, a dynamic balance piece, and one end of a connecting rod; the other end of the connecting rod is fixed on a slide block, the slide block is connected with a block adjusting and guiding device; a dynamic balance piece is provided with eccentric lantern rings which are arranged at two ends of a crankshaft; and a double connecting rob, a bearing and a pin which are connected with the eccentric lantern rings are connectedwith the dynamic balance piece to form the eccentric lantern rings, so that eccentric force generated by the motion of the crankshaft is offset, and left and right swing and deformation are preventedsimultaneously. When processing different products, the dieing machine needs to change moulds and adjust the height of the slide block; and after the height of the slide is adjusted, a locking oil cylinder locks the slide lock so as to ensure that the position of the arranged mould does not change and the machining accuracy does not change. The slide block adopts a guide ring guiding structure soas to break a four guide pillar structure which is used for multiple years in punching machine industry. The over-positioning of the prior four guide pillar is replaced by the freely-jointed positioning of a guide sleeve, so that the assembling error can be solved through free displacement.

Owner:宁波米斯克精密机械工程技术有限公司

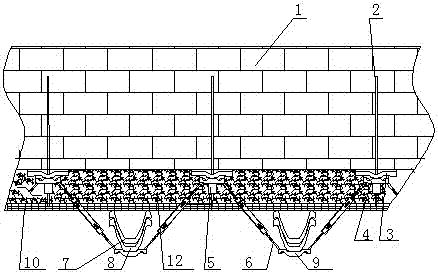

Anchor cable and metal support combined complementary supporting device and method

InactiveCN105201526BCapable of deformingGood deformabilityUnderground chambersTunnel liningWire meshMetal mesh

The invention relates to a combined complementary support device and method for an anchor cable and a metal support for shaft engineering, comprising a U-shaped metal support, the opening of which is buckled on a metal mesh; The bracket is turned to the load beam. An anchor cable is arranged between two adjacent metal supports. One end of the anchor cable is located inside the surrounding rock, and the other end is located outside the surrounding rock. Diagonal stay rods are connected between the bracket rotating load beam and the anchor cable rotating load beam, forming a continuous V-shaped anchoring system on the installation surface of the metal mesh. In the present invention, the anchor cable directly reinforces the surrounding rock through the tray, the tensile component directly reinforces the weak part of the metal support, and the metal support independently supports the surrounding rock, and the anchor cable support area is significantly increased by connecting the tensile component with the support. The metal bracket and the anchor cable are organically combined and complementary. The device of the present invention can be used in any roadways supported by scaffolding, and can be recycled and reused if used in mining roadways.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Method and device for switching user input method on touch screen device

ActiveCN106406567BDoes not occupy effective spaceReduce misuseInput/output processes for data processingUser inputTouchscreen

The invention provides a method and device for switching a user input method on a touch screen device. The method comprises the steps of displaying a code screening field in response to selection of a user for a text coding key displayed on the touch screen device, wherein the code screening filed is used for displaying candidate codes corresponding to the text coding key selected by the user according to a first input method; and changing the first input method into a second input method in response to a gesture of the user at the position of the code screening field in a first direction, thereby displaying the candidate codes corresponding to the text coding key selected by the user in the code screening field according to the second input method. The invention also provides a scheme for switching the input method rapidly and accurately on the premise of not occupying an effective space of a touch screen.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

Road-crossing translation double-side parking and picking-up garage and method for parking and picking up vehicles and crossing roads

PendingCN114753687ADoes not occupy effective spaceNew parking spaceParkingsTraffic diversionRoad surface

The invention discloses a road-crossing translation double-side parking and taking garage and a vehicle parking and taking and road passing method. The garage comprises a bottom layer, a vehicle storage layer, a top layer, a roadway type stacking machine and a lifting hoister. The parking lot crosses the road and is built in an idle space above the road at a certain height from the road surface for parking; the stand columns are arranged on the road isolation center line, so that the supporting strength of the bottom layer can be improved, and the traffic diversion effect is achieved; the lifting hoisters are installed on the two sides of the road, the trolleys can be stored and taken out on the two sides of the road, the trolleys can be steered on the rotating platform, the trolleys transversely pass through the road through the garage, and the turning-around function is achieved. Therefore, a certain number of garages provided by the invention can be newly built in a city, the dilemma of'difficult parking 'and'difficult garage building' is solved at the same time, and the congestion problem caused by the fact that the cars transversely pass through the road is solved.

