Method for simultaneously improving strength and percentage elongation of aluminum alloy

A technology of elongation and aluminum alloy, which is applied in the field of plastic deformation and heat treatment of metal materials, can solve the problems of extrusion equipment capacity limitation, coarsening, limited deformation, etc., achieve excellent comprehensive performance, improve strength and elongation, and tensile strength The effect of strength and elongation improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

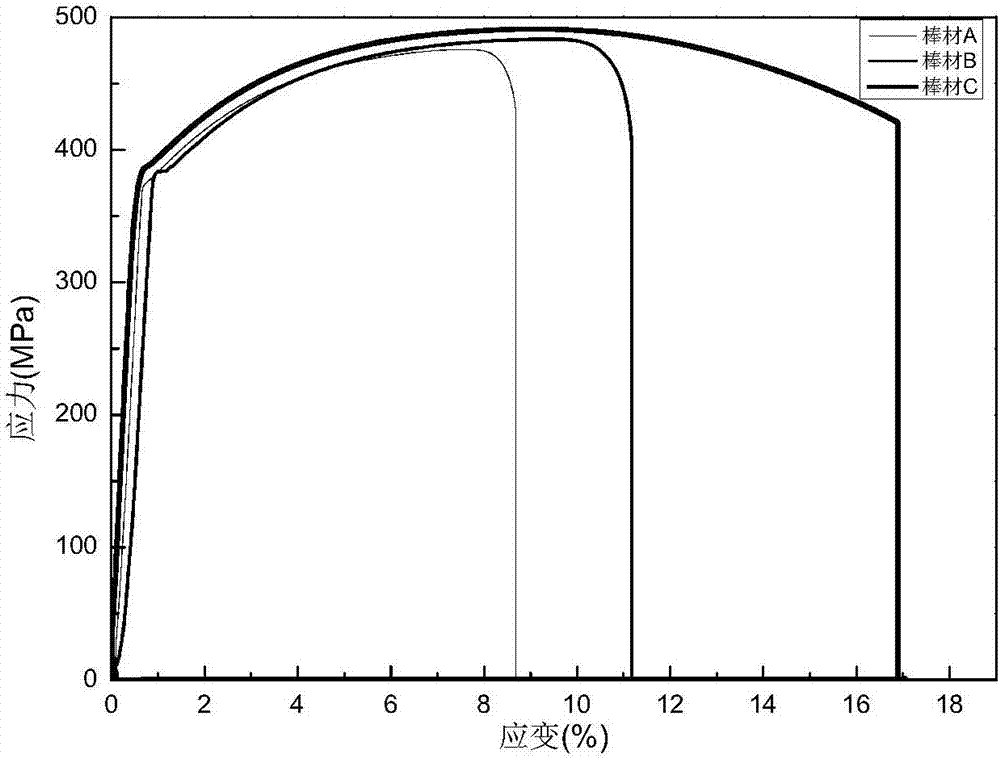

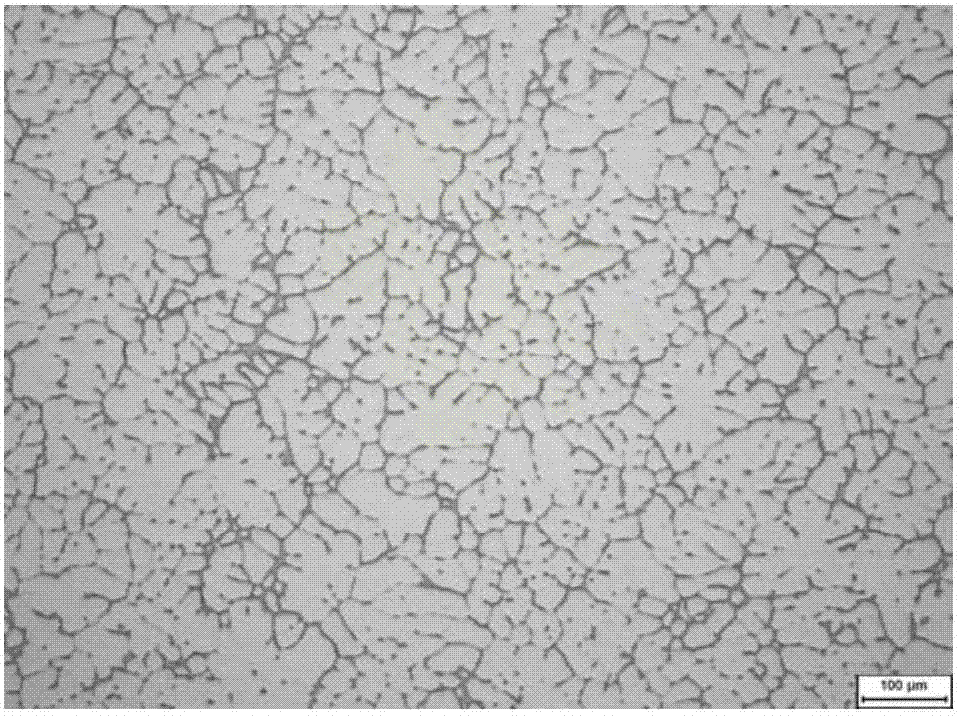

[0035] Three Al-Cu-Mg alloys through DC casting (direct water-cooled semi-continuous casting). %, Mg: 1.41%, Mn: 0.64%, Fe: 0.17%, Si: 0.09%, Zn: 0.0074%, Ti: 0.06%, Cr: 0.02%, and the balance is Al. The deformation heat treatment methods adopted by the three aluminum alloy ingots are as follows.

