Wall putty material and its preparation method and use method

A putty, wall technology, applied in the direction of filling slurry, etc., can solve the problems of strong penetration ability and low surface tension, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

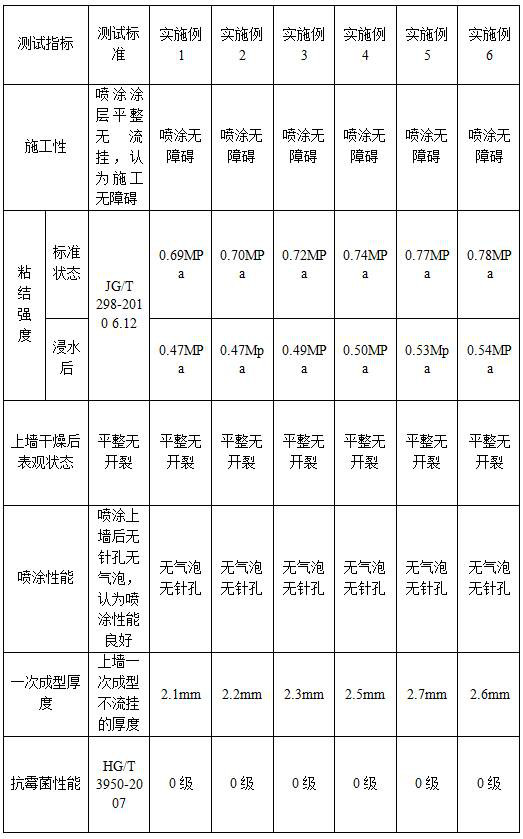

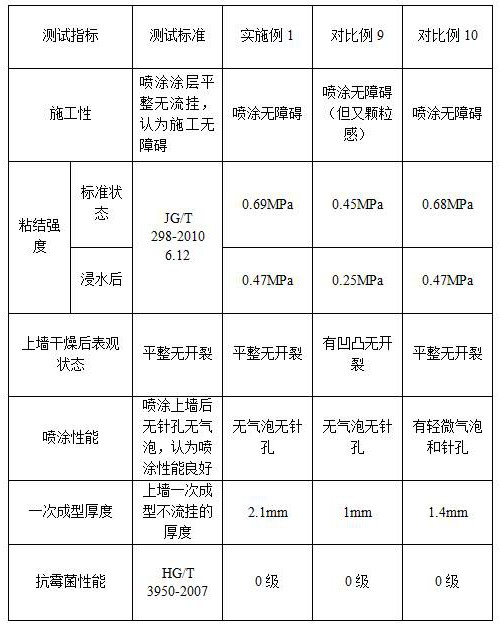

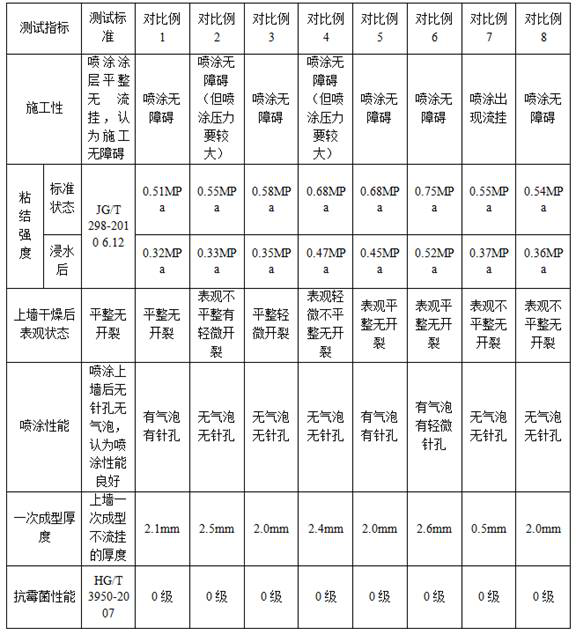

Examples

preparation example Construction

[0115] A method for preparing a wall putty material, comprising the following steps: mixing a base material, calcium carbonate whiskers, polyethylene glycol and a filler to obtain component A;

[0116] Get fumed silica to get component B;

[0117] The parts by weight of the base material are 3 parts-31 parts; the parts by weight of calcium carbonate whiskers are 3 parts-7 parts; the parts by weight of polyethylene glycol are 0.5 parts-1 part; the parts by weight of the filler 30-60 parts; the parts by weight of fumed silica are 15-25 parts.

[0118] A method for using a wall putty material, comprising the following steps:

[0119] Mix component B and water, stir first time, add component A, stir a second time and let stand, stir a third time.

[0120] The purpose of the first stirring and the second stirring is to mix the raw materials evenly, and high-speed stirring can be used, and the stirring speed is preferably 1200r / min-1500r / min. This will generate more heat, and the...

Embodiment 1

[0133] This embodiment provides a wall putty material and its preparation method and use method, the steps are as follows:

[0134] In parts by weight, weigh 3.5 parts of polymer latex powder, 25 parts of white cement, 50 parts of heavy calcium, 15 parts of fumed silica, 3 parts of calcium carbonate whiskers, 0.5 parts of polyethylene glycol, 0.5 parts of hydroxypropyl Methyl cellulose ether, 0.5 part of defoamer, 1 part of water repellent, 0.5 part of modified hydroxypropyl starch ether, 0.5 part of antifungal agent.

[0135] Preparation method: polymer latex powder, white cement, heavy calcium, calcium carbonate whiskers, polyethylene glycol, hydroxypropyl methylcellulose ether, defoamer, water repellent, modified hydroxypropyl starch ether, The antifungal agent is poured into the mixing equipment, mixed evenly, weighed and packaged to obtain component A; the fumed silica is weighed and packaged separately to obtain component B.

[0136] How to use: Mix component B and 40 p...

Embodiment 2

[0138] This embodiment provides a wall putty material and its preparation method and use method, which are basically the same as in Embodiment 1, the only difference being that the weight parts of heavy calcium and calcium carbonate whiskers are different, and the steps are as follows:

[0139] In parts by weight, weigh 3.5 parts of polymer latex powder, 25 parts of white cement, 48 parts of heavy calcium, 15 parts of fumed silica, 5 parts of calcium carbonate whiskers, 0.5 parts of polyethylene glycol, 0.5 parts of hydroxypropyl Methyl cellulose ether, 0.5 part of defoamer, 1 part of water repellent, 0.5 part of modified hydroxypropyl starch ether, 0.5 part of antifungal agent.

[0140] Preparation method: polymer latex powder, white cement, heavy calcium, calcium carbonate whiskers, polyethylene glycol, hydroxypropyl methylcellulose ether, defoamer, water repellent, modified hydroxypropyl starch ether, The antifungal agent is poured into the mixing equipment, mixed evenly, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com