Owner:HUBEI SAIER AUTOMATION EQUIP

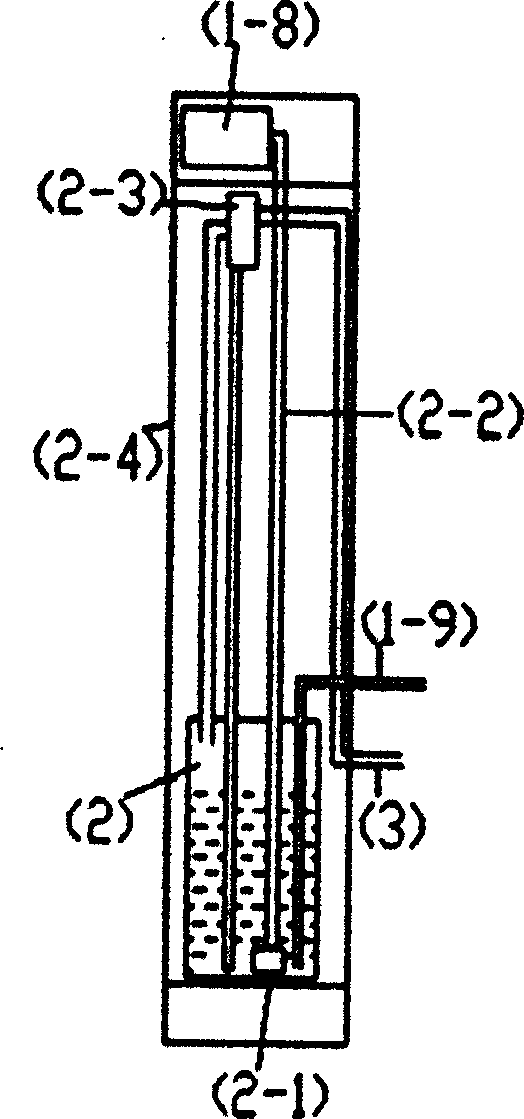

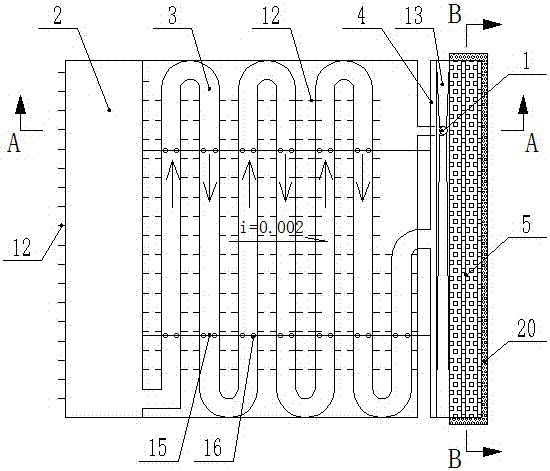

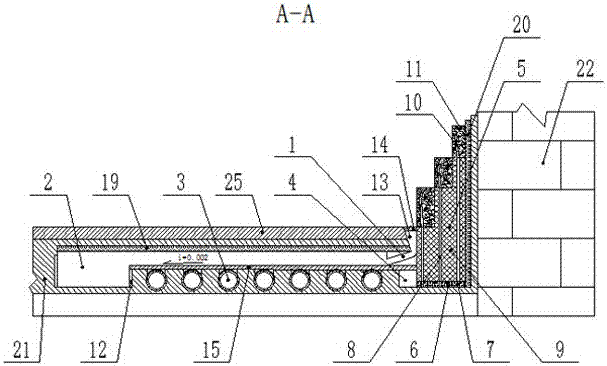

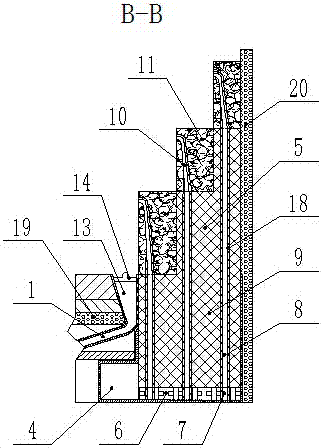

floor heating invisible humidifier

InactiveCN105650793BIncrease surface areaRegulate humidityLighting and heating apparatusAir humidification systemsElectricityWarm water

The invention discloses an invisible humidifier of a floor heating system, and belongs to the technical field of humidifiers. The technical problem to be solved is to provide the invisible humidifier of the floor heating system, which utilizes the floor-heating temperature, does not waste power, does not occupy space, and is very good in effect. According to the technical scheme adopted by the invention, the invisible humidifier of the floor heating system comprises a water inlet, a cold water storage tank, an S-shaped heating tube, a warm water storage tank and a water absorption evaporation module, wherein the cold water storage tank and the warm water storage tank are separately arranged at the two sides of the S-shaped heating tube, and communicate with the S-shaped heating tube; the cold water storage tank communicates with the water inlet through a pipeline; the side surface of the warm water storage tank communicates with the bottom of the water absorption evaporation module; and the water inlet is close to the water absorption evaporation module. The invisible humidifier of the floor heating system is suitable for a house with a floor heating system, and has the advantages of being environmentally-friendly, energy-saving, free of space occupation, and good in humidifying effect.