[0036] Bar A

[0037] After the Al-Cu-Mg alloy casting, the homogenization annealing treatment is carried out, the Al-Cu-Mg alloy is heated for 10h to 450°C, and the heat preservation is started; the homogenization treatment temperature is 450°C, the heat preservation time is 12h, and then cooled in the air to Room temperature; reheat the alloy to 450°C, keep it warm for 4 hours, start extrusion (reverse extrusion), the initial temperature of extrusion is 450°C, and the temperature after extrusion is 390°C, then cool to room temperature in air, The diameter of the aluminum alloy rod after extrusion is Φ50mm. Then carry out solid solution treatment, the solution treatment temperat...

Embodiment 2

[0048] Three Al-Cu-Mg alloys through DC casting (direct water-cooled semi-continuous casting). %, Mg: 1.41%, Mn: 0.64%, Fe: 0.17%, Si: 0.09%, Zn: 0.0074%, Ti: 0.06%, Cr: 0.02%, and the balance is Al. The deformation heat treatment methods adopted by the three aluminum alloy ingots are as follows.

[0049] Bar A

[0050] After the Al-Cu-Mg alloy casting, the homogenization annealing treatment is carried out, the Al-Cu-Mg alloy is heated for 10h to 450°C, and the heat preservation is started; the homogenization treatment temperature is 450°C, the heat preservation time is 12h, and then cooled in the air to Room temperature; reheat the alloy to 450°C, keep it warm for 4 hours, start extrusion (reverse extrusion), the initial temperature of extrusion is 450°C, and the temperature after extrusion is 390°C, then cool to room temperature in air, The diameter of the aluminum alloy rod after extrusion is Φ50mm. Then carry out solid solution treatment, the solution treatment temperat...

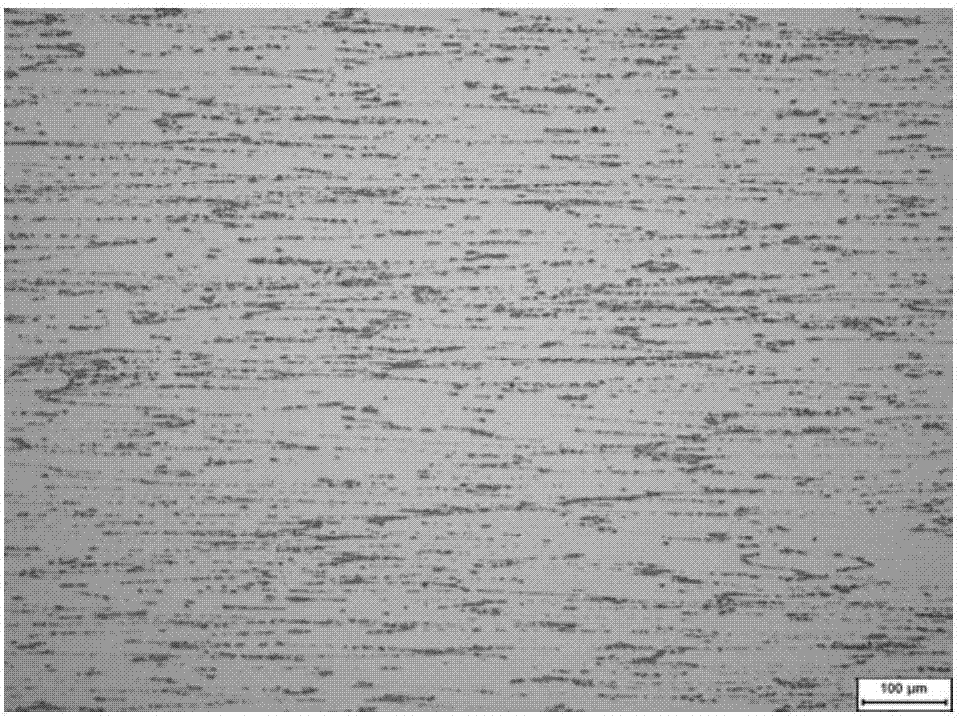

Embodiment 3

[0060] Three Al-Cu-Mg series alloys through DC casting (direct water-cooled semi-continuous casting), the diameter of the aluminum alloy rod is Φ152mm, and the diameter of the rear of the car is Φ150mm; the chemical composition of the Al-Cu-Mg alloy is as follows: Cu: 4.50 %, Mg: 1.75%, Mn: 0.74%, Fe: 0.15%, Si: 0.04%, Zn: 0.0056%, Ti: 0.043%, Cr: 0.015%, and the balance is Al. The processing methods of the three aluminum alloy ingots are as follows.

[0061] Bar E

[0062] After the Al-Cu-Mg alloy casting, the homogenization annealing treatment is carried out, the Al-Cu-Mg alloy is heated for 10h to 450°C, and the heat preservation is started; the homogenization treatment temperature is 450°C, the heat preservation time is 12h, and then cooled in the air to Room temperature; heat the alloy to 450°C, keep it warm for 4 hours, start extrusion (reverse extrusion), the initial temperature of extrusion is 450°C, the temperature after extrusion is 390°C, the diameter of the alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com