Automatic box folding fixture

A fixture and automatic technology, applied in the direction of manufacturing tools, manipulators, program-controlled manipulators, etc., can solve the problems that it is difficult for employees to guarantee the time and quantity, defective products, etc., and achieve the effect of low production cost, quality assurance and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

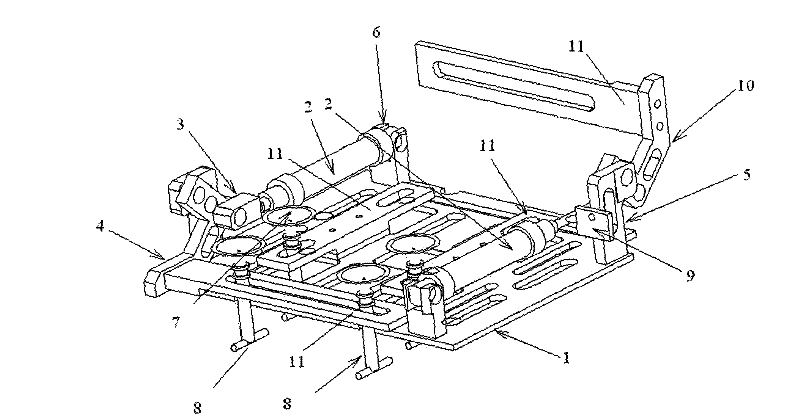

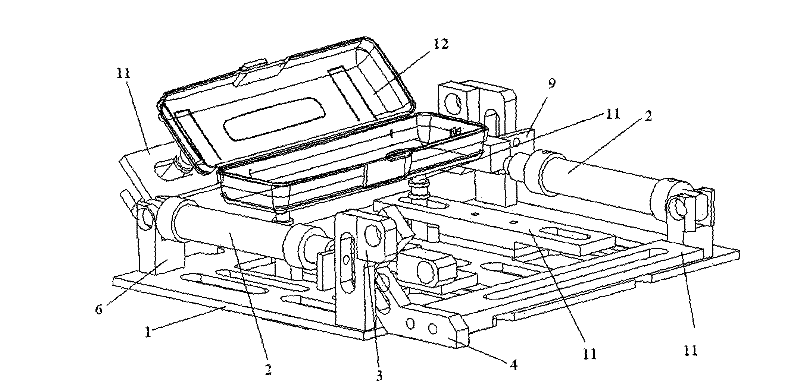

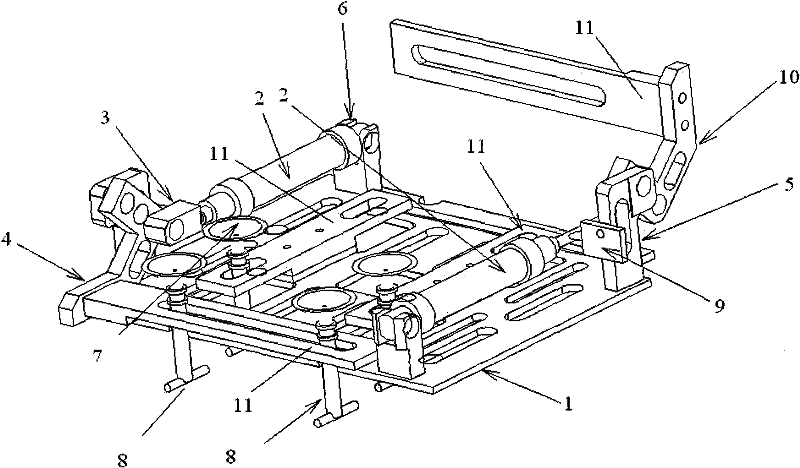

[0018] A box automatic folding jig, its structure is as follows figure 1 As shown, the fixture includes a mounting plate 1, a miniature cylinder 2, a cylinder adapter 3, a first side posture arm 4, a side posture arm connecting seat 5, a cylinder fixing seat 6, a suction cup 7, a suction cup seat 8, and a side posture limiter. Position block 9, second side posture arm 10, suction cup seat fixing strip 11, installation fixing plate 1 is located at the bottom of the fixture, is connected with the manipulator, miniature cylinder 2 has 2, is located at the both sides of installation fixing plate 1, The cylinder adapter 3 is located at the front end of the mini cylinder 2, the first side posture arm 4 is connected to the mini cylinder 2 on the left side, and the side posture arm connection seat 5 is connected to the mini cylinder 2 on the right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com