Owner:ZHONGBEI UNIV

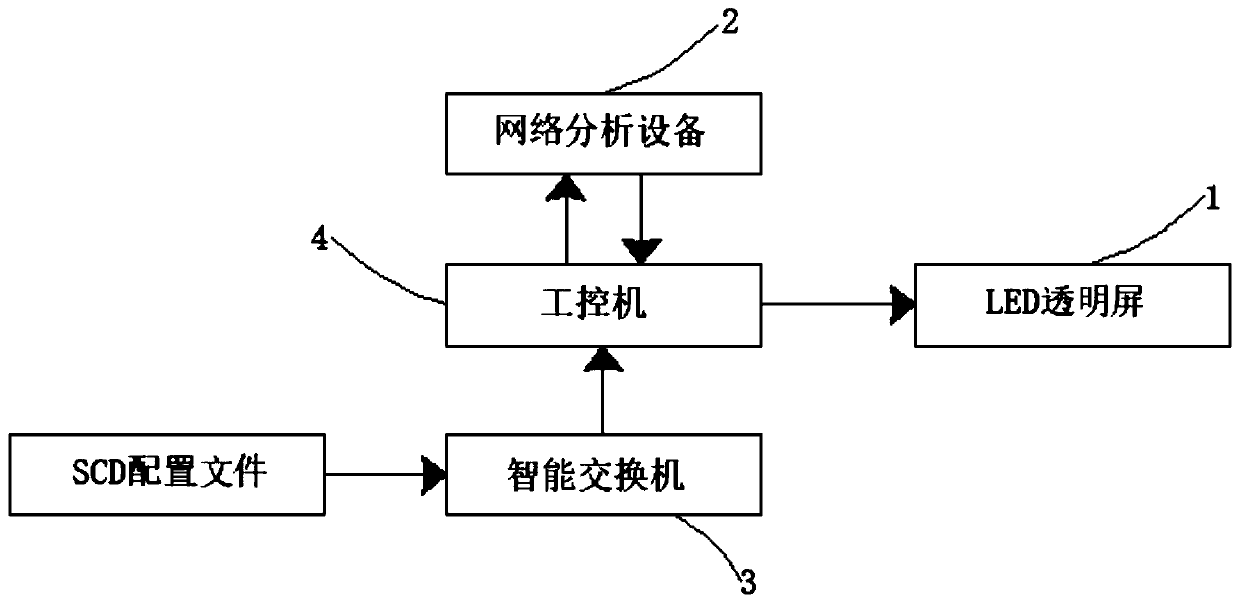

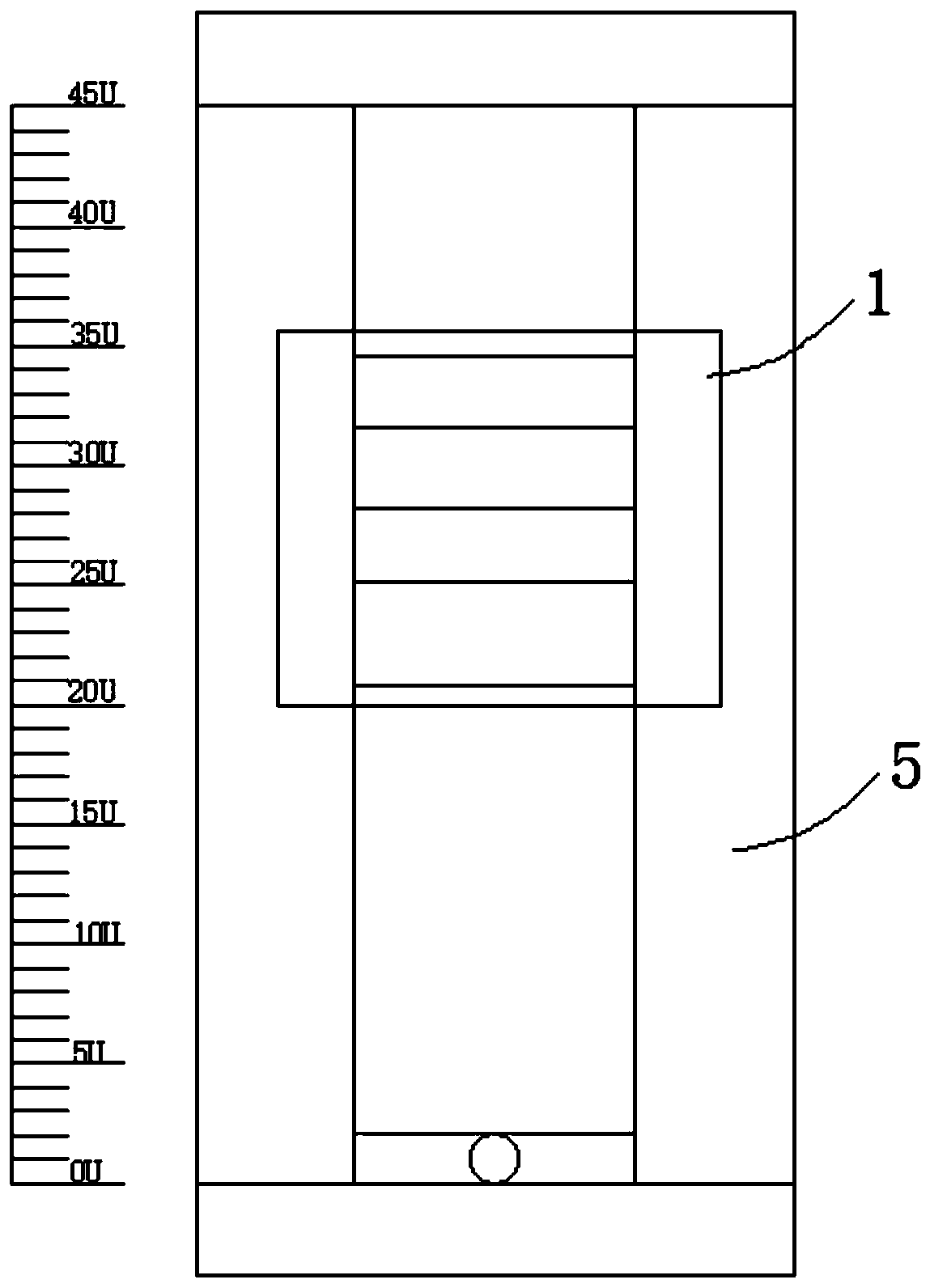

Graphical display method of transparent LED display screen based on intelligent substation secondary circuit

ActiveCN110753094AImprove efficiencyIncrease usageCircuit arrangementsData switching networksGraphical displayOnline analysis

The invention relates to the field of design of intelligent substations and particularly relates to a graphical display method of a transparent LED display screen based on an intelligent substation secondary circuit. An LED transparent screen is installed on the upper portion in a screen cabinet of the intelligent substation. The SCD configuration file is loaded and analyzed through the intelligent switch; sV / GOOSE message configuration information of each IED is extracted; the industrial personal computer receives SV / GOOSE message configuration information from the intelligent switch; communication link message and physical connection and communication link and function loop matching are carried out on each IED; the matching result is transmitted to the network analysis equipment; the network analysis equipment is accessed to a real-time network of the intelligent substation to carry out online analysis and proofreading on SV / GOOSE message configuration information; an analysis resultis sent back to the industrial personal computer for graphical processing and then is transmitted to the LED transparent screen; the secondary circuit of the intelligent substation is displayed in agraphical display mode through the LED transparent screen, the LED transparent screen is used for replacing a traditional displayer to display the secondary circuit, and transformation and upgrading of a traditional station and popularization of a secondary circuit visualization scheme are facilitated.

Owner:贵州电网有限责任公司六盘水供电局 +1

Integrated water purifying equipment for concurrent inclined plate precipitation

ActiveCN103172155BCompact structureSmall footprintWater/sewage treatment by flocculation/precipitationFlocculationFully developed

The invention relates to integrated water purifying equipment for concurrent inclined plate precipitation. A main body is concentrically partitioned into inner, middle and outer cylinders, which are respectively a flocculation zone, a filter zone and a concurrent inclined plate precipitation zone, wherein a water distributing zone is arranged at the upper segment of the concurrent inclined plate precipitation zone; an inclined plate group zone is arranged at the middle segment; a sludge concentrating chamber is arranged at the lower end; a water collecting zone is arranged between the water distributing zone, the inclined plate group zone and the filter zone; the bottom part of the water collecting zone is respectively communicated with the inclined plate group zone and the filter zone through pores; a circle of inclined plates are evenly distributed in the inclined plate group zone; the inclination angles theta of the inclined plates are 30-45 degrees; and the pores are arranged at the positions between the tail ends of two adjacent inclined plates at the bottom part of the water collecting zone and are communicated with the inclined plate group zone and the water collecting zone. The concurrent inclined plate precipitation technique is applied to the integrated water purifying equipment; flocculation, concurrent inclined plate precipitation and filtering are combined together; and the treatment process is independently and synergetically finished, so that the flocculation, concurrent inclined plate precipitation and filtering fully develop the advantages; and the integrated water purifying equipment is good in treatment effect, compact and reasonable, small in floor area, and convenient to install.

