An import and export port door of a continuous vacuum production line

A production line, import and export technology, used in door/window accessories, wing fan operating mechanisms, furnaces, etc., can solve the problems of high processing accuracy, unsatisfactory, complex main structure and process, and achieve low processing accuracy requirements and convenience. The effect of installation and maintenance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

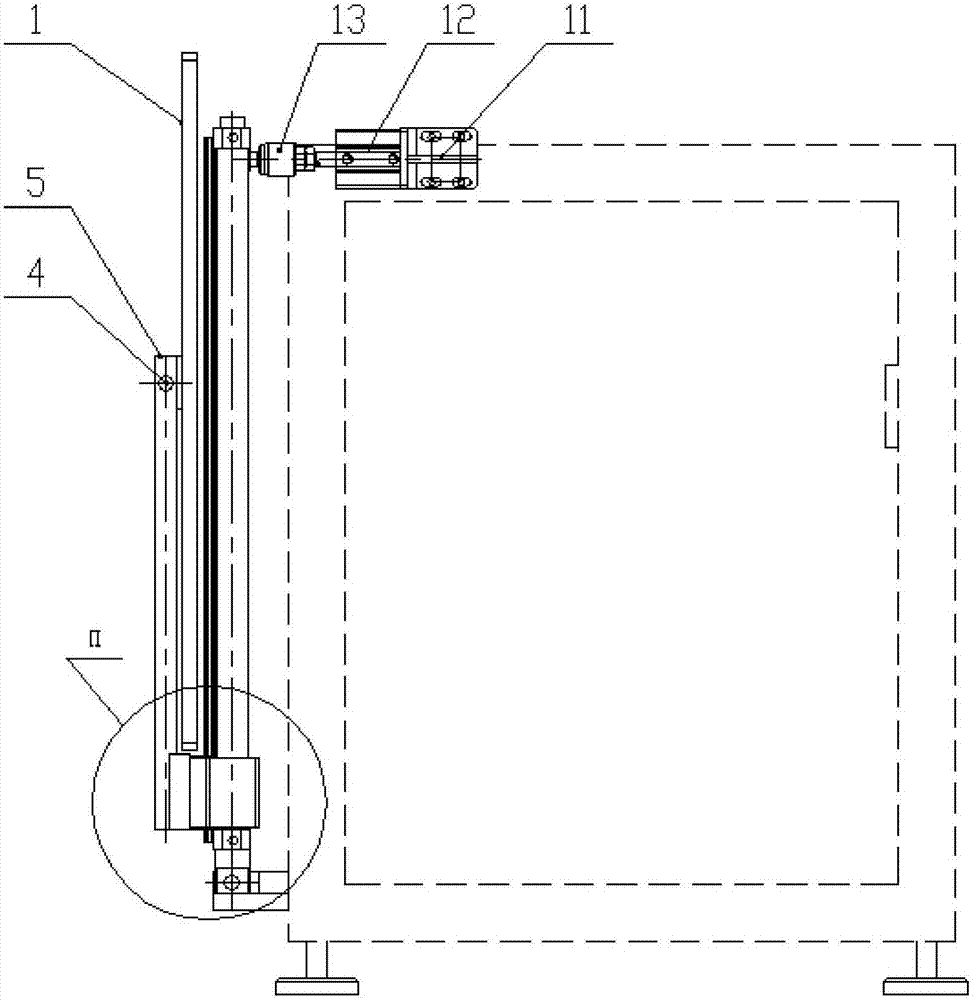

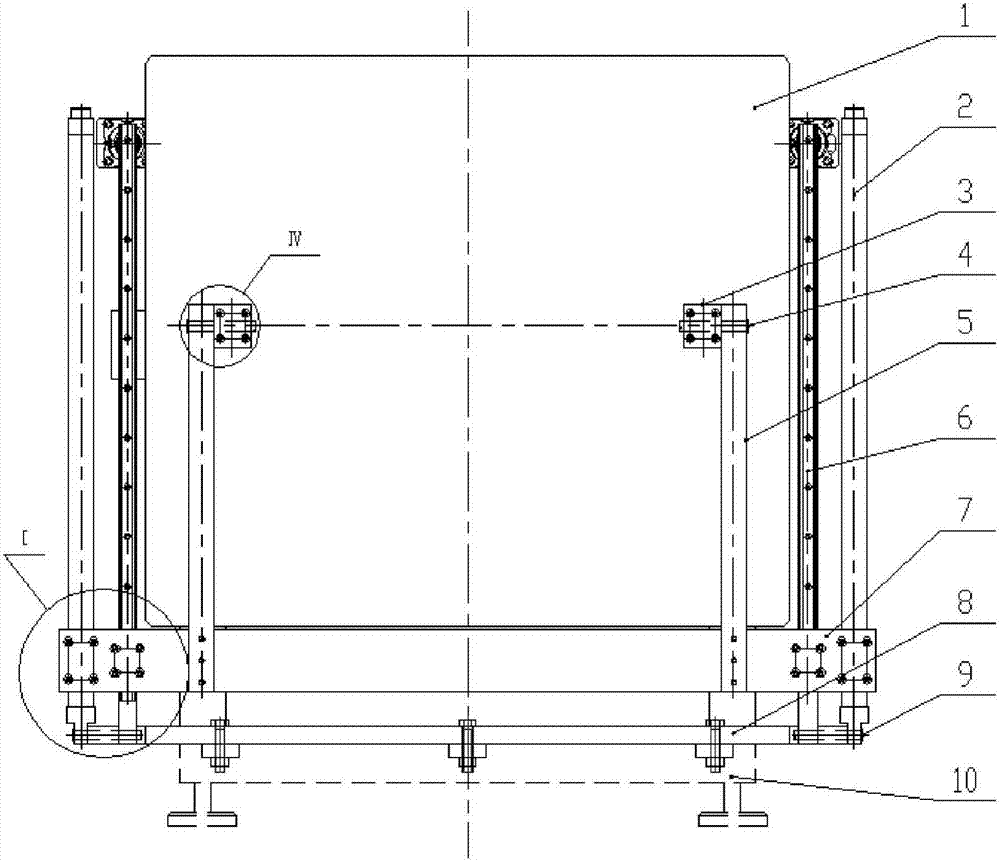

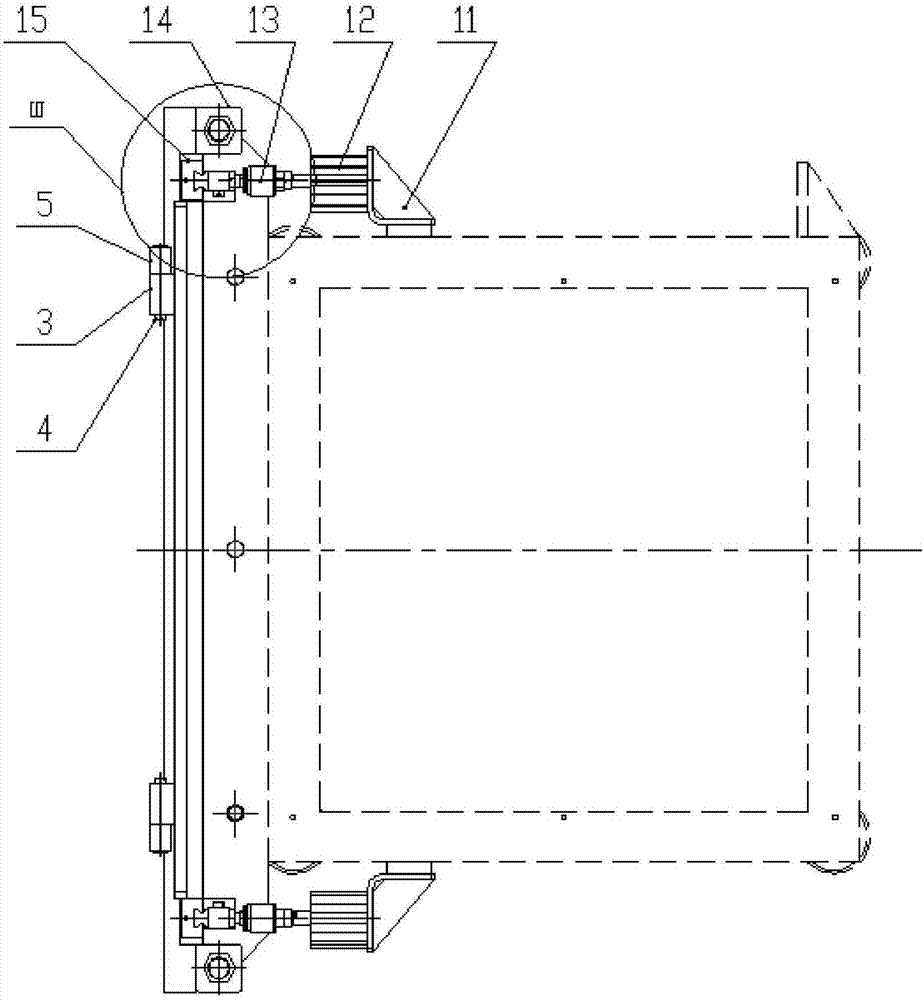

[0028] see figure 1 , figure 2 and image 3 , are respectively the front view, left view and top view schematic diagrams of the entrance and exit end door structure, Figure 4 , Figure 5 , Figure 6 and Figure 7 The partial enlarged schematic diagrams of the connection of each key component are respectively, Figure 8 , Figure 9 , Figure 10 and Figure 11 They are three-dimensional schematic diagrams in different directions of the two positions of the entrance and exit gates.

[0029] The embodiment of the import and export end door of the continuous vacuum production line of the present invention, the continuous vacuum production line includes a frame, the end door adopts a push-off-closed type, and the end door is arranged at the lower part of the frame at the port of the vacuum production line.

[0030] The main structure of the end door includes the lifting and lowering movement assembly of the end door panel, the end door panel assembly and the push-off-clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com