Ordinary temperature curing high-hardness organic-inorganic hybrid coating as well as preparation and use method thereof

A room temperature curing, high hardness technology, applied in the direction of coating, etc., can solve the problems of limiting application range, increasing energy consumption, and easy gelation of products, and achieve the effect of overcoming easy gelation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

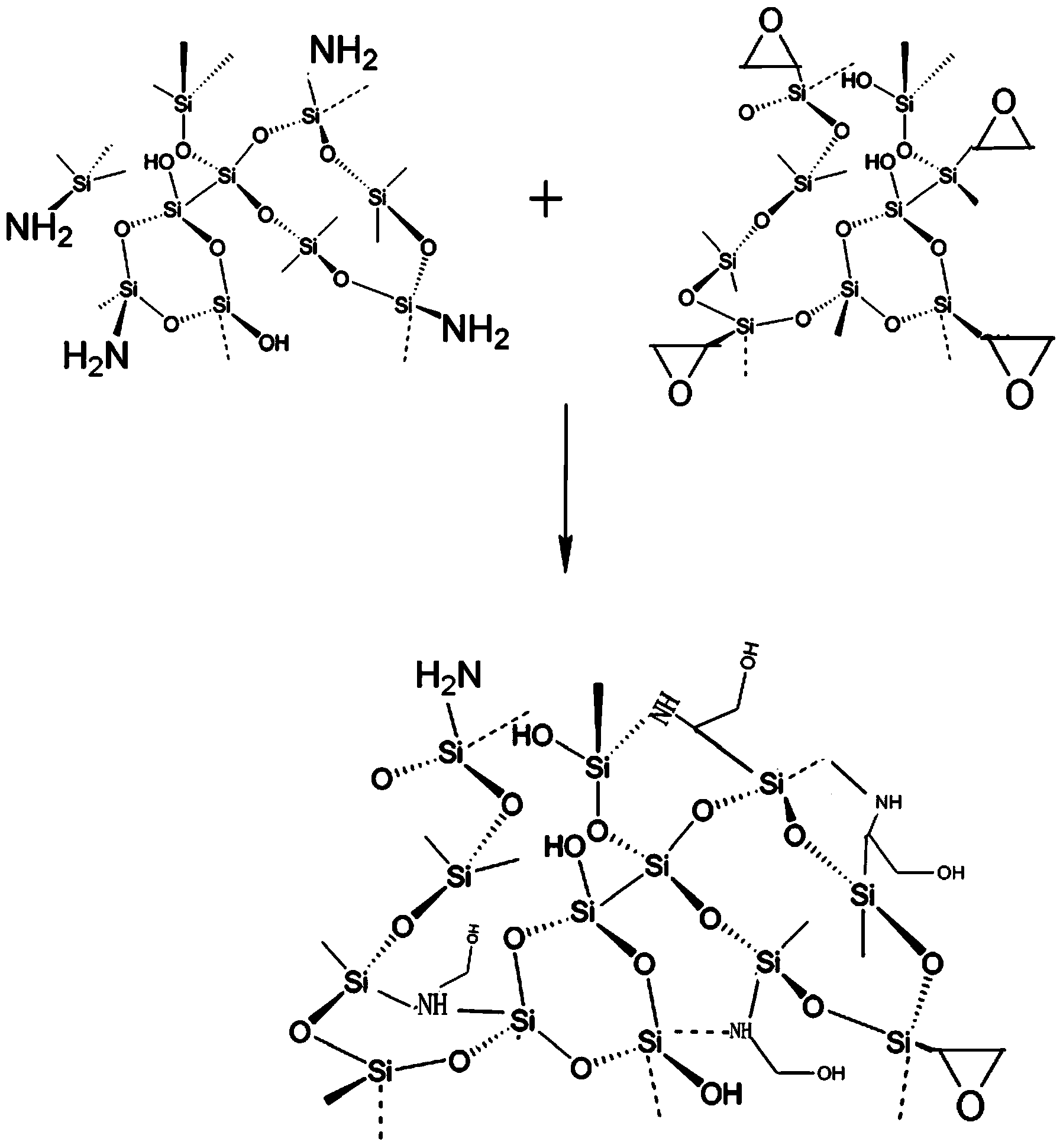

Method used

Image

Examples

Embodiment 1

[0042] (1) A component amino-modified organic-inorganic hybrid sol: add 70g of γ-aminopropyltrimethoxysilane, 10g of ethyl orthosilicate, 70g of ethanol and 5g of water into the reactor, and stir evenly at room temperature; Add a mixed liquid of 0.1g hydrochloric acid (37%) and 2g water at 10°C, condense and reflux at 60°C for 1 hour; then age at room temperature for 8 hours to obtain an amino-modified organic-inorganic hybrid sol ;

[0043] (2) B-component epoxy-modified organic-inorganic hybrid sol: add γ-(2,3-epoxypropoxy)propyltrimethoxysilane 70g, methyl orthosilicate 5g, 5g of diphenyldimethoxysilane, 18g of ethanol and 5g of water, stir well at room temperature; at 30°C, add a mixed liquid of 0.5g of hydrochloric acid (37%) and 2g of water, and reflux for 1h at 50°C ; Then aging 20h at room temperature to obtain epoxy-modified organic-inorganic hybrid sol;

[0044] Components A and B are mixed at a weight ratio of 8:7 and stirred evenly to form a two-component organic...

Embodiment 2

[0053] (1) Amino-modified organic-inorganic hybrid sol of component A: add 10g of γ-aminopropyltrimethoxysilane, 5g of methyltriethoxysilane, 2g of phenyltriethoxysilane, 80g of ethanol, 5g of propanol, and 5g of water were stirred evenly at room temperature; condensed and refluxed for 3 hours at 40°C; then aged for 48 hours at room temperature to obtain the amino-modified organic-inorganic hybrid sol;

[0054] (2) B component epoxy modified organic-inorganic hybrid sol: add 2-(3,4-epoxycyclohexyl)ethyltriethoxysilane 10g, methyl orthosilicate to the reactor 5g, 80g of isopropanol, stirred at room temperature; at 60°C, add a mixed liquid of 0.003g hydrochloric acid (37%) and 2.5g of water, at 60°C, reflux for 8h; then age at room temperature 72h, to obtain epoxy modified organic-inorganic hybrid sol;

[0055] Components A and B are mixed at a weight ratio of 1:10, stirred evenly, and then configured into a two-component organic-inorganic hybrid coating that can be cured at ro...

Embodiment 3

[0064] (1) Amino-modified organic-inorganic hybrid sol of component A: add 50g of N-β(aminoethyl)-γ-aminopropyltrimethoxysilane, 20g of ethyl orthosilicate, methyl 10g of trimethoxysilane, 80g of methanol and 0.1g of water were stirred at room temperature; at 30°C, a mixed liquid of 0.5g of hydrochloric acid (37%) and 2g of water was added, and reflux was condensed for 3h at 50°C; Aging at room temperature for 4 hours to obtain amino-modified organic-inorganic hybrid sol;

[0065] (2) Component B epoxy modified organic-inorganic hybrid sol: add 50g of 2-(3,4-epoxycyclohexane)ethyltrimethoxysilane, 5g of methyl orthosilicate, 28g of 1,2-bistriethoxysilylethane, 50g of ethanol, 5g of n-butanol and 1g of water, stir well at room temperature; add 0.5g of phosphoric acid (85%) and 40g of water at 35°C , at 40°C, condensed and refluxed for 8 hours; then aged at room temperature for 20 hours to obtain epoxy-modified organic-inorganic hybrid sol;

[0066] Components A and B are mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pencil hardness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com