Owner:CHONGQING UNIV

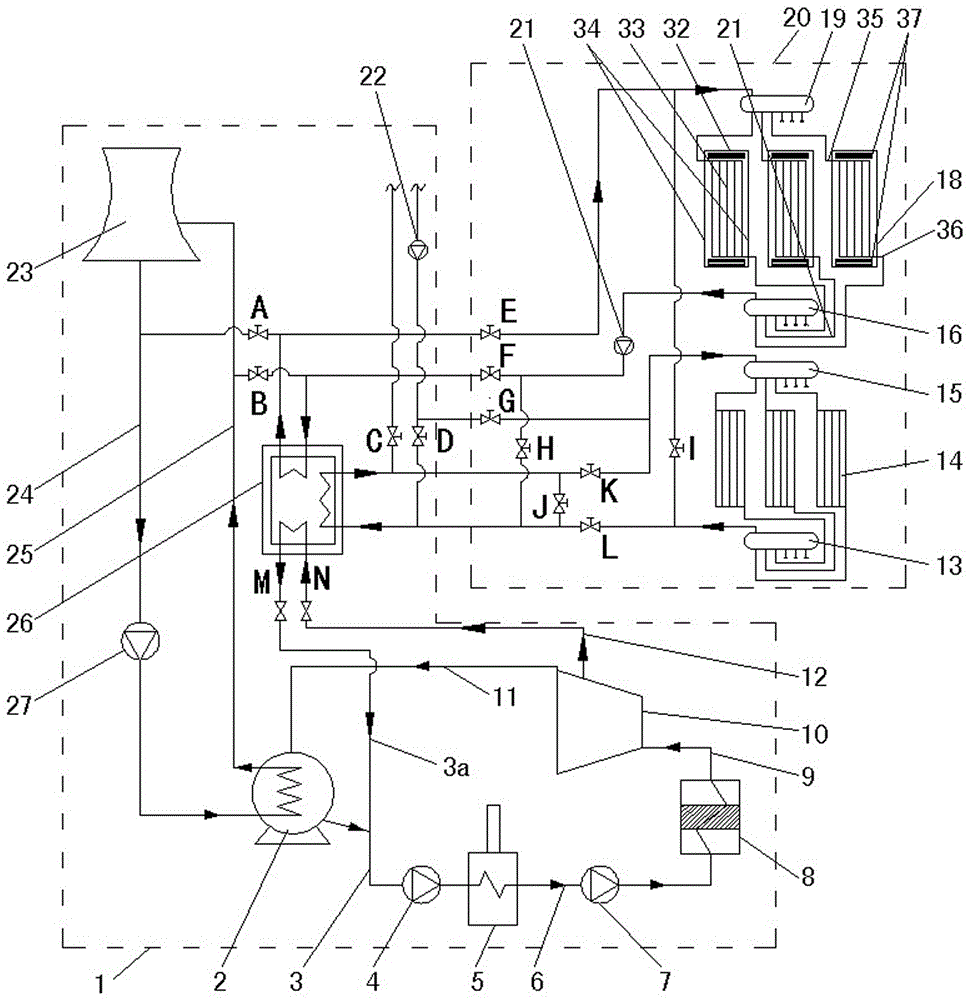

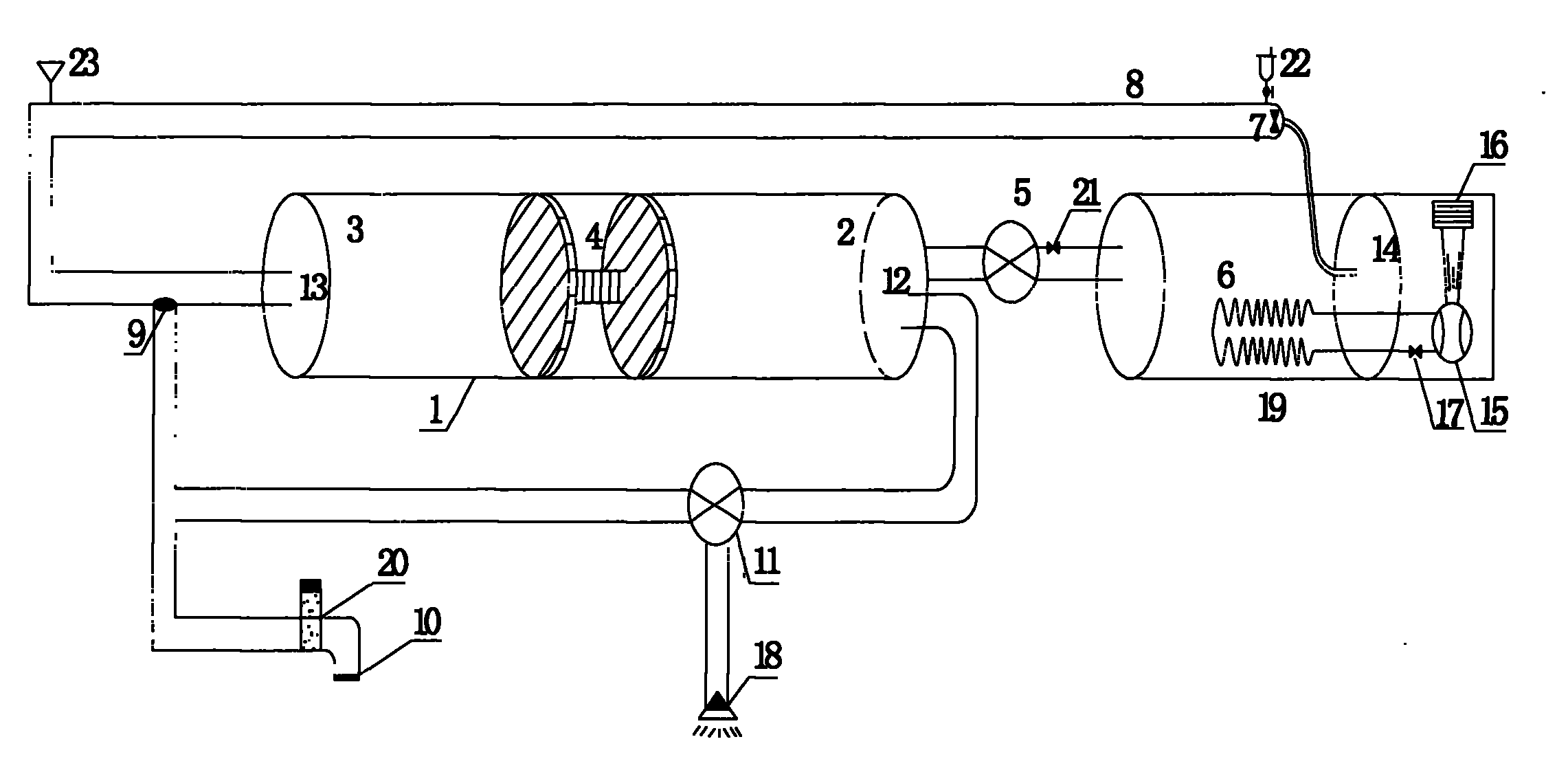

Modular radiation heat exchange terminal and waste heat recovery radiation pipe network heat pump system

InactiveCN103743153BImprove energy savingReduce heat transfer fluidityEnergy industrySpace heating and ventilation detailsThermodynamicsCooling tower

A waste heat recovery radiation pipe network heat pump system using a modularized radiation heat exchange terminal comprises a waste heat recovery system, wherein the waste heat recovery system is used for recovering energy from waste heat of circulating cooling water of a power plant, heating water at the temperature from 29 DEG C to 34 DEG C is obtained and conveyed into a radiation heat exchange pipe network water distributor which is connected with the modularized radiation heat exchange terminal, and the heating water flowing out of the modularized radiation heat exchange terminal passes through a water collector I and then enters a self-drooping radiation heat exchange humidity-adjusting cabinet water distributor; an outlet of the self-drooping radiation heat exchange humidity-adjusting cabinet water distributor is connected with an inlet of a self-drooping radiation heat exchange humidity-adjusting cabinet, an outlet of the self-drooping radiation heat exchange humidity-adjusting cabinet is connected with an inlet of a water collector II, and finally the water collector II is used for conveying the heating water into the waste heat recovery system again. The waste heat recovery radiation pipe network heat pump system is environmentally friendly, saves energy, lowers water loss of a cooling tower, reduces the flow of the circulating cooling water getting in the tower, reduces power consumption of the circulating cooling water, recovers the exhausted waste heat of the circulating cooling water, increases the energy utilization rate of the power plant, reduces comprehensive coal consumption, makes use of waste heat recovery, saves 40% of energy compared with a traditional air-conditioner heat pump system, and is significant in energy-saving effect.

