Signal cabinet

A signal and cabinet technology, applied in electrical equipment shell/cabinet/drawer, cooling/ventilation/heating renovation, electrical components, etc., can solve the problem that heat cannot be discharged as soon as possible, and achieve good exhaust effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

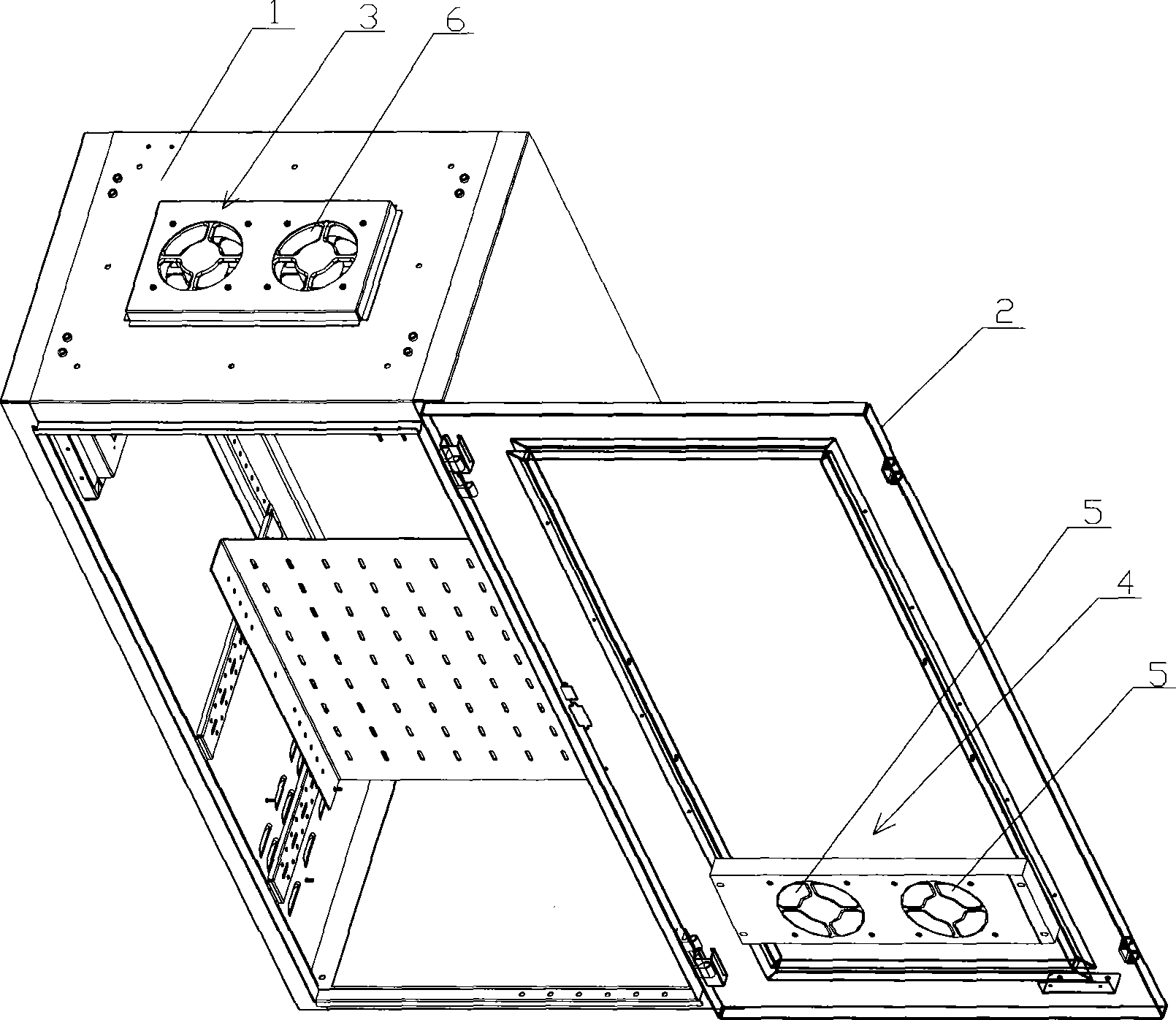

[0019] Embodiment one, such as figure 1 As shown, the signal machine cabinet of the present invention includes a top cover 1 and a cabinet door 2, and a main control module (not shown in the figure), an exhaust device 3 and an air suction device 4 are arranged in the cabinet, wherein the air suction device 4 is provided In the cabinet bottom plate, the suction device 4 includes two AC fans 5 connected in parallel, and the two AC fans 5 connected in parallel form a fan module, and each fan 5 is covered with a dust-proof net (not shown in the figure), and the exhaust The gas device 3 is arranged in the top cover 1 of the cabinet, which includes a similar fan module. The fan module includes two AC fans 6 connected in parallel. The specific structure is similar and will not be described here; The temperature and humidity sensors connected to the module, the temperature and humidity sensors transmit the sensed temperature and humidity signals to the main control module, and the mai...

Embodiment 2

[0020] Embodiment 2 differs from Embodiment 1 in that: the suction device 4 of this embodiment is arranged below the cabinet door 2 inside the cabinet, and of course it can also be arranged at other positions below the cabinet door. Others are the same as Embodiment 1. This is not the case. repeat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com