Modular radiation heat exchange terminal and waste heat recovery radiation pipe network heat pump system

A waste heat recovery system and radiation heat exchange technology, applied in heating systems, hot water central heating systems, air conditioning systems, etc., can solve the problems of industrial waste heat not being used, polluting the environment, etc., to improve energy utilization, reduce comprehensive The effect of coal consumption and reduction of upper tower flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described.

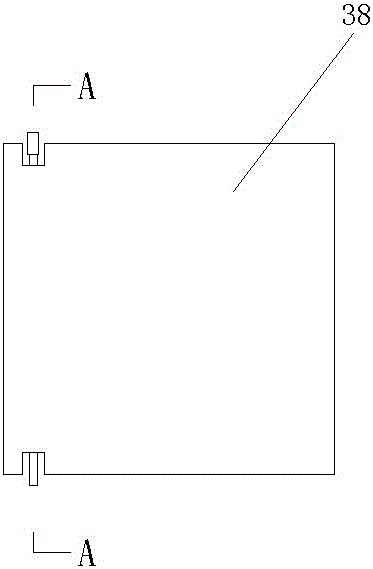

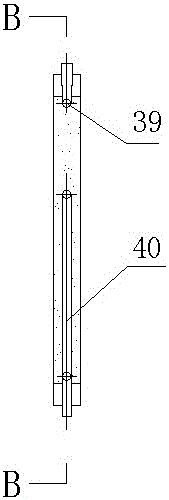

[0019] Such as figure 2 , image 3 , Figure 4 As shown, a modular radiation heat exchange terminal 14 is composed of a plurality of radiation heat exchange modules 38, and each heat exchange module 38 is composed of several three-type copolymer polypropylene dry pipes 39 arranged horizontally and several branch pipes 40 arranged vertically. and a gypsum protective layer 41 between the main pipe and branch pipes; wherein, the distance between adjacent main pipes 39 is 150--170mm, and the distance between adjacent branch pipes is 35-45mm.

[0020] Preferably, the distance between adjacent main pipes 39 is 165 mm, and the diameter of a single main pipe is Φ15 mm; the distance between adjacent branch pipes is 40 mm, and the diameter of a single branch pipe is Φ4 mm.

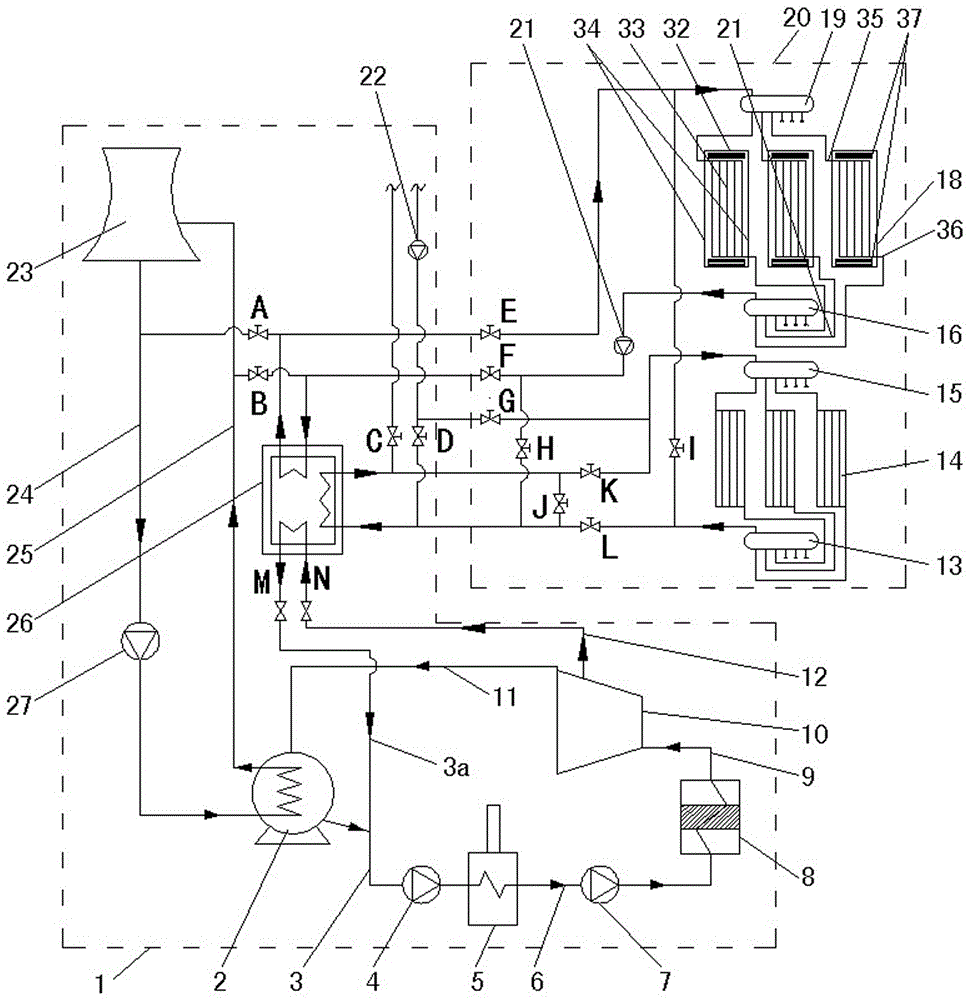

[0021] Such as Figure 1-Figure 4 As shown, a waste heat recovery radiant pipe network heat pump system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com