Owner:HENAN AIMOKA ENERGY SAVING TECH

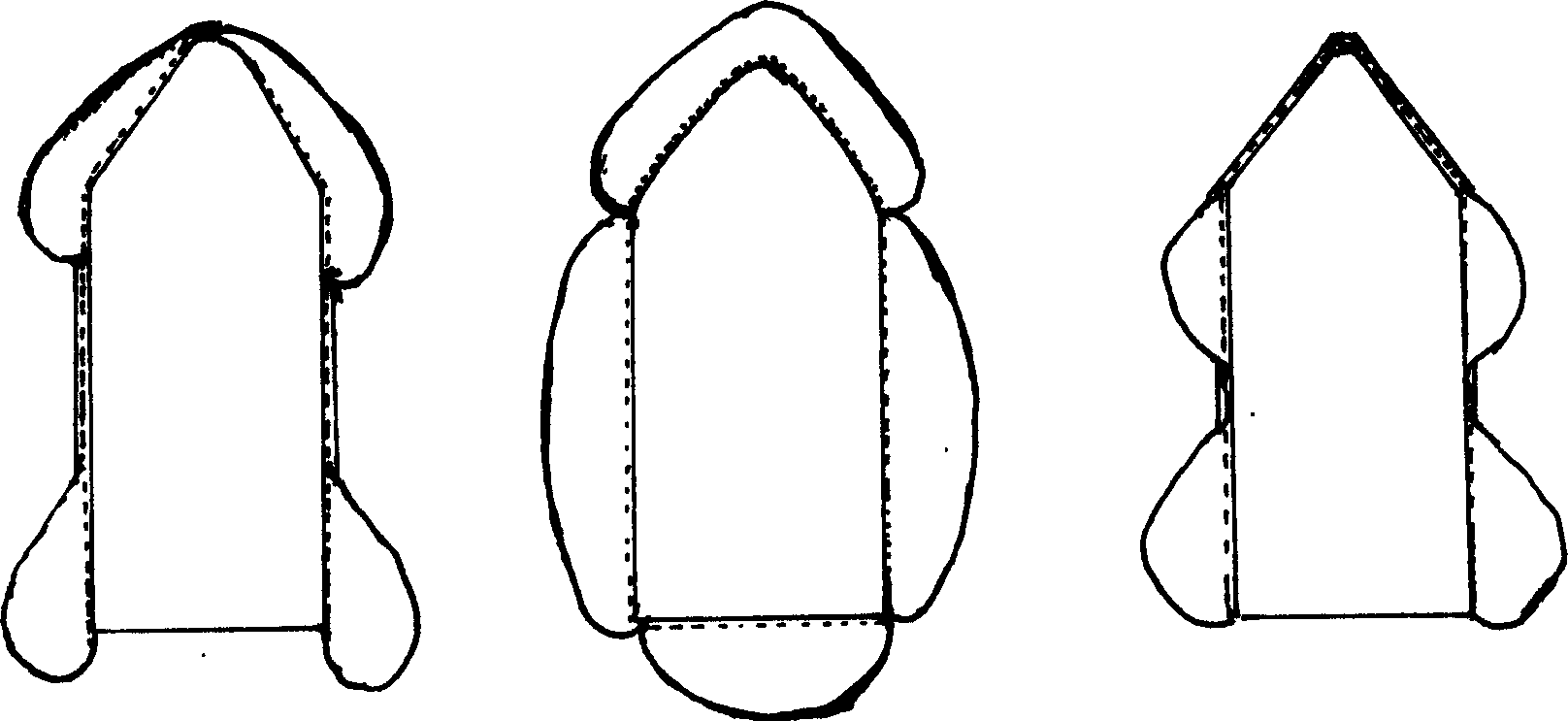

Automatic box folding fixture

InactiveCN102009410BReduce manufacturing costLow costProgramme-controlled manipulatorAgricultural engineeringCost savings

