Integrated water purifying equipment for concurrent inclined plate precipitation

A technology of inclined plate sedimentation and water purification equipment, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of inconvenient construction and assembly, easy blockage of holes in the water collection area, and failure to work normally, so as to increase space utilization and reduce pollution. The effect of mud concentration is good, and it is convenient for construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

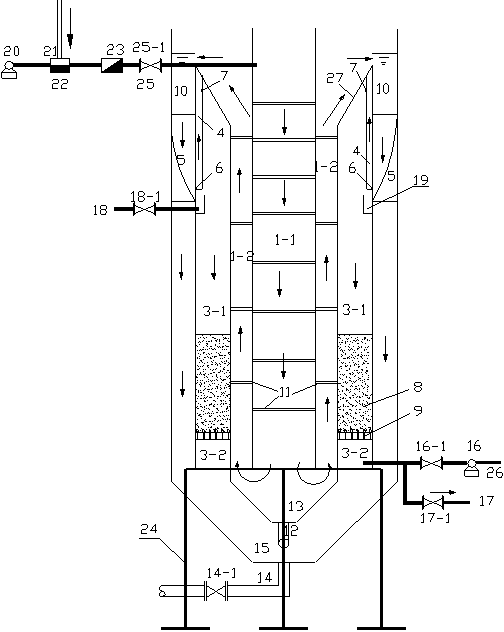

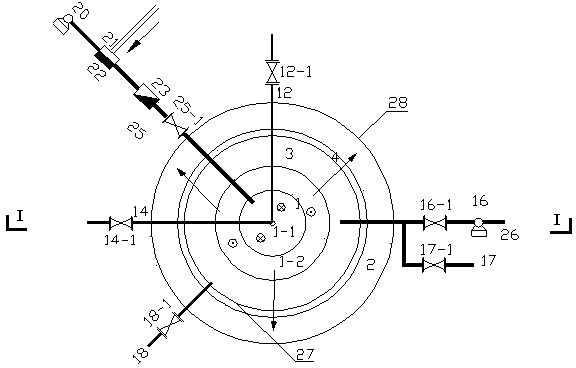

[0026] Structure and working process of the present invention are described in detail below in conjunction with accompanying drawing:

[0027] 1. Structural composition

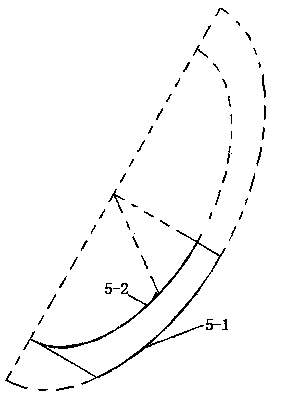

[0028] see figure 1 and figure 2 As shown, the main structure of the device of the present invention is a cylindrical body 28, and the cylindrical body 28 is supported by an inner equilateral triangular support 24 to form an integral structure with an open upper end and a closed lower end. The cylindrical body can be divided into upper and lower parts in terms of shape, wherein the upper part is cylindrical and the lower part is truncated. The upper cylindrical area is concentrically divided into three large areas. From the inside to the outside are the flocculation area 1, the filtration area 3 (including the water collection area 4), and the sedimentation area 2. The lower part mainly has a mud chamber with a frustum-shaped inner layer. 13 and the truncated sludge concentration chamber 15 of the outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com