Owner:MANSHENG PACKAGING SHANGHAI +1

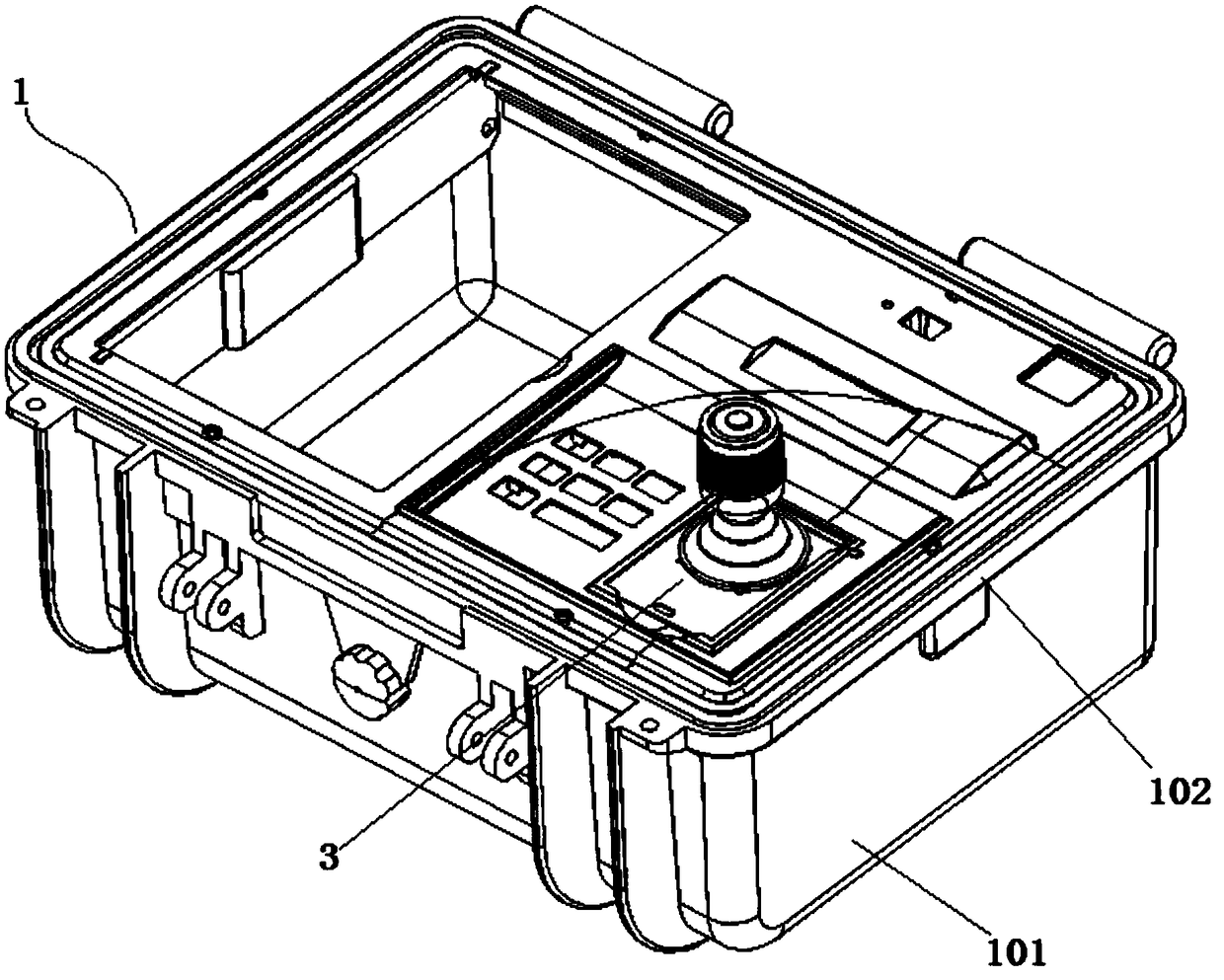

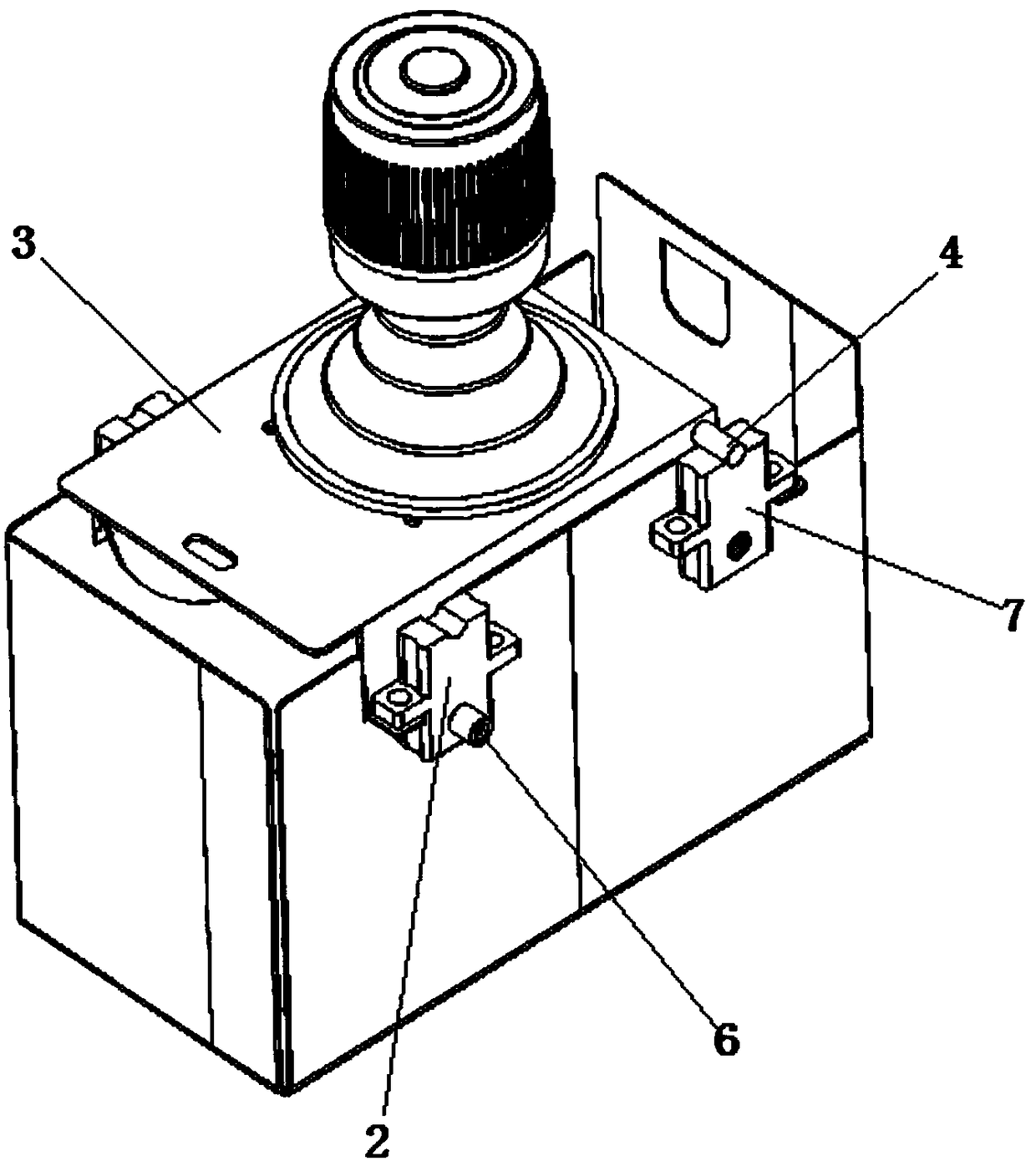

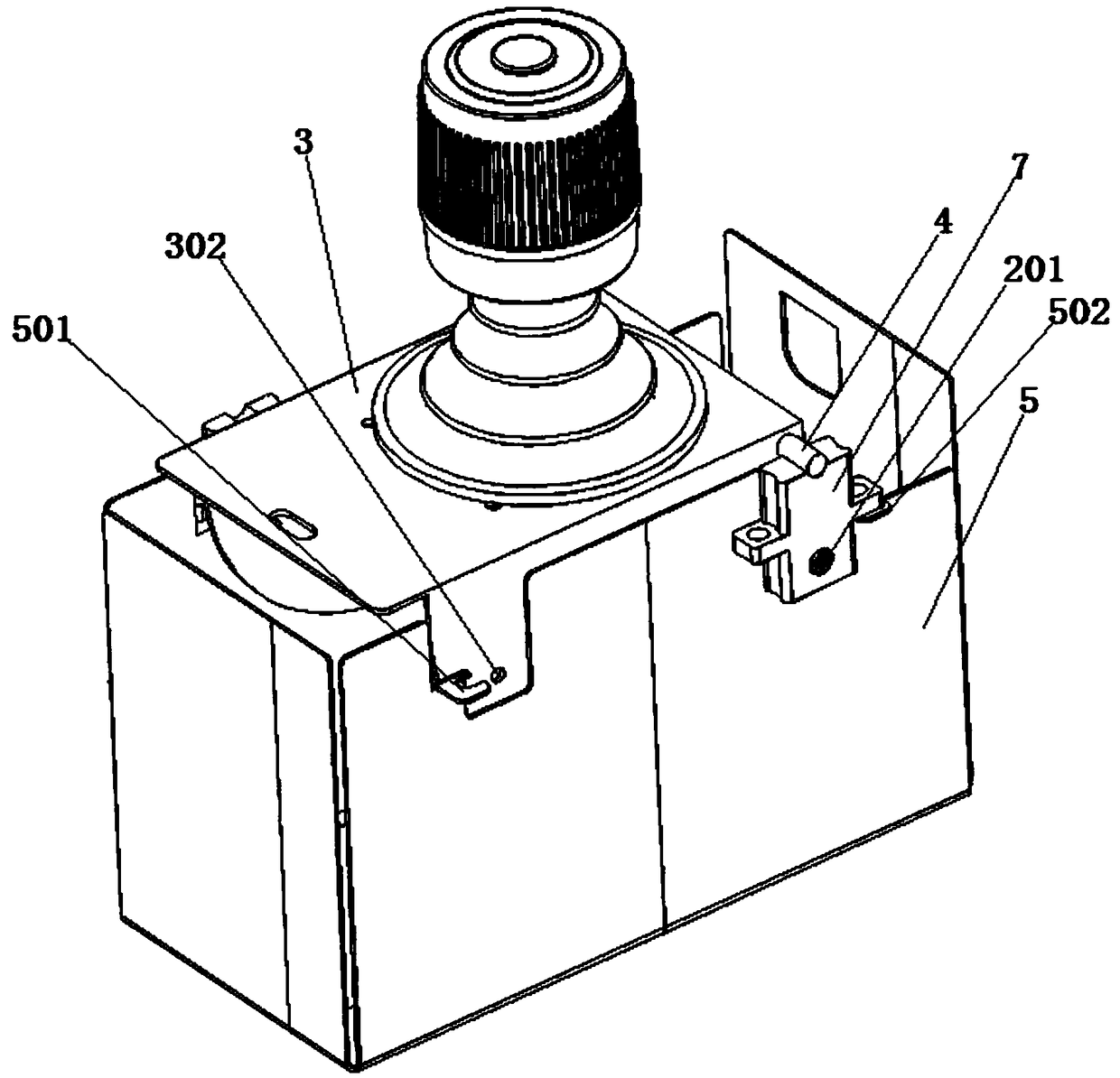

Self-locking and accommodating apparatus of portable device control lever

ActiveCN108491028ARealize operational useDoes not occupy effective spaceControlling membersSelf locking

Owner:ANHUI CREARO TECH

An import and export port door of a continuous vacuum production line

ActiveCN105758186BLow costLow machining accuracy requirementsFurnace componentsPower-operated mechanismProduction lineEngineering

The invention discloses an entrance / exit end door of a continuous vacuum production line. The continuous vacuum production line comprises a stander. The entrance / exit end door is characterized by adopting a push away-closing type. The end door is arranged at the lower part of the stander at a port of the vacuum production line. The entrance / exit end door has the benefits that 1, no expensive gate valve is adopted, so that the cost is greatly reduced; 2, the whole structure is arranged at a free space position of the stander at the front lower side of the production line, so that no effective space is occupied; 3, by the adoption of the push away-closing type openable furnace door structure, the requirement on the processing precision is low, mounting and maintenance are facilitated, and the manufacturing cost is low.

Owner:DONGGUAN HUICHENG VACUUM TECH

A plateau type cooking vehicle

ActiveCN111016769BImprove sealingQuick cookCooking-vessel materialsDomestic stoves or rangesRubber ringPressure cooking

The invention relates to the technical field of plateau cooking, and discloses a high-altitude cooking vehicle, including a cooking vehicle, a carriage fixedly installed on the rear side of the cooking vehicle, the carriage is a rectangular hollow box, and a vegetable washing pool is fixedly installed inside the cooking vehicle. The inner middle position of the compartment is fixed and installed with a working platform in parallel, the inner top of the compartment is fixed with an equipment box, the lower end of the working platform is fixed with a locker, the right side of the locker is fixed with a heating pipe, and the inside of the working platform is fixed. A pressure cooker is installed, and the pressure cooker is a cylindrical hollow barrel. Vertical grooves are vertically provided on the inner wall of the pressure cooker and there are two groups of vertical grooves, and the vertical grooves are rectangular grooves. In the present invention, the fixing sleeve will press the pot cover downwards so that the pot cover and the pressure cooker are tightly attached, and the rubber ring squeezed by the pot cover makes the inside of the pressure cooker have a good airtightness, and the fixed block is manually changed according to the conditions of plateau air pressure The air pressure inside the pressure cooker enables the food to be cooked quickly until it is fully cooked when using a cooking cart on a plateau.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA

A new type of tube-panel water-tube heat exchanger integrated with electrostatic precipitator

ActiveCN103604113BMake full use of the flue spaceSmall footprintCombustion technology mitigationFeed-water heatersEngineeringSoot

A novel tube panel type water tube heat exchanger integrated with an electrostatic precipitator consists of a plurality of rows of tube panels, wherein each row of tube panels consists of heat exchanger headers at two ends and a plurality of heat exchanging tube bundles which are connected with the heat exchanger headers at the two ends; tube ends of the heat exchanger heads at the two ends of each of the adjacent tube panels are connected to one another through large-diameter elbows, so that working media of the adjacent tube panels are connected to one another; and heat exchanging tube bundles of each tube panel are arranged in a flue structure in a middle section of an extension section of an inlet of the precipitator. The heat exchanger does not occupy the other effective space in front of the inlet of the electrostatic precipitator; the waste heat of the smoke can be reasonably used; and the specific resistance of the soot is reduced, so that the efficiency of the electrostatic precipitator is improved. The novel tube panel type water tube heat exchanger integrated with the electrostatic precipitator has the advantages that the structure is simple and compact, modular production and modular assembly can be realized, and field installation is quite convenient.

Owner:CENT SOUTHERN CHINA ELECTRIC POWER DESIGN INST CHINA POWER ENG CONSULTING GROUP CORP +1

Three-tank four-cavity indoor air source heat pump water heater

InactiveCN101666544BDoes not affect room temperatureAvoid mixingFluid heatersHeat pumpsWater productionIndoor air

The invention relates to the field of air source heat pump utilization, in particular to a three-tank four-cavity indoor air source heat pump water heater, which uses three water tanks which include a horizontal heat preservation pressure water tank, a water storage and cold water supply water tank and a heat pump heating water tank and are combined to form four independent cavities including a cold water cavity, a hot water cavity, a water storage and cold water supply cavity and heat pump heating water cavity, wherein the four cavities are combined to form a cold-hot water closed circulation system. The three-tank four-cavity indoor air source heat pump water heater solves the problem of low hot water utilization rate caused by cold and hot water mixing of the prior air source heat pumpwater heater of a heat pump and the problem of indoor floor effective area occupation of the a vertical heat pump water heater, realizes demand-based hot water production and avoids waste and problems caused by the overlong heating time of a large amount of water to be heated at one time. A surface cooler is closely attached with a ventilator, an exhaust hole is led out by a hose, and the indoor waste gases can be directly discharged outside. Based on an indoor ventilation theory, the hour discharge amount of the ventilator is 180 to 210 cubic meters, and the ventilator can be used in winter without influencing indoor temperature.

Owner:北京格瑞那环能